Global Smart Distribution For Industrial Application Market

Market Size in USD Billion

CAGR :

%

USD

5.30 Billion

USD

15.22 Billion

2024

2032

USD

5.30 Billion

USD

15.22 Billion

2024

2032

| 2025 –2032 | |

| USD 5.30 Billion | |

| USD 15.22 Billion | |

|

|

|

|

Smart Distribution for Industrial Application Market Size

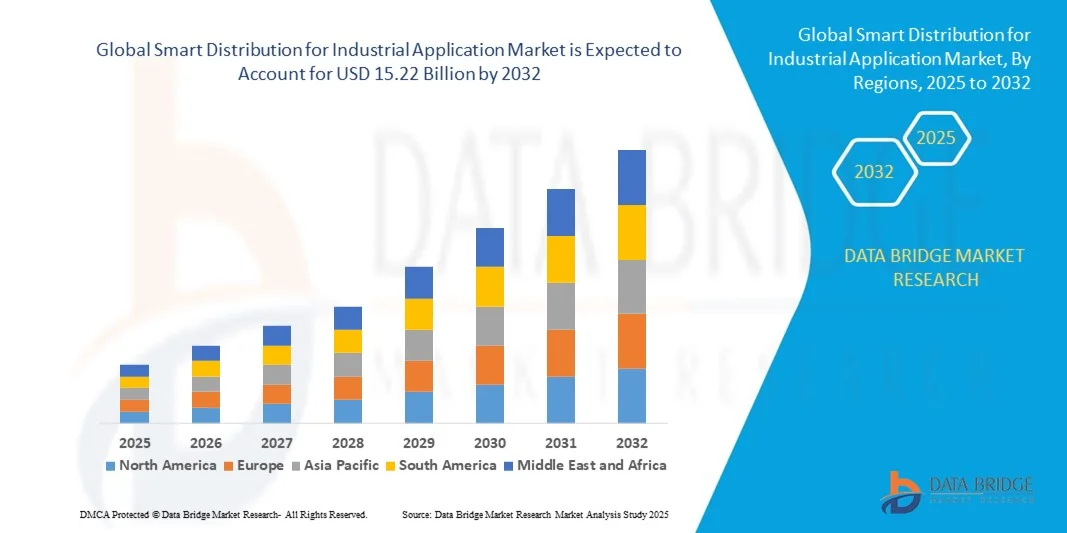

- The global smart distribution for industrial application market size was valued at USD 5.30 billion in 2024 and is expected to reach USD 15.22 billion by 2032, at a CAGR of 14.10% during the forecast period

- The market growth is largely fuelled by the rising adoption of automation, Industry 4.0 initiatives, and smart grid integration across industrial sectors, which enhance operational efficiency and reduce downtime

- Increasing demand for energy-efficient distribution systems and advanced monitoring solutions is further driving investments in smart distribution technologies, enabling predictive maintenance and improved safety

Smart Distribution for Industrial Application Market Analysis

- The market is witnessing significant developments in sensor integration, real-time data analytics, and IoT-enabled distribution solutions that support smarter industrial operations

- Growing government initiatives and industrial digitalization policies across North America, Europe, and Asia-Pacific are fostering the deployment of intelligent distribution systems and associated software platforms

- North America dominated the smart distribution for industrial application market with the largest revenue share in 2024, driven by increasing industrial automation, demand for efficient energy management, and growing adoption of Industry 4.0 technologies

- Asia-Pacific region is expected to witness the highest growth rate in the global smart distribution for industrial application market, driven by expanding manufacturing hubs, rising energy demand, and growing implementation of IoT-enabled industrial distribution systems

- The intelligent medium voltage switchgear segment held the largest market revenue share in 2024, driven by its critical role in controlling, protecting, and isolating electrical equipment in industrial power networks. These systems provide enhanced operational safety, reliability, and real-time monitoring, making them a preferred choice for industrial operators

Report Scope and Smart Distribution for Industrial Application Market Segmentation

|

Attributes |

Smart Distribution for Industrial Application Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Smart Distribution for Industrial Application Market Trends

Increasing Integration Of Smart Distribution Systems In Industrial Operations

The growing adoption of smart distribution systems is transforming industrial operations by enabling real-time monitoring, automated control, and efficient energy management. These systems allow predictive maintenance, reduce downtime, and optimize power distribution across complex industrial networks, improving operational efficiency. In addition, data analytics and cloud integration allow managers to identify inefficiencies, prevent failures, and make informed decisions to enhance overall productivity

Rising demand for energy-efficient and automated industrial solutions is accelerating deployment in manufacturing plants, chemical industries, and large-scale processing facilities. Smart distribution systems are particularly valuable where reliable and continuous power supply is critical for production and safety. Furthermore, integration with renewable energy sources and microgrids is creating opportunities for sustainable operations and cost reductions across the industrial sector

The affordability, scalability, and modular design of modern smart distribution solutions are making them increasingly attractive for both large enterprises and small to medium-sized industrial operators. Manufacturers can deploy these systems across diverse facilities, enhancing monitoring, fault detection, and energy optimization. Their flexible architecture also allows upgrades and expansions without disrupting existing operations, which supports long-term operational resilience

For instance, in 2023, several manufacturing plants in Europe and North America reported reduced energy losses and improved uptime after implementing advanced smart distribution systems integrated with IoT sensors and predictive analytics. The enhanced system visibility also allowed maintenance teams to proactively address electrical issues, minimize equipment wear, and improve compliance with industrial safety standards

While smart distribution systems are improving industrial efficiency, their impact depends on continued technological innovation, cybersecurity measures, and integration with existing plant infrastructure. Collaboration between solution providers, system integrators, and end-users is key to fully capitalize on growing demand. In addition, government incentives for digitalization and energy efficiency are further accelerating adoption and market growth

Smart Distribution for Industrial Application Market Dynamics

Driver

Rising Industrial Automation And Demand For Efficient Energy Management

The increasing adoption of Industry 4.0 technologies and automated industrial processes is driving the deployment of smart distribution systems. These systems enable predictive maintenance, real-time monitoring, and fault detection to reduce operational downtime and costs. The integration of AI and machine learning for predictive insights further enhances operational efficiency and decision-making

The expansion of manufacturing, energy, and process industries across emerging and developed markets is encouraging the integration of intelligent distribution networks. These solutions support scalable, reliable, and efficient power management in industrial facilities of varying sizes. Continuous industrial growth, coupled with rising production complexity, necessitates smart, automated distribution systems to optimize operations

OEMs and system integrators are increasingly offering modular and IoT-enabled smart distribution solutions, simplifying installation, reducing operational costs, and improving network resilience. This trend supports wider adoption across industrial sectors. In addition, remote monitoring capabilities are helping industries maintain system reliability while reducing onsite labor requirements

For instance, in 2022, several large-scale chemical and manufacturing plants in North America implemented smart distribution systems to optimize energy usage, enhance safety compliance, and improve overall operational efficiency. The systems allowed real-time alerts, automated load balancing, and predictive maintenance scheduling, which minimized unplanned outages and extended equipment life

While industrial automation and energy efficiency are driving market growth, ensuring system interoperability, cybersecurity, and seamless integration with legacy infrastructure remains crucial for sustained adoption. Companies are increasingly investing in standardized protocols, encryption, and secure cloud connectivity to address operational and security challenges

Restraint/Challenge

High Initial Investment And Technical Complexity

The high cost of implementing advanced smart distribution systems, including sensors, controllers, and software platforms, limits adoption among cost-sensitive industrial operators. Budget constraints are a significant barrier for small and medium-sized facilities. In addition, recurring maintenance, firmware updates, and training costs add to the total cost of ownership, delaying ROI

In many regions, there is a lack of skilled personnel capable of designing, installing, and maintaining complex smart distribution networks. Technical expertise is required to optimize system performance, integrate with legacy equipment, and ensure operational safety. This skill gap is particularly acute in emerging markets where automation adoption is still in its early stages

Market penetration is also restricted by supply chain challenges and installation complexity, particularly for retrofitting older industrial facilities. Ensuring consistent performance and reliability across diverse industrial environments adds engineering challenges. Delays in component delivery or software integration can further slow deployment and increase project costs

For instance, in 2023, several mid-sized manufacturing plants in Asia-Pacific delayed smart distribution system adoption due to high upfront costs and a shortage of trained technical staff. Many facilities had to rely on phased deployment plans and external consultants to implement systems successfully, highlighting operational and financial constraints

While technological advancements continue to enhance system capabilities, addressing cost, complexity, and integration challenges is essential. Collaboration between component suppliers, system integrators, and industrial operators is necessary to unlock the full potential of the smart distribution for industrial application market. Government incentives, training programs, and standardization efforts are also crucial to accelerate adoption and support long-term industrial digitization

Smart Distribution for Industrial Application Market Scope

The market is segmented on the basis of product type and end use.

- By Product Type

On the basis of product type, the smart distribution for industrial application market is segmented into distribution automation terminal, intelligent medium voltage switchgear, and complete set of low voltage electrical equipment. The intelligent medium voltage switchgear segment held the largest market revenue share in 2024, driven by its critical role in controlling, protecting, and isolating electrical equipment in industrial power networks. These systems provide enhanced operational safety, reliability, and real-time monitoring, making them a preferred choice for industrial operators.

The distribution automation terminal segment is expected to witness the fastest growth rate from 2025 to 2032, driven by its ability to enable real-time monitoring, automated fault detection, and remote control across industrial power distribution networks. Distribution automation terminals are particularly popular for improving energy efficiency, reducing downtime, and integrating with IoT-enabled smart grid solutions.

- By End Use

On the basis of end use, the market is segmented into power systems, intelligent building, petrochemical, medical, metallurgy, traffic, and other sectors. The power systems segment held the largest revenue share in 2024, fueled by the growing demand for reliable and efficient electrical distribution in industrial and utility infrastructures. These systems enhance operational continuity, support energy management, and enable predictive maintenance across high-demand industrial environments.

The intelligent building segment is expected to witness the fastest growth rate from 2025 to 2032, driven by rising adoption of automated energy management, smart metering, and connected building solutions. Intelligent building applications benefit from modular smart distribution systems that enhance energy optimization, safety, and operational efficiency, making them increasingly attractive in commercial and industrial construction projects.

Smart Distribution for Industrial Application Market Regional Analysis

- North America dominated the smart distribution for industrial application market with the largest revenue share in 2024, driven by increasing industrial automation, demand for efficient energy management, and growing adoption of Industry 4.0 technologies

- Industrial operators in the region highly value the benefits of smart distribution systems, including real-time monitoring, predictive maintenance, and optimized energy usage, which improve operational efficiency and reduce downtime

- This widespread adoption is further supported by advanced industrial infrastructure, high capital investment capabilities, and a strong focus on sustainable energy management, establishing smart distribution systems as a preferred solution across manufacturing, chemical, and processing industries

U.S. Smart Distribution for Industrial Application Market Insight

The U.S. smart distribution for industrial application market captured the largest revenue share in 2024 within North America, fueled by the rapid adoption of intelligent industrial solutions and the integration of IoT-enabled systems. Companies are increasingly prioritizing real-time monitoring, predictive maintenance, and energy optimization across facilities. The growing trend of automation in manufacturing plants, petrochemical units, and other industrial sectors, combined with government initiatives promoting energy efficiency, further propels the market’s expansion. Moreover, the presence of advanced system integrators and technology providers is significantly contributing to market growth.

Europe Smart Distribution for Industrial Application Market Insight

The Europe market is expected to witness the fastest growth rate from 2025 to 2032, primarily driven by stringent industrial safety regulations, rising energy efficiency standards, and the need for reliable power management across large industrial facilities. Increasing urbanization, coupled with the growing adoption of automated industrial solutions, is fostering demand. European industrial operators are also drawn to modular, IoT-enabled smart distribution systems for better fault detection, predictive maintenance, and operational reliability. The region is witnessing significant growth across manufacturing, energy, and process industries.

U.K. Smart Distribution for Industrial Application Market Insight

The U.K. market is expected to witness strong growth from 2025 to 2032, driven by government initiatives supporting smart energy management and industrial automation. Industrial operators are adopting advanced smart distribution systems to enhance operational efficiency, reduce energy losses, and improve system reliability. In addition, investments in Industry 4.0 technologies and digitalized infrastructure are encouraging deployment across large-scale manufacturing, petrochemical, and traffic management facilities. The country’s emphasis on energy optimization and sustainability is expected to continue to stimulate market growth.

Germany Smart Distribution for Industrial Application Market Insight

The Germany market is expected to witness strong growth from 2025 to 2032, fueled by increasing awareness of energy efficiency, industrial automation, and advanced electrical distribution solutions. Germany’s robust industrial infrastructure, emphasis on innovation, and strict environmental regulations promote the adoption of smart distribution systems. Operators in manufacturing, metallurgy, and medical industries are increasingly integrating intelligent, IoT-enabled distribution networks for predictive maintenance, optimized power usage, and reliable operations. The demand for eco-friendly and scalable systems is driving adoption across commercial and industrial applications.

Asia-Pacific Smart Distribution for Industrial Application Market Insight

The Asia-Pacific market is expected to witness the highest growth rate from 2025 to 2032, driven by rapid industrialization, increasing urbanization, rising energy demand, and technological advancements in countries such as China, Japan, and India. Governments in the region are promoting smart grid and industrial automation initiatives, which are fueling deployment. Furthermore, the region is emerging as a manufacturing hub for smart distribution components and systems, increasing affordability and accessibility for industrial operators across manufacturing, petrochemical, and traffic sectors.

Japan Smart Distribution for Industrial Application Market Insight

The Japan market is expected to witness strong growth from 2025 to 2032 due to the country’s focus on automation, energy optimization, and advanced industrial technologies. Japanese operators prioritize the deployment of intelligent distribution solutions for predictive maintenance, fault detection, and operational efficiency. The integration of smart distribution systems with IoT and AI-enabled monitoring tools is accelerating growth. In addition, Japan’s aging workforce is driving the need for automated solutions that reduce human intervention while improving reliability in industrial operations.

China Smart Distribution for Industrial Application Market Insight

The China market accounted for the largest revenue share in Asia-Pacific in 2024, attributed to rapid industrialization, growing energy demand, and adoption of smart manufacturing technologies. China stands as one of the largest markets for industrial automation and intelligent distribution solutions. The push towards smart factories, smart cities, and digitalized industrial processes, alongside strong domestic manufacturers and system integrators, is propelling market growth. Affordable, modular, and IoT-enabled smart distribution systems are increasingly deployed across power systems, petrochemical facilities, and manufacturing plants, enhancing operational efficiency and energy management.

Smart Distribution for Industrial Application Market Share

The Smart Distribution for Industrial Application industry is primarily led by well-established companies, including:

• ABB (Switzerland)

• Siemens (Germany)

• Schneider Electric (France)

• General Electric Company (U.S.)

• Emerson Electric Co. (U.S.)

• Rockwell Automation, Inc. (U.S.)

• Yokogawa India Ltd. (India)

• Mitsubishi Electric Corporation (Japan)

• Danaher (U.S.)

• Honeywell International Inc. (U.S.)

• Hitachi, Ltd. (Japan)

• Eaton (Ireland)

• OMRON Corporation (Japan)

• Itron Inc. (U.S.)

• Landis+Gyr (Switzerland)

• Aclara Technologies LLC. (U.S.)

• Cisco (U.S.)

• Open Systems International, Inc. (U.S.)

• IBM Corporation (U.S.)

• Wipro Limited (India)

• Oracle (U.S.)

• S&C Electric Company (U.S.)

• Kamstrup A/S (Denmark)

• Trilliant Holdings Inc. (U.S.)

• Globema (Poland)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Smart Distribution For Industrial Application Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Smart Distribution For Industrial Application Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Smart Distribution For Industrial Application Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.