Global Smart Pneumatic Module Market

Market Size in USD Billion

CAGR :

%

USD

4.67 Billion

USD

8.51 Billion

2024

2032

USD

4.67 Billion

USD

8.51 Billion

2024

2032

| 2025 –2032 | |

| USD 4.67 Billion | |

| USD 8.51 Billion | |

|

|

|

|

Smart Pneumatic Module Market Size

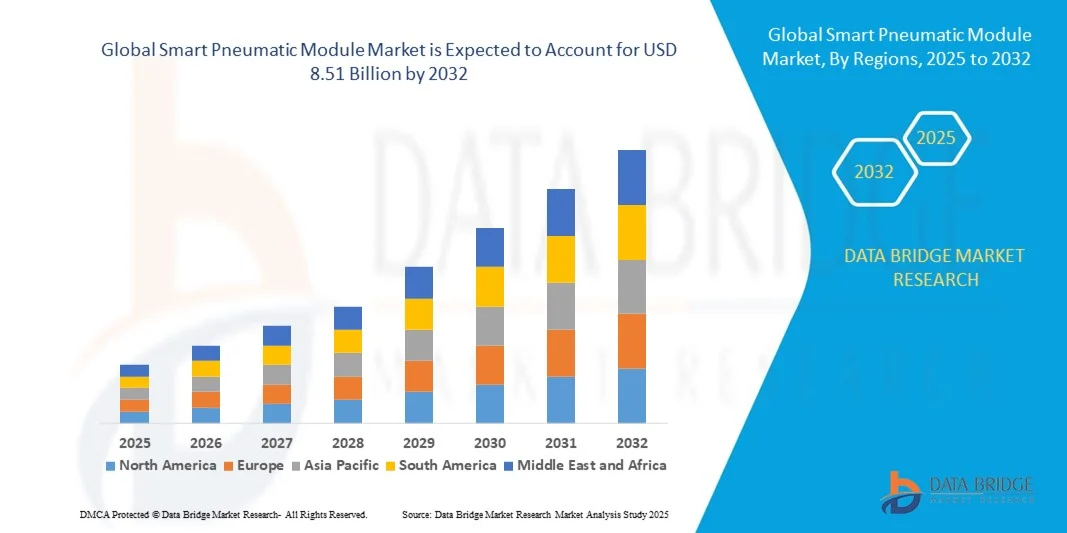

- The global smart pneumatic module market size was valued at USD 4.67 billion in 2024 and is expected to reach USD 8.51 billion by 2032, at a CAGR of 7.80% during the forecast period

- The market growth is largely fuelled by the increasing adoption of automation in industrial processes, rising demand for energy-efficient pneumatic systems, and integration of IoT-enabled devices for real-time monitoring and predictive maintenance

- The growing need for precise motion control in sectors such as automotive, electronics, and packaging is further driving the deployment of smart pneumatic modules

Smart Pneumatic Module Market Analysis

- The adoption of smart pneumatic modules is enhancing operational efficiency, reducing downtime, and minimizing energy consumption in automated production lines

- Increasing investments in smart manufacturing and Industry 4.0 initiatives are supporting the integration of these modules across various industrial applications

- North America dominated the smart pneumatic module market with the largest revenue share in 2024, driven by increasing adoption of industrial automation, advanced manufacturing practices, and the integration of IoT-enabled devices across factories and process industries

- Asia-Pacific region is expected to witness the highest growth rate in the global smart pneumatic module market, driven by increasing manufacturing activities, expansion of industrial automation, and growing investment in smart factories across China, Japan, and Southeast Asian countries

- The hardware segment held the largest market revenue share in 2024, driven by the widespread deployment of IoT-enabled modules, sensors, actuators, and controllers in industrial automation systems. Hardware components often provide reliable, high-performance operation and form the backbone of automated pneumatic systems, making them a preferred choice for large-scale manufacturing facilities

Report Scope and Smart Pneumatic Module Market Segmentation

|

Attributes |

Smart Pneumatic Module Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Smart Pneumatic Module Market Trends

Rise Of IoT-Enabled And Intelligent Pneumatic Modules

- The growing adoption of smart pneumatic modules is transforming industrial automation by enabling precise control and real-time monitoring of pneumatic systems. These modules improve operational efficiency, reduce energy consumption, and allow predictive maintenance, minimizing downtime and operational losses. In addition, integration with cloud platforms allows operators to monitor multiple facilities simultaneously, enhancing operational transparency and decision-making across global operations

- The increasing demand for automated manufacturing processes and Industry 4.0 integration is accelerating the deployment of connected pneumatic modules. These solutions are particularly effective in factories and process industries where precise motion control and monitoring are critical for productivity. They also enable predictive fault detection, helping avoid costly breakdowns and ensuring smoother production workflows in high-volume manufacturing environments

- The affordability and modularity of modern pneumatic modules are making them attractive for both new installations and retrofitting projects. Manufacturers and industrial operators benefit from scalable, plug-and-play modules that reduce installation complexity and maintenance efforts. This modular approach allows easy expansion or upgrades of pneumatic systems without significant downtime or additional infrastructure investment

- For instance, in 2023, several automotive and packaging plants in Germany implemented IoT-enabled pneumatic modules for assembly line automation, resulting in improved energy efficiency, faster throughput, and reduced machine downtime. These deployments also enhanced remote monitoring capabilities, allowing plant managers to optimize performance and reduce human intervention in critical processes

- While smart pneumatic modules enhance productivity and reliability, their effectiveness depends on ongoing technological innovation, standardized protocols, and workforce training. Providers must focus on modularity, connectivity, and cost-efficiency to capitalize on global demand. Moreover, increased interoperability with other industrial automation components is essential for seamless integration into diverse production ecosystems

Smart Pneumatic Module Market Dynamics

Driver

Increasing Adoption Of Industrial Automation And Focus On Operational Efficiency

- The rise of automated manufacturing and smart factories is driving the adoption of pneumatic modules that can be integrated into larger industrial IoT ecosystems. These systems enable real-time data collection and analytics for performance optimization. They also support predictive maintenance strategies, reducing unplanned downtime and extending equipment lifecycle, which is particularly valuable in high-output manufacturing facilities

- Companies are increasingly aware of the benefits of predictive maintenance, energy savings, and precise motion control offered by smart pneumatic modules, leading to higher adoption across automotive, packaging, and food processing industries. In addition, the ability to integrate modules with ERP and MES systems provides manufacturers with actionable insights, boosting operational efficiency and reducing labor costs

- Government initiatives promoting Industry 4.0, energy efficiency, and sustainable manufacturing practices are supporting investment in smart pneumatic technologies, encouraging upgrades to intelligent control systems. These programs often include incentives or grants, which reduce the financial burden of adoption and accelerate the transition to digitalized production environments

- For instance, in 2022, several European industrial facilities implemented connected pneumatic modules to monitor and control compressed air systems, resulting in reduced energy consumption and lower operational costs. This also enabled predictive alerts for system maintenance, improving uptime and enhancing workplace safety by reducing the risk of sudden equipment failure

- While industrial automation and regulatory support are key drivers, challenges such as interoperability, integration complexity, and upfront investment must be addressed for long-term adoption. In addition, market growth is influenced by the increasing demand for scalable solutions capable of adapting to varying production requirements in different industry sectors

Restraint/Challenge

High Initial Cost And Technical Complexity Of Smart Pneumatic Modules

- The high price of advanced pneumatic modules, including IoT-enabled and intelligent systems, limits adoption among small and mid-sized industrial operators. Capital-intensive equipment remains a barrier to widespread deployment. Companies often delay purchasing due to budget constraints, and this slows overall market growth despite growing awareness of benefits

- The technical complexity of installation, configuration, and maintenance requires skilled personnel, which restricts accessibility for facilities in developing regions or with limited technical expertise. Training programs and service support are essential to ensure proper usage, but lack of such resources in remote areas hampers efficient adoption of smart pneumatic modules

- Supply chain challenges, including availability of sensors, controllers, and connectivity modules, can delay deployment and increase operational costs, particularly for remote manufacturing sites. Global disruptions in electronics manufacturing can also affect production schedules and module pricing, creating uncertainty for industrial buyers

- For instance, in 2023, several Asian manufacturing units reported delays in retrofitting smart pneumatic modules due to limited local availability of components and trained service providers. These delays not only increased project costs but also impacted production timelines, highlighting the need for better supply chain management and localized support networks

- While pneumatic technology continues to evolve, addressing cost, technical complexity, and workforce training is essential. Market stakeholders must focus on scalable, modular, and user-friendly solutions to expand adoption and ensure sustainable growth. Continuous development of plug-and-play solutions and standardization of communication protocols can further mitigate integration challenges and encourage wider industry adoption

Smart Pneumatic Module Market Scope

The market is segmented on the basis of component and end users.

- By Component

On the basis of component, the smart pneumatic module market is segmented into hardware, software, and services. The hardware segment held the largest market revenue share in 2024, driven by the widespread deployment of IoT-enabled modules, sensors, actuators, and controllers in industrial automation systems. Hardware components often provide reliable, high-performance operation and form the backbone of automated pneumatic systems, making them a preferred choice for large-scale manufacturing facilities.

The software segment is expected to witness the fastest growth rate from 2025 to 2032, driven by its ability to enable real-time monitoring, predictive maintenance, and seamless integration with industrial IoT platforms. Software solutions allow operators to analyze performance data, optimize system efficiency, and remotely control multiple pneumatic modules across production lines, making them critical for modern smart factories.

- By End Users

On the basis of end users, the market is segmented into oil and gas, energy and power, water and wastewater, automotive, semiconductor, food and beverages, and others. The automotive segment held a significant market revenue share in 2024, fueled by the increasing adoption of smart pneumatic modules for assembly line automation, robotics, and material handling systems. Automotive manufacturers rely on these modules for precise motion control and energy-efficient operations.

The food and beverages segment is expected to witness the fastest growth rate from 2025 to 2032, driven by the rising demand for automated packaging, filling, and processing systems. Smart pneumatic modules enhance operational efficiency, reduce downtime, and ensure compliance with hygiene and safety standards, making them indispensable in food and beverage manufacturing facilities.

Smart Pneumatic Module Market Regional Analysis

- North America dominated the smart pneumatic module market with the largest revenue share in 2024, driven by increasing adoption of industrial automation, advanced manufacturing practices, and the integration of IoT-enabled devices across factories and process industries

- Manufacturers and industrial operators in the region highly value energy efficiency, predictive maintenance, and real-time monitoring capabilities offered by smart pneumatic modules

- This widespread adoption is further supported by technological expertise, availability of skilled workforce, and government incentives for Industry 4.0 implementation, establishing smart pneumatic modules as a preferred solution for manufacturing and processing facilities

U.S. Smart Pneumatic Module Market Insight

The U.S. smart pneumatic module market captured the largest revenue share in 2024 within North America, fueled by the growing focus on smart factories, industrial automation, and operational efficiency. Companies are increasingly investing in connected modules to monitor and optimize compressed air systems, reduce downtime, and lower energy consumption. The presence of leading automation technology providers and advanced industrial infrastructure is significantly contributing to market expansion.

Europe Smart Pneumatic Module Market Insight

The Europe smart pneumatic module market is expected to witness the fastest growth rate from 2025 to 2032, primarily driven by stringent environmental regulations, focus on energy efficiency, and the rise of smart factories. The region is witnessing extensive adoption across automotive, food and beverage, and semiconductor industries. European manufacturers are increasingly implementing IoT-enabled and modular pneumatic modules for retrofitting and new production lines, improving process efficiency and productivity.

U.K. Smart Pneumatic Module Market Insight

The U.K. smart pneumatic module market is expected to witness rapid growth from 2025 to 2032, driven by industrial digitalization initiatives, rising demand for automation, and a focus on energy-efficient manufacturing solutions. Adoption is further accelerated by government programs promoting Industry 4.0 and sustainable production methods. Companies in the U.K. are leveraging smart modules for enhanced system control, predictive maintenance, and integration with industrial IoT platforms.

Germany Smart Pneumatic Module Market Insight

The Germany smart pneumatic module market is expected to witness substantial growth from 2025 to 2032, fueled by strong industrial infrastructure, high adoption of automated manufacturing systems, and emphasis on energy conservation. German industries are increasingly integrating smart pneumatic modules into production lines for real-time monitoring and process optimization. The country’s robust R&D ecosystem supports innovation in IoT-enabled and intelligent pneumatic solutions, further driving market growth.

Asia-Pacific Smart Pneumatic Module Market Insight

The Asia-Pacific smart pneumatic module market is expected to witness the fastest growth rate from 2025 to 2032, driven by rapid industrialization, growing adoption of smart factories, and increasing investments in automation in countries such as China, Japan, and India. The region’s expanding manufacturing base and rising focus on productivity and energy efficiency are fueling demand. In addition, APAC is emerging as a hub for smart pneumatic module manufacturing, enabling cost-effective and widely accessible solutions.

Japan Smart Pneumatic Module Market Insight

The Japan smart pneumatic module market is expected to witness significant growth from 2025 to 2032 due to the country’s advanced manufacturing culture, adoption of Industry 4.0 technologies, and strong emphasis on operational efficiency. Japanese manufacturers are increasingly integrating IoT-enabled pneumatic modules into automated assembly lines, enabling predictive maintenance, energy savings, and precise process control. The aging industrial workforce is also driving the demand for user-friendly, automated solution.

China Smart Pneumatic Module Market Insight

The China smart pneumatic module market accounted for the largest market revenue share in Asia-Pacific in 2024, attributed to rapid industrial growth, rising adoption of smart manufacturing technologies, and increased focus on energy-efficient production systems. China is one of the largest markets for automation and industrial IoT solutions, and smart pneumatic modules are being widely deployed across automotive, packaging, and semiconductor industries. Government initiatives promoting smart factories and sustainable manufacturing practices are key factors propelling market growth.

Smart Pneumatic Module Market Share

The Smart Pneumatic Module industry is primarily led by well-established companies, including:

- Emerson Electric Co. (U.S.)

- Rotork (U.K.)

- Festo Corporation (Germany)

- Bosch Rexroth Ltd. (Germany)

- Chicago Pneumatic (U.S.)

- Delton Pneumatics (India)

- MITSUBISHI HEAVY INDUSTRIES MACHINERY SYSTEMS, LTD. (Japan)

- Eaton (U.S.)

- Gardner Denver (U.S.)

- Jiffy Air Tool (U.S.)

- Bimba Manufacturing Company (U.S.)

- Thomson Industries, Inc. (U.S.)

- Ingersoll-Rand plc (Ireland/U.S.)

- Makita Corporation (Japan)

- MANN+HUMMEL (Germany)

- Pepperl+Fuchs (India) Pvt. Ltd. (India)

- NINGBO SMART PNEUMATIC CO LTD (China)

- PARKER HANNIFIN CORP (U.S.)

- SMC Corporation of America (U.S.)

- Stanley Black & Decker, Inc. (U.S.)

- VAC-U-MAX (U.S.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Smart Pneumatic Module Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Smart Pneumatic Module Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Smart Pneumatic Module Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.