Global Starch Recovery Systems For Frozen Food Market

Market Size in USD Million

CAGR :

%

USD

195.27 Million

USD

290.71 Million

2025

2033

USD

195.27 Million

USD

290.71 Million

2025

2033

| 2026 –2033 | |

| USD 195.27 Million | |

| USD 290.71 Million | |

|

|

|

|

Global Starch Recovery Systems for Frozen Food Market Size

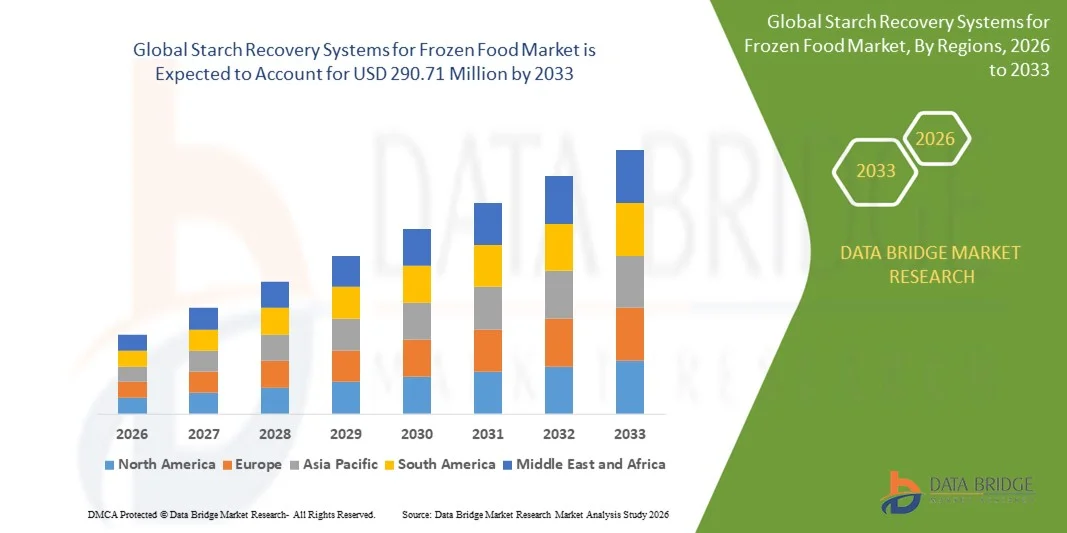

- The global Starch Recovery Systems for Frozen Food Market size was valued at USD 195.27 million in 2025 and is expected to reach USD 290.71 million by 2033, at a CAGR of 5.10% during the forecast period.

- The market growth is primarily driven by increasing demand for sustainable food processing solutions and the need to optimize resource utilization in frozen food production, resulting in higher adoption of starch recovery technologies.

- Additionally, growing regulatory focus on food waste reduction and operational efficiency, coupled with advancements in automation and filtration technologies, is encouraging manufacturers to implement starch recovery systems, thereby propelling the overall market expansion.

Global Starch Recovery Systems for Frozen Food Market Analysis

- Starch recovery systems for frozen food, designed to capture and recycle starch from production processes, are becoming increasingly essential in modern frozen food manufacturing due to their ability to enhance operational efficiency, reduce waste, and support sustainable production practices.

- The growing adoption of starch recovery systems is primarily driven by rising demand for cost-effective food processing, stringent regulations on food waste, and the need for improved resource utilization in frozen food production facilities.

- North America dominated the Global Starch Recovery Systems for Frozen Food Market with the largest revenue share of 32.1% in 2025, supported by advanced food processing infrastructure, early adoption of sustainable technologies, and the presence of key market players, with the U.S. witnessing significant implementation of starch recovery systems in large-scale frozen food plants, driven by innovations in filtration and recycling technologies.

- Asia-Pacific is expected to be the fastest-growing region in the Global Starch Recovery Systems for Frozen Food Market during the forecast period due to increasing industrialization, expanding frozen food production, and rising investment in sustainable processing technologies.

- The hydro cyclones and centrifuges segment dominated the market with the largest market revenue share of 41.5% in 2025, driven by its superior efficiency in separating starch from water and slurry, high recovery rates, and suitability for large-scale production.

Report Scope and Global Starch Recovery Systems for Frozen Food Market Segmentation

|

Attributes |

Starch Recovery Systems for Frozen Food Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Global Starch Recovery Systems for Frozen Food Market Trends

Enhanced Efficiency Through Automation and AI Integration

- A significant and accelerating trend in the global Starch Recovery Systems for Frozen Food Market is the deepening integration of artificial intelligence (AI) and advanced automation technologies into starch recovery processes. This combination is significantly improving operational efficiency, yield optimization, and process control in frozen food manufacturing.

- For instance, modern starch recovery systems equipped with AI-enabled sensors can continuously monitor slurry viscosity, moisture content, and starch concentration, automatically adjusting separation parameters to maximize recovery rates and minimize waste. Similarly, some Bühler and GEA systems utilize machine learning algorithms to optimize process flow based on real-time production data, reducing downtime and energy consumption.

- AI integration in starch recovery systems enables predictive maintenance by identifying potential equipment failures before they occur, thereby reducing unplanned downtime and extending machine lifespan. Additionally, process optimization algorithms can suggest adjustments to improve starch purity and throughput, enhancing overall production efficiency.

- The seamless integration of starch recovery systems with broader factory automation platforms allows centralized control over multiple stages of frozen food production, from washing and peeling to drying and packaging. Through a single interface, operators can monitor, control, and optimize starch recovery alongside other production processes, creating a unified and highly efficient manufacturing environment.

- This trend toward smarter, more automated, and interconnected recovery systems is fundamentally transforming operational standards in the frozen food industry. Consequently, companies such as GEA, Bühler, and ANDRITZ are developing AI-enabled starch recovery solutions with features like real-time process optimization, automated cleaning cycles, and predictive maintenance.

- The demand for starch recovery systems with advanced automation and AI capabilities is growing rapidly across both large-scale and mid-sized frozen food facilities, as manufacturers increasingly prioritize efficiency, sustainability, and process intelligence.

Global Starch Recovery Systems for Frozen Food Market Dynamics

Driver

Growing Need Due to Rising Demand for Sustainable and Efficient Food Processing

- The increasing focus on sustainability in the food industry, coupled with rising demand for operational efficiency in frozen food manufacturing, is a significant driver for the heightened adoption of starch recovery systems.

- For instance, in 2025, GEA Group introduced an advanced automated starch recovery system for frozen vegetable processing, featuring real-time monitoring and process optimization. Such innovations by key companies are expected to drive the starch recovery systems market growth during the forecast period.

- As manufacturers aim to reduce food waste and improve cost-efficiency, starch recovery systems offer advanced features such as high-yield separation, automated filtration, and energy-efficient operations, providing a compelling upgrade over traditional waste management methods.

- Furthermore, the growing adoption of integrated food processing lines and automated factories is making starch recovery systems an essential component, offering seamless integration with washing, peeling, and packaging processes.

- The benefits of recovering and reusing starch, reducing water and chemical usage, and optimizing production throughput are key factors propelling the adoption of these systems across large-scale and mid-sized frozen food facilities. The trend towards smart, automated production lines and increasing regulatory pressure for waste reduction further contribute to market growth.

Restraint/Challenge

High Initial Investment and Operational Complexity

- The relatively high capital expenditure required for installing advanced starch recovery systems, combined with the complexity of operating and maintaining these systems, poses a significant challenge to broader market adoption.

- For instance, smaller frozen food manufacturers may hesitate to invest in automated recovery systems due to upfront costs and the need for trained personnel to manage the equipment effectively.

- Addressing these challenges through modular and scalable system designs, operator training programs, and after-sales service support is crucial for increasing adoption. Companies such as Bühler and ANDRITZ emphasize ease of integration, automated monitoring, and remote diagnostic capabilities to mitigate operational challenges.

- Additionally, energy consumption and maintenance requirements for large-scale systems can be perceived as operational drawbacks, particularly in regions with limited infrastructure or technical expertise.

- Overcoming these barriers through cost-effective system models, automation, and technical support will be vital for sustained growth of the starch recovery systems market in the frozen food industry.

Global Starch Recovery Systems for Frozen Food Market Scope

The starch recovery systems for frozen food market are segmented on the basis of component, applications and organization size.

- By Component

On the basis of component, the Global Starch Recovery Systems for Frozen Food Market is segmented into refining sieves, hydro cyclones and centrifuges, vacuum fitters, screw conveyors, and filling stations. The hydro cyclones and centrifuges segment dominated the market with the largest market revenue share of 41.5% in 2025, driven by its superior efficiency in separating starch from water and slurry, high recovery rates, and suitability for large-scale production. These systems are widely adopted in frozen food processing plants due to their ability to operate continuously, reduce labor requirements, and maintain high product quality.

The screw conveyors and filling stations segment is expected to witness the fastest CAGR of 22.3% from 2026 to 2033, fueled by increasing automation in frozen food plants, demand for integrated material handling systems, and the need for precise, efficient starch transfer and storage. Manufacturers are increasingly deploying these components to improve production line efficiency and minimize starch losses.

- By Applications

On the basis of application, the Global Starch Recovery Systems for Frozen Food Market is segmented into frozen products, chips and snack pellets, and dehydrated products. The frozen products segment accounted for the largest market revenue share of 46.8% in 2025, driven by the high volume of frozen vegetables, ready-to-eat meals, and seafood production requiring efficient starch recovery. The growing consumer preference for frozen foods, combined with stringent waste reduction policies, further supports adoption in this category.

The chips and snack pellets segment is anticipated to witness the fastest CAGR of 21.9% from 2026 to 2033, fueled by the rapid growth of the snack food industry and the need to recover starch during frying, extrusion, and drying processes. Manufacturers are investing in specialized recovery systems to improve yield, reduce production costs, and comply with sustainability mandates.

- By Organization Size

On the basis of organization size, the Global Starch Recovery Systems for Frozen Food Market is segmented into large, medium, and small-sized organizations. The large-sized organization segment dominated the market with a revenue share of 52.3% in 2025, attributed to higher capital investment capacity, large-scale frozen food production, and the ability to integrate advanced recovery technologies into existing processing lines. Large manufacturers benefit from enhanced operational efficiency, reduced wastage, and improved cost-effectiveness.

The medium-sized organization segment is expected to witness the fastest CAGR of 20.8% from 2026 to 2033, driven by increasing industrialization, modernization of mid-sized food processing plants, and growing awareness of sustainable production practices. Medium-sized enterprises are adopting modular and scalable starch recovery solutions to optimize production, minimize waste, and compete with larger players while maintaining operational flexibility.

Global Starch Recovery Systems for Frozen Food Market Regional Analysis

- North America dominated the Global Starch Recovery Systems for Frozen Food Market with the largest revenue share of 32.1% in 2025, driven by the region’s advanced food processing infrastructure, high adoption of automation technologies, and increasing focus on sustainable production practices.

- Frozen food manufacturers in the region prioritize operational efficiency, cost reduction, and waste minimization, which are effectively addressed by starch recovery systems. The demand is further supported by strict food safety and environmental regulations, incentivizing manufacturers to implement recovery solutions that optimize starch reuse and reduce wastewater.

- This widespread adoption is reinforced by the presence of key market players, technological innovations in recovery systems, and large-scale production facilities. North American manufacturers increasingly integrate automated and AI-enabled starch recovery systems into their production lines, enhancing throughput, process control, and sustainability, establishing these systems as a standard solution in the frozen food industry for both residential and commercial frozen food production facilities.

U.S. Starch Recovery Systems Market Insight

The U.S. starch recovery systems market captured the largest revenue share of 38% in 2025 within North America, driven by the widespread adoption of advanced frozen food processing technologies and the focus on sustainable production practices. Manufacturers are increasingly prioritizing operational efficiency, waste reduction, and cost optimization, fueling demand for high-performance starch recovery systems. The trend of automating food processing lines, coupled with stringent food safety and environmental regulations, further supports market growth. Additionally, technological innovations such as automated centrifuges and hydrocyclone-based recovery systems are enhancing throughput and product quality, strengthening adoption across large-scale and mid-sized frozen food plants.

Europe Starch Recovery Systems Market Insight

The Europe starch recovery systems market is projected to expand at a substantial CAGR throughout the forecast period, primarily driven by strict food safety regulations and increasing demand for sustainable manufacturing. The rise in urbanization, coupled with higher consumption of frozen foods, is boosting adoption in countries such as Germany, France, and Italy. Manufacturers are increasingly integrating automated starch recovery technologies into both new and existing production lines to improve efficiency and reduce waste. The market growth is further supported by innovations in energy-efficient processing equipment and increasing investments in eco-friendly frozen food operations.

U.K. Starch Recovery Systems Market Insight

The U.K. starch recovery systems market is expected to grow at a noteworthy CAGR during the forecast period, driven by rising frozen food production, the need for cost-effective operations, and sustainability initiatives. The emphasis on reducing waste and improving process efficiency encourages both small and large manufacturers to adopt starch recovery systems. Furthermore, technological advancements in compact and automated recovery solutions, suitable for mid-sized and large-scale facilities, are expected to stimulate market growth in the U.K.

Germany Starch Recovery Systems Market Insight

The Germany starch recovery systems market is expected to expand at a considerable CAGR during the forecast period, fueled by increasing awareness of sustainable food production and efficiency optimization. Germany’s well-established frozen food industry, coupled with the government’s focus on environmental compliance, drives the adoption of advanced starch recovery technologies. Manufacturers are increasingly integrating hydrocyclones, centrifuges, and screw conveyors into production lines to minimize starch wastage while maintaining high product quality, particularly in frozen vegetables and processed food segments.

Asia-Pacific Starch Recovery Systems Market Insight

The Asia-Pacific starch recovery systems market is poised to grow at the fastest CAGR of 23% from 2026 to 2033, driven by rapid urbanization, increasing frozen food consumption, and rising industrialization in countries such as China, India, and Japan. The region’s growing manufacturing capacity, coupled with government initiatives promoting food sustainability and digitalization, supports the adoption of automated and high-efficiency starch recovery systems. Cost-effective solutions and the availability of domestic manufacturers further enhance accessibility, making APAC the fastest-growing regional market globally.

Japan Starch Recovery Systems Market Insight

The Japan starch recovery systems market is gaining momentum due to high technological adoption, rising demand for processed and frozen foods, and a strong focus on sustainable production. Manufacturers in Japan are increasingly integrating automated starch recovery systems with production lines to optimize efficiency, reduce water and starch wastage, and meet stringent environmental regulations. The emphasis on compact, energy-efficient systems suitable for smaller plants is also driving growth in both residential-scale and commercial food processing operations.

China Starch Recovery Systems Market Insight

The China starch recovery systems market accounted for the largest market revenue share in Asia-Pacific in 2025, driven by rapid industrialization, a growing frozen food market, and rising demand for cost-efficient production. The country’s large-scale food processing facilities increasingly adopt hydrocyclones, centrifuges, and screw conveyors to recover starch and enhance process sustainability. Government initiatives promoting waste reduction, coupled with strong domestic manufacturing capabilities and affordable recovery solutions, are key factors propelling market growth in China.

Global Starch Recovery Systems for Frozen Food Market Share

The Starch Recovery Systems for Frozen Food industry is primarily led by well-established companies, including:

• Bühler Group (Switzerland)

• GEA Group (Germany)

• Tetra Pak (Sweden)

• ANDRITZ AG (Austria)

• Clextral (France)

• Fenco Food Machinery (Italy)

• Alfa Laval (Sweden)

• Flottweg SE (Germany)

• SPX FLOW (U.S.)

• Kason Corporation (U.S.)

• Viking Masek (U.S.)

• Shanghai Jwell Machinery (China)

• Yantai Oriental Machinery (China)

• Zhangjiagang King Machine (China)

• Kemper GmbH (Germany)

• Maris SpA (Italy)

• Rivulis Food Tech (Israel)

• ProSys Engineering (India)

• Future Food Technologies (U.S.)

• Hoppecke Industrial Systems (Germany)

What are the Recent Developments in Global Starch Recovery Systems for Frozen Food Market?

- In April 2024, Bühler Group, a global leader in food processing technologies, launched a strategic initiative in South Africa to enhance frozen food production efficiency through its advanced starch recovery systems. This program underscores the company’s commitment to delivering high-performance, sustainable processing solutions tailored to the local food manufacturing sector. By leveraging its global expertise and cutting-edge technologies, Bühler aims to optimize starch recovery, reduce waste, and strengthen its presence in the rapidly growing Global Starch Recovery Systems for Frozen Food Market.

- In March 2024, GEA Group, a leading provider of process engineering solutions, introduced an upgraded centrifuge-based starch recovery system designed specifically for high-volume frozen food manufacturers. The system enhances operational efficiency, maximizes starch yield, and reduces energy consumption, reflecting GEA’s focus on sustainable and cost-effective solutions for the food processing industry.

- In March 2024, Tetra Pak successfully deployed its automated starch recovery and separation solution at a major frozen food facility in Bengaluru, India. The project leveraged state-of-the-art hydrocyclone and vacuum filtration technologies to improve process efficiency and minimize starch wastage, highlighting Tetra Pak’s dedication to innovation in sustainable food manufacturing.

- In February 2024, ANDRITZ AG, a global supplier of processing technologies, announced a strategic partnership with several leading frozen food manufacturers in the U.S. to implement advanced starch recovery systems. This collaboration focuses on optimizing starch extraction, improving product quality, and reducing production costs, demonstrating ANDRITZ’s commitment to advancing operational efficiency in the frozen food sector.

- In January 2024, GEA Group unveiled its next-generation screw conveyor and filling station systems at the International FoodTech Exhibition 2024. These systems, designed for seamless integration with existing frozen food production lines, enable higher starch recovery rates, lower energy usage, and enhanced process automation, reflecting the company’s focus on innovative, high-efficiency solutions for the global frozen food market.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Starch Recovery Systems For Frozen Food Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Starch Recovery Systems For Frozen Food Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Starch Recovery Systems For Frozen Food Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.