Global Stick Welding Electrode Market

Market Size in USD Million

CAGR :

%

USD

950.36 Million

USD

1,341.20 Million

2024

2032

USD

950.36 Million

USD

1,341.20 Million

2024

2032

| 2025 –2032 | |

| USD 950.36 Million | |

| USD 1,341.20 Million | |

|

|

|

|

Stick Welding Electrode Market Size

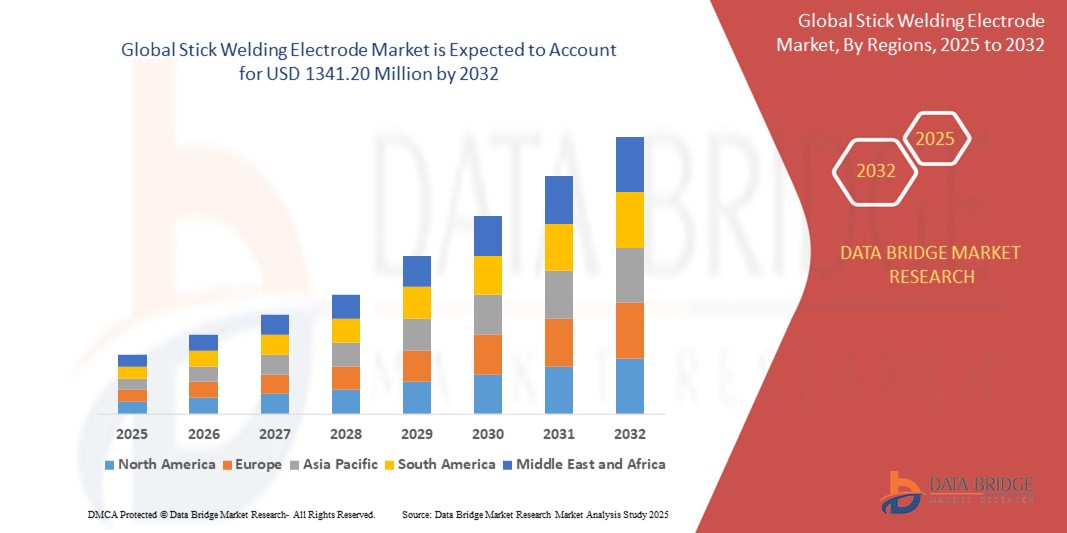

- The global stick welding electrode market size was valued at USD 950.36 million in 2024 and is expected to reach USD 1341.20 million by 2032, at a CAGR of 4.4% during the forecast period

- The market growth is largely fueled by increasing infrastructure development, rising industrialization across emerging economies, and the continued demand for cost-effective, versatile welding solutions across construction, manufacturing, and energy sectors

- Furthermore, the growing need for high-strength, durable welds in challenging field environments is reinforcing stick welding electrodes as the preferred choice, especially in outdoor, remote, or high-moisture conditions. These factors are accelerating the deployment of stick welding electrodes, thereby significantly boosting the industry's growth

Stick Welding Electrode Market Analysis

- Stick welding electrodes, also known as shielded metal arc welding (SMAW) electrodes, are consumable rods coated with flux that generate a protective gas shield during welding. They are widely used in construction, shipbuilding, heavy machinery, and pipeline projects due to their portability, arc stability, and ability to perform in adverse conditions

- The market is witnessing strong demand due to ongoing infrastructure upgrades, increasing preference for durable weld joints, and the cost-efficiency of stick welding systems, especially in areas lacking advanced welding infrastructure

- Asia-Pacific dominated the stick welding electrode market with a share of 38.5% in 2024, due to robust industrialization, expanding infrastructure development, and high demand from manufacturing and construction sectors in emerging economies

- North America is expected to be the fastest growing region in the stick welding electrode market during the forecast period due to increased investments in oil & gas pipeline networks, construction modernization, and reshoring of manufacturing operations

- Heat-resistant steel electrode segment dominated the market with a market share of 48.1% in 2024, due to its high performance in extreme thermal environments such as boilers, furnaces, and power plant equipment. These electrodes are highly favored in industries requiring welds that can withstand prolonged exposure to elevated temperatures without compromising structural integrity or mechanical strength. The segment's dominance is also supported by the rising adoption of heat-resistant alloys in thermal power generation and petrochemical applications, where weld reliability is critical

Report Scope and Stick Welding Electrode Market Segmentation

|

Attributes |

Stick Welding Electrode Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Stick Welding Electrode Market Trends

Rising Development of New Electrode Coatings

- The stick welding electrode market is experiencing robust growth, shaped by continuous innovations in electrode coatings aimed at enhancing weld quality, arc stability, and performance in demanding industrial environments

- For instance, leading manufacturers such as Lincoln Electric and ESAB are investing in R&D to introduce advanced low-hydrogen and high-efficiency coating formulations, enabling reduced weld defects and improved mechanical properties for automotive and infrastructure projects

- New coatings incorporate alloying elements and engineered fluxes, offering benefits such as easier slag removal, higher deposition rates, and better tolerance to contaminants, making them suitable for specialized applications including offshore, pipeline, and repair welding

- The drive for environmentally friendly and low-emission electrodes is prompting the introduction of coatings that lower fume generation and comply with stricter workplace safety and environmental guidelines

- Demand for consistent weld bead appearance and reduced post-weld cleaning is propelling adoption of next-generation coated electrodes across construction, shipbuilding, and heavy machinery manufacturing

- Rapid urbanization and the expansion of industrial infrastructure—particularly in Asia Pacific and emerging markets—accelerate the need for reliable stick electrodes featuring innovative coatings tailored to diverse field conditions

Stick Welding Electrode Market Dynamics

Driver

Rising Automotive Industry Demand

- The accelerating global automotive industry is a primary driver for the stick welding electrode market, with increasing vehicle production and electric vehicle (EV) adoption demanding high-quality welded joints for chassis, exhaust, and body parts

- For instance, major automakers and suppliers—including in China and the US—are ramping up welding electrode purchases as robotic and manual welding processes scale to meet production targets in new vehicle platforms and battery assemblies

- The need for robust and fatigue-resistant welds in modern, lightweight auto designs stimulates demand for specialized electrodes with improved properties, such as flexibility, crack resistance, and adaptability to coated and uncoated steels

- Ongoing migration toward automation in auto manufacturing necessitates consistent, high-performance electrodes suitable for integration in both manual and robotic welding systems

- Rising investments in commercial transport, off-road, and specialty vehicles support market growth, as these segments require frequent welding repairs, maintenance, and retrofits using versatile stick electrodes

Restraint/Challenge

High Raw Material Costs

- Volatility in the pricing and supply of core raw materials—such as steel, nickel, iron, and alloying elements—poses a significant challenge to stick welding electrode producers, directly impacting production costs and price stability

- For instance, recent fluctuations in global steel and ferroalloy prices have driven up input costs for major electrode manufacturers, making it challenging to maintain profit margins while meeting growing demand

- Disruptions in raw material supply chains—exacerbated by geopolitical tensions or energy crises—can lead to shortages, longer lead times, and price escalation for both basic and specialized electrode grades

- Environmental regulations and sustainability pressures may further increase the cost of sourcing and processing raw materials, particularly for electrodes requiring high-purity or certified inputs

- Price-sensitive customers in construction, agriculture, and small manufacturing may delay procurement or shift to alternative joining technologies when faced with substantial increases in electrode costs

Stick Welding Electrode Market Scope

The market is segmented on the basis of product type and application.

- By Product Type

On the basis of product type, the stick welding electrode market is segmented into heat-resistant steel electrode, low temperature steel electrode, and others. The heat-resistant steel electrode segment held the largest market revenue share of 48.1% in 2024, driven by its high performance in extreme thermal environments such as boilers, furnaces, and power plant equipment. These electrodes are highly favored in industries requiring welds that can withstand prolonged exposure to elevated temperatures without compromising structural integrity or mechanical strength. The segment's dominance is also supported by the rising adoption of heat-resistant alloys in thermal power generation and petrochemical applications, where weld reliability is critical.

The low temperature steel electrode segment is projected to witness the fastest growth rate from 2025 to 2032, fueled by its increasing use in cryogenic applications and cold climate construction. These electrodes provide excellent toughness and impact resistance at sub-zero temperatures, making them ideal for structures in Arctic and high-altitude environments. Their growing adoption in LNG facilities, refrigerated storage construction, and offshore platforms highlights their critical role in ensuring weld durability and performance under thermal stress.

- By Application

On the basis of application, the stick welding electrode market is segmented into automobile industry, construction industry, aerospace and defense industry, shipbuilding industry, and pipeline industry. The construction industry segment dominated the market in 2024 owing to the high volume demand for durable, cost-effective welding solutions in infrastructure development and structural fabrication. Stick welding electrodes are particularly valued in construction due to their versatility, ease of use in outdoor environments, and ability to perform well on rusty or dirty surfaces—an advantage on many job sites.

The pipeline industry segment is anticipated to witness the fastest CAGR from 2025 to 2032, driven by increasing global investments in oil & gas and water transmission infrastructure. Stick welding electrodes are preferred in pipeline welding for their strong arc stability, deep penetration capabilities, and consistent performance in field conditions with limited access or adverse weather. The surge in cross-country pipeline projects and stringent quality standards for weld integrity are further driving the demand for high-performance electrodes in this application.

Stick Welding Electrode Market Regional Analysis

- Asia-Pacific dominated the stick welding electrode market with the largest revenue share of 38.5% in 2024, driven by robust industrialization, expanding infrastructure development, and high demand from manufacturing and construction sectors in emerging economies

- The region’s growing automotive and shipbuilding industries, coupled with an abundant availability of skilled labor and cost-effective electrode production, are key contributors to market expansion

- In addition, rising investments in energy and pipeline projects, along with government-backed industrialization initiatives and training programs for welders, are accelerating adoption across key applications

Japan Stick Welding Electrode Market Insight

The Japan market is growing steadily due to continuous technological innovation in welding materials and equipment. High standards in manufacturing and construction quality have led to strong demand for premium electrodes that ensure durable and defect-free welds. Japan’s aging infrastructure and ongoing renovation projects also support the uptake of reliable stick welding solutions, especially in the railway and shipbuilding sectors.

China Stick Welding Electrode Market Insight

The China stick welding electrode market held the largest share in Asia-Pacific in 2024, supported by massive infrastructure investment, expanding energy and heavy machinery sectors, and a vast domestic base of welders and manufacturers. Favorable policies for manufacturing modernization, coupled with local production scalability, position China as both a top consumer and exporter of welding electrodes.

Europe Stick Welding Electrode Market Insight

The Europe stick welding electrode market is projected to grow at a moderate CAGR over the forecast period, driven by rising investments in renewable energy projects, maintenance of aging industrial infrastructure, and demand for eco-compliant welding consumables. Stringent quality standards and adoption of advanced welding processes in automotive and aerospace sectors are propelling market growth, especially in Western and Central Europe.

U.K. Stick Welding Electrode Market Insight

The U.K. market is anticipated to grow steadily, driven by increasing construction activity and the country’s focus on modernizing its pipeline and utility infrastructure. Emphasis on workforce upskilling and adherence to welding quality certifications are supporting demand for standardized electrode types, particularly in energy and public sector projects.

Germany Stick Welding Electrode Market Insight

The Germany stick welding electrode market is witnessing stable expansion due to its well-established automotive and manufacturing base. Strong environmental and safety regulations encourage the use of high-performance, low-emission electrodes. Additionally, Germany’s leadership in precision engineering and industrial innovation continues to boost the need for high-reliability welding materials.

North America Stick Welding Electrode Market Insight

The North America market is projected to grow at the fastest CAGR from 2025 to 2032, driven by increased investments in oil & gas pipeline networks, construction modernization, and reshoring of manufacturing operations. Rising emphasis on durable and field-reliable welding solutions for outdoor and remote locations favors the use of stick electrodes. Technological upgrades in electrode coating and arc stability are also contributing to market momentum.

U.S. Stick Welding Electrode Market Insight

The U.S. stick welding electrode market captured the largest revenue share in 2024 within North America, supported by a broad industrial base and high demand from construction, defense, and energy sectors. Growth in shipbuilding and military infrastructure upgrades, combined with training initiatives for skilled welders, is enhancing electrode consumption. The presence of leading electrode manufacturers and innovations in welding consumable performance are further propelling domestic demand.

Stick Welding Electrode Market Share

The stick welding electrode industry is primarily led by well-established companies, including:

- voestalpine Böhler Welding Group GmbH (Austria)

- Ador Welding Limited (India)

- D&H Sécheron (France)

- Daido Steel Co., Ltd. (Japan)

- The Lincoln Electric Company (U.S.)

- Miller Electric Mfg. LLC (U.S.)

- KOBE STEEL, LTD. (Japan)

- ZULFI WELDING ELECTRODES FACTORY CO. LTD (Saudi Arabia)

- ESAB (Sweden)

- CS Corporation (South Korea)

- RME MIDDLE EAST FZCO (U.A.E)

- capilla GmbH (Germany)

- Tianjin Golden Bridge Welding Materials Group Co., Ltd (China)

Latest Developments in Global Stick Welding Electrode Market

- In September 2023, Kjellberg Finsterwalde expanded its product portfolio with the launch of the Duoweld double-coated electrode, designed to deliver superior handling and high-strength weld metal. This innovation is expected to enhance the company’s competitiveness in the global stick welding electrode market by offering a versatile solution suitable for diverse industrial applications, including steel construction, boiler manufacturing, and shipbuilding

- In November 2022, ESAB introduced the Renegade VOLT ES 200i, a battery-powered Stick/TIG welding system, during its SparkWeek virtual launch event. This breakthrough in portable welding technology is poised to reshape the stick welding market by meeting the rising demand for flexible, cordless welding solutions across remote, off-grid, and mobile work environments

- In February 2021, Bohler Welding, a subsidiary of voestalpine AG, introduced a new range of low-hydrogen welding electrodes tailored for the oil and gas industry. These electrodes are engineered to excel in harsh environments, including sour gas and high-pressure conditions, enhancing performance and reliability in demanding applications

- In March 2021, Researchers at the Fraunhofer Institute for Laser Technology ILT unveiled an advanced laser welding process that facilitates the creation of lightweight components with exceptionally strong welds. This innovation promises significant improvements in manufacturing efficiency and component durability

- In September 2020, The Indian government launched the National Infrastructure Pipeline (NIP), a major initiative aiming to invest USD 1.4 trillion in diverse infrastructure projects by 2025. This ambitious plan is anticipated to drive increased demand for welding electrodes throughout India during the forecast period

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Stick Welding Electrode Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Stick Welding Electrode Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Stick Welding Electrode Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.