Global Styrene Butadiene Styrene Sbs Block Copolymer Market

Market Size in USD Million

CAGR :

%

USD

710.39 Million

USD

1,098.52 Million

2025

2033

USD

710.39 Million

USD

1,098.52 Million

2025

2033

| 2026 –2033 | |

| USD 710.39 Million | |

| USD 1,098.52 Million | |

|

|

|

|

Styrene Butadiene Styrene (SBS) Block Copolymer Market Size

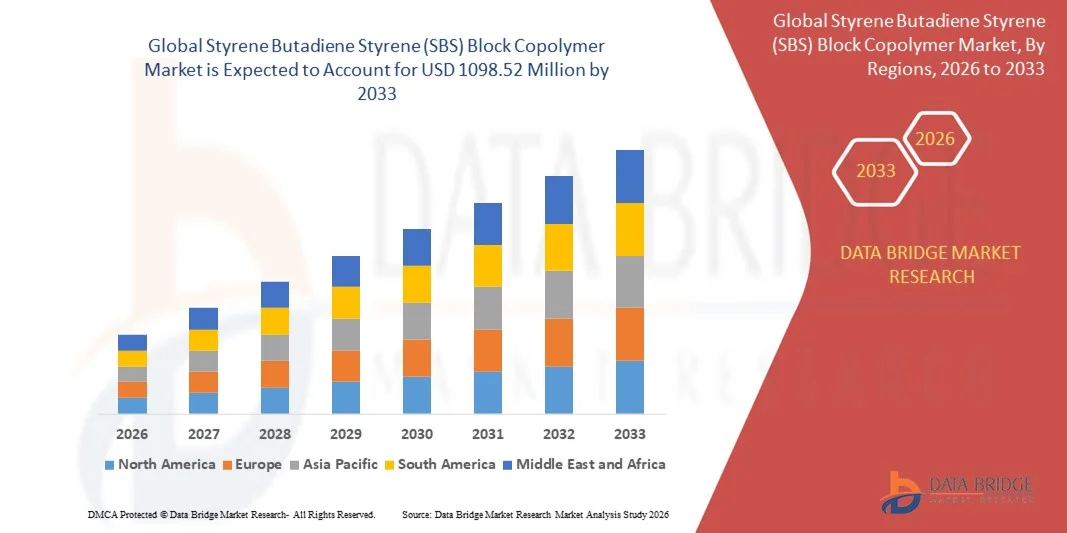

- The global styrene butadiene styrene (SBS) block copolymer market size was valued at USD 710.39 million in 2025 and is expected to reach USD 1098.52 million by 2033, at a CAGR of 5.60% during the forecast period

- The market growth is largely fuelled by the rising adoption of SBS in paving, roofing, adhesives, sealants, and polymer modification

- Increasing demand from construction and infrastructure development projects is further supporting market expansion

Styrene Butadiene Styrene (SBS) Block Copolymer Market Analysis

- The market is witnessing strong growth due to the superior flexibility, durability, and impact resistance offered by SBS across end-use industries

- Rising investments in road maintenance, waterproofing systems, and sustainable construction materials are strengthening the market outlook

- North America dominated the Styrene Butadiene Styrene (SBS) Block Copolymer market with the largest revenue share of 38.5% in 2025, driven by the high demand for lightweight, durable, and impact-resistant materials across automotive, construction, and packaging industries

- Asia-Pacific region is expected to witness the highest growth rate in the global styrene butadiene styrene (SBS) block copolymer market, driven by rising urbanization, expanding industrial base, and growing demand for durable, versatile polymer materials

- The TPS-SBS segment held the largest market revenue share in 2025, driven by its excellent thermoplastic properties, ease of processing, and versatility in construction and automotive applications. TPS-SBS is particularly preferred for applications requiring flexibility, durability, and thermal stability

Report Scope and Styrene Butadiene Styrene (SBS) Block Copolymer Market Segmentation

|

Attributes |

Styrene Butadiene Styrene (SBS) Block Copolymer Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Styrene Butadiene Styrene (SBS) Block Copolymer Market Trends

Growing Adoption of SBS in Construction and Automotive Applications

- The increasing demand for high-performance thermoplastic elastomers is transforming the SBS block copolymer market by enabling improved flexibility, durability, and resistance in asphalt, adhesives, and sealants. This shift allows manufacturers to meet stringent performance standards in construction and automotive applications, resulting in enhanced product quality and extended service life

- The rising emphasis on road infrastructure development and high-quality paving materials is accelerating the adoption of SBS-modified asphalt binders. These binders enhance road durability, reduce maintenance costs, and improve performance under varying temperature and load conditions, driving market growth

- The versatility and cost-effectiveness of SBS block copolymers are making them attractive for manufacturers across multiple industries. Their ability to blend with other polymers and enhance mechanical properties supports broader application in adhesives, footwear, coatings, and automotive components

- For instance, in 2023, several European and North American construction companies reported improved road performance and reduced cracking after using SBS-modified asphalt, demonstrating the polymer’s effectiveness in infrastructure projects

- While adoption of SBS in construction and automotive applications is growing, market expansion depends on continued research, product innovation, and process optimization. Manufacturers must focus on developing tailored formulations to meet industry-specific requirements and capitalize on rising demand

Styrene Butadiene Styrene (SBS) Block Copolymer Market Dynamics

Driver

Rising Demand in Construction and Automotive Industries

- The rapid expansion of urban infrastructure and road networks is driving the need for SBS-modified asphalt and high-performance polymer solutions. Governments and private developers are prioritizing durable and sustainable materials, which has boosted the adoption of SBS block copolymers. In addition, the trend toward smart cities and long-lasting roadways is encouraging wider use of SBS in large-scale civil projects, further supporting market growth

- Automotive manufacturers are increasingly using SBS in interior components, gaskets, and adhesives to enhance durability, elasticity, and temperature resistance. This trend is driven by the need for lightweight, high-performance materials in electric and conventional vehicles. Rising consumer expectations for safer, more resilient automotive products and the shift toward electric vehicle production are also pushing SBS adoption in critical automotive components

- Supportive regulatory policies promoting quality road construction and sustainable materials are further accelerating market growth. Incentives and standards for long-lasting infrastructure encourage the use of SBS in paving and industrial applications. Moreover, governments across Europe, North America, and Asia are introducing mandates for improved road quality and sustainability, strengthening market demand for SBS-modified asphalt

- For instance, in 2022, several highway projects in the U.S. and Germany incorporated SBS-modified asphalt to improve road performance, durability, and resistance to rutting and fatigue cracking. Similar initiatives were also reported in Asia-Pacific, where SBS solutions were integrated into new urban road networks to withstand extreme climatic conditions and heavy traffic loads, demonstrating the polymer’s effectiveness across geographies

- While demand is increasing across construction and automotive sectors, consistent supply of high-quality raw materials, product standardization, and cost-effective production methods remain critical to sustaining market growth. Market participants are also focusing on technological innovations, such as modified formulations and eco-friendly production techniques, to meet evolving industry requirements and reduce environmental impact

Restraint/Challenge

High Production Costs and Volatility of Raw Materials

- The cost of producing SBS block copolymers is relatively high due to the volatility of styrene and butadiene feedstocks. Price fluctuations can impact profitability and limit adoption, especially among cost-sensitive manufacturers and regions. This price sensitivity is further compounded by global supply chain disruptions, making budget forecasting and production planning challenging for SBS producers

- In many developing regions, limited availability of advanced manufacturing facilities and technical expertise restricts the production and widespread use of SBS block copolymers. This leads to reliance on imported products, increasing overall costs and supply chain complexity. In addition, the lack of localized R&D capabilities slows innovation and adaptation to region-specific application requirements, limiting market penetration in these areas

- Market growth is also constrained by environmental and safety regulations associated with handling styrene and butadiene. Compliance with emission standards and safe manufacturing practices can increase operational expenses for producers. Heightened scrutiny over chemical handling and waste management further pressures manufacturers to adopt sustainable practices, which may raise production costs

- For instance, in 2023, several SBS manufacturers in Asia reported supply chain disruptions and increased production costs due to styrene price volatility and regulatory compliance requirements. Delays in raw material procurement and transportation added further uncertainty, affecting delivery schedules for construction and automotive projects

- While SBS technology continues to advance, addressing cost, raw material volatility, and regulatory challenges is essential. Stakeholders must focus on process efficiency, sustainable production methods, and localized manufacturing to unlock the long-term growth potential of the SBS block copolymer market. Furthermore, investment in alternative feedstocks, recycling strategies, and energy-efficient production can help stabilize costs and ensure consistent supply for global demand

Styrene Butadiene Styrene (SBS) Block Copolymer Market Scope

The Styrene Butadiene Styrene (SBS) Block Copolymer market is segmented into four notable segments based on type, grade, application, and processing method.

- By Type

On the basis of type, the market is segmented into Thermoplastic Styrene Butadiene Styrene (TPS-SBS) and Thermoset Styrene Butadiene Styrene (TS-SBS). The TPS-SBS segment held the largest market revenue share in 2025, driven by its excellent thermoplastic properties, ease of processing, and versatility in construction and automotive applications. TPS-SBS is particularly preferred for applications requiring flexibility, durability, and thermal stability.

The TS-SBS segment is expected to witness the fastest growth rate from 2026 to 2033, driven by its superior mechanical strength, chemical resistance, and heat stability, making it ideal for high-performance automotive, industrial, and adhesive applications.

- By Grade

On the basis of grade, the market is segmented into Standard Grade, High Impact Grade, Low Styrene Content Grade, and Copolymer Grade. The Standard Grade segment held the largest market revenue share in 2025, driven by its balanced performance, cost-effectiveness, and broad applicability across construction, automotive, and industrial applications.

The High Impact Grade segment is expected to witness the fastest growth rate from 2026 to 2033, fueled by increasing demand for superior impact resistance, mechanical strength, and durability in automotive parts, packaging materials, and infrastructure projects.

- By Application

On the basis of application, the market is segmented into Automotive, Medical, Electronics, Construction, and Packaging. The Construction segment held the largest market revenue share in 2025, attributed to the extensive use of SBS-modified asphalt and polymer-based construction materials for roads, bridges, and commercial buildings.

The Automotive segment is projected to witness the fastest growth rate from 2026 to 2033, supported by the growing use of SBS in gaskets, adhesives, and interior components to enhance durability, elasticity, and thermal performance.

- By Processing Method

On the basis of processing method, the market is segmented into Injection Molding, Extrusion, Compression Molding, and Blow Molding. The Extrusion segment held the largest market revenue share in 2025, driven by its efficiency in producing continuous profiles, construction components, and industrial parts with consistent quality.

The Injection Molding segment is expected to witness the fastest growth rate from 2026 to 2033, fueled by rising adoption in automotive, packaging, and medical industries requiring precise shapes, high-quality finishes, and reliable mechanical performance.

Styrene Butadiene Styrene (SBS) Block Copolymer Market Regional Analysis

- North America dominated the Styrene Butadiene Styrene (SBS) Block Copolymer market with the largest revenue share of 38.5% in 2025, driven by the high demand for lightweight, durable, and impact-resistant materials across automotive, construction, and packaging industries

- Manufacturers in the region are increasingly adopting SBS block copolymers due to their versatility, high performance, and ability to enhance product quality and longevity

- The widespread use is further supported by advanced manufacturing infrastructure, strong industrial growth, and a preference for high-performance materials in applications such as automotive parts, medical devices, and electronics

U.S. Styrene Butadiene Styrene (SBS) Block Copolymer Market Insight

The U.S. SBS block copolymer market captured the largest revenue share in 2025 within North America, fueled by growing automotive production and demand for lightweight, high-strength materials. The adoption of SBS in packaging and medical applications is also rising due to its durability and flexibility. In addition, ongoing innovations in processing techniques and the integration of SBS into extrusion, injection molding, and blow molding applications are further expanding the market.

Europe Styrene Butadiene Styrene (SBS) Block Copolymer Market Insight

The Europe SBS block copolymer market is expected to witness the fastest growth rate from 2026 to 2033, driven by stringent regulations for sustainable and high-performance materials in automotive and construction sectors. The demand for eco-friendly, energy-efficient, and recyclable polymers is promoting the adoption of SBS block copolymers across various applications. Increased urbanization, industrial expansion, and the trend toward lightweight materials are further supporting market growth.

U.K. Styrene Butadiene Styrene (SBS) Block Copolymer Market Insight

The U.K. SBS block copolymer market is expected to witness rapid growth from 2026 to 2033, driven by the increasing use of high-performance polymers in automotive, electronics, and packaging industries. The adoption is fueled by the focus on durability, impact resistance, and product efficiency. Moreover, government initiatives promoting industrial innovation and advanced material usage are supporting the market expansion.

Germany Styrene Butadiene Styrene (SBS) Block Copolymer Market Insight

The Germany SBS block copolymer market is expected to witness significant growth from 2026 to 2033, fueled by the country’s emphasis on innovation, high-quality industrial standards, and sustainability in polymer applications. SBS copolymers are increasingly used in automotive parts, construction materials, and medical devices due to their superior mechanical properties. Integration into advanced manufacturing processes such as extrusion and injection molding is further boosting adoption.

Asia-Pacific Styrene Butadiene Styrene (SBS) Block Copolymer Market Insight

The Asia-Pacific SBS block copolymer market is expected to witness the fastest growth rate from 2026 to 2033, driven by rapid industrialization, urbanization, and rising automotive and construction activities in countries such as China, Japan, and India. Increasing investment in electronics and packaging industries, along with government initiatives promoting advanced polymer adoption, is accelerating the market. The presence of cost-effective manufacturing facilities and expanding local production capacities is also enhancing accessibility and adoption.

Japan Styrene Butadiene Styrene (SBS) Block Copolymer Market Insight

The Japan SBS block copolymer market is expected to witness steady growth from 2026 to 2033 due to the country’s advanced automotive and electronics industries. Demand for high-performance, lightweight, and durable materials is driving SBS adoption. The integration of SBS copolymers in precision manufacturing, medical applications, and eco-friendly products is contributing to market expansion.

China Styrene Butadiene Styrene (SBS) Block Copolymer Market Insight

The China SBS block copolymer market accounted for the largest market revenue share in Asia-Pacific in 2025, attributed to rapid industrialization, expanding automotive and construction sectors, and high polymer consumption. The country’s focus on smart manufacturing, cost-effective production, and availability of domestic SBS manufacturers is supporting widespread adoption. Rising applications in packaging, electronics, and medical devices are further propelling market growth.

Styrene Butadiene Styrene (SBS) Block Copolymer Market Share

The Styrene Butadiene Styrene (SBS) Block Copolymer industry is primarily led by well-established companies, including:

- Kraton Polymers (U.S.)

- LCY Chemical Corp (Taiwan)

- Mitsui Chemicals Inc (Japan)

- Versalis S.p.A. (Italy)

- Lanxess AG (Germany)

- Trinseo S.A. (U.S.)

- TotalEnergies S.A. (France)

- Synthomer plc (U.K.)

- Kuraray Co., Ltd. (Japan)

- JSR Corporation (Japan)

Latest Developments in Global Styrene Butadiene Styrene (SBS) Block Copolymer Market

- In August 2025, Kraton Polymers (US) announced a strategic partnership with a leading automotive manufacturer to develop advanced SBS materials for electric vehicle applications. This collaboration aims to enhance Kraton’s product portfolio and market presence while supporting the growing demand for specialized, sustainable materials in the automotive sector. The move is expected to strengthen the company’s position in the EV market and align with industry trends toward innovation and sustainability

- In September 2025, LCY Chemical Corp (TW) inaugurated a new production facility to increase its SBS output and meet rising global demand. The expansion is intended to improve supply chain reliability, reduce lead times, and better serve customer requirements. By localizing production, LCY is positioned to enhance operational efficiency and respond quickly to market needs, reflecting a broader trend of regional production scaling

- In July 2025, Mitsui Chemicals Inc (JP) launched a new line of high-performance SBS products targeting the construction industry. This development is designed to cater to growing infrastructure and construction demands globally, providing industry-specific, innovative solutions. The initiative is expected to boost Mitsui’s market reach, strengthen its competitive position, and support the adoption of durable, high-performance polymer materials

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Styrene Butadiene Styrene Sbs Block Copolymer Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Styrene Butadiene Styrene Sbs Block Copolymer Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Styrene Butadiene Styrene Sbs Block Copolymer Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.