Global Swine Feed Processing Market

Market Size in USD Billion

CAGR :

%

USD

112.86 Billion

USD

160.49 Billion

2025

2033

USD

112.86 Billion

USD

160.49 Billion

2025

2033

| 2026 –2033 | |

| USD 112.86 Billion | |

| USD 160.49 Billion | |

|

|

|

|

Global Swine Feed Processing Market Size

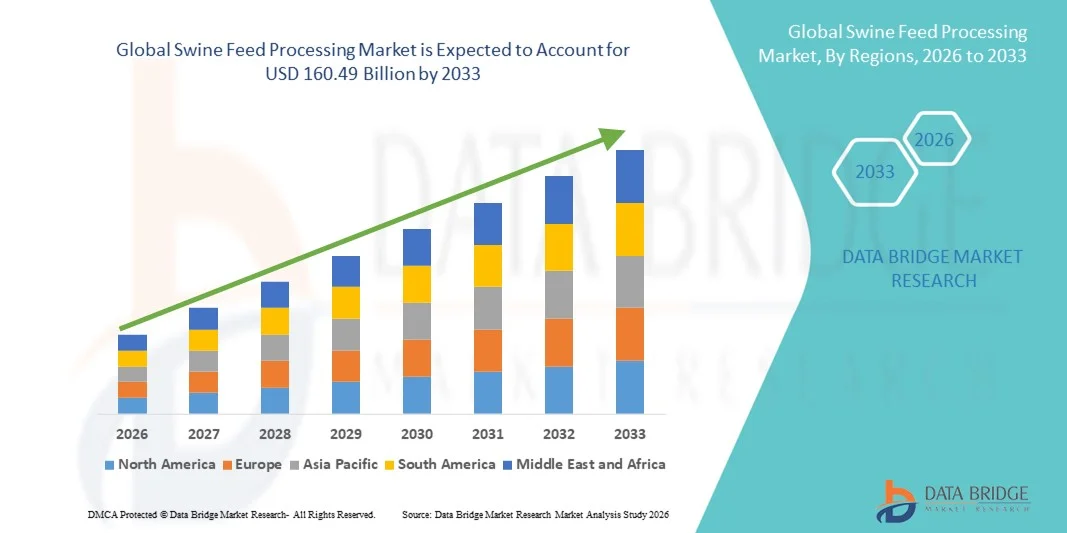

- The global Swine Feed Processing Market size was valued at USD 112.86 billion in 2025 and is expected to reach USD 160.49 billion by 2033, at a CAGR of 4.50% during the forecast period.

- The market growth is largely driven by increasing demand for high-quality swine feed, advancements in feed processing technology, and the adoption of automated and efficient feed production systems across commercial pig farms.

- Furthermore, rising focus on improving animal health, feed efficiency, and sustainable farming practices is encouraging producers to invest in modern feed processing equipment and solutions. These converging factors are accelerating the adoption of advanced swine feed processing systems, thereby significantly boosting the industry's growth.

Global Swine Feed Processing Market Analysis

- Swine feed processing, involving the production and formulation of nutritionally balanced feed for pigs, is increasingly vital for modern pig farming operations in both commercial and small-scale settings due to its role in improving growth rates, feed efficiency, and overall herd health.

- The escalating demand for swine feed processing solutions is primarily fueled by rising pork consumption, increasing focus on sustainable and efficient livestock production, and technological advancements in feed formulation and automation.

- Asia-Pacific dominated the Global Swine Feed Processing Market with the largest revenue share of 35% in 2025, characterized by advanced livestock farming practices, high adoption of automated feed systems, and a strong presence of key industry players, with the U.S. experiencing substantial growth in feed processing infrastructure, driven by innovations from both established manufacturers and emerging technology providers.

- North America is expected to be the fastest-growing region in the Global Swine Feed Processing Market during the forecast period due to increasing pork demand, rapid modernization of pig farms, and rising investments in advanced feed processing technologies.

- The automatic segment dominated the market with the largest revenue share of 47.5% in 2025, driven by its ability to deliver consistent feed quality, reduce labor dependency, and improve operational efficiency in large-scale pig farming operations.

Report Scope and Global Swine Feed Processing Market Segmentation

|

Attributes |

Swine Feed Processing Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Global Swine Feed Processing Market Trends

Enhanced Efficiency Through AI and Automation Integration

- A significant and accelerating trend in the global Swine Feed Processing Market is the deepening integration of artificial intelligence (AI) and automation technologies in feed production and formulation. This fusion of technologies is significantly improving feed efficiency, operational accuracy, and overall herd health management.

- For instance, AI-powered feed formulation systems can analyze nutritional requirements in real time and automatically adjust ingredient proportions, optimizing growth rates and minimizing waste. Similarly, automated pelleting and mixing machines can precisely control feed consistency, temperature, and moisture content to improve feed quality.

- AI integration in feed processing enables predictive maintenance of equipment, real-time monitoring of production efficiency, and advanced data analytics for feed performance evaluation. Some modern systems can even suggest nutritional adjustments based on growth performance or environmental conditions in pig farms, ensuring maximum productivity.

- The seamless integration of feed processing systems with farm management software facilitates centralized control over the entire livestock operation. Through a single interface, farmers can monitor feed inventory, production schedules, and animal performance, enabling a unified and efficient farm management experience.

- This trend towards more intelligent, automated, and data-driven feed processing systems is fundamentally reshaping expectations in swine farming. Consequently, companies such as CP Group and Cargill are developing AI-enabled feed processing solutions with features such as predictive analytics, automated formulation adjustments, and remote monitoring capabilities.

- The demand for AI- and automation-integrated swine feed processing solutions is growing rapidly across both commercial and industrial pig farms, as producers increasingly prioritize efficiency, sustainability, and optimized animal growth.

Global Swine Feed Processing Market Dynamics

Driver

Growing Need Due to Rising Demand for Efficient and Sustainable Swine Production

- The increasing demand for pork products globally, coupled with the need for efficient and sustainable pig farming practices, is a significant driver for the heightened adoption of advanced swine feed processing solutions.

- For instance, in 2025, CP Group introduced a next-generation automated feed processing system capable of real-time nutrient optimization, demonstrating how technological advancements by key companies are expected to drive market growth during the forecast period.

- As farmers seek to maximize feed efficiency, reduce waste, and improve herd health, modern feed processing systems offer precise formulation, consistent nutrient delivery, and scalable solutions, providing a compelling upgrade over traditional manual feed mixing practices.

- Furthermore, the increasing trend of integrated farm management systems and precision livestock farming is making automated feed processing an essential component of modern pig farming operations, facilitating seamless integration with monitoring and data analytics platforms.

- The ability to manage feed production schedules, monitor consumption, and adjust formulations through centralized software, along with the benefits of consistent feed quality, are key factors propelling adoption in both large-scale commercial farms and emerging industrial pig farms.

Restraint/Challenge

Concerns Regarding High Initial Costs and Technological Complexity

- High initial investment costs for advanced feed processing systems pose a significant challenge to broader adoption, particularly for small- and medium-sized pig farms. While automated and AI-enabled systems improve efficiency and reduce long-term operational costs, the upfront expense can be a barrier in price-sensitive regions.

- For instance, many smaller farms in developing countries continue to rely on conventional feed mixing methods due to the perceived high capital requirement for modern processing equipment.

- Addressing these concerns through scalable, modular solutions, leasing models, and government-supported subsidies is crucial for increasing market penetration. Additionally, the complexity of operating advanced feed processing systems, which may require skilled personnel and regular maintenance, can discourage adoption among farmers unfamiliar with automation and AI technologies.

- While training programs and user-friendly interfaces are helping to reduce the operational learning curve, the perceived technological complexity remains a limiting factor, especially for smaller farms with limited technical expertise.

- Overcoming these challenges through cost-effective solutions, farmer education programs, and service support will be vital for sustained growth in the global swine feed processing market.

Global Swine Feed Processing Market Scope

Swine feed processing market is segmented on the basis of mode of operation, form of feed and method of processing.

- By Mode of Operation

On the basis of mode of operation, the Global Swine Feed Processing Market is segmented into automatic, semi-automatic, and manual systems. The automatic segment dominated the market with the largest revenue share of 47.5% in 2025, driven by its ability to deliver consistent feed quality, reduce labor dependency, and improve operational efficiency in large-scale pig farming operations. Automatic feed processing systems are increasingly preferred for commercial farms due to their capacity to handle high-volume feed production while minimizing human error and operational downtime.

Semi-automatic systems are anticipated to witness the fastest growth rate of 18.9% from 2026 to 2033, fueled by rising adoption in small- to medium-scale farms that seek a balance between cost efficiency and operational control. Semi-automatic systems allow partial automation of feed processing steps while still offering flexibility for manual intervention, making them an attractive option for emerging markets.

- By Form of Feed

On the basis of form of feed, the Global Swine Feed Processing Market is segmented into pellets, crumbles, mash, and others. The pelleted feed segment held the largest market revenue share of 43.2% in 2025, attributed to its enhanced digestibility, uniform nutrient distribution, and ease of handling and storage. Pelleted feed ensures consistent feed intake, improves feed conversion ratios, and is widely preferred by commercial pig farmers.

The crumbles segment is expected to witness the fastest CAGR of 22.1% from 2026 to 2033, driven by its suitability for weaning pigs and young piglets, where smaller particle sizes promote easier consumption and digestion. Crumbled feed also allows producers to gradually transition piglets from starter to grower diets, supporting better growth performance and overall herd health.

- By Method of Processing

On the basis of method of processing, the Global Swine Feed Processing Market is segmented into cleaning and sorting, grinding, mixing, conditioning and expanding, dosing and batching, cooling and drying, testing and analysis, pelleting, extrusion, and others. The grinding segment dominated the market with the largest revenue share of 38.7% in 2025, due to its critical role in reducing particle size for better feed digestibility and uniform nutrient distribution. Grinding is an essential first step in swine feed production, influencing both feed quality and performance outcomes.

The pelleting segment is anticipated to witness the fastest CAGR of 20.5% from 2026 to 2033, driven by the growing preference for feed pellets that enhance feed intake efficiency, improve storage stability, and reduce wastage. Advanced pelleting technologies are also being integrated with automated and AI-enabled systems, further boosting adoption in commercial pig farming.

Global Swine Feed Processing Market Regional Analysis

- Asia-Pacific dominated the Global Swine Feed Processing Market with the largest revenue share of 35% in 2025, driven by the increasing adoption of advanced livestock farming practices, automation in feed processing, and rising demand for high-quality pork products.

- Producers in the region highly prioritize feed efficiency, consistency, and nutrient optimization, making modern feed processing solutions such as automated pelleting and AI-enabled formulation systems increasingly essential.

- This widespread adoption is further supported by high technological readiness, access to advanced equipment, and strong government and private sector support for sustainable livestock production, establishing North America as a leading market for swine feed processing across both commercial and industrial pig farming operations.

U.S. Swine Feed Processing Market Insight

The U.S. swine feed processing market captured the largest revenue share of 81% in 2025 within North America, driven by the adoption of advanced feed automation systems and precision livestock farming technologies. Producers are increasingly prioritizing feed efficiency, consistent nutrient delivery, and operational scalability to meet rising pork demand. The growing preference for automated pelleting, grinding, and mixing systems, combined with software-enabled feed formulation and monitoring, is further propelling market growth. Moreover, government support for sustainable livestock production and technological innovations in feed processing equipment are significantly contributing to the market's expansion.

Europe Swine Feed Processing Market Insight

The Europe swine feed processing market is projected to expand at a substantial CAGR during the forecast period, primarily driven by stringent food safety regulations, high-quality pork production standards, and the adoption of energy-efficient processing systems. Urbanization and the rising trend of industrial pig farming are fostering the adoption of automated feed processing solutions. European producers are increasingly focusing on feed optimization, waste reduction, and integration with smart farm management systems, supporting market growth across residential, commercial, and industrial farming applications.

U.K. Swine Feed Processing Market Insight

The U.K. swine feed processing market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by modernization in livestock farming and rising demand for high-quality pork products. Additionally, the adoption of semi-automatic and automatic feed processing systems, along with real-time feed monitoring solutions, is enabling enhanced productivity and operational efficiency. The U.K.’s strong agricultural infrastructure and technological readiness are expected to continue stimulating market growth, particularly among commercial and industrial pig farms.

Germany Swine Feed Processing Market Insight

The Germany swine feed processing market is expected to expand at a considerable CAGR during the forecast period, fueled by increasing awareness of feed efficiency, sustainable livestock practices, and the demand for technologically advanced processing equipment. Germany’s emphasis on innovation, automation, and eco-conscious farming promotes the adoption of advanced feed grinders, mixers, and pelleting systems. Integration of feed processing with farm management software and IoT-enabled monitoring systems is becoming prevalent, supporting growth in both commercial and industrial pig farming operations.

Asia-Pacific Swine Feed Processing Market Insight

The Asia-Pacific swine feed processing market is poised to grow at the fastest CAGR of 24% during the forecast period of 2026 to 2033, driven by rapid urbanization, rising disposable incomes, and technological advancements in countries such as China, Japan, and India. The region’s growing demand for pork products, combined with government initiatives supporting industrial livestock farming and digitalization, is accelerating the adoption of automated feed processing systems. Furthermore, APAC’s emergence as a manufacturing hub for feed processing equipment is increasing affordability and accessibility, expanding the market across small, medium, and large-scale farms.

Japan Swine Feed Processing Market Insight

The Japan swine feed processing market is gaining momentum due to the country’s high-tech farming culture, advanced livestock infrastructure, and focus on operational efficiency. The market is driven by increased adoption of automated feed grinders, mixers, and pelleting systems that ensure consistent nutrition and optimize feed conversion ratios. Japan’s aging farming population is also accelerating demand for user-friendly, automated feed processing solutions that reduce labor requirements while maintaining high productivity in both commercial and industrial pig farms.

China Swine Feed Processing Market Insight

The China swine feed processing market accounted for the largest market revenue share in Asia-Pacific in 2025, attributed to rapid urbanization, rising pork consumption, and strong government initiatives supporting industrial pig farming. China is one of the largest markets for swine feed processing equipment, with producers increasingly adopting automated grinding, mixing, and pelleting systems to improve feed efficiency and reduce waste. The growth of large-scale commercial farms, the push for smart farm management, and the presence of domestic equipment manufacturers are key factors propelling market expansion in China.

Global Swine Feed Processing Market Share

The Swine Feed Processing industry is primarily led by well-established companies, including:

• AGCO Corporation (U.S.)

• Big Dutchman Inc. (Germany)

• Cargill, Inc. (U.S.)

• Valmetal Inc. (Canada)

• Sukup Manufacturing Co. (U.S.)

• Andritz Group (Austria)

• Schaumann Feed (Germany)

• TecnoFeed S.p.A. (Italy)

• Bühler Group (Switzerland)

• JY Machinery Co., Ltd. (China)

• Zhejiang Dingsheng Machinery Co., Ltd. (China)

• Hunan Sunway Group (China)

• VDL Agrotech (Netherlands)

• Feedtech Ltd. (U.K.)

• Nanjing Feed Machinery Group Co., Ltd. (China)

• Farm King Inc. (Canada)

• Zhengzhou Taida Feed Equipment Co., Ltd. (China)

• Hongda Machinery Co., Ltd. (China)

• Trioliet B.V. (Netherlands)

• Foshan Chuangxin Feed Equipment Co., Ltd. (China)

What are the Recent Developments in Global Swine Feed Processing Market?

- In April 2024, AGCO Corporation, a global leader in agricultural equipment, launched a strategic initiative in South Africa to introduce advanced automated swine feed processing systems. This initiative aims to improve feed efficiency and livestock productivity by leveraging AGCO’s cutting-edge grinding, mixing, and pelleting technologies. By combining global expertise with solutions tailored to local farming practices, AGCO is addressing regional challenges while strengthening its position in the rapidly growing global Swine Feed Processing Market.

- In March 2024, Big Dutchman Inc., a leading provider of livestock feeding equipment, introduced its next-generation automated feed batching and dosing system specifically designed for commercial pig farms. The innovative system enhances feed consistency, reduces waste, and optimizes nutrition delivery, demonstrating Big Dutchman’s commitment to developing advanced, efficient solutions for modern swine production.

- In March 2024, Cargill, Inc. successfully implemented a smart feed management system in a major pig farming cluster in Bengaluru, India. The project integrates IoT-enabled monitoring and real-time feed formulation technologies to optimize nutrition and reduce operational inefficiencies. This initiative underscores Cargill’s focus on combining technology and sustainability to support the growth of smarter, more efficient livestock operations.

- In February 2024, Hog Slat, Inc., a prominent provider of automated livestock equipment, announced a strategic collaboration with the Southeast Asian Pig Farmers Association to deploy advanced feed processing and delivery systems across commercial farms. The partnership is designed to improve feed efficiency, streamline operations, and ensure consistent nutrition for pigs, highlighting Hog Slat’s commitment to innovation and operational excellence in the swine industry.

- In January 2024, Valmetal Inc., a leading manufacturer of feed processing machinery, unveiled its new PelletPro Automated Swine Feed System at the International Livestock Expo 2024. The system, equipped with real-time monitoring and automated batching capabilities, enables farmers to optimize feed production while reducing labor and energy costs. This launch reflects Valmetal’s dedication to integrating advanced technology into swine feed processing for enhanced productivity and operational control.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.