Global Synchronous Drum Market

Market Size in USD Billion

CAGR :

%

USD

1.27 Billion

USD

4.58 Billion

2024

2032

USD

1.27 Billion

USD

4.58 Billion

2024

2032

| 2025 –2032 | |

| USD 1.27 Billion | |

| USD 4.58 Billion | |

|

|

|

|

Synchronous Drum Market Size

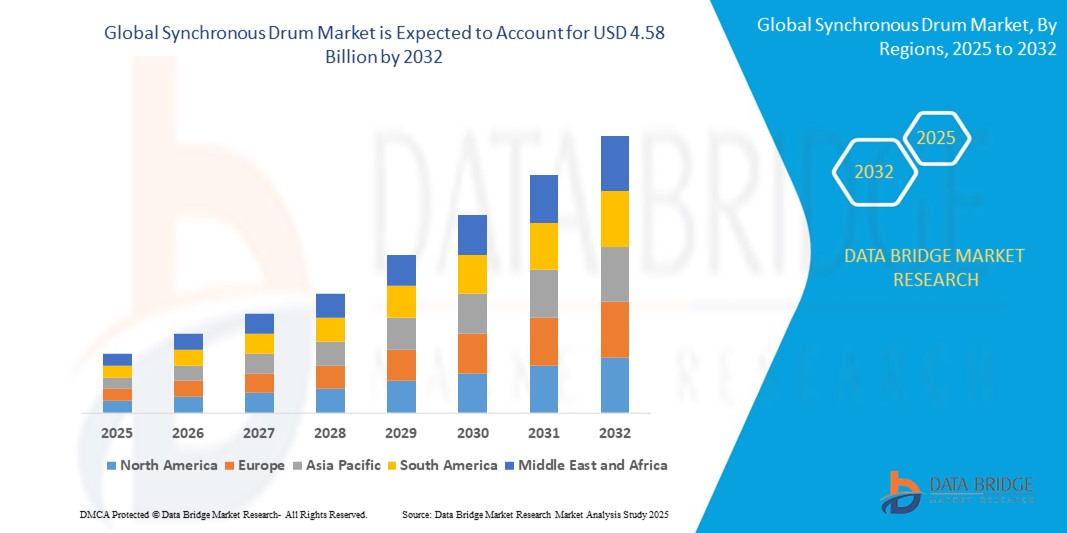

- The global synchronous drum market size was valued at USD 1.27 billion in 2024 and is expected to reach USD 4.58 billion by 2032, at a CAGR of 17.3% during the forecast period

- The market growth is largely fueled by the increasing demand for efficient, safe, and standardized material handling systems across industries such as chemicals, pharmaceuticals, and food processing, where precise containment and controlled dispensing are critical

- Furthermore, rising industrial automation, strict safety regulations, and the need for environmentally compliant storage solutions are accelerating the adoption of synchronous drums, thereby significantly boosting the industry's growth

Synchronous Drum Market Analysis

- Synchronous drums are industrial containers designed to store, transport, and dispense semi-solid or liquid materials with high precision, ensuring minimal waste and enhanced safety. These drums are widely used across manufacturing, construction, and processing sectors for their ability to streamline material flow and improve operational efficiency

- The market is primarily driven by growing industrialization, heightened focus on workplace safety, and increasing usage in chemical and fertilizer applications where spill control, contamination prevention, and reliable discharge are essential

- North America dominated the synchronous drum market with a share of 34.83% in 2024, due to the well-established chemical, pharmaceutical, and food processing industries that rely heavily on efficient and safe material handling solutions

- Asia-Pacific is expected to be the fastest growing region in the synchronous drum market during the forecast period due to rapid industrialization, rising production activities, and infrastructure development across countries such as China, India, and Southeast Asian nations

- 100 to 250 liter segment dominated the market with a market share of 39% in 2024, due to its optimal balance between portability and storage capacity, making it highly preferred across medium-scale industrial and commercial applications. These drums are particularly suitable for transporting and storing moderate volumes of semi-solid or viscous materials where manual handling and compatibility with standard machinery are essential. Their widespread adoption in sectors such as paints, dyes, and food processing further supports their leading market position

Report Scope and Synchronous Drum Market Segmentation

|

Attributes |

Synchronous Drum Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Synchronous Drum Market Trends

“Rising Shift Towards Energy-Efficient Solutions”

- The synchronous drum market is expanding rapidly as manufacturers and industrial users seek energy-efficient drive solutions that can meet sustainability targets and reduce overall operating costs

- For instance, Interroll’s synchronous drum motors have been adopted by major logistics and food processing plants because they consume at least 40% less energy and require zero maintenance compared to traditional drives, greatly improving efficiency and reducing heat emissions

- Market demand is increasing for low-maintenance equipment that provides reliable, consistent torque and higher operational accuracy in conveyor and material handling systems

- Integration of smart monitoring and control technology, including IoT connectivity and predictive analytics, is enabling real-time performance tracking and preventive maintenance, raising operational uptime and productivity

- The shift toward quieter, more compact conveyor systems in automated facilities is boosting adoption of synchronous drum motors, which offer silent operation and minimal vibration for enhanced workplace safety and comfort

- Regulatory requirements for lower carbon emissions and higher electrical efficiency are prompting both new installations and retrofit activities, making synchronous drum solutions more popular across logistics, packaging, and manufacturing sectors

Synchronous Drum Market Dynamics

Driver

“Increasing Industrial Automation”

- Broad trends in industrial automation and the need for precise, reliable motorized systems are driving deployment of synchronous drum motors in warehouses, distribution centers, and food processing plants

- For instance, Marel—a leader in food processing technology—relies on oil-free synchronous drum motors for their high-efficiency, maintenance-free operation, significantly optimizing production line speeds and hygiene standards

- Automated conveyor and material handling systems require compact, integrated, and high-torque motors that can be easily controlled and networked, spurring demand for synchronous drum solutions

- Growth in e-commerce, logistics, and high-speed manufacturing is boosting the need for robust systems capable of 24/7 operation, where synchronous drums’ longer lifespan and minimized downtime are advantageous

- Advancements in machine learning and artificial intelligence are supporting the use of synchronous motors in complex, adaptable automation environments, improving throughput and quality control

Restraint/Challenge

“Initial Costs of Synchronous Motors”

- High initial investment costs for synchronous drum motors, especially those featuring oil-free, hygienic, or highly automated options, represent a substantial barrier to adoption for small- and medium-sized enterprises

- For instance, many food production and logistics companies have cited budget limitations as a reason for delayed upgrades to energy-efficient synchronous drum systems, despite long-term savings potential

- Advanced system integration and technical training requirements add to the upfront cost and complexity, often necessitating specialized personnel or external contractors for commissioning and long-term support

- Some industrial operations encounter challenges in justifying the short-term expenditure, particularly where ROI calculations are hindered by legacy system compatibility concerns

- Market competition from less expensive asynchronous and conventional drum motors, and concerns over supply chain volatility for high-tech motor components, further constrain rapid market penetration of synchronous drum solutions

Synchronous Drum Market Scope

The market is segmented on the basis of capacity and application.

- By Capacity

On the basis of capacity, the synchronous drum market is segmented into up to 100 liter, 100 to 250 liter, 250 to 500 liter, and above 500 liter. The 100 to 250 liter segment dominated the largest market revenue share of 39% in 2024 due to its optimal balance between portability and storage capacity, making it highly preferred across medium-scale industrial and commercial applications. These drums are particularly suitable for transporting and storing moderate volumes of semi-solid or viscous materials where manual handling and compatibility with standard machinery are essential. Their widespread adoption in sectors such as paints, dyes, and food processing further supports their leading market position.

The above 500 liter segment is projected to witness the fastest growth rate from 2025 to 2032, driven by rising demand for bulk handling solutions in heavy industries and chemical manufacturing. These high-capacity drums enable efficient storage and transport of large volumes of raw materials and finished products, reducing operational downtime and logistics costs. Increasing automation and industrial scaling are also encouraging adoption of large-capacity synchronous drums in centralized processing facilities.

- By Application

On the basis of application, the synchronous drum market is segmented into building and construction, chemical and fertilizers, food and beverages, paints, inks and dyes, petroleum and lubricants, pharmaceuticals, and others. The chemical and fertilizers segment held the largest market revenue share in 2024, supported by the growing need for robust containment and precise flow control of hazardous and reactive substances. Synchronous drums offer enhanced safety, controlled discharge, and chemical resistance—key features that make them integral in fertilizer blending plants and chemical production lines.

The pharmaceuticals segment is expected to grow at the fastest CAGR from 2025 to 2032, owing to strict regulatory demands for hygiene, contamination control, and accurate material handling. The pharmaceutical industry increasingly relies on synchronous drums for handling APIs, excipients, and sterile compounds, as they provide controlled dispensing and ease of integration into automated filling systems. The push for cleaner production environments and precise dosing in formulation processes is accelerating adoption in this segment.

Synchronous Drum Market Regional Analysis

- North America dominated the synchronous drum market with the largest revenue share of 34.83% in 2024, driven by the well-established chemical, pharmaceutical, and food processing industries that rely heavily on efficient and safe material handling solutions

- Industries in this region prioritize compliance with safety and environmental standards, leading to increased adoption of synchronous drums for controlled dispensing and transport

- The presence of key manufacturers, high investment in industrial automation, and rising demand for reliable packaging and storage across sectors support continued market leadership

U.S. Synchronous Drum Market Insight

The U.S. synchronous drum market captured the largest share in 2024 within North America, fueled by strong demand from the chemical, fertilizer, and construction sectors. The growing need for standardized, efficient drum systems to manage high-volume and hazardous materials has led to greater adoption. Moreover, the U.S. industrial sector’s focus on operational safety, waste reduction, and automation is contributing significantly to market expansion.

Europe Synchronous Drum Market Insight

The Europe synchronous drum market is projected to grow at a substantial CAGR during the forecast period, driven by increased demand for environmentally safe and standardized material handling solutions. Regulatory compliance related to chemical handling, sustainability in packaging, and workplace safety is pushing industries to adopt advanced drum systems. The region also sees growing integration of synchronous drums in manufacturing, food production, and paint sectors, particularly in Germany, France, and Italy.

Germany Synchronous Drum Market Insight

The Germany synchronous drum market is expected to expand steadily, supported by the country’s strong manufacturing base and emphasis on industrial innovation. Demand is rising across the chemical and food sectors, where precise material containment and hygiene standards are critical. Germany’s push for eco-efficient production and stringent workplace safety guidelines further drive adoption of synchronous drum systems.

Asia-Pacific Synchronous Drum Market Insight

The Asia-Pacific synchronous drum market is expected to witness the fastest CAGR from 2025 to 2032, fueled by rapid industrialization, rising production activities, and infrastructure development across countries such as China, India, and Southeast Asian nations. The region’s growing need for cost-effective and safe bulk material handling solutions, along with increasing investment in chemical and food processing industries, supports robust market growth.

China Synchronous Drum Market Insight

China accounted for the largest revenue share in the Asia-Pacific synchronous drum market in 2024, driven by its dominant chemical manufacturing base and rising demand for efficient storage systems. The country’s expanding construction and fertilizer industries also contribute to strong drum adoption. Domestic production capabilities and affordability further enhance China’s position as a leading market in the region.

India Synchronous Drum Market Insight

India is poised to be the fastest-growing country in the Asia-Pacific synchronous drum market, due to increasing investments in infrastructure, fertilizers, and industrial chemicals. The government’s focus on “Make in India,” along with rising manufacturing activity and improving industrial safety standards, is accelerating demand for standardized and safe material handling equipment such as synchronous drums.

Synchronous Drum Market Share

The synchronous drum industry is primarily led by well-established companies, including:

- Greif, Inc. (U.S.)

- Balmer Lawrie (India)

- Time Technoplast Ltd (India)

- SCHÜTZ GmbH & Co. KGaA (Germany)

- BWAY Corporation (U.S.)

- Industrial Container Services, Inc. (U.S.)

- TPL Plastech Limited (India)

- Eagle Manufacturing Company (U.S.)

- Coexcell Inc (U.S.)

- Chicago Steel Container Corporation (U.S.)

- C. L. Smith (U.S.)

- Great Western Containers Inc. (Canada)

- Curtec International B.V. (Netherlands)

- Remcon Plastics (U.S.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Synchronous Drum Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Synchronous Drum Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Synchronous Drum Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.