Global Textile Finishing Chemicals Market

Market Size in USD Billion

CAGR :

%

USD

9.81 Billion

USD

14.83 Billion

2025

2033

USD

9.81 Billion

USD

14.83 Billion

2025

2033

| 2026 –2033 | |

| USD 9.81 Billion | |

| USD 14.83 Billion | |

|

|

|

|

Textile Finishing Chemicals Market Size

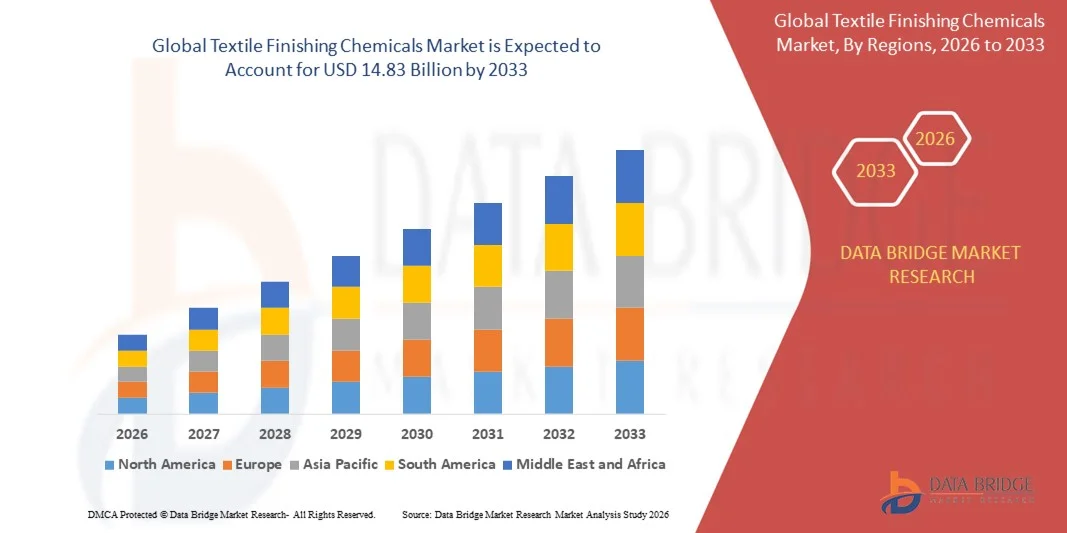

- The global textile finishing chemicals market size was valued at USD 9.81 billion in 2025 and is expected to reach USD 14.83 billion by 2033, at a CAGR of 5.30% during the forecast period

- The market growth is largely fuelled by the rising demand for high-performance, functional, and sustainable textiles, driven by industries such as apparel, home furnishing, technical textiles, and automotive

- Growing adoption of eco-friendly finishing agents in response to stringent environmental norms and rising consumer preference for green textiles

Textile Finishing Chemicals Market Analysis

- Increasing focus on enhancing fabric durability, functionality, and aesthetics is boosting the adoption of advanced finishing formulations

- Strong shift toward bio-based and non-toxic finishing chemicals as manufacturers align with global sustainability initiatives

- North America dominated the textile finishing chemicals market with the largest revenue share in 2025, driven by strong demand for high-performance and value-added textiles across apparel, home furnishings, and technical textile sectors

- Asia-Pacific region is expected to witness the highest growth rate in the global textile finishing chemicals market, driven by increasing textile production, rising disposable incomes, government support for industrial modernization, and growing demand for functional and sustainable textile finishes

- The Softening Finishes segment held the largest market revenue share in 2025 driven by its extensive use in apparel, home textiles, and everyday fabrics to enhance texture, drape, and comfort. Its broad applicability across cotton, blends, and synthetic substrates continues to support widespread adoption

Report Scope and Textile Finishing Chemicals Market Segmentation

|

Attributes |

Textile Finishing Chemicals Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

• Evonik Industries AG (Germany) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Textile Finishing Chemicals Market Trends

Shift Toward Sustainable and Eco-Friendly Textile Finishes

- The rising adoption of eco-friendly and bio-based finishing solutions is transforming the textile finishing chemicals landscape as manufacturers prioritize reducing environmental impact and complying with stricter global sustainability standards. Green formulations such as plant-based softeners, biodegradable coatings, and low-VOC agents are increasingly preferred for apparel, home textiles, and technical fabrics

- The growing consumer demand for sustainable fashion is accelerating the shift toward non-toxic, water-efficient, and energy-saving finishing technologies. Brands are investing in renewable chemistry and circular textile processes to reduce waste, enhance recyclability, and improve material performance without compromising product quality

- The affordability and improved performance of next-generation sustainable finishes are encouraging textile mills to replace conventional chemical-intensive processes. This helps manufacturers reduce operational costs, meet compliance obligations, and appeal to environmentally conscious buyers across global markets

- For instance, in 2024, several textile clusters across Southeast Asia reported a surge in demand for bio-based softeners and low-impact wrinkle-free finishes as exporters aligned with international green certification standards. These sustainable alternatives improved fabric feel and durability while enabling mills to lower effluent loads

- While eco-friendly finishing continues to expand, its long-term success depends on scalable production, cost competitiveness, and wider industry collaboration. Manufacturers must focus on localized innovation and broader adoption strategies to fully capitalize on this green transition

Textile Finishing Chemicals Market Dynamics

Driver

Rising Demand for High-Performance and Functional Textiles

- The growing need for performance-enhancing fabric properties such as wrinkle resistance, flame retardancy, water repellency, and antimicrobial protection is boosting the adoption of advanced finishing chemicals across apparel, technical textiles, and industrial applications. These finishes enhance comfort, safety, and durability, making them indispensable in modern textile production

- Consumers are increasingly aware of the benefits of functional textiles, particularly in activewear, sportswear, medical textiles, and protective clothing. This rising awareness is pushing manufacturers to invest in multi-functional finishes that deliver superior fabric performance while maintaining sustainability standards

- Public and private sector initiatives promoting innovation in textile processing technologies have further strengthened market development. R&D investments, pilot-scale testing facilities, and industry–academia collaborations are enhancing product performance, supporting manufacturers in achieving consistent and efficient finishing outcomes

- For instance, in 2023, several European textile research institutes partnered with industry players to develop advanced antimicrobial and moisture-management finishes for medical and hygiene applications, significantly increasing the demand for specialized finishing solutions across the region

- While demand for performance textiles continues to grow, manufacturers need to ensure scalability, regulatory compliance, and cost-effective production to maintain momentum in the functional finishing chemicals segment

Restraint/Challenge

Stringent Environmental Regulations and High Cost of Advanced Finishing Technologies

- The strict regulatory environment governing chemical usage, wastewater discharge, and worker safety is increasing compliance costs for textile mills. Many regions now restrict the use of conventional chemical agents such as formaldehyde-based resins, heavy metals, and high-VOC solvents, creating challenges for manufacturers reliant on traditional processes

- In many developing textile hubs, limited access to advanced, low-impact finishing technologies restricts modernization efforts. High equipment costs, lack of technical expertise, and outdated processing infrastructure make it difficult for mills to adopt eco-friendly alternatives at scale

- Market expansion is also limited by inconsistent availability of high-quality raw materials for sustainable finishing chemicals. Supply chain fragmentation and regional disparities in chemical sourcing often delay production cycles and increase operational expenses

- For instance, in 2023, textile associations in South Asia reported that a significant share of small and medium-sized mills faced difficulties adopting low-water and low-energy finishing systems due to high installation costs and limited vendor support

- While environmental compliance is essential, addressing cost barriers, improving supply chains, and expanding training programs remain critical. Stakeholders must promote affordable green technologies and decentralized support systems to accelerate sustainable transformation across the textile finishing chemicals market

Textile Finishing Chemicals Market Scope

The market is segmented on the basis of type, communication protocol, unlocking mechanism, and application.

- By Type

On the basis of type, the textile finishing chemicals market is segmented into Softening Finishes, Repellent Finishes, Wrinkle Free Finishes, Coating Finishes, and Mothproofing Finishes. The Softening Finishes segment held the largest market revenue share in 2025 driven by its extensive use in apparel, home textiles, and everyday fabrics to enhance texture, drape, and comfort. Its broad applicability across cotton, blends, and synthetic substrates continues to support widespread adoption.

The Repellent Finishes segment is expected to witness the fastest growth rate from 2026 to 2033, supported by rising demand for water-, stain-, and oil-resistant fabrics across outdoor wear, workwear, and technical textiles. Increasing consumer preference for functional and protective apparel is further accelerating the use of repellent technologies.

- By Process

On the basis of process, the market is segmented into the Pad-Dry Cure Process and the Exhaust Dyeing Process. The Pad-Dry Cure Process held the largest market share in 2025 due to its high efficiency, consistent finish application, and ability to support large-scale continuous production in textile mills. Its compatibility with a wide range of finishing formulations strengthens its dominance in the global industry.

The Exhaust Dyeing Process is expected to witness the fastest growth from 2026 to 2033, driven by its suitability for specialty finishes and sensitive fabrics where controlled chemical absorption is required. Growing demand for precision finishing in premium apparel and technical textiles is supporting its accelerating adoption.

- By Chemical Type

On the basis of chemical type, the textile finishing chemicals market is segmented into Textile Auxiliaries, Textile Colorants, and Textile Finishes. The Textile Auxiliaries segment accounted for the largest revenue share in 2025 owing to their essential role in improving process efficiency, fabric quality, and chemical performance across multiple finishing stages. Their use across diverse textile categories supports sustained dominance.

The Textile Finishes segment is projected to exhibit the fastest growth from 2026 to 2033, propelled by rising demand for functional and value-added fabric properties such as antimicrobial, wrinkle-free, moisture management, and flame retardant capabilities.

- By Application Type

On the basis of application type, the market is segmented into Exhaust Application and Pad-Dry Cure Application. The Pad-Dry Cure Application segment held the largest market share in 2025 due to its widespread use in bulk finishing operations and its capability to deliver uniform coatings with high production throughput.

The Exhaust Application segment is expected to register the fastest growth from 2026 to 2033 as manufacturers increasingly adopt it for specialty and high-performance fabric finishes requiring deeper chemical penetration and controlled absorption.

- By Product

On the basis of product, the textile finishing chemicals market is segmented into Coating & Sizing Chemicals, Colorants & Auxiliaries, Finishing Agents, Surfactants, Desizing Agents, Bleaching Agents, Scouring Agents, and Yarn Lubricants. The Coating & Sizing Chemicals segment held the largest revenue share in 2025 owing to their critical role in improving fabric strength, processability, and overall textile performance, especially in weaving and technical fabric production.

The Finishing Agents segment is expected to record the fastest growth rate from 2026 to 2033, driven by the rising demand for advanced functional finishes such as water repellency, antimicrobial protection, UV resistance, and wrinkle recovery across high-performance textile categories.

Textile Finishing Chemicals Market Regional Analysis

- North America dominated the textile finishing chemicals market with the largest revenue share in 2025, driven by strong demand for high-performance and value-added textiles across apparel, home furnishings, and technical textile sectors

- Consumers and manufacturers in the region prioritize advanced finishing technologies that enhance durability, comfort, and sustainability, such as wrinkle-free, antimicrobial, and water-repellent solutions

- This growing adoption is further supported by a well-established textile processing industry, rising preference for eco-friendly formulations, and rapid integration of innovative finishing systems, solidifying North America’s position as a leading market for high-quality textile finishes

U.S. Textile Finishing Chemicals Market Insight

The U.S. textile finishing chemicals market captured the largest revenue share in 2025 within North America, fuelled by the high demand for functional and sustainable textiles across fashion, healthcare, automotive, and home décor industries. Manufacturers are increasingly adopting advanced finishing agents that enhance fabric performance, such as stain resistance, moisture management, and antimicrobial protection. The rising trend of premium apparel and technical textiles, combined with ongoing investments in R&D and digital textile processing technologies, continues to accelerate market expansion. Moreover, the shift toward eco-certified and low-impact chemicals is significantly influencing product developments in the U.S. market.

Europe Textile Finishing Chemicals Market Insight

The Europe textile finishing chemicals market is expected to witness the fastest growth rate from 2026 to 2033, primarily driven by strict environmental regulations, rising demand for sustainable fabrics, and the region’s strong focus on quality and compliance. Growing urbanization and increased consumer preference for high-performance textiles are also contributing to market development. European manufacturers are rapidly integrating energy-efficient, water-saving, and bio-based finishing solutions across apparel, industrial textiles, and home furnishings. The adoption of advanced finishing technologies is rising across both new production facilities and modernization projects in the textile sector.

U.K. Textile Finishing Chemicals Market Insight

The U.K. textile finishing chemicals market is expected to witness the fastest growth rate from 2026 to 2033, driven by the expanding trend of sustainable fashion, enhanced textile quality requirements, and increasing investments in functional finishing solutions. Concerns regarding product longevity, comfort, and performance are encouraging manufacturers to adopt innovative chemicals such as water-repellent, antimicrobial, and wrinkle-resistant finishes. The country’s strong retail ecosystem and rising demand for eco-certified textiles are expected to continue propelling market growth.

Germany Textile Finishing Chemicals Market Insight

The Germany textile finishing chemicals market is expected to witness the fastest growth rate from 2026 to 2033, fuelled by high awareness of sustainability, strong industrial textile demand, and the nation’s focus on technologically advanced production systems. Germany’s robust manufacturing infrastructure and emphasis on innovation support the adoption of environmentally friendly and high-performance finishing agents. The integration of smart production technologies and a preference for quality-driven, durable textiles are accelerating the use of advanced finishing chemicals in both residential and industrial textile applications.

Asia-Pacific Textile Finishing Chemicals Market Insight

The Asia-Pacific textile finishing chemicals market is expected to witness the fastest growth rate from 2026 to 2033, driven by the region’s expanding textile manufacturing base, rapid industrialization, and rising disposable incomes in countries such as China, India, and Japan. Growing adoption of functional and aesthetic finishes, combined with government support for modernization and digitalization in the textile sector, is driving strong market growth. As APAC serves as a major global textile production hub, the demand for affordable, high-quality finishing chemicals continues to expand across numerous applications.

Japan Textile Finishing Chemicals Market Insight

The Japan textile finishing chemicals market is expected to witness the fastest growth rate from 2026 to 2033 due to the country’s strong focus on technological advancement, premium textile production, and innovation in performance fabrics. Japanese consumers prioritize quality, durability, and functionality, which is accelerating adoption of finishes such as antimicrobial, moisture-wicking, and anti-wrinkle agents. Moreover, Japan’s aging population is likely to increase demand for comfortable, skin-friendly, and easy-care textiles across both residential and institutional sectors.

China Textile Finishing Chemicals Market Insight

The China textile finishing chemicals market accounted for the largest revenue share in Asia-Pacific in 2025, supported by a massive textile manufacturing ecosystem, rapid urbanization, and strong demand for functional and fashionable apparel. As one of the world’s largest producers and exporters of textiles, China is witnessing rising adoption of advanced finishing chemicals across apparel, home textiles, and technical fabric categories. The push toward smart manufacturing, availability of cost-effective finishing solutions, and the growing role of domestic chemical suppliers are key factors driving the market’s expansion in China.

Textile Finishing Chemicals Market Share

The Textile Finishing Chemicals industry is primarily led by well-established companies, including:

• Evonik Industries AG (Germany)

• Wacker Chemie AG (Germany)

• Rudolf GmbH (Germany)

• GIOVANNI BOZZETTO S.p.A (Italy)

• Akzo Nobel N.V. (Netherlands)

• Kiri Industries Ltd (India)

• Fashion Chemicals GmbH & Co. KG (Germany)

• OMNOVA Solutions Inc. (U.S.)

• Covestro AG (Germany)

• CHT Group (Germany)

• Clariant (Switzerland)

• Bayer AG (Germany)

• Sumitomo Chemicals Co. Ltd. (Japan)

• Sarex (India)

• Quality Colours (London) Ltd (U.K.)

• Buckman (U.S.)

• The Lubrizol Corporation (U.S.)

• Omya (Switzerland)

• Transfar Group Co., Ltd. (China)

• Chungyo Chem (Taiwan)

• Kolor Jet Chemical Pvt. Ltd. (India)

• Jay Chemical Industries Ltd. (India)

• Univar Inc (U.S.)

• Americos Industries Inc. (U.S.)

• DPI Max, Inc (U.S.)

• Astro American Chemical (U.S.)

Latest Developments in Global Textile Finishing Chemicals Market

- In August 2025, Clariant AG (Switzerland) entered into a strategic partnership with a major textile manufacturer to co-develop eco-friendly finishing agents. The collaboration focuses on expanding sustainable product offerings, strengthening Clariant’s position in the green chemistry space, and meeting the rising industry demand for environmentally responsible solutions. This move is expected to enhance market competitiveness and accelerate the adoption of sustainable textile finishing technologies

- In September 2025, Solvay SA (Belgium) introduced a new range of textile finishing chemicals aimed at boosting durability and performance while reducing environmental impact. The launch underscores Solvay’s commitment to innovation in sustainable chemistry and supports the industry’s shift toward high-performance, eco-conscious solutions. This development is likely to broaden Solvay’s customer base and reinforce its presence in the global market

- In October 2025, Archroma (Switzerland) rolled out a digital platform designed to streamline customer interactions and simplify the ordering process for its textile finishing solutions. The platform enhances operational efficiency, improves customer engagement, and supports Archroma’s broader digital transformation strategy. This initiative is expected to elevate customer satisfaction and strengthen Archroma’s competitive edge in the market

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Textile Finishing Chemicals Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Textile Finishing Chemicals Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Textile Finishing Chemicals Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.