Global Thermoformed Plastic Packaging Market

Market Size in USD Billion

CAGR :

%

USD

58.09 Billion

USD

85.83 Billion

2025

2033

USD

58.09 Billion

USD

85.83 Billion

2025

2033

| 2026 –2033 | |

| USD 58.09 Billion | |

| USD 85.83 Billion | |

|

|

|

|

Thermoformed Plastic Packaging Market Size

- The global thermoformed plastic packaging market size was valued at USD 58.09 billion in 2025 and is expected to reach USD 85.83 billion by 2033, at a CAGR of 5.00% during the forecast period

- The market growth is largely fueled by the increasing demand for convenient, protective, and visually appealing packaging solutions across food, beverage, pharmaceutical, and consumer goods industries. Rising consumer preference for ready-to-eat meals, packaged fresh produce, and portion-controlled products is driving the adoption of thermoformed plastic packaging globally

- Furthermore, growing environmental awareness and regulatory support for sustainable and recyclable packaging are encouraging manufacturers to invest in advanced thermoforming technologies. For instance, companies such as Sonoco and ProAmpac are introducing recyclable and high-barrier thermoformed trays, which enhance product shelf life while aligning with sustainability goals. These factors are accelerating the uptake of eco-friendly packaging solutions, significantly boosting market growth

Thermoformed Plastic Packaging Market Analysis

- Thermoformed plastic packaging, providing high product protection, tamper-evident features, and clear product visibility, is increasingly preferred by food, pharmaceutical, and personal care brands. Its versatility across various shapes, sizes, and barrier properties makes it essential for maintaining product integrity and enhancing consumer appeal

- The rising adoption of automated packaging lines and advanced manufacturing processes is supporting the efficient production of thermoformed plastic packaging. Manufacturers are leveraging these technologies to produce high-quality packaging at scale, meeting the growing global demand while optimizing operational costs

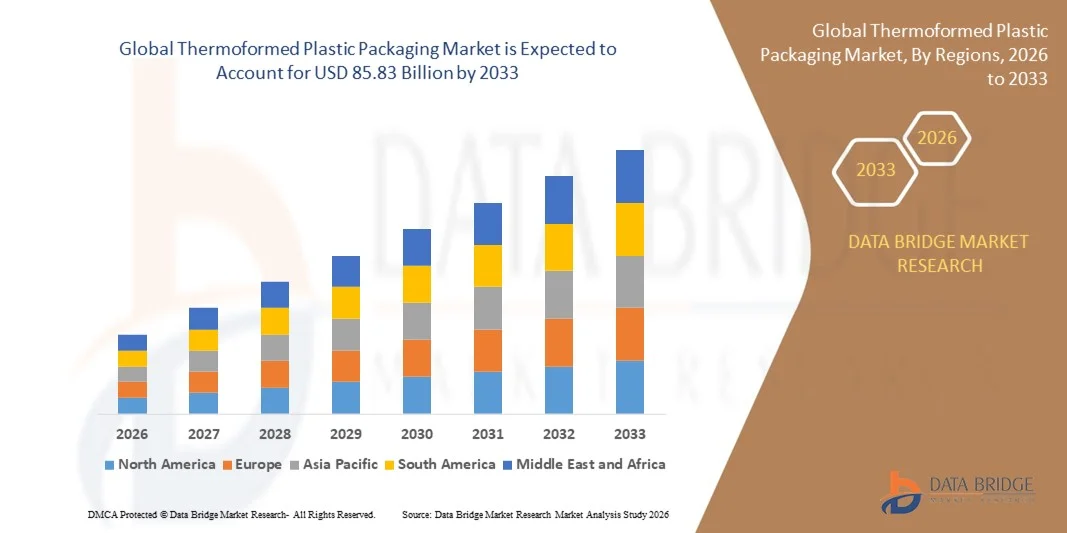

- North America dominated the thermoformed plastic packaging market with a share of 39% in 2025, due to the growing demand for packaged convenience foods, pharmaceuticals, and consumer goods, as well as increasing awareness of sustainable and protective packaging solutions

- Asia-Pacific is expected to be the fastest growing region in the thermoformed plastic packaging market during the forecast period due to rising urbanization, increasing disposable incomes, and technological advancements in countries such as China, Japan, and India

- Thermoformed clamshell packaging segment dominated the market with a market share of 42% in 2025, due to its high visibility, protective nature, and convenience for both retail and food applications. Consumers and manufacturers favor clamshell packaging for its durability, tamper-evident properties, and ability to showcase products attractively while maintaining product integrity. The market also experiences strong demand due to the compatibility of clamshells with automated packaging lines and their adaptability for a variety of food and consumer goods products

Report Scope and Thermoformed Plastic Packaging Market Segmentation

|

Attributes |

Thermoformed Plastic Packaging Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Thermoformed Plastic Packaging Market Trends

Rising Adoption of Sustainable and Recyclable Thermoformed Packaging

- The global thermoformed plastic packaging market is witnessing a significant trend toward the adoption of sustainable and recyclable packaging solutions, driven by growing environmental awareness and regulatory support for eco-friendly materials. Companies and consumers are increasingly prioritizing packaging that minimizes waste while maintaining product protection and shelf appeal

- For instance, in May 2025, Sonoco launched a 100% recycled PET thermoformed tray for fresh produce in North America, offering both sustainability and enhanced product integrity. Such initiatives by key companies are encouraging widespread adoption of recyclable thermoformed solutions across food, beverage, and pharmaceutical sectors

- Sustainable thermoformed packaging solutions also provide brands with an opportunity to align with corporate social responsibility (CSR) goals and meet consumer expectations for environmentally responsible products. The use of recyclable and high-barrier materials allows for preservation of product quality while reducing plastic footprint

- The integration of renewable and fiber-based materials into thermoformed packaging is becoming increasingly prevalent, offering both environmental benefits and functional performance. These materials can provide high durability, maintain product visibility, and support recyclability, making them attractive for both manufacturers and retailers

- Growing collaborations between packaging manufacturers and material suppliers are accelerating innovation in recyclable and biodegradable thermoformed materials, fostering market growth. Companies are developing advanced materials that balance sustainability with operational efficiency, enabling broader adoption of eco-friendly packaging

- The trend toward sustainable and recyclable thermoformed packaging is expected to continue expanding across all regions, driven by rising consumer awareness, regulatory mandates, and the focus of companies such as ProAmpac and Huhtamaki on eco-conscious solutions. This trend is fundamentally reshaping packaging strategies and driving market growth

Thermoformed Plastic Packaging Market Dynamics

Driver

Growing Demand for Convenient and Protective Packaging Solutions

- The increasing demand for packaging that provides convenience, protection, and product visibility is a key driver of the thermoformed plastic packaging market. Brands are seeking solutions that safeguard products during transport and display while enhancing consumer experience

- For instance, in April 2025, Toppan Holdings acquired Sonoco’s Thermoformed & Flexibles Packaging business, enabling the company to expand its capabilities in high-performance protective packaging. Such strategic moves by leading companies are expected to accelerate market growth by offering innovative, convenient packaging solutions across multiple industries

- Consumers are increasingly opting for ready-to-eat, pre-portioned, and portion-controlled products, creating the need for thermoformed packaging that is easy to use and preserves product freshness. Features such as tamper-evident designs and clear product visibility further enhance adoption

- The growing e-commerce sector is driving demand for packaging that protects products during shipping while maintaining aesthetic appeal, prompting manufacturers to invest in robust thermoformed solutions. This is particularly relevant for food, pharmaceuticals, and personal care products that require both protection and shelf-ready presentation

- The convenience, durability, and functionality of thermoformed packaging, combined with its ability to support brand differentiation through innovative designs, continue to drive adoption globally. In addition, manufacturers focusing on operational efficiency and sustainability are contributing to the accelerated uptake of these solutions

Restraint/Challenge

High Cost and Complexity of Thermoforming Technologies

- The relatively high cost of advanced thermoforming machinery and materials poses a significant challenge to market growth. Investments in sophisticated equipment and specialized materials can be prohibitive, particularly for small- and medium-sized manufacturers

- For instance, the development of high-barrier, fiber-based sheets by companies such as ProAmpac requires significant R&D and capital investment, which can limit rapid adoption by all market participants. Such instances highlight the cost barrier associated with advanced thermoforming technologies

- The complexity of producing consistent, high-quality thermoformed products adds to operational challenges, requiring skilled labor and advanced manufacturing processes. These factors can delay production scaling and increase overall manufacturing costs

- Companies must balance the benefits of high-performance and sustainable thermoformed packaging with the financial and technical challenges involved in production. Investments in automation and process optimization are often required to mitigate these issues

- Overcoming the cost and complexity barriers through technology optimization, process standardization, and strategic collaborations will be crucial for sustained growth in the thermoformed plastic packaging market. In addition, addressing these challenges will enable wider adoption of advanced, sustainable packaging solutions across industries

Thermoformed Plastic Packaging Market Scope

The market is segmented on the basis of type, heat seal coating, process type, and end user.

- By Type

On the basis of type, the thermoformed plastic packaging market is segmented into thermoformed clamshell packaging, thermoformed blister packaging, thermoformed skin packaging, and others. The thermoformed clamshell packaging segment dominated the market with the largest revenue share of 42% in 2025, driven by its high visibility, protective nature, and convenience for both retail and food applications. Consumers and manufacturers favor clamshell packaging for its durability, tamper-evident properties, and ability to showcase products attractively while maintaining product integrity. The market also experiences strong demand due to the compatibility of clamshells with automated packaging lines and their adaptability for a variety of food and consumer goods products.

The thermoformed blister packaging segment is anticipated to witness the fastest growth rate from 2026 to 2033, fueled by increasing adoption in pharmaceuticals and consumer electronics. For instance, companies such as Amcor leverage blister packaging for secure tablet, capsule, and small electronic device packaging, providing both protection and convenience. The segment’s growth is further supported by its ability to offer portion control, longer shelf life, and consumer-friendly design that enhances product appeal.

- By Heat Seal Coating

On the basis of heat seal coating, the market is segmented into water-based heat seal coating, solvent-based heat seal coating, and hot melt-based heat seal coating. The water-based heat seal coating segment held the largest market revenue share in 2025 due to its eco-friendly properties, regulatory compliance, and strong bonding performance with various plastic substrates. Manufacturers prefer water-based coatings as they reduce environmental impact while maintaining effective sealing for food, pharmaceutical, and personal care packaging.

The solvent-based heat seal coating segment is expected to witness the fastest growth from 2026 to 2033, driven by its superior adhesion and high-temperature resistance. For instance, companies such as Berry Global utilize solvent-based coatings in high-barrier packaging applications, enhancing product shelf life and safety. The segment’s growth is also propelled by the increasing need for packaging solutions that can withstand rigorous transportation and storage conditions without compromising seal integrity.

- By Process Type

On the basis of process type, the market is segmented into vacuum, pressure, and mechanical thermoforming. The vacuum thermoforming segment dominated the market in 2025, owing to its cost-effectiveness, versatility in producing thin to medium-gauge packaging, and suitability across food and consumer goods industries. Manufacturers favor vacuum forming for its precision, consistent quality, and ability to create complex shapes with minimal material waste.

The pressure thermoforming segment is projected to witness the fastest growth from 2026 to 2033 due to its ability to form thicker, more rigid packaging and enhanced dimensional stability. For instance, Printpack incorporates pressure thermoforming for premium food trays and industrial packaging that require stronger structural integrity. This segment’s growth is further supported by rising demand for protective packaging that ensures product safety during transportation and storage.

- By End User

On the basis of end user, the thermoformed plastic packaging market is segmented into food, beverages, pharmaceuticals, cosmetics and personal care, homecare and toiletries, industrial goods, electrical and electronics, and others. The food segment dominated the market with the largest revenue share in 2025, driven by increasing demand for packaged convenience foods, ready-to-eat meals, and perishable items requiring protective and tamper-evident packaging. Consumers prioritize food packaging that maintains freshness, extends shelf life, and offers visibility of the product inside.

The pharmaceuticals segment is expected to witness the fastest growth from 2026 to 2033, fueled by rising demand for blister and clamshell packaging to ensure drug safety, accurate dosing, and compliance with regulatory standards. For instance, companies such as West Pharmaceutical Services utilize thermoformed packaging for tablets, capsules, and medical devices, providing secure and convenient solutions. The segment’s growth is also supported by expanding healthcare infrastructure and increasing pharmaceutical production across emerging markets.

Thermoformed Plastic Packaging Market Regional Analysis

- North America dominated the thermoformed plastic packaging market with the largest revenue share of 39% in 2025, driven by the growing demand for packaged convenience foods, pharmaceuticals, and consumer goods, as well as increasing awareness of sustainable and protective packaging solutions

- Manufacturers and consumers in the region highly value packaging that ensures product safety, extends shelf life, and enhances product visibility for retail appeal

- This widespread adoption is further supported by high disposable incomes, technologically advanced manufacturing facilities, and strong regulatory standards promoting food and pharmaceutical safety, establishing thermoformed plastic packaging as a preferred solution for both industrial and retail applications

U.S. Thermoformed Plastic Packaging Market Insight

The U.S. thermoformed plastic packaging market captured the largest revenue share in North America in 2025, fueled by the swift adoption of ready-to-eat food products and packaged pharmaceuticals. Companies are increasingly prioritizing packaging solutions that combine product protection with sustainability and consumer convenience. The growing trend of e-commerce and online food delivery further propels demand, alongside the integration of recyclable and high-barrier packaging materials. Moreover, the expansion of automated packaging systems and smart manufacturing processes is significantly contributing to market growth in the U.S.

Europe Thermoformed Plastic Packaging Market Insight

The Europe thermoformed plastic packaging market is projected to expand at a substantial CAGR during the forecast period, primarily driven by strict food safety regulations, growing pharmaceutical production, and increasing demand for convenience packaging. Rising urbanization, coupled with the adoption of advanced packaging technologies, is fostering the use of thermoformed plastic solutions. European consumers are drawn to packaging that offers transparency, tamper-evidence, and extended shelf life. The market is witnessing significant growth across food, beverage, pharmaceutical, and personal care segments, with manufacturers adopting eco-friendly and recyclable thermoformed solutions.

U.K. Thermoformed Plastic Packaging Market Insight

The U.K. market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by increasing demand for packaged foods, pharmaceuticals, and cosmetics. Consumers and businesses are focusing on packaging that ensures product safety, convenience, and sustainability. The rise of e-commerce, coupled with modern retail infrastructure, supports the adoption of thermoformed plastic packaging. Moreover, growing awareness of environmental concerns and regulations promoting recyclable materials are expected to continue stimulating market growth in the U.K.

Germany Thermoformed Plastic Packaging Market Insight

The Germany market is expected to expand at a considerable CAGR during the forecast period, fueled by increasing production of pharmaceuticals, consumer goods, and packaged foods. Germany’s well-established manufacturing infrastructure, combined with a focus on innovation and sustainable packaging, promotes the adoption of thermoformed plastics. The integration of high-barrier materials and automated packaging solutions is increasingly prevalent, with a strong preference for eco-conscious and safe packaging solutions aligning with local consumer expectations.

Asia-Pacific Thermoformed Plastic Packaging Market Insight

The Asia-Pacific market is poised to grow at the fastest CAGR during the forecast period of 2026 to 2033, driven by rising urbanization, increasing disposable incomes, and technological advancements in countries such as China, Japan, and India. The region’s growing packaged food and pharmaceutical industries, supported by government initiatives promoting modern packaging standards, is driving adoption. Moreover, as APAC emerges as a manufacturing hub for thermoformed packaging materials and equipment, affordability and accessibility are expanding to a wider industrial and retail base.

Japan Thermoformed Plastic Packaging Market Insight

The Japan market is gaining momentum due to the country’s high-tech manufacturing capabilities, urbanization, and demand for convenient and protective packaging. Japanese manufacturers and consumers prioritize packaging that maintains product freshness, offers transparency, and aligns with environmental regulations. The adoption of automated thermoforming lines and integration with advanced production processes is fueling market growth. Moreover, Japan’s aging population is expected to increase demand for easy-to-use, safe packaging for food and pharmaceutical products in both residential and commercial sectors.

China Thermoformed Plastic Packaging Market Insight

China accounted for the largest revenue share in the Asia-Pacific region in 2025, attributed to rapid urbanization, a growing middle class, and high rates of industrial and technological adoption. The demand for packaged convenience foods, pharmaceuticals, and consumer goods is rising sharply, supported by the expansion of e-commerce and modern retail channels. Domestic manufacturers are increasingly offering cost-effective, high-quality thermoformed packaging solutions, while government policies promoting food safety and packaging standards further propel the market in China.

Thermoformed Plastic Packaging Market Share

The thermoformed plastic packaging industry is primarily led by well-established companies, including:

- Amcor plc (U.S.)

- Anchor Packaging LLC (U.S.)

- Berry Global Inc. (U.S.)

- Blisterpak, Inc. (U.S.)

- Brentwood Industries, Inc. (U.S.)

- CJK Thermoforming Solutions, LLC (U.S.)

- Constantia Flexibles (Austria)

- D&W Fine Pack (U.S.)

- Dart Container Corporation (U.S.)

- Sonoco Products Company (U.S.)

- Sabert Corporation (U.S.)

- UFP Technologies, Inc. (U.S.)

- Universal Plastics (U.S.)

- DS Smith (U.K.)

- Placon (U.S.)

- Genpak, LLC (U.S.)

- Pactiv LLC (U.S.)

- Huhtamaki Flexible Packaging (Finland)

- EasyPak (U.S.)

- Sealed Air (U.S.)

Latest Developments in Global Thermoformed Plastic Packaging Market

- In July 2025, Sonoco earned accreditation from the Pet Sustainability Coalition (PSC), highlighting its commitment to sustainable packaging in the pet care sector. This accreditation positions Sonoco as a leading provider of recyclable and environmentally conscious packaging solutions, fostering collaboration and innovation in the development of sustainable thermoformed products. The initiative enhances the company’s ESG credentials and makes its packaging more attractive to environmentally conscious brands and consumers, supporting broader adoption of circular economy practices

- In June 2025, Sonoco launched a 100% recycled PET thermoformed tray for fresh produce in North America. This launch promotes sustainability while maintaining product freshness and shelf life, aligning with increasing consumer and regulatory demand for eco-friendly packaging. The tray is compatible with automated packaging lines, supporting operational efficiency and scalability for manufacturers. The initiative demonstrates Sonoco’s focus on delivering recyclable, high-performance thermoformed packaging solutions that meet the evolving needs of retailers and end consumers

- In April 2025, Amcor completed an all-stock merger with Berry Global, creating a significantly more diversified packaging company with expanded thermoforming capabilities. This merger enhances the combined entity’s ability to offer a comprehensive portfolio of rigid and flexible packaging solutions, promoting innovation in sustainable and high-performance packaging. The consolidation is expected to generate operational synergies and strengthen cash flow, enabling further investment in advanced thermoforming technologies. The initiative reflects Amcor’s strategic focus on market leadership and delivering environmentally responsible packaging solutions

- In April 2025, Toppan Holdings completed the acquisition of Sonoco’s Thermoformed & Flexibles Packaging business for US$ 1.8 billion. This acquisition strengthens Toppan’s global footprint in sustainable thermoformed packaging and expands its manufacturing capabilities. The move enables Toppan to serve North and South American food, retail, and medical markets more effectively while accelerating innovation in protective and high-visibility packaging solutions. The initiative underscores Toppan’s commitment to providing advanced, sustainable packaging solutions and supporting circular economy goals within the industry

- In February 2024, ProAmpac introduced FibreSculpt, a high-barrier, fiber-based sheet for thermoformed trays with over 90% renewable fiber content. FibreSculpt enables recyclable, sustainable thermoformed packaging for products such as meat, cheese, and fish, reducing plastic content without compromising performance. The material supports high-speed production and maintains durability, helping brands meet both sustainability and operational efficiency goals. The initiative underscores ProAmpac’s commitment to innovation in sustainable packaging and advancing circular economy solutions within the thermoformed plastics industry

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Thermoformed Plastic Packaging Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Thermoformed Plastic Packaging Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Thermoformed Plastic Packaging Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.