Global Tire Marking Machine Market

Market Size in USD Billion

CAGR :

%

USD

510.48 Billion

USD

621.97 Billion

2024

2032

USD

510.48 Billion

USD

621.97 Billion

2024

2032

| 2025 –2032 | |

| USD 510.48 Billion | |

| USD 621.97 Billion | |

|

|

|

|

Tire Marking Machine Market Size

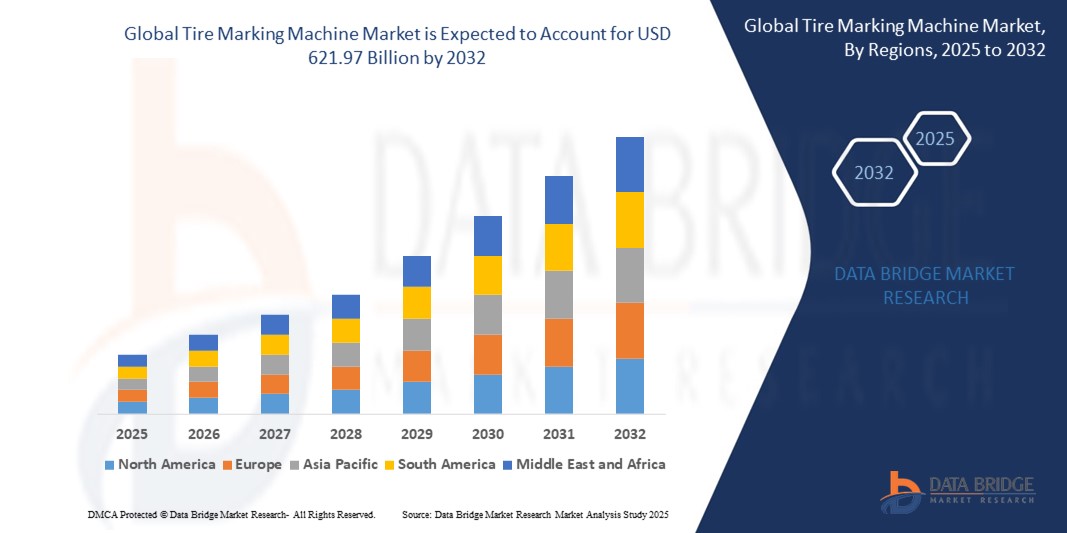

- The global tire marking machine market size was valued at USD 510.48 million in 2024 and is expected to reach USD 621.97 billion by 2032, at a CAGR of 2.50% during the forecast period

- The market growth is primarily driven by the rising demand for tire traceability, regulatory compliance, and the growing emphasis on product quality and safety in the automotive industry

- Moreover, the integration of automation and Industry 4.0 technologies in manufacturing processes is boosting the need for efficient, precise, and durable marking systems, reinforcing tire marking machines as an essential part of modern tire production lines. These combined factors are catalyzing market expansion and technological innovation in the sector

Tire Marking Machine Market Analysis

- Tire marking machines, essential for imprinting identification codes, batch numbers, and branding on tires, are becoming increasingly crucial in modern tire manufacturing due to the growing need for traceability, quality assurance, and regulatory compliance across automotive supply chains

- The rising demand for tire marking machines is primarily driven by the surge in global tire production, strict government regulations for tire labeling and tracking, and the growing focus on automation and process optimization in manufacturing facilities

- Asia-Pacific dominated the tire marking machine market with the largest revenue share of 47.3% in 2024, supported by the region’s strong automotive manufacturing base, particularly in countries such as China, India, and Japan, coupled with growing investments in factory automation and industrial infrastructure

- North America is expected to witness notable growth during the forecast period due to stringent regulatory frameworks around tire traceability and increased technological adoption by tire manufacturers

- The inkjet marking segment dominated the tire marking machine market with a market share of 40.1% in 2024, attributed to its high-speed marking capability, low operational cost, and flexibility in printing detailed alphanumeric and barcode data on diverse tire surfaces

Report Scope and Tire Marking Machine Market Segmentation

|

Attributes |

Tire Marking Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Tire Marking Machine Market Trends

“Integration of Automation and Industry 4.0 Technologies”

- A notable and accelerating trend in the global tire marking machine market is the integration of automation and Industry 4.0 technologies, enabling enhanced productivity, traceability, and precision in tire manufacturing environments

- For instance, leading manufacturers are deploying fully automated tire marking solutions integrated with smart sensors and robotics to achieve higher throughput and reduce human error. Companies such as Codikett and Rea Jet are introducing advanced systems capable of real-time data exchange and intelligent control across production lines

- These automated marking machines are increasingly equipped with connectivity features that allow seamless communication with centralized production systems and enterprise resource planning (ERP) software, thereby supporting digital traceability throughout the tire's lifecycle

- Furthermore, integration with machine vision and AI technologies enables automatic verification of print quality and positioning, improving operational efficiency and compliance with quality standards. For instance, systems using AI algorithms can detect marking anomalies and alert operators in real time

- This convergence of automation and smart manufacturing in tire marking is reshaping production standards, with manufacturers shifting from manual or semi-automated systems to intelligent, fully digitized operations

- As regulatory bodies continue to enforce stricter product traceability standards, demand is growing for tire marking machines that not only apply durable marks but also integrate into broader quality assurance and inventory management systems. This trend is driving innovation and adoption of high-end marking systems globally

Tire Marking Machine Market Dynamics

Driver

“Rising Demand for Tire Traceability and Regulatory Compliance”

- The increasing need for tire traceability and compliance with evolving regulatory standards is a key driver accelerating the adoption of tire marking machines across the global automotive manufacturing sector

- For instance, regulations from authorities such as the U.S. Department of Transportation (DOT) and the European Union require clear identification codes and batch numbers on tires to ensure accountability and facilitate recalls or quality audits

- Tire manufacturers are increasingly investing in advanced marking systems to meet these mandates, improve supply chain transparency, and enhance brand integrity

- Furthermore, the growing emphasis on quality assurance and customer safety in the automotive industry has amplified the need for accurate and permanent tire identification, especially in markets with high vehicle production volumes

- Modern tire marking machines offer advantages such as contactless operation, high-speed performance, and compatibility with a range of tire materials and sizes, making them indispensable in high-capacity production lines. The need to streamline production workflows and reduce manual labor is also contributing to their widespread adoption

Restraint/Challenge

“High Initial Investment and Integration Complexity”

- A significant challenge facing the tire marking machine market is the high initial investment required for procuring and installing advanced automated systems, particularly for small and medium-sized tire manufacturers

- Modern high-performance marking machines, especially those offering automation, vision inspection, and connectivity features, often involve substantial capital expenditure and infrastructure adjustments

- For instance, integrating new marking systems with legacy production environments or ERP systems can be complex and may require customized engineering solutions, thereby increasing implementation time and cost

- Moreover, operational downtime during installation and the need for operator training can pose further barriers to rapid adoption, especially in cost-sensitive markets

- While long-term efficiency gains and compliance advantages are significant, the upfront cost and complexity of integration can deter some manufacturers from upgrading, especially in regions with lower automation adoption rates

- Addressing these challenges through modular system designs, scalable pricing models, and better support for system integration will be essential to drive broader market acceptance and adoption across diverse manufacturing setups

Tire Marking Machine Market Scope

The market is segmented on the basis of product type, application, and sales channel.

- By Product Type

On the basis of product type, the tire marking machine market is segmented into laser marking systems, indent markers, and embossed tags. The laser marking systems segment dominated the market with the largest market revenue share in 2024, driven by its precision, durability, and ability to mark high-resolution alphanumeric and barcode data. Its non-contact operation and low maintenance make it ideal for high-speed production environments where consistent quality is essential.

The indent markers segment is expected to witness the fastest growth from 2025 to 2032 due to its affordability and suitability for permanent marking on various tire surfaces. It remains widely adopted by mid-tier manufacturers that prioritize deep, tamper-proof marking for regulatory compliance and traceability.

- By Application

On the basis of application, the tire marking machine market is segmented into tire tread code printing, automated striping and stenciling, and ink jet printing. The ink jet printing segment dominated the tire marking machine market with the largest revenue share of 40.1% in 2024, driven by its high-speed, cost-effective, and flexible printing capabilities. Ink jet systems are widely preferred for applying batch numbers, branding, and real-time data due to their easy integration, minimal contact, and adaptability to various tire sizes and surfaces. These systems are especially valued in high-volume production lines for their ability to perform consistent marking without compromising tire integrity.

The automated striping and stenciling segment is expected to witness the fastest growth from 2025 to 2032, supported by increased automation in tire plants and the need for clear visual identifiers for sorting, classification, and internal logistics.

- By Sales Channel

On the basis of sales channel, the tire marking machine market is segmented into direct and indirect sales. The direct sales segment accounted for the largest market share in 2024, as tire manufacturers often prefer to work directly with original equipment manufacturers (OEMs) for system customization, technical support, and after-sales service. This channel is particularly prominent in large-scale facilities that require seamless integration into automated production lines.

The indirect sales segment is expected to witness the fastest growth from 2025 to 2032, due to expanding global distributor networks and increased demand from small- and medium-sized manufacturers. Availability through third-party vendors and regional suppliers also enhances market reach, especially in emerging markets

Tire Marking Machine Market Regional Analysis

- Asia-Pacific dominated the tire marking machine market with the largest revenue share of 47.3% in 2024, supported by the region’s strong automotive manufacturing base, particularly in countries such as China, India, and Japan, coupled with growing investments in factory automation and industrial infrastructure

- Manufacturers in the region are increasingly prioritizing efficient traceability, regulatory compliance, and high-volume tire production, prompting greater adoption of advanced marking solutions such as inkjet and laser systems

- This strong regional demand is further supported by the presence of major tire producers, expanding automotive exports, and government-backed initiatives promoting smart manufacturing, positioning Asia-Pacific as a critical hub for tire marking machine deployment across both domestic and global supply chains

India Tire Marking Machine Market Insight

The India tire marking machine market accounted for the largest market revenue share in Asia-Pacific in 2024, attributed to its rapidly growing automotive sector, large tire production capacity, and increasing demand for traceability solutions. With a focus on exports and compliance with global labeling standards, tire manufacturers are investing in automated inkjet and laser marking systems. The government’s support for “Make in India” and industrial digitalization is also promoting widespread technology adoption across both established factories and emerging manufacturing hubs.

Japan Tire Marking Machine Market Insight

The Japan tire marking machine market is gaining momentum due to the country’s emphasis on high-quality manufacturing, automation, and safety. The adoption of tire marking systems is driven by stringent industry standards, increasing production of premium and electric vehicle tires, and the need for real-time traceability. Integration with intelligent factory systems and IoT-based quality inspection tools is fueling demand for high-performance marking solutions, particularly laser and inkjet technologies known for speed and precision.

U.S. Tire Marking Machine Market Insight

The U.S. tire marking machine market captured the largest revenue share of 78.3% in 2024 within North America, fueled by strong regulatory enforcement, advanced manufacturing practices, and growing automation in tire production facilities. The need to comply with DOT labeling standards and support product recalls has led to increased adoption of high-speed marking systems. Moreover, the rise of smart manufacturing, coupled with the presence of global tire OEMs, is encouraging investment in technologically advanced and integrated marking solutions across the U.S. market.

Europe Tire Marking Machine Market Insight

The Europe tire marking machine market is projected to expand at a substantial CAGR throughout the forecast period, driven by strict EU compliance standards, demand for sustainable tire production, and the need for traceability. The region’s tire manufacturers are embracing inkjet and laser marking technologies to meet export and safety labeling requirements while enhancing efficiency. Growing investments in smart factories, especially in countries such as Germany, France, and Italy, are further accelerating adoption across new and retrofitted production lines.

U.K. Tire Marking Machine Market Insight

The U.K. tire marking machine market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by increasing regulatory pressure and the growing focus on digital transformation in manufacturing. As tire producers aim to meet international traceability standards, demand is rising for automated, non-contact marking solutions that offer consistent performance and integration with digital quality management systems. In addition, the expansion of electric vehicle infrastructure and smart factory development is supporting broader adoption across the U.K.’s industrial landscape.

Germany Tire Marking Machine Market Insight

The Germany tire marking machine market is expected to expand at a considerable CAGR during the forecast period, fueled by the country's leadership in industrial automation, precision engineering, and environmental compliance. German tire manufacturers prioritize advanced marking technologies that align with Industry 4.0 principles, ensuring integration with ERP systems and real-time process monitoring. The focus on sustainable manufacturing and product traceability, combined with innovation-driven infrastructure, makes Germany a key market for high-end tire marking machine adoption.

Tire Marking Machine Market Share

The Tire Marking Machine industry is primarily led by well-established companies, including:

- Markem-Imaje (France)

- REA JET (Germany)

- Tianjin Saixiang Technology Co., Ltd. (China)

- 4JET Technologies GmbH (Germany)

- Rational Engineering Works Pvt. Ltd. (India)

- Zhejiang Meicheng Machinery Co., Ltd. (China)

- Rubber & Tyre Machinery Company (India)

- Shenyang Blue Silver Industry Automatic Equipment Co., Ltd. (China)

- ALBÉNIZ (Spain)

- VMI Group (Netherlands)

- MESNAC Co., Ltd. (China)

- BALTECH GmbH (Germany)

- General Machinery & Manufacturing Company (U.S.)

- Cimcorp Oy (Finland)

- Nidec Corporation (U.K.)

- Codlaser Co., Ltd. (China)

- Laserax Inc. (Canada)

- K.S.M. Engineering Ltd. (India)

- VIDEOJET Technologies Inc. (U.S.)

- KGK Jet India Private Limited (India)

What are the Recent Developments in Global Tire Marking Machine Market?

- In April 2023, Markem-Imaje, a global leader in product identification and traceability solutions, announced the launch of its next-generation inkjet marking system tailored for the tire manufacturing industry. This innovation enhances coding performance on rubber substrates under high-speed production environments. With improved ink adhesion and environmental resistance, the system addresses the sector’s growing demand for durable, high-contrast markings, reinforcing Markem-Imaje’s commitment to providing reliable solutions for traceable tire production globally

- In March 2023, Rational Engineering Works Pvt. Ltd., a leading Indian manufacturer of tire machinery, introduced its fully automated striping and stenciling machine designed for radial truck and bus tire production lines. This advancement significantly increases operational efficiency, offering synchronized multi-color striping, customizable patterns, and reduced downtime. It highlights Rational Engineering’s focus on high-volume OEM solutions aligned with the needs of India’s fast-growing automotive manufacturing sector

- In March 2023, REA JET, a Germany-based industrial coding specialist, unveiled its enhanced laser marking system for permanent tire sidewall identification. The new system ensures deep, high-resolution marking with minimal surface damage, ideal for high-end and performance tire brands. This development demonstrates REA JET’s strategic push toward sustainable, consumable-free marking technologies to meet stringent EU labeling and traceability regulations

- In February 2023, Control Techniques, a subsidiary of Nidec Corporation, collaborated with a Southeast Asian tire manufacturer to deploy an integrated servo-driven tire tread coding solution. The installation improved line flexibility, enabling variable code marking without mechanical changeovers. This move reflects Control Techniques’ capability to provide precision drive systems that align with the evolving needs of smart tire production environments

- In January 2023, Tianjin Saixiang Technology Co., Ltd. (TST), a prominent Chinese tire machinery provider, announced a major upgrade to its automated tire marking platform, adding a modular embossed tag applicator for OTR (off-the-road) tires. This solution enhances tag durability and improves traceability during harsh operating conditions. The innovation reinforces TST’s commitment to robust and adaptable solutions for heavy-duty tire manufacturers seeking compliance with global labeling standards

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.