Global Tunnel Klin Market

Market Size in USD Billion

CAGR :

%

USD

1.20 Billion

USD

2.37 Billion

2024

2032

USD

1.20 Billion

USD

2.37 Billion

2024

2032

| 2025 –2032 | |

| USD 1.20 Billion | |

| USD 2.37 Billion | |

|

|

|

|

Tunnel Klin Market Size

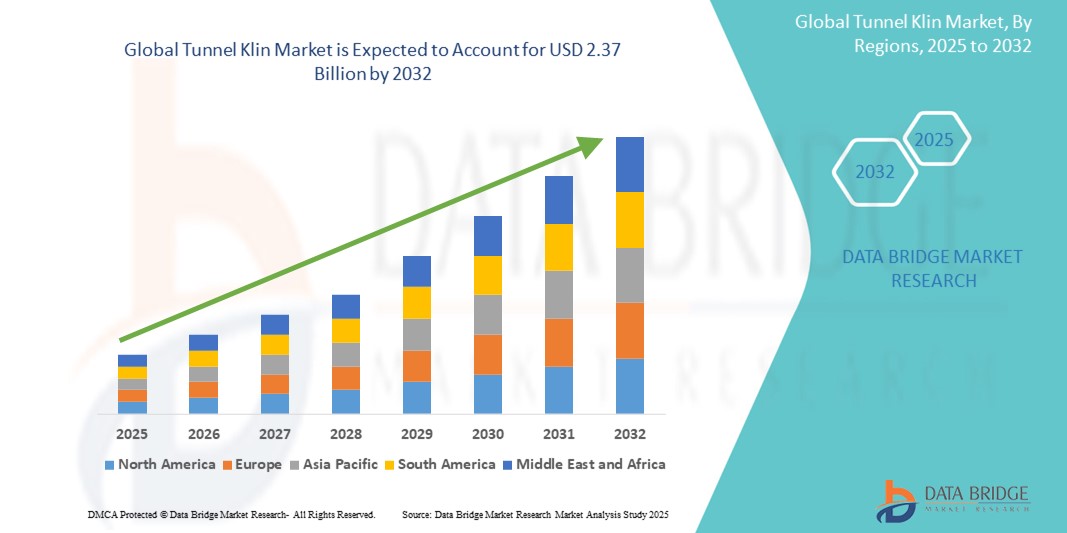

- The global tunnel klin market was valued at USD 1.2 billion in 2024 and is expected to reach USD 2.37 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 8.9%, primarily driven by the rising demand from the ceramics and construction industries

- This growth is driven by factors such as increased infrastructure development, energy-efficient firing technologies, and growing adoption of automation in industrial kilns

Tunnel Klin Market Analysis

- Tunnel kilns are continuous kilns commonly used in the ceramics, refractory, and construction materials industries for firing bricks, tiles, sanitary ware, and technical ceramics. They offer consistent temperature control, fuel efficiency, and scalability, making them essential for mass production

- The demand for tunnel kilns is significantly driven by the rise in global construction activities, increasing infrastructure development, and growing industrialization in emerging economies. A major share of global demand stems from the brick and ceramics manufacturing sector, especially in Asia-Pacific and the Middle East

- The Asia-Pacific region stands out as the dominant market for tunnel kilns, attributed to rapid urbanization, rising investments in housing projects, and the presence of large-scale ceramics production facilities

- For instance, countries like China and India have seen significant expansion in brick production facilities, with several manufacturers upgrading to tunnel kiln technology for higher efficiency and reduced environmental impact

- Globally, tunnel kilns are regarded as one of the most critical components in modern ceramic production lines, offering energy savings, automation compatibility, and reduced production time, thereby enhancing overall operational efficiency in industrial manufacturing

Report Scope and Tunnel Klin Market Segmentation

|

Attributes |

Tunnel Klin Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Tunnel Klin Market Trends

“Integration of Automation and Energy-Efficient Technologies”

- One prominent trend in the global tunnel kiln market is the increasing integration of automation and energy-efficient technologies in kiln operations

- These advancements enhance production efficiency, reduce fuel consumption, and improve the overall quality and consistency of fired products, particularly in ceramics and brick manufacturing

- For instance, modern tunnel kilns equipped with automated temperature control systems and real-time monitoring sensors allow manufacturers to precisely regulate firing conditions, leading to improved product uniformity and reduced waste

- Energy-efficient tunnel kilns also incorporate features like regenerative burners, better insulation materials, and waste heat recovery systems, which significantly lower carbon emissions and operational cost

- This trend is transforming the kiln manufacturing sector by supporting sustainable production, meeting stricter environmental regulations, and driving increased adoption of technologically advanced tunnel kilns across key industries

Tunnel Klin Market Dynamics

Driver

“Growing Demand from the Construction and Ceramics Industries”

- The expanding global construction sector and rising demand for ceramic and refractory products are significantly contributing to the increased adoption of tunnel kilns

- As urbanization accelerates—especially in developing regions—there is a growing need for durable and cost-effective building materials like bricks, tiles, and sanitary ware, which rely heavily on tunnel kiln technology for large-scale production

- Tunnel kilns offer continuous, energy-efficient, and high-capacity firing solutions, making them a preferred choice for manufacturers seeking consistent quality and reduced operational costs

- Ongoing technological innovations, such as automation, improved insulation, and digital controls, are also enhancing the productivity and efficiency of tunnel kilns, aligning with the industry’s push for sustainable and smart manufacturing solutions

- The rising adoption of tunnel kilns supports higher throughput and helps manufacturers meet strict environmental regulations and increasing market demand

For instance,

- In August 2022, Wienerberger AG, one of the world's largest brick producers, announced investments in modernizing its tunnel kiln systems across multiple European plants to reduce emissions and enhance energy efficiency, in line with EU sustainability goals

- In October 2021, RAK Ceramics, a major global ceramics manufacturer based in the UAE, expanded its production capacity by installing advanced tunnel kiln systems in its new production lines to cater to the rising demand in the Middle East and Africa regions

- As a result of growing infrastructure projects and the increasing demand for energy-efficient manufacturing, the global tunnel kiln market is experiencing robust growth, especially in emerging economies and industrial hubs

Opportunity

“Smart Manufacturing and Digital Integration in Tunnel Kiln Operations”

- The integration of digital technologies and smart manufacturing solutions in tunnel kiln operations is creating significant growth opportunities for manufacturers and technology providers alike

- Intelligent kiln management systems equipped with sensors, IoT connectivity, and data analytics can monitor real-time kiln performance, enabling predictive maintenance, optimizing firing cycles, and reducing fuel consumption

- These advancements allow operators to make data-driven decisions, ensuring consistent product quality, minimizing downtime, and improving overall operational efficiency

For instance,

- In March 2024, Ceramifor, a leading kiln system provider, introduced its “Smart Kiln” technology platform that enables real-time data tracking and remote management of kiln operations, allowing manufacturers to adjust temperature profiles and optimize energy use without manual intervention

- In June 2023, SABO S.A., a global supplier of industrial kiln systems, launched a digital twin solution for tunnel kilns, allowing manufacturers to simulate and optimize their firing processes before physical execution, thus reducing energy waste and enhancing product yield

- The integration of AI and digital technologies in tunnel kiln systems also allows for predictive diagnostics, improved emissions control, and enhanced resource planning—contributing to both environmental compliance and cost savings

- As sustainability and efficiency become key priorities in industrial production, smart kiln solutions represent a major opportunity for companies aiming to modernize their operations and stay competitive in the global market

Restraint/Challenge

“High Equipment Costs Hindering Market Penetration”

- The significant capital expenditure required for tunnel kiln systems remains a key barrier to wider market adoption, especially among small- and medium-scale manufacturers in developing regions

- Modern tunnel kilns, which offer advanced automation, energy efficiency, and digital integration, often require multimillion-dollar investments, including costs for installation, land, and auxiliary systems

- This financial constraint limits the ability of smaller manufacturers to transition from traditional periodic kilns to modern tunnel kiln systems, slowing down technological modernization in the ceramics and refractory industries

For instance,

- In June 2023, Wienerberger India, a major player in the brick manufacturing industry, reported challenges in expanding its tunnel kiln operations due to the high capital investment needed for setting up new energy-efficient kiln lines. The company highlighted financing as a key bottleneck in scaling sustainable brick production across India

- In October 2022, the Vietnamese Ministry of Construction acknowledged in its national ceramics strategy report that the transition from traditional to tunnel kilns has been slow, citing high setup and machinery costs as the primary obstacle for many local brick and tile producers, especially in rural provinces

- In December 2021, the Bangladesh Brick Manufacturing Owners Association stated that while tunnel kilns offer long-term cost savings, the initial investment of over USD 1.5 million per facility makes them unaffordable for most small manufacturers without government subsidies or external funding

- As a result, many regional players continue to rely on older, less efficient kiln technologies, which not only increase operational costs and emissions but also restrict product consistency and scalability—ultimately slowing down the overall growth of the global tunnel kiln market

Tunnel Klin Market Scope

The market is segmented on the basis of product type, application, technology, end-user industry, and ownership model.

|

Segmentation |

Sub-Segmentation |

|

By Product Type |

|

|

By Application |

|

|

By Technology |

|

|

By End-User Industry |

|

|

By Ownership Model |

|

Tunnel Klin Market Regional Analysis

“Asia-Pacific is the Dominant Region in the Tunnel Kiln Market”

- Asia-Pacific dominates the tunnel kiln market, driven by rapid industrialization, robust growth in the construction sector, and increasing demand for ceramic and refractory products across emerging economies

- China holds a significant share due to its extensive manufacturing base, large-scale production of bricks and ceramics, and the presence of numerous tunnel kiln manufacturers catering to domestic and international markets’

- Government initiatives supporting energy-efficient and sustainable industrial technologies are promoting the adoption of tunnel kilns across countries such as India, China, and Vietnam

- In addition, the growing urban population, infrastructure development projects, and rising exports of ceramic products are further fueling the tunnel kiln market expansion across the region

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- The Asia-Pacific region is expected to witness the highest growth rate in the tunnel kiln market, driven by accelerating urbanization, growing demand for energy-efficient manufacturing technologies, and rapid infrastructure development across emerging economies

- Countries such as China, India, and Vietnam are emerging as key markets due to the booming construction and ceramics industries, which rely heavily on tunnel kiln technology for efficient and consistent production

- India, with its expanding construction sector and increasing adoption of advanced kiln technologies, remains a critical growth market. The government’s push for sustainable infrastructure and modernization of brick production further fuels tunnel kiln adoption

- China and Vietnam, with their strong industrial bases and rising exports of ceramic and refractory products, are witnessing significant investments in tunnel kiln upgrades and installations. Supportive environmental regulations and the shift toward cleaner and more energy-efficient production methods are further contributing to the region’s robust market expansion

Tunnel Klin Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Sacmi Group (Italy)

- Riedhammer GmbH (Germany)

- Nutec Bickley (Mexico)

- KEDA Industrial Group Co., Ltd. (China)

- Linn High Therm GmbH (Germany)

- Keramischer OFENBAU GmbH (Germany)

- Zhejiang Huarui Combustion Equipment Co., Ltd. (China)

- Swindell Dressler International Company (U.S.)

- H.E.R.A. S.r.l. (Italy)

- M.E. Schupp Industriekeramik GmbH (Germany)

- CERIC Technologies (France)

- Ashutosh Furnace & Engineering Company (India)

- SABO S.A. (Greece)

- Therser UK Ltd. (U.K.)

- I.C.F. & Welko S.p.A. (Italy)

- Ipsen International GmbH (Germany)

- Keith Company (U.S.)

- Mantec Technical Ceramics Ltd. (U.K.)

- Elino Industrieofenbau GmbH (Germany)

- Harrop Industries, Inc. (U.S.)

Latest Developments in Global Tunnel Klin Market

- In December 2023, Roca Group, in collaboration with Keramischer OFENBAU, successfully commissioned the world's first electric tunnel kiln at its Laufen plant in Gmunden, Austria. This innovative kiln aims to decarbonize ceramic production by eliminating the use of fossil fuels, marking a significant step toward sustainable manufacturing in the sanitaryware industry

- In January 2021, brick manufacturer Vandersanden introduced a new environmentally friendly tunnel kiln at its Tolkamer production site in the Netherlands. The kiln reduces CO₂ emissions by approximately 25% through enhanced insulation and advanced kiln techniques, contributing to more sustainable brick production

- In February 2023, a German consortium initiated a research project to investigate hydrogen as a sustainable alternative fuel for tunnel kiln operations. This effort aligns with Germany's national hydrogen strategy, aiming to decarbonize industrial heat processes

- In September 2023, Steuler Group initiated the construction of a new tunnel kiln at its Höhr-Grenzhausen facility in Germany. This project is designed to enhance production capacity and efficiency, with the kiln expected to become operational by March 2024

- In October 2022, SACMI-Riedhammer launched the TWS Neo tunnel kiln series, emphasizing improved thermal efficiency, reduced emissions, and advanced digital process control. The design incorporates cutting-edge EMS (Energy Management System) technology, achieving up to 30% energy savings

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.