Global Ultra Violet Uv Curable Packaging Tapes Market

Market Size in USD Billion

CAGR :

%

USD

4.44 Billion

USD

7.18 Billion

2024

2032

USD

4.44 Billion

USD

7.18 Billion

2024

2032

| 2025 –2032 | |

| USD 4.44 Billion | |

| USD 7.18 Billion | |

|

|

|

|

Ultra Violet (UV)-Curable Packaging Tapes Market Size

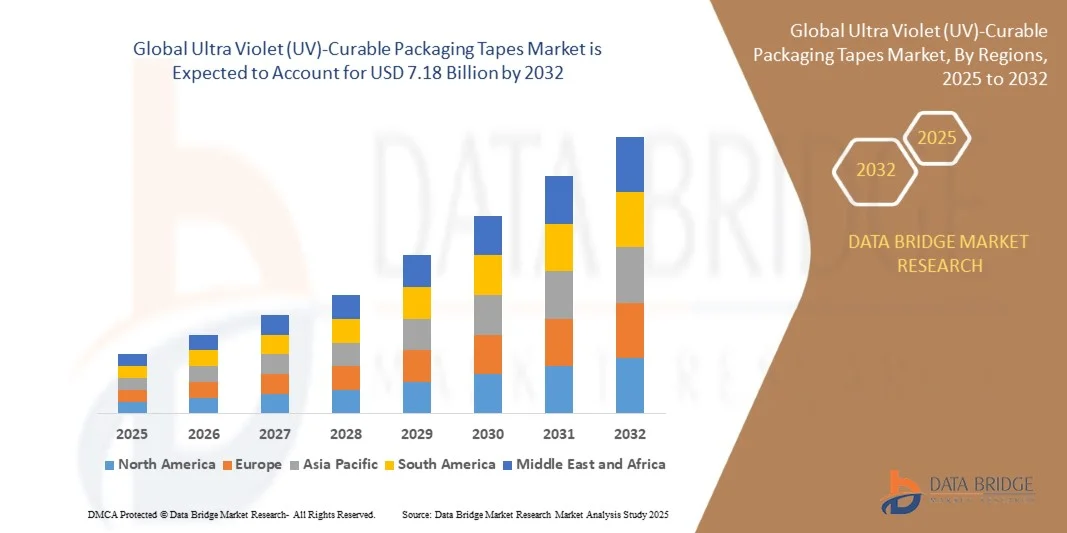

- The global ultra violet (UV)-curable packaging tapes market size was valued at USD 4.44 billion in 2024 and is expected to reach USD 7.18 billion by 2032, at a CAGR of 6.2% during the forecast period

- The market growth is largely fueled by the increasing demand for sustainable, high-performance adhesive solutions across packaging, automotive, electronics, and construction industries, supported by the advantages of fast curing, reduced emissions, and superior bonding strength offered by UV-curable packaging tapes

- Furthermore, rising awareness of eco-friendly materials, regulatory support for low-VOC adhesive technologies, and the need for efficient production processes are accelerating the adoption of UV-curable packaging tapes, thereby driving significant expansion of the market

Ultra Violet (UV)-Curable Packaging Tapes Market Analysis

- UV-curable packaging tapes are advanced adhesive solutions that cure instantly under ultraviolet light, providing strong bonding, high durability, and resistance to environmental stress, making them suitable for applications in packaging, automotive, electronics, aerospace, and construction industries

- The escalating demand for UV-curable packaging tapes is primarily driven by their eco-friendly curing process, faster production efficiency, and growing applications in high-performance sectors such as automotive and electronics, coupled with increasing emphasis on lightweight, sustainable, and energy-efficient adhesive technologies

- North America dominated the ultra violet (UV)-curable packaging tapes market in 2024, due to strong demand from automotive, electronics, and construction industries

- Asia-Pacific is expected to be the fastest growing region in the ultra violet (UV)-curable packaging tapes market during the forecast period due to rapid industrialization, rising disposable incomes, and expanding electronics and automotive manufacturing

- Non-foamed tapes segment dominated the market with a market share of 42.1% in 2024, due to its extensive adoption across industries requiring high bonding strength and durability. These tapes are widely used in packaging, electronics, and construction due to their excellent adhesion, resistance to UV degradation, and long service life. Non-foamed variants are also cost-effective compared to specialty tapes, making them a preferred choice for mass applications. Their compatibility with diverse surfaces and ease of application further strengthen their dominance in the market

Report Scope and Ultra Violet (UV)-Curable Packaging Tapes Market Segmentation

|

Attributes |

Ultra Violet (UV)-Curable Packaging Tapes Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Ultra Violet (UV)-Curable Packaging Tapes Market Trends

Rising Shift Toward Sustainable UV-Curable Adhesive Solutions

- The increasing emphasis on sustainable adhesives is driving significant changes in the UV-curable packaging tapes market. These solutions are gaining traction as manufacturers seek environmentally friendly alternatives that reduce volatile organic compound emissions while delivering high performance and durability

- For instance, Avery Dennison has expanded its UV-curable adhesive portfolio focusing on sustainable pressure-sensitive tapes for packaging and electronics applications. Henkel has also invested in UV-curable adhesive technologies, emphasizing eco-compliant formulations that meet stringent environmental standards across global markets

- The ability of UV-curable packaging tapes to achieve rapid curing under UV light significantly reduces energy consumption compared to heat-based curing systems. This accelerates production processes and also contributes to sustainability goals by lowering carbon output during manufacturing

- Growing demand for high-performance tapes that exhibit stronger adhesion, chemical resistance, and durability across multiple industries is accelerating the adoption of UV-curable solutions. The versatility of these tapes makes them suitable for applications ranging from industrial packaging to electronic component assembly

- Manufacturers are investing in R&D to enhance the recyclability and bio-based content of UV-curable adhesives. The development of tapes using renewable raw materials while maintaining superior performance is rapidly emerging as a core focus in product innovation strategies

- The trend toward sustainable adhesives, combined with efficiency in production and superior bonding performance, is reshaping market dynamics. Market participants are converging on eco-friendly UV-curable technologies, reinforcing the expectation that these tapes will replace traditional solvent-based systems in high-demand industries

Ultra Violet (UV)-Curable Packaging Tapes Market Dynamics

Driver

Rising Demand from Automotive and Electronics Sectors

- The automotive and electronics industries are increasingly adopting UV-curable tapes due to their ability to provide precision, durability, and high-strength bonding under demanding conditions. These industries require advanced materials capable of delivering consistent performance under stress and environmental fluctuations

- For instance, 3M has expanded its range of UV-curable adhesive tapes for automotive lightweight assembly and electronic device protection, meeting both safety and efficiency requirements. Similarly, Nitto Denko has focused on developing UV adhesives optimized for sensitive electronic applications while ensuring compliance with sustainability regulations

- In the automotive sector, UV-curable packaging tapes support lightweighting initiatives by replacing mechanical fasteners, reducing vehicle weight while enhancing durability. In electronics, these tapes facilitate the precise bonding of delicate components, offering high thermal stability and improving product reliability

- The shift toward electric vehicles and compact consumer electronics is further intensifying demand for advanced adhesive tapes. Growing production volumes in these industries are directly fueling the need for technologically advanced packaging tapes that ensure safe material handling and reduced energy consumption during manufacturing

- The integration of UV-curable tapes into automotive and electronics sectors underlines their critical role in modern industrial applications. Their superior adhesion, coupled with sustainability credentials, ensures strong growth prospects across these vital high-demand sectors

Restraint/Challenge

High Cost of UV Curing Equipment

- The reliance on specialized UV curing systems significantly increases investment costs for manufacturers, creating a barrier to the wider adoption of UV-curable packaging tapes. Smaller enterprises particularly struggle with the upfront cost of advanced curing equipment and maintenance requirements

- For instance, several small-scale packaging firms in Asia have limited adoption of UV-curable tapes due to the high cost associated with ultraviolet curing units, compared with traditional adhesive solutions. This cost disparity continues to hinder broader accessibility of UV-curable technologies

- The complexity of operating UV curing equipment requires skilled labor and regular technical monitoring, adding to operational expenses for manufacturers. Firms must allocate resources for workforce training and equipment upkeep, further elevating cost burdens in competitive markets

- The initial cost is compounded by recurring expenses such as replacement of UV lamps, safety systems, and energy-intensive setups. This creates reluctance to adopt UV-curable tapes in cost-sensitive industries, despite their sustainability advantages and technical superiority

- In conclusion, high equipment costs combined with operational complexities represent a significant restraint on market expansion. Overcoming this challenge requires advancements that lower system costs and technological innovations that simplify curing methods, enabling wider market penetration and long-term growth sustainability

Ultra Violet (UV)-Curable Packaging Tapes Market Scope

The market is segmented on the basis of product type and end use.

• By Product Type

On the basis of product type, the UV-curable packaging tapes market is segmented into foamed tapes, non-foamed tapes, thermally conductive tapes, flame retardant tapes, and others. The non-foamed tapes segment dominated the largest market revenue share of 42.1% in 2024, driven by its extensive adoption across industries requiring high bonding strength and durability. These tapes are widely used in packaging, electronics, and construction due to their excellent adhesion, resistance to UV degradation, and long service life. Non-foamed variants are also cost-effective compared to specialty tapes, making them a preferred choice for mass applications. Their compatibility with diverse surfaces and ease of application further strengthen their dominance in the market.

The thermally conductive tapes segment is anticipated to witness the fastest growth rate from 2025 to 2032, propelled by rising demand in electronics and automotive applications where efficient heat dissipation is critical. With growing miniaturization of electronic devices and the increasing adoption of electric vehicles, the need for thermal management solutions has surged. UV-curable thermally conductive tapes provide superior bonding alongside enhanced thermal conductivity, making them an essential component in high-performance systems. Their ability to replace mechanical fasteners while ensuring lightweight design also accelerates adoption in advanced engineering sectors.

• By End Use

On the basis of end use, the UV-curable packaging tapes market is segmented into automotive, electricals & electronics, aerospace, building & construction, and others. The automotive segment accounted for the largest revenue share in 2024, owing to extensive use in bonding, insulation, and lightweight component assembly. UV-curable tapes provide faster curing, high resistance to environmental stress, and long-term durability, which align well with the automotive industry’s focus on safety and efficiency. Growing production of electric and hybrid vehicles has also intensified the demand for high-performance tapes that can withstand extreme temperatures and vibrations. Their role in reducing vehicle weight by replacing conventional fastening methods has made them indispensable in modern automotive manufacturing.

The electricals & electronics segment is projected to register the fastest CAGR from 2025 to 2032, driven by the increasing demand for compact, reliable, and high-performing devices. With rising consumer electronics consumption and advancements in 5G and IoT-enabled products, the need for efficient bonding, insulation, and heat management solutions is rising rapidly. UV-curable tapes offer precise application, strong adhesion, and long-term reliability for delicate electronic components, making them ideal for circuit boards, displays, and microelectronics. Their eco-friendly curing process and reduced energy consumption during manufacturing also align with the sustainability goals of electronics producers, further driving segment growth.

Ultra Violet (UV)-Curable Packaging Tapes Market Regional Analysis

- North America dominated the ultra violet (UV)-curable packaging tapes market with the largest revenue share in 2024, driven by strong demand from automotive, electronics, and construction industries

- The region benefits from well-established manufacturing capabilities and an early adoption of advanced adhesive technologies

- Growing emphasis on sustainable and high-performance bonding solutions is encouraging industries to adopt UV-curable packaging tapes. High R&D investments, coupled with a technologically mature market, further support the expansion of these products across multiple industrial applications

U.S. UV-Curable Packaging Tapes Market Insight

The U.S. market captured the largest revenue share in 2024 within North America, fueled by its robust automotive sector, advanced electronics manufacturing, and strong packaging industry. Manufacturers are increasingly shifting toward UV-curable solutions due to their fast curing, reduced emissions, and enhanced bonding performance. Regulatory support for eco-friendly adhesives and the rising focus on lightweight vehicle production are further propelling growth. In addition, the presence of leading market players and continuous innovation in adhesive technologies strengthen the U.S. position as a key revenue contributor.

Europe UV-Curable Packaging Tapes Market Insight

The Europe UV-curable packaging tapes market is projected to expand at a substantial CAGR throughout the forecast period, supported by strict environmental regulations and the growing adoption of sustainable packaging materials. Rising demand for high-performance adhesives in construction, aerospace, and automotive sectors is fueling market growth. European industries value the eco-friendly curing process, superior bonding, and durability offered by UV-curable tapes. Widespread applications in lightweight manufacturing and electronics assembly are further accelerating adoption across the region.

U.K. UV-Curable Packaging Tapes Market Insight

The U.K. market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by the packaging and construction sectors’ increasing demand for efficient and sustainable bonding solutions. Companies are adopting UV-curable tapes to meet regulatory compliance and consumer demand for eco-conscious materials. The country’s robust R&D landscape and growing industrial innovation further enhance product adoption.

Germany UV-Curable Packaging Tapes Market Insight

The Germany market is expected to grow at a considerable CAGR, supported by its strong automotive and electronics industries. Germany’s focus on advanced engineering, sustainability, and high-performance materials aligns with the adoption of UV-curable packaging tapes. Their use in lightweight structures, electronic assemblies, and renewable energy projects reflects the country’s commitment to innovative and durable bonding solutions.

Asia-Pacific UV-Curable Packaging Tapes Market Insight

The Asia-Pacific market is poised to grow at the fastest CAGR from 2025 to 2032, fueled by rapid industrialization, rising disposable incomes, and expanding electronics and automotive manufacturing. Countries such as China, Japan, and India are major contributors to this growth, supported by government initiatives promoting industrial modernization and eco-friendly technologies. APAC’s role as a global manufacturing hub ensures wide availability and affordability of UV-curable tapes, extending adoption across diverse applications.

Japan UV-Curable Packaging Tapes Market Insight

The Japan market is experiencing steady growth due to the country’s technological advancements and demand for precision in electronics and automotive sectors. UV-curable tapes are widely adopted in assembly lines where fast curing and strong adhesion are critical. In addition, Japan’s commitment to sustainable and high-quality manufacturing practices supports increased utilization of these tapes across industries.

China UV-Curable Packaging Tapes Market Insight

The China market accounted for the largest revenue share in Asia-Pacific in 2024, attributed to its booming automotive, electronics, and construction industries. Rapid urbanization and large-scale industrial activity continue to drive demand for advanced adhesive solutions. Strong domestic production capabilities and the presence of competitive local manufacturers ensure wide accessibility and affordability of UV-curable packaging tapes. China’s push toward smart manufacturing and eco-friendly materials further enhances market growth.

Ultra Violet (UV)-Curable Packaging Tapes Market Share

The ultra violet (UV)-curable packaging tapes industry is primarily led by well-established companies, including:

- Collano AG (Switzerland)

- Nitto Denko Corporation (Japan)

- 3M (U.S.)

- Weifang Haibin Chemical Co. Ltd. (China)

- Henkel AG (Germany)

- Avery Dennison Corporation (U.S.)

- Biolink Gesellschaft für Verbindungstechnologien GmbH (Germany)

- Denka Company Limited (Japan)

- Eurobond Adhesives (U.K.)

- H.B. Fuller Company (U.S.)

- Delo (Germany)

- Dymax Corporation (U.S.)

- No-Tape Industrial Co. Ltd. (Taiwan)

- Scapa Group plc. (U.K.)

- Toyochem Co. Ltd. (Japan)

Latest Developments in Ultra Violet (UV)-Curable Packaging Tapes Market

- In August 2023, Evonik introduced TEGO RC 2000 LCF, a UV LED-curable release coating made from recycled silicone feedstocks. This launch highlights the industry’s shift toward sustainable raw materials while maintaining curing efficiency and long-term performance. By integrating recycled inputs, Evonik addresses regulatory and consumer demand for eco-friendly adhesives and also strengthens its competitive positioning in the UV-curable packaging tapes market, particularly within the sustainable packaging segment

- In July 2023, Elkem launched SILCOLEASE UV POLY 126 and its UV LED silicone solutions for sustainable release coatings. The development marks a significant advancement in reducing energy usage and curing times in industrial applications. For the UV-curable packaging tapes market, Elkem’s move broadens the adoption of UV LED curing technologies, which are increasingly preferred for their efficiency, scalability, and compliance with environmental standards across the packaging and labeling industries

- In May 2023, Nitto Denko, in collaboration with Kyushu University, developed a new UV-sensitive tape tailored for transferring 2D materials such as graphene and hBN. This innovation demonstrates the growing convergence of advanced materials research with adhesive technologies. For the market, it expands the potential application scope of UV-curable tapes beyond traditional packaging into precision electronics and nanotechnology, reinforcing UV-curable tapes’ role in next-generation semiconductor and electronics manufacturing

- In March 2023, Lintec Corporation rolled out its dual-layer UV dicing tape designed to deliver high adhesion during wafer dicing and easy detachment upon UV exposure. This advancement directly supports semiconductor fabrication processes, ensuring higher yields and cleaner separation. The launch enhances the role of UV-curable packaging tapes in electronics manufacturing, driving adoption in industries where precision and efficiency are paramount

- In January 2023, Mitsui Chemicals unveiled its eco-friendly UV tape solution for electronics assembly. This product aligns with the global trend of sustainable innovation by incorporating environmentally responsible materials while maintaining adhesion strength and process reliability. For the UV-curable packaging tapes market, the move underscores how green innovations are increasingly becoming a decisive factor in product differentiation and customer preference, particularly in electronics and high-performance packaging

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Ultra Violet Uv Curable Packaging Tapes Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Ultra Violet Uv Curable Packaging Tapes Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Ultra Violet Uv Curable Packaging Tapes Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.