Global Vacuum Insulation Panel Market

Market Size in USD Billion

CAGR :

%

USD

9.62 Billion

USD

14.61 Billion

2024

2032

USD

9.62 Billion

USD

14.61 Billion

2024

2032

| 2025 –2032 | |

| USD 9.62 Billion | |

| USD 14.61 Billion | |

|

|

|

|

Vacuum Insulation Panel Market Size

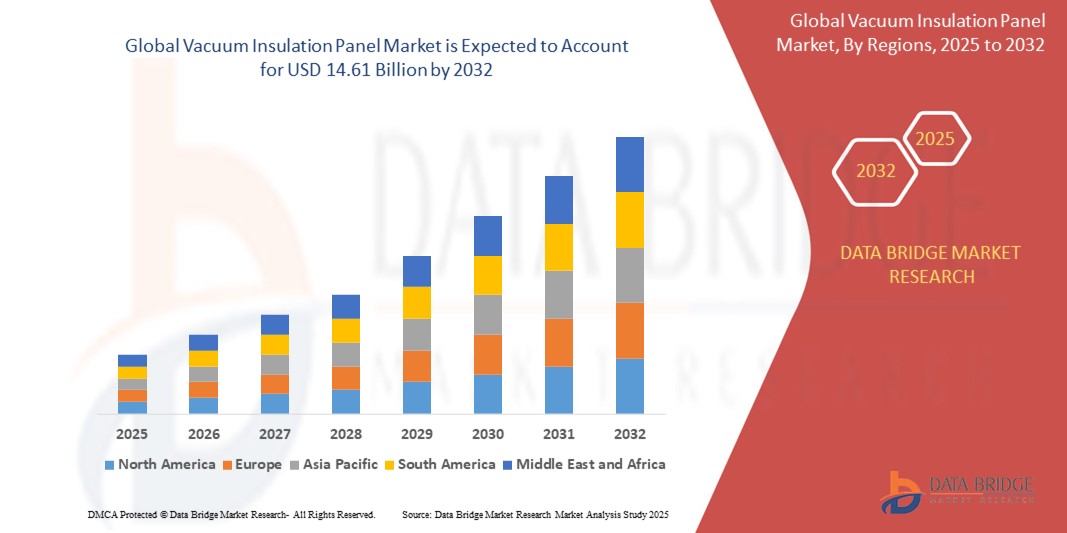

- The global vacuum insulation panel market size was valued at USD 9.62 billion in 2024 and is expected to reach USD 14.61 billion by 2032, at a CAGR of 5.36 % during the forecast period

- This growth is driven by factors such as the increasing demand for energy-efficient building materials, growing awareness of sustainable insulation solutions, and the expansion of the cold chain industry, where vacuum insulation panels are used for efficient temperature control in storage and transportation

Vacuum Insulation Panel Market Analysis

- The vacuum insulation panel market is experiencing steady growth due to increased demand in the construction and cold storage industries, driven by the need for better insulation solutions that offer high performance in limited spaces

- Advancements in technology have led to improved vacuum insulation panel efficiency, making them more cost-effective and expanding their application in areas such as home appliances and automotive industries

- North America is expected to dominate the Vacuum Insulation Panels market due to rapid urbanization, increasing demand for energy-efficient buildings, and growing construction activities across emerging economies

- Asia-Pacific is expected to be the fastest growing region in the Vacuum Insulation Panel market during the forecast period due to the rise in energy-efficient building regulations and the growing adoption of advanced insulation solutions in the automotive and refrigeration sectors

- Silica segment is expected to dominate the market with a market share of 45.7% due to its superior thermal insulation properties and widespread use in the construction and refrigeration industries

Report Scope and Vacuum Insulation Panel Market Segmentation

|

Attributes |

Vacuum Insulation Panel Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Vacuum Insulation Panel Market Trends

“Integration of Self-Healing Barrier Coatings to Enhance Durability”

- Self-healing barrier coatings are being developed to repair punctures in vacuum insulation panels, which ensures that the panels maintain their thermal performance even after damage

- For instance, a recent breakthrough by researchers at the University of Cambridge introduced a self-healing material that could be applied to insulation panels for longer-lasting performance

- Research has shown that incorporating self-healing technology in vacuum insulation panels improves their long-term durability, reducing the need for frequent replacements

- These coatings can automatically seal punctures or damage, keeping the internal vacuum intact, which is critical for maintaining the insulating properties of the panels

- For instance, this technology is especially valuable in the cold storage and food packaging industry, where consistent insulation is essential

- The self-healing capability is anticipated to reduce maintenance costs and improve the reliability of vacuum insulation panels in various applications, including refrigeration and building insulation

Vacuum Insulation Panel Market Dynamics

Driver

“Growing Demand for Energy-Efficient Building Materials”

- The growing demand for energy-efficient building materials is significantly driving the vacuum insulation panel market, as both residential and commercial sectors seek solutions to reduce energy consumption

- For instance, in the U.S., the U.S. Green Building Council has been promoting energy-efficient buildings through programs such as LEED, which encourages the use of materials such as vacuum insulation panels to achieve higher energy ratings

- Vacuum insulation panels offer superior thermal insulation, providing better energy savings than traditional materials and thus are increasingly being used in construction projects worldwide

- Governments and construction industries in regions such as Europe and North America are adopting stringent energy-efficiency regulations, boosting the demand for advanced insulation materials such as vacuum insulation panels

- The rise of green buildings, which focus on sustainability, is increasing the use of energy-efficient materials such as vacuum insulation panels to help meet environmental standards and energy-saving targets

- For instance, in Germany, the government’s emphasis on energy-efficient building codes has led to the increased adoption of vacuum insulation panels in both residential and commercial sectors, contributing to the growth of the market

Opportunity

“Growing Trend towards Sustainable Construction”

- The growing trend towards sustainable construction presents significant opportunities for the vacuum insulation panel market, driven by the increasing demand for energy-efficient buildings

- For instance, in Saudi Arabia, the Vision 2030 initiative is driving large-scale housing projects that prioritize energy-efficient materials, creating substantial demand for vacuum insulation panels, such as in the development of the King Salman Park project, which aims to incorporate sustainable construction methods

- In Saudi Arabia, the Vision 2030 initiative is driving large-scale housing projects that prioritize energy-efficient materials, creating substantial demand for vacuum insulation panels in the region

- For instance, major automotive manufacturers, such as Tesla, have begun using vacuum insulation panels in their electric vehicle battery packs to improve energy efficiency and safety, while companies such as Audi are also exploring the technology for enhancing battery performance in their EV models

- The integration of vacuum insulation panels in the transportation sector is gaining traction, especially with the growing demand for electric vehicles and the need for efficient battery thermal management

- Leading automotive manufacturers, such as Tesla and BMW, are exploring the use of vacuum insulation panels to enhance battery performance and energy efficiency in electric vehicles, expanding their applications beyond traditional uses

- Advancements in manufacturing technologies, such as automated production lines and alternative core materials, are making vacuum insulation panels more cost-effective and accessible for a wider range of applications

- In developing regions such as Africa and Southeast Asia, where budget constraints have previously limited the use of advanced insulation materials, the cost reduction in vacuum insulation panels is opening up new market opportunities

- The increasing focus on energy efficiency in household appliances, such as refrigerators and freezers, is further driving the demand for vacuum insulation panels to meet energy standards and consumer preferences for sustainable products

Restraint/Challenge

“High Cost of Vacuum Insulation Panels”

- The high cost of vacuum insulation panels remains a significant challenge, as the advanced materials and manufacturing processes involved contribute to their elevated prices compared to traditional insulation materials

- For instance, vacuum insulation panels are more expensive than traditional fiberglass insulation, which can deter customers in developing countries such as India where cost sensitivity is high

- Limited manufacturing capacity for vacuum insulation panels also poses an obstacle, as specialized production processes are not widespread, leading to supply constraints

- For instance, only a few manufacturers in Europe are able to produce high-quality vacuum panels, causing delays in meeting the growing demand from various industries

- The fragility of vacuum insulation panels makes them susceptible to damage during handling and installation, with minor punctures compromising their insulating properties, as seen in the construction of energy-efficient buildings where workers must follow strict guidelines to avoid damaging the panels, adding to installation costs

- This sensitivity requires careful handling and specialized installation techniques, increasing the overall cost and complexity of using vacuum insulation panels, as evidenced by the added installation costs for builders in the commercial sector who are increasingly opting for vacuum panels but face difficulties in ensuring safe handling and installation

- The complexity of recycling vacuum insulation panels presents environmental challenges, as the materials used are not easily recyclable, raising concerns about their long-term environmental impact

- For instance, several manufacturers are researching new materials to create recyclable versions, but these alternatives are still in development stages

Vacuum Insulation Panel Market Scope

The market is segmented on the basis raw material, core material, type, end-user industry.

|

Segmentation |

Sub-Segmentation |

|

By Raw Material |

|

|

By Core Material |

|

|

By Type |

|

|

By End-User Industry |

|

In 2025, the silica is projected to dominate the market with a largest share in core material segment

The silica segment is expected to dominate the Vacuum Insulation Panel market with the largest share of 45.7% in 2025 due to its excellent thermal insulation properties, which make it ideal for a wide range of applications requiring high thermal resistance.

The flat is expected to account for the largest share during the forecast period in type market

In 2025, the flat panel segment is expected to dominate the market with the largest market share of 55.6% due to its widespread use in construction and refrigeration industries, where space efficiency and ease of installation are critical.

Vacuum Insulation Panel Market Regional Analysis

“Asia-Pacific Holds the Largest Share in the Vacuum Insulation Panel Market”

- Asia-Pacific dominates the vacuum insulation panel market due to rapid urbanization, expanding construction activities, and a growing emphasis on energy efficiency

- The rising demand for energy-efficient buildings, along with increasing sustainability awareness, is driving market dominance in countries such as China and India

- The rapid adoption of electric vehicles and the growing need for improved battery insulation is fuelling the market's growth in the region

- The affordability of manufacturing processes and the increased availability of vacuum insulation panels in emerging markets contribute to Asia-Pacific's dominance

“North America is Projected to Register the Highest CAGR in the Vacuum Insulation Panel Market”

- North America is the fastest growing region in the vacuum insulation panel market, driven by increased demand for energy-efficient building materials

- Strong environmental regulations and the focus on sustainability in countries such as the U.S. and Canada are accelerating market growth

- The adoption of vacuum insulation panels in household appliances such as refrigerators and freezers are expanding in North America

- Rising investments in energy-efficient construction and infrastructure projects are further boosting the demand for vacuum insulation panels in the region

Vacuum Insulation Panel Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- BASF SE (Germany)

- M&I Materials Limited (U.K)

- Morgan Advanced Materials (U.K.)

- Evonik Industries AG (Germany)

- LG Hausys (South Korea)

- Panasonic Corporation (Japan)

- Dow (U.S.), OCI Company Ltd. (Korea)

- Kevothermal (Mexico)

- Morgan Advanced Materials (Germany)

- ThermoCor (U.S.)

- Va-Q-Tec AG (Germany)

- AVERY DENNISON CORPORATION (U.S.)

- Kingspan Group (Ireland)

- KCC CORPORATION (South Korea)

- Microtherm Sentronic GmbH (Belgium)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Vacuum Insulation Panel Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Vacuum Insulation Panel Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Vacuum Insulation Panel Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.