Global Vinyl Electrical Tape Market

Market Size in USD Billion

CAGR :

%

USD

10.34 Billion

USD

14.59 Billion

2024

2032

USD

10.34 Billion

USD

14.59 Billion

2024

2032

| 2025 –2032 | |

| USD 10.34 Billion | |

| USD 14.59 Billion | |

|

|

|

|

Vinyl Electrical Tape Market Size

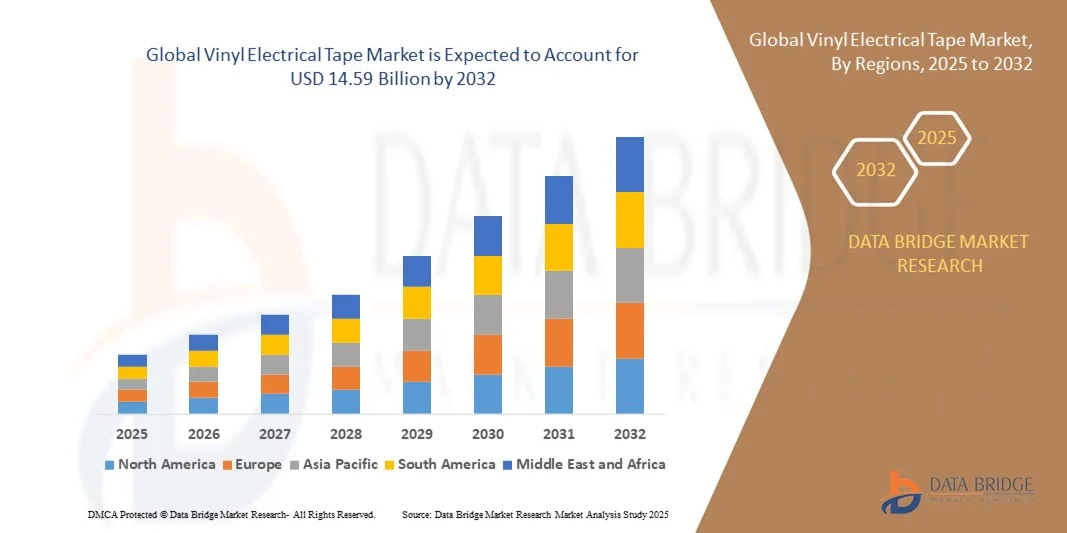

- The global vinyl electrical tape market size was valued at USD 10.34 billion in 2024 and is expected to reach USD 14.59 billion by 2032, at a CAGR of 4.40% during the forecast period

- The market growth is largely fueled by the increasing demand for reliable insulation solutions in electrical and electronic applications, driven by expanding infrastructure projects, industrial automation, and growing focus on electrical safety across residential and commercial sectors. The versatility, durability, and cost-effectiveness of vinyl electrical tapes make them indispensable for insulation, bundling, and wire protection in diverse end-use industries

- Furthermore, rising adoption of high-performance and flame-retardant insulation materials across construction, automotive, and power distribution networks is significantly supporting market expansion. These tapes’ resistance to heat, moisture, and abrasion enhances their utility in harsh environments, reinforcing their growing importance in energy-efficient and safety-compliant electrical systems

Vinyl Electrical Tape Market Analysis

- Vinyl electrical tapes, widely used for insulation, protection, and maintenance in electrical wiring and cable management, play a crucial role in ensuring safety, reliability, and performance of electrical systems across residential, industrial, and commercial applications. Their superior flexibility, adhesion, and resistance to extreme conditions make them an essential component in the electrical and electronics industry

- The escalating demand for vinyl electrical tapes is primarily driven by rapid industrialization, infrastructure modernization, and the expansion of renewable energy and smart grid projects. Increasing emphasis on electrical safety standards, product innovation, and sustainable materials is expected to further strengthen the market’s growth trajectory in the coming years

- Asia-Pacific dominated the vinyl electrical tape market with a share of 57.3% in 2024, due to expanding electrical and electronics manufacturing, rising infrastructure development, and the growing demand for insulation materials in industrial applications

- North America is expected to be the fastest growing region in the vinyl electrical tape market during the forecast period due to rising infrastructure modernization, electrical safety upgrades, and increased demand from the construction and automotive sectors

- Plastic segment dominated the market with a market share of 58.9% in 2024, due to its superior electrical insulation properties, flexibility, and cost-effectiveness. Plastic-based vinyl electrical tapes, particularly those made from PVC, are widely used for wire harnessing, insulation, and color coding in both industrial and residential applications. Their resistance to moisture, abrasion, and varying temperatures enhances their performance and longevity, making them a preferred choice across electrical maintenance and repair activities. The ease of manufacturing and recyclability of plastic tapes further boost their adoption among sustainable producers

Report Scope and Vinyl Electrical Tape Market Segmentation

|

Attributes |

Vinyl Electrical Tape Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Vinyl Electrical Tape Market Trends

Growing Shift Toward Eco-Friendly Vinyl Electrical Tapes

- The vinyl electrical tape market is witnessing a significant shift toward the development of eco-friendly and sustainable tape solutions, driven by rising environmental concerns and regulatory focus on reducing plastic waste. Manufacturers are increasingly adopting greener production processes and bio-based raw materials to produce vinyl tapes that maintain performance while minimizing ecological impact

- For instance, 3M Company has introduced a line of low-VOC and recyclable vinyl electrical tapes formulated with reduced halogen content to meet global sustainability and safety standards. These products demonstrate how the industry is transitioning toward environmentally responsible alternatives without compromising electrical insulation efficiency

- The demand for bio-based and phthalate-free plasticizers is growing as an alternative to conventional petroleum-based formulas. This transition enhances the recyclability and safety of vinyl electrical tapes used in power distribution networks, automotive wiring, and electronic assemblies, ensuring compliance with evolving environmental standards

- Manufacturers are also focusing on sustainable production methods that reduce carbon emissions and energy consumption during the extrusion and coating stages. Such innovations support global initiatives aimed at achieving resource efficiency and waste reduction in industrial manufacturing activities

- Growing regulatory pressure from regions such as the European Union on the use of PVC-based materials is further encouraging companies to explore hybrid formulations that incorporate recyclable polymers. For instance, Tesa SE is developing eco-compliant vinyl tape products optimized for insulation applications in both residential and commercial sectors, ensuring safety and durability

- The ongoing shift toward sustainable and eco-conscious vinyl electrical tapes marks an important evolution in the electrical insulation materials sector. As industries prioritize environmental performance alongside operational reliability, the adoption of recyclable and low-impact vinyl tape products is expected to accelerate globally in the coming years

Vinyl Electrical Tape Market Dynamics

Driver

Rising Demand for High-Performance Insulation Solutions

- The growing demand for advanced electrical insulation solutions across industrial, construction, and automotive sectors is a key driver fueling the vinyl electrical tape market. Vinyl tapes are preferred for their strong adhesive properties, high dielectric strength, and durability under mechanical stress and temperature variations

- For instance, HellermannTyton has expanded its range of vinyl electrical tapes tailored for high-voltage applications and extreme temperature conditions. These products deliver superior resistance to abrasion and moisture, offering reliable performance for both indoor and outdoor electrical insulation requirements

- In the automotive sector, increased production of electric vehicles and advanced wiring systems is boosting demand for heat- and chemical-resistant vinyl tapes. These tapes play an essential role in insulating wiring harnesses, reducing energy loss, and preventing electrical faults in high-performance systems

- The construction industry continues to rely heavily on vinyl electrical tapes for efficient installation and repair of wiring systems in residential and commercial buildings. Their ease of application and long-lasting adhesion contribute to safer and more efficient electrical maintenance practices

- As the focus on energy safety and reliability strengthens across manufacturing, energy infrastructure, and mobility sectors, the use of high-performance insulation materials such as vinyl electrical tapes is expected to expand further. This growth highlights the material’s importance in ensuring consistent electrical conductivity and operational safety across various environments

Restraint/Challenge

Volatility in Raw Material Prices

- Price fluctuations in the raw materials used for vinyl electrical tape production, particularly PVC and plasticizers, pose a major restraint to market stability. These materials are derived from petrochemical feedstocks, making their costs sensitive to global crude oil price variations and supply chain disruptions

- For instance, fluctuations in PVC resin and phthalate-based plasticizer prices during 2023–2024 caused cost instability for manufacturers, affecting product profitability and pricing strategies. Companies such as Saint-Gobain and Nitto Denko have reported challenges in balancing production costs amid volatile raw material markets

- The global shortage of petrochemical intermediates and disruptions in transportation logistics add further pressure to procurement costs. In addition, increasing environmental restrictions on certain additive chemicals used in vinyl tape formulations create incremental compliance expenses for manufacturers adapting to regulatory frameworks

- High dependency on petroleum-based inputs also limits manufacturers’ flexibility to adopt long-term cost control measures. Sudden price surges may result in reduced margins or periodic supply shortages that affect contractual supply commitments across industries

- To address these challenges, manufacturers are diversifying sourcing channels, developing bio-based plasticizer alternatives, and investing in recycling technologies to manage material cost fluctuations. Stabilizing input costs through sustainable material innovation and efficient supply chain management will be critical to ensuring profitability and consistency in the vinyl electrical tape market

Vinyl Electrical Tape Market Scope

The market is segmented on the basis of material, thickness, application, and type.

- By Material

On the basis of material, the vinyl electrical tape market is segmented into plastic and rubber. The plastic segment dominated the market with the largest revenue share of 58.9% in 2024, primarily due to its superior electrical insulation properties, flexibility, and cost-effectiveness. Plastic-based vinyl electrical tapes, particularly those made from PVC, are widely used for wire harnessing, insulation, and color coding in both industrial and residential applications. Their resistance to moisture, abrasion, and varying temperatures enhances their performance and longevity, making them a preferred choice across electrical maintenance and repair activities. The ease of manufacturing and recyclability of plastic tapes further boost their adoption among sustainable producers.

The rubber segment is projected to witness the fastest growth rate from 2025 to 2032, driven by increasing demand in high-voltage insulation and moisture-sealing applications. Rubber-based vinyl electrical tapes provide superior adhesion and elasticity, making them suitable for outdoor and heavy-duty electrical environments. Their self-fusing nature ensures excellent sealing performance against water ingress, which is essential for power distribution and automotive wiring. Growing adoption in industrial settings and infrastructure projects due to their durability and resilience under extreme conditions supports the segment’s strong growth outlook.

- By Thickness

On the basis of thickness, the market is segmented into below 5 mil., 5–7 mil., 7–10 mil., and above 10 mil. The 5–7 mil. segment dominated the market with the largest revenue share in 2024, as this thickness range provides an optimal balance between flexibility and insulation strength. It is extensively used across general-purpose electrical insulation, wire wrapping, and color coding tasks. These tapes are lightweight, easy to handle, and compatible with both low- and medium-voltage applications, making them a preferred choice among electricians and contractors. The affordability and versatility of 5–7 mil. vinyl electrical tapes continue to sustain their high market demand.

The above 10 mil. segment is anticipated to witness the fastest CAGR from 2025 to 2032, attributed to its growing adoption in industrial, automotive, and high-voltage electrical applications. Thicker vinyl tapes offer enhanced mechanical protection, abrasion resistance, and dielectric strength, ensuring reliable insulation in challenging environments. Their robustness makes them ideal for heavy-duty cabling, underground wiring, and outdoor installations where environmental exposure is significant. The increasing focus on infrastructure upgrades and renewable energy networks further drives demand for this segment.

- By Application

On the basis of application, the vinyl electrical tape market is segmented into building & construction, electrical & electronics, and others. The electrical & electronics segment dominated the market with the largest share in 2024, driven by the high demand for insulation, splicing, and cable protection solutions. Vinyl electrical tapes are extensively used in wiring assemblies, switchboards, transformers, and appliances to prevent short circuits and ensure safety. The rise in consumer electronics production and expanding electrical infrastructure worldwide further fuel the segment’s leadership position.

The building & construction segment is expected to record the fastest growth rate from 2025 to 2032, fueled by increasing electrical installations in residential and commercial projects. Vinyl electrical tapes are widely used in wiring, lighting, and HVAC systems, where their flame-retardant and UV-resistant properties enhance safety and longevity. The ongoing urbanization and expansion of smart infrastructure projects globally are key factors supporting the segment’s accelerated growth.

- By Type

On the basis of type, the market is segmented into cloth electrical tape, PVC electrical tape, PET electrical tape, and others. The PVC electrical tape segment dominated the market with the largest revenue share in 2024, due to its superior insulation capability, flexibility, and wide availability across industrial and consumer markets. PVC tapes are highly resistant to temperature variations, corrosion, and wear, making them suitable for both indoor and outdoor applications. Their cost-effectiveness and easy customization in various colors and widths enhance their utility across diverse industries.

The PET electrical tape segment is anticipated to witness the fastest CAGR from 2025 to 2032, supported by its exceptional thermal stability, tensile strength, and moisture resistance. PET-based tapes are increasingly used in electronics, automotive, and aerospace applications where long-term insulation reliability is critical. Their eco-friendly composition and superior performance under high-temperature environments make them a preferred choice for next-generation electrical insulation solutions. Growing demand for advanced and sustainable materials in high-performance applications further accelerates this segment’s expansion.

Vinyl Electrical Tape Market Regional Analysis

- Asia-Pacific dominated the vinyl electrical tape market with the largest revenue share of 57.3% in 2024, driven by expanding electrical and electronics manufacturing, rising infrastructure development, and the growing demand for insulation materials in industrial applications

- The region’s large-scale construction activities, supported by rapid urbanization and industrialization, are fueling market demand

- In addition, the availability of low-cost raw materials, skilled labor, and supportive trade policies are strengthening regional production capacities and export competitiveness in vinyl electrical tapes

China Vinyl Electrical Tape Market Insight

China held the largest share in the Asia-Pacific vinyl electrical tape market in 2024 due to its strong dominance in electronics production, construction expansion, and industrial manufacturing. The country’s thriving automotive and electrical appliance industries generate substantial demand for insulation tapes used in wiring and assembly applications. Supportive government initiatives aimed at boosting domestic manufacturing and infrastructure projects further enhance the consumption of vinyl electrical tapes across sectors.

India Vinyl Electrical Tape Market Insight

India is witnessing the fastest growth in the Asia-Pacific region, propelled by increasing investments in construction, electrical infrastructure, and renewable energy projects. The country’s growing focus on electrification and smart city development is driving demand for durable and heat-resistant insulation tapes. Rising production in the consumer electronics and automotive industries, supported by initiatives such as “Make in India,” is further amplifying the market’s expansion potential.

Europe Vinyl Electrical Tape Market Insight

The Europe vinyl electrical tape market is expanding steadily, supported by stringent electrical safety regulations, high-quality manufacturing standards, and growing adoption of advanced insulation materials. The region’s focus on energy efficiency, green building standards, and sustainable electrical systems is boosting the use of vinyl tapes in both industrial and residential applications. The demand for eco-friendly and low-VOC tape products is also gaining traction, reflecting the region’s sustainability-driven growth approach.

Germany Vinyl Electrical Tape Market Insight

Germany’s market is driven by its advanced electrical engineering sector, widespread use of automation systems, and leadership in energy-efficient infrastructure. The country’s emphasis on high-performance materials for industrial cabling and electronic applications supports consistent demand for premium-grade vinyl electrical tapes. Strong R&D investment in innovative adhesive technologies and partnerships with automotive and renewable energy manufacturers further enhance market growth.

U.K. Vinyl Electrical Tape Market Insight

The U.K. market is supported by growing investment in smart grid systems, electrical safety modernization, and renovation of commercial infrastructure. The country’s expanding renewable energy capacity and emphasis on sustainable building codes are contributing to the steady use of vinyl electrical tapes in wiring, cable management, and insulation applications. A strong distribution network and focus on product innovation continue to reinforce the U.K.’s presence in the regional market.

North America Vinyl Electrical Tape Market Insight

North America is projected to grow at the fastest CAGR from 2025 to 2032, driven by rising infrastructure modernization, electrical safety upgrades, and increased demand from the construction and automotive sectors. The region’s growing focus on energy-efficient installations and advancements in adhesive and flame-retardant technologies are propelling market growth. In addition, reshoring of manufacturing activities and higher spending on smart home and industrial automation systems are strengthening the regional outlook.

U.S. Vinyl Electrical Tape Market Insight

The U.S. accounted for the largest share in the North America vinyl electrical tape market in 2024, supported by its robust construction activity, well-established electrical safety standards, and extensive adoption in industrial and commercial projects. The presence of major electrical product manufacturers, coupled with technological innovations in insulation materials, drives consistent demand. The focus on renewable energy infrastructure and retrofitting of aging electrical networks further cements the U.S.’s leadership in the regional market.

Vinyl Electrical Tape Market Share

The vinyl electrical tape industry is primarily led by well-established companies, including:

- 3M Company (U.S.)

- Can-Do National Tape (U.S.)

- Parafix Tapes & Conversions Ltd (U.K.)

- HellermannTyton (U.K.)

- Electro Tape Specialties, Inc. (U.S.)

- Bron Tapes, Inc. (U.S.)

- Godson Tapes Pvt. Limited (India)

- Euro Tapes Private Limited (Unit of Euro Technologies) (India)

- PPM Industries UK (U.K.)

- Saint-Gobain Performance Plastics h-old S.p.A (Italy)

- Pro Tapes & Specialties, Inc. (U.S.)

- Plymouth Rubber Europa, S.A. (Spain)

- Teraoka Seisakusho Co., Ltd. (Japan)

- Nitto Denko Corporation (Japan)

- Avery Dennison Corporation (U.S.)

- Berry Global Inc. (U.S.)

- Furukawa Electric Co., Ltd. (Japan)

Latest Developments in Global Vinyl Electrical Tape Market

- In October 2025, Saint-Gobain (CHR) launched a new range of eco-friendly vinyl electrical tapes designed to meet growing global sustainability demands. These tapes are manufactured using low-emission materials and recyclable components while maintaining high adhesion strength, flexibility, and insulation efficiency. The development reflects the company’s commitment to reducing carbon footprints in industrial operations and promoting eco-conscious manufacturing. This innovation enhances Saint-Gobain’s product appeal among environmentally responsible consumers and also accelerates the adoption of sustainable insulation materials across construction, electrical, and industrial sectors

- In August 2025, Scapa Group Ltd. completed the acquisition of a leading manufacturer of cloth electrical tapes, significantly broadening its product portfolio and strengthening its presence in the global electrical insulation market. This acquisition allows Scapa to integrate advanced adhesive technologies and expand its customer base across industrial and infrastructure sectors. By leveraging the acquired company’s expertise and production capabilities, Scapa is expected to improve its operational efficiency, enhance supply chain resilience, and introduce innovative insulation solutions tailored for specialized applications. This strategic move reinforces Scapa’s competitive advantage and growth potential in high-performance tape solutions

- In June 2025, Nitto Denko Corporation developed a new line of self-amalgamating tapes designed specifically for splicing and insulation of high-voltage power cables. These tapes provide exceptional sealing, resistance to moisture ingress, and thermal stability, ensuring long-lasting performance even under extreme environmental conditions. The innovation addresses the increasing global demand for durable and easy-to-apply insulation materials used in power distribution and renewable energy systems. By enhancing reliability and reducing maintenance costs, Nitto’s latest product strengthens its position in the premium electrical insulation segment and supports ongoing global infrastructure upgrades

- In March 2025, 3M Company introduced flame-retardant electrical tapes engineered for high-voltage and critical safety applications, aligning with the industry’s shift toward advanced fire-protection standards. These tapes are formulated to resist high temperatures and electrical stress, ensuring consistent insulation performance under demanding conditions. The launch underscores 3M’s continued focus on innovation and safety enhancement, addressing the needs of industrial users seeking reliable and compliant solutions. This development bolsters 3M’s leadership in electrical tape technology and expands its influence across sectors such as utilities, manufacturing, and heavy engineering

- In January 2025, Tesa SE unveiled a high-durability vinyl electrical tape series specifically designed for automotive and electronic applications requiring superior mechanical and thermal stability. The new tapes offer enhanced resistance to abrasion, chemicals, and temperature fluctuations, providing dependable insulation and long-term performance in complex wiring systems. This launch supports the growing adoption of high-performance adhesives in next-generation vehicles and smart electronic devices. Tesa’s innovation positions the company as a strong contender in the premium insulation segment, meeting the increasing demand for advanced, durable, and efficiency-driven tape solutions in industrial markets

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Vinyl Electrical Tape Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Vinyl Electrical Tape Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Vinyl Electrical Tape Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.