Global Weighing Inspection Market

Market Size in USD Billion

CAGR :

%

USD

3.19 Billion

USD

4.40 Billion

2024

2032

USD

3.19 Billion

USD

4.40 Billion

2024

2032

| 2025 –2032 | |

| USD 3.19 Billion | |

| USD 4.40 Billion | |

|

|

|

|

Weighing and Inspection Market Size

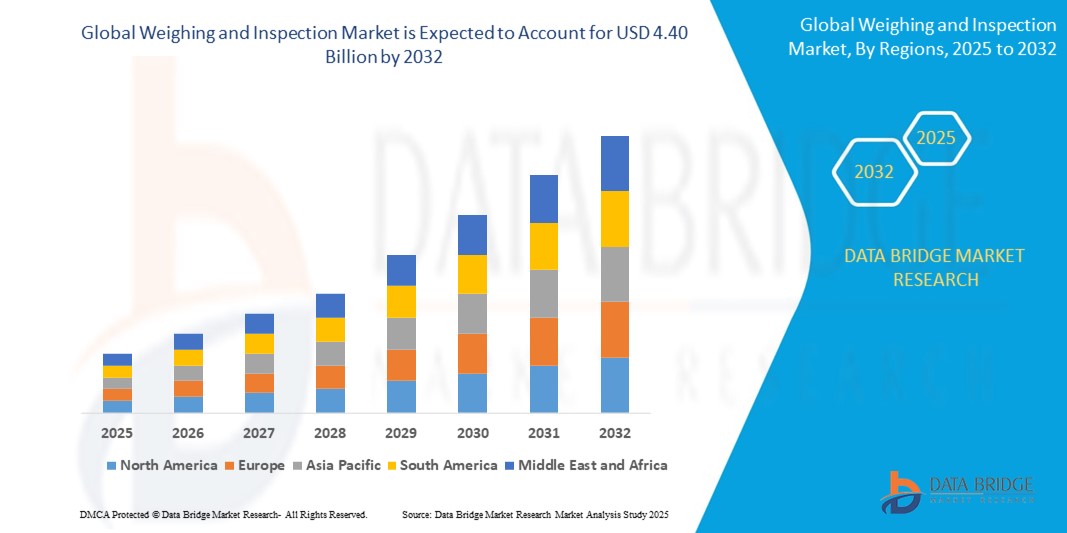

- The global Weighing and Inspection market size was valued at USD 3.19 billion in 2024 and is expected to reach USD 4.40 billion by 2032, at a CAGR of 4.10% during the forecast period

- This growth is driven by factors such as the increasing demand for quality control and inspection in manufacturing industries, technological advancements in weighing and inspection equipment, and the rising need for compliance with stringent regulations across various sectors

Weighing and Inspection Market Analysis

- Weighing and inspection refer to processes used in various industries to measure product weight and ensure quality control. Weighing involves the use of scales or sensors to accurately determine the mass of products, ensuring consistency and meeting regulatory requirements

- Inspection, on the other hand, involves checking for defects, contamination, or irregularities using tools such as X-rays, metal detectors, and vision systems. These processes are crucial in sectors such as food, pharmaceuticals, and manufacturing, where precise measurement and quality standards are essential to maintain safety, efficiency, and compliance with industry regulations

- North America is expected to dominate the weighing and inspections market with 36.2% due to well-developed industrial infrastructure, encompassing sectors such as manufacturing, logistics, and healthcare

- Asia-Pacific is expected to be the fastest growing region in the weighing and inspection market during the forecast period due to increased demand for weighing and inspection equipment

- X-Ray detection systems segment is expected to dominate the market with a market share of 56.22% due to their ability to detect a wide range of contaminants, including metals, plastics, and glass, in packaged products

Report Scope and Weighing and Inspection Market Segmentation

|

Attributes |

Weighing and Inspection Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand. |

Weighing and Inspection Market Trends

“Integration of AI and Automation”

- The adoption of artificial intelligence (AI) in weighing and inspection systems is revolutionizing the industry by enhancing accuracy and efficiency. AI algorithms enable real-time data analysis, predictive maintenance, and anomaly detection, leading to reduced downtime and improved product quality

- Industries are increasingly integrating automated weighing and inspection systems into their production lines. This shift towards automation is driven by the need for consistent quality control, higher throughput, and reduced human error

- The Internet of Things (IoT) is facilitating seamless communication between weighing and inspection devices, allowing for centralized monitoring and control. This connectivity enhances operational efficiency and enables data-driven decision-making

- The ongoing Industry 4.0 revolution is pushing manufacturers to adopt smart technologies, including AI and automation, to stay competitive. These technologies are integral to achieving higher productivity and meeting stringent regulatory standards

- The ability to collect and analyze data in real time allows for immediate corrective actions, minimizing defects and ensuring compliance with quality standards. This capability is particularly crucial in industries like food and pharmaceuticals

Weighing and Inspection Market Dynamics

Driver

“Stringent Regulatory Compliance”

- Governments worldwide are implementing strict food safety regulations that require accurate weighing and inspection of products to prevent contamination and ensure consumer safety

- The pharmaceutical industry is governed by rigorous standards that mandate precise measurement and inspection of products to maintain efficacy and safety

- Manufacturers are compelled to adopt advanced weighing and inspection systems to meet quality assurance requirements, thereby reducing the risk of product recalls and enhancing brand reputation

- International trade agreements necessitate compliance with specific standards, prompting companies to invest in reliable weighing and inspection equipment to facilitate smooth cross-border transactions

- Increasing environmental regulations are encouraging industries to adopt sustainable practices, including the use of efficient weighing and inspection systems that minimize waste and energy consumption

Opportunity

“Expansion in Emerging Markets”

- Countries in the Asia-Pacific region, such as China and India, are experiencing rapid industrialization, leading to increased demand for weighing and inspection equipment in sectors like manufacturing and logistics

- Ongoing infrastructure projects in emerging markets are driving the need for advanced inspection systems to ensure the quality and safety of construction materials.

- Governments in emerging economies are offering incentives and subsidies to encourage the adoption of modern weighing and inspection technologies, creating a favorable market environment

- Growing awareness among consumers about product quality and safety is prompting manufacturers in emerging markets to invest in reliable inspection systems to meet expectations

- The expansion of e-commerce platforms in emerging markets is increasing the demand for efficient inspection systems to handle the surge in product volumes and ensure quality control

Restraint/Challenge

“High Initial Investment Costs”

- The high upfront costs associated with purchasing and installing advanced weighing and inspection systems can be a significant barrier for small and medium-sized enterprises (SMEs)

- Ongoing maintenance and calibration of sophisticated equipment add to the operational costs, impacting the financial viability for businesses with limited budgets

- The need for specialized training to operate and maintain advanced systems incurs additional costs and time investments, potentially disrupting regular operations

- Businesses may be hesitant to invest in high-cost equipment without a clear and immediate ROI, especially in volatile market conditions

- Rapid advancements in technology can render newly purchased equipment outdated, leading to concerns about the longevity and future-proofing of investments

Weighing and Inspection Market Scope

The market is segmented on the basis of product type and industry.

|

Segmentation |

Sub-Segmentation |

|

By Product Type |

|

|

By Industry |

|

In 2025, the X-Ray detection systems is projected to dominate the market with a largest share in product type segment

The X-Ray detection systems segment is expected to dominate the Weighing and Inspection market with the largest share of 40.5% in 2025 due to their ability to detect a wide range of contaminants, including metals, plastics, and glass, in packaged products. Their advanced capabilities make them the fastest-growing segment in the inspection equipment market.

The food and beverage is expected to account for the largest share during the forecast period in industry market

In 2025, the food and beverage segment is expected to dominate the market with the largest market share of 50.5% due to its stringent safety regulations and the need for quality assurance in mass production.

Weighing and Inspection Market Regional Analysis

“North America Holds the Largest Share in the Weighing and Inspection Market”

- North America commands a significant share of the global weighing and inspection market of 36.20%, with the U.S. accounting for approximately 21.1% of the market by 2033

- The region boasts a well-developed industrial infrastructure, encompassing sectors such as manufacturing, logistics, and healthcare, all of which require precise weighing and inspection systems

- Stringent regulatory standards in industries like pharmaceuticals and food processing drive the demand for accurate and reliable weighing and inspection equipment to ensure product safety and quality

- North America is at the forefront of adopting advanced technologies, including automation and digitalization, in weighing and inspection systems, enhancing operational efficiency and accuracy.

- The region's stable economic environment and continuous investment in infrastructure development contribute to sustained growth in the weighing and inspection market

“Asia-Pacific is Projected to Register the Highest CAGR in the Weighing and Inspection Market”

- Countries like China and India are experiencing swift industrial growth, leading to an increased demand for weighing and inspection equipment in various sectors such as manufacturing, logistics, and agriculture

- The ongoing urbanization in Asia-Pacific nations is driving the need for efficient infrastructure and transportation systems, thereby boosting the demand for weighbridges and other inspection equipment

- Supportive government policies and investments in industrial automation and infrastructure development are creating favorable conditions for market expansion in the region

- The increasing adoption of advanced technologies, such as automated weighing systems and digital inspection tools, is enhancing the efficiency and accuracy of operations in the Asia-Pacific region

Weighing and Inspection Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Precia (France)

- WIPOTEC-OCS GmbH (Germany)

- MARCO LTD (U.K.)

- Marel (Iceland)

- Thermo Fisher Scientific (U.S.)

- Bizerba (Germany)

- MinebeaMitsumi Inc. (Japan)

- METTLER TOLEDO (Switzerland)

- Sesotec GmbH (Germany)

- Anritsu (Japan)

- JBT (U.S.)

- Heat and Control, Inc. (U.S.)

- ISHIDA CO., LTD. (Japan)

- REHOO INDUSTRIAL LIMITED (China)

- Murata Machinery, Ltd. (Japan)

- Yangzhou Aerosol Machinery Equipment CO., LTD (China)

- MULTIVAC (Germany)

- YAMATO-SCALE (Japan)

- VARPE (Spain)

- Fortress Technology Inc. (Canada)

- NIKKA DENSOK (Japan)

- Techik Instrument (Shanghai) (China)

Latest Developments in Global Weighing and Inspection Market

- In September 2024, Blue HMI for Checkweighers introduced advanced user interface for dynamic checkweighers with intuitive navigation, equipment effectiveness tracking, and audit-friendly logging

- In September 2024, Mitus Metal Detector introduced with MiWave Technology, a flexible and precise metal contaminant detection for various products.

- In August 2024, General Measure Technology introduced GMC-P7 F8 Static Weighing Controller new static weighing controller for easy integration in industrial applications

- In August 2024, General Measure Technology launches GMC-X802CD Linear Feeder Controller Weighing controller for linear feeder systems, offering stable and accurate performance

- In May 2024, FUTEK Advanced Sensor Technology launches LSB206 Digital Miniature S-Beam Jr Load Cell for miniature load cell offering enhanced digital capabilities for compact applications and precise force measurement

- In April, Satepesa S.L. launches STP-Camións System a digital truck weighing system designed to improve operations in transport and logistics, ensuring efficiency and compliance

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Weighing Inspection Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Weighing Inspection Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Weighing Inspection Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.