Global Wind Turbine Composites Material Market

Market Size in USD Million

CAGR :

%

USD

303.90 Million

USD

620.54 Million

2024

2032

USD

303.90 Million

USD

620.54 Million

2024

2032

| 2025 –2032 | |

| USD 303.90 Million | |

| USD 620.54 Million | |

|

|

|

|

Wind Turbine Composite Material Market Size

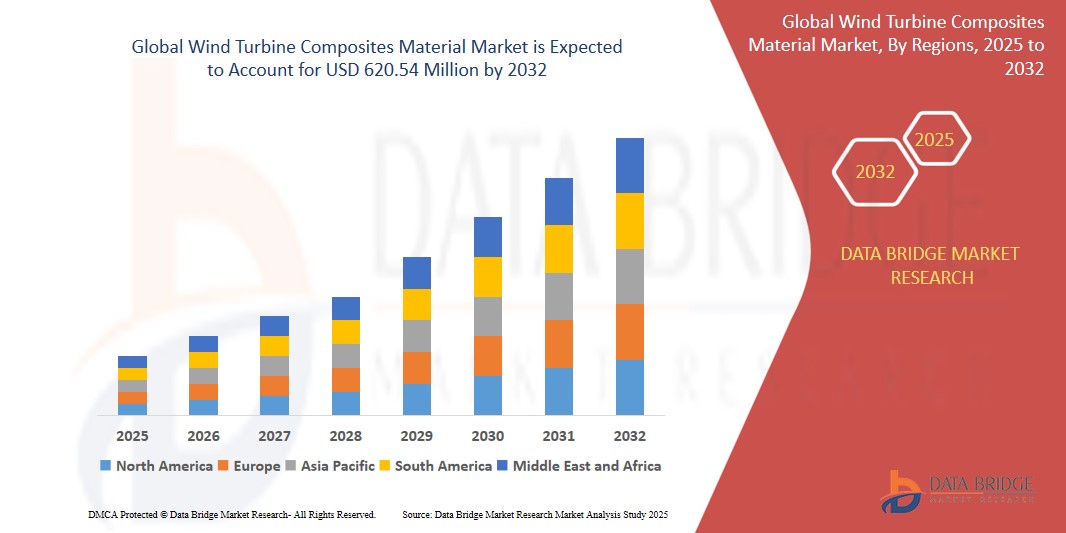

- The Global Wind Turbine Composite Material Market was valued at USD 303.90 Million in 2024 and is expected to reach USD 620.54 Million by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 7.40%, primarily driven by rising renewable energy demand, increasing wind turbine installations, need for lightweight durable materials, and technological advancements in composite manufacturing for enhanced turbine

- The growth of the global Wind Turbine Composite Material market is driven by factors such as rising wind energy adoption, lightweight material demand, offshore wind projects, and advancements in composite manufacturing technologies.

Wind Turbine Composite Material Market Analysis

- The market is propelled by the need for high-performance, lightweight, and durable materials in turbine blades. Composites like carbon and glass fiber reduce overall turbine weight, improve efficiency, and enhance lifespan, especially in large-scale turbines.

- Offshore wind energy projects are growing globally due to stronger, consistent wind speeds. These require corrosion-resistant, high-strength composite materials, creating strong demand in the market, particularly across Europe, Asia-Pacific, and parts of North America.

- Innovations in resin systems, automated molding processes, and recyclable composite materials are enhancing production efficiency and reducing costs. This encourages broader adoption among wind turbine manufacturers, further boosting market competitiveness and long-term sustainability.

Report Scope and Wind Turbine Composite Material Market Segmentation

|

Attributes |

Wind Turbine Composite Material Key Market Insights |

|

Segments Covered |

• By Material Type: Glass Fiber Composites, Carbon Fiber Composites, Hybrid Composites and Other Materials • By Manufacturing Process: Vacuum Injection Molding, Hand Lay-Up, Compression Molding, Resin Transfer Molding (RTM), Filament Winding and Others • By Application: Wind Turbine Blades, Nacelle Components, Towers and Hub & Other Structural Components • By Resin Type: Epoxy, Polyester, Vinyl Ester, Polyurethane and Others • By Installation Type: Onshore Wind Turbines and Offshore Wind Turbines |

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Wind Turbine Composite Material Market Trends

“Increasing demand for lightweight, durable materials in turbines”

- Lightweight composite materials like carbon and glass fibers improve the aerodynamics and performance of wind turbine blades, leading to greater efficiency in energy generation while reducing material costs and overall weight, optimizing turbine operation.

- Durable composite materials enhance the lifespan of wind turbine components, especially blades, reducing maintenance costs and the frequency of replacements. This is particularly critical in offshore wind farms where exposure to harsh environmental conditions accelerates material degradation.

- For instance, An IIT Mandi-incubated startup has developed an AI-enabled yoga mat, aligning with the growing health consciousness driving the adoption of Wind Turbine Composite Material s. This "Make in India" innovation enhances personalized fitness experiences by leveraging advanced technology, offering real-time feedback and personalized coaching to users seeking better fitness outcomes.

- Technological advancements in composite material manufacturing, such as automated processes and resin systems, have led to cost-effective production. These innovations make lightweight, durable materials more affordable, accelerating their adoption in turbine manufacturing.

Wind Turbine Composite Material Market Dynamics

Driver

“Rising renewable energy demand drives growth in composite materials.”

- Governments and private sector investments in wind energy infrastructure are driving the demand for high-performance composite materials, as wind turbines are crucial for achieving renewable energy goals and sustainability targets..

- Continuous improvements in turbine efficiency and size require advanced composite materials that provide durability, lightweight properties, and optimal performance, thus increasing demand for these materials in wind energy applications..

- Consumers are increasingly seeking personalized fitness options, and Wind Turbine Composite As countries aim to reduce carbon emissions, the rising adoption of clean and renewable energy sources like wind power boosts the demand for composite materials used in turbine blades, nacelles, and towers.

For instance,

- In November 2024, Nationwide News Pty Ltd stated that consumers are increasingly turning to probiotic skincare to manage sensitive skin. These products support the skin's natural barrier by promoting beneficial bacteria, helping reduce irritation, inflammation, and breakouts. As highlighted in The Advertiser (Nov 2024), this trend is driven by a growing preference for microbiome-friendly, science-backed formulations..

Opportunity

“Expansion of offshore wind projects creates material demand opportunities”

- Offshore wind projects require composites with enhanced strength and corrosion resistance to withstand challenging marine conditions, creating opportunities for the development and supply of advanced materials like carbon and glass fibers.

- As offshore wind turbines grow in size for higher energy generation, the demand for lightweight and durable composite materials rises, offering opportunities for innovation and expansion in material technologies and manufacturing methods.

- Government support for offshore wind projects, through subsidies and renewable energy targets, fosters demand for materials like composites, providing market opportunities for suppliers to meet growing infrastructure needs and sustainability goals.

- The push for environmentally sustainable offshore wind energy accelerates the need for recyclable and eco-friendly composite materials, presenting opportunities to develop innovative, green materials that align with renewable energy initiatives.

For instance,

- In February 2025 Hale & Hush article explores the crucial role of the skin microbiome in managing sensitive and sensitized skin. It emphasizes how microbial balance supports skin health, reduces inflammation, and enhances barrier function—highlighting the growing relevance of microbiome-friendly skincare in addressing rising skin sensitivity concerns.

Restraint/Challenge

“High material costs and manufacturing complexities limit market growth.”

- The high cost of advanced composite materials like carbon fiber and the complex manufacturing processes involved in producing wind turbine components lead to increased overall costs, limiting widespread adoption, particularly in cost-sensitive regions and markets.

- The availability of high-quality raw materials for composites, such as carbon and glass fibers, is limited, leading to supply chain constraints. This impacts production rates and increases costs, restraining the scalability of wind turbine manufacturing.

- The intricate and labor-intensive processes required to manufacture composite materials for wind turbines, such as resin infusion, filament winding, and molding, contribute to high production costs and slow manufacturing times, hindering market growth potential.

- Recycling composite materials used in wind turbines remains technologically challenging. The absence of effective and cost-efficient recycling solutions for composites limits the industry's ability to meet sustainability goals, adding to production costs and slowing the adoption of green materials.

Wind Turbine Composite Material Market Scope

The market is segmented on the basis material type, manufacturing process, application, resin type and installation type.

|

Segmentation |

Sub-Segmentation |

|

By Material Type |

|

|

By Manufacturing Process |

|

|

By Application

|

|

|

By Resin Type |

|

|

By Installation Type |

|

Wind Turbine Composite Material Market Regional Analysis

“Asia-Pacific (APAC) is the Dominant Region in the Wind Turbine Composite Material Market”

- Countries like China and India heavily invest in renewable energy, driving composite material demand.

- Favorable government policies, subsidies, and renewable energy targets promote wind energy projects in the region.

- Rapid industrialization and increasing wind turbine manufacturing capacity in APAC contribute to rising composite material needs.

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- China and India are heavily investing in renewable energy, with strong government policies and incentives supporting the growth of wind energy projects and infrastructure.

- Rising energy needs and a shift toward clean energy sources in APAC are driving the adoption of wind power, leading to higher demand for composite materials used in turbines..

- As APAC economies expand and urbanize, there's an increase in wind turbine manufacturing and installations, particularly in offshore projects, fueling the demand for advanced composite materials in the region.

Wind Turbine Composite Material Market Share

The competitive landscape of the Wind Turbine Composite Material market offers insights into key players and their market positioning. Key details include company overview, financial performance, revenue generation, market potential, and investment in research and development. Additionally, the analysis covers new market initiatives, global presence, production facilities, manufacturing capacities, and strategic expansions. Companies are evaluated based on their strengths, weaknesses, product innovation, and competitive advantages in nutraceuticals, pharmaceuticals, cosmetics, and functional foods.

The Major Market Leaders Operating in the Market Are:

- LM Wind Power (Denmark)

- TPI Composites Inc. (United States)

- Siemens Gamesa Renewable Energy (Spain)

- GE Renewable Energy (France/United States)

- Suzlon Energy Ltd. (India)

- Vestas Wind Systems A/S (Denmark)

- MFG Wind (United States)

- Hexcel Corporation (United States)

- Toray Industries Inc. (Japan)

- SGL Carbon SE (Germany)

- Mitsubishi Chemical Group Corporation (Japan)

- Owens Corning (United States)

- Teijin Limited (Japan)

- Nordex SE (Germany)

- Enercon GmbH (Germany)

Latest Developments in Global Wind Turbine Composite Material Market

- In January 2025, ExoTechnologies and Ventum Dynamics have announced the launch of a fully recyclable wind turbine. The product utilize ExoTechnologies’ natural fiber-reinforced thermoplastic Danu composite, which reduces overall turbine weight by 40% and improve structural integrity by 30-65%, in accordance with the type of component used.

- In November 2024, EOLIAN project developed a new generation of sustainable, recyclable wind turbine blades. These blades feature a longer service life, easier maintenance, and enhanced recyclability, contributing to a circular economy by reducing waste at the end of their life.

- In October 2024, The ZEBRA Project developed a closed-loop recycling process for wind turbine blades. This innovative process enables the recycling of composite materials from decommissioned blades, reducing waste and enhancing material recovery, contributing to a more eco-friendly and circular economy in wind energy.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Wind Turbine Composites Material Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Wind Turbine Composites Material Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Wind Turbine Composites Material Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.