Middle East And Africa Flow Chemistry Market

Market Size in USD Million

CAGR :

%

USD

159.39 Million

USD

367.32 Million

2024

2032

USD

159.39 Million

USD

367.32 Million

2024

2032

| 2025 –2032 | |

| USD 159.39 Million | |

| USD 367.32 Million | |

|

|

|

|

Middle East and Africa Flow Chemistry Market Size

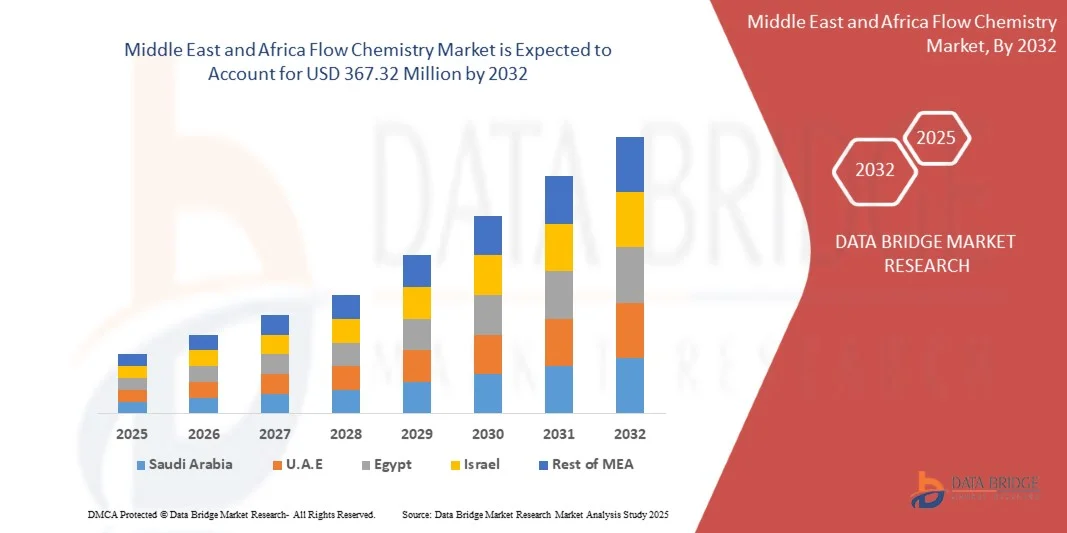

- The Middle East and Africa flow chemistry market size was valued at USD 159.39 million in 2024 and is expected to reach USD 367.32 million by 2032, at a CAGR of 11.00% during the forecast period

- The market growth is largely fuelled by the increasing adoption of continuous flow systems in pharmaceuticals and fine chemicals, rising demand for safer and greener chemical processes, and technological advancements enhancing production efficiency

- Additional growth factors include government initiatives supporting sustainable industrial practices and growing investments in R&D for innovative chemical synthesis methods

Middle East and Africa Flow Chemistry Market Analysis

- The market is experiencing steady growth as industries transition from traditional batch processing to continuous flow systems, which offer higher efficiency, better scalability, and improved safety

- Flow chemistry enables faster reactions, precise control over parameters, and reduced environmental impact, making it a preferred choice across multiple applications

- Saudi Arabia dominated the Middle East and Africa flow chemistry market in 2024, supported by strong government initiatives to diversify industrial growth beyond oil and gas and significant investments in pharmaceutical and specialty chemical manufacturing

- South Africa is expected to witness the highest compound annual growth rate (CAGR) in the Middle East and Africa flow chemistry market due to increasing investments in research and development, rising adoption of sustainable and continuous flow processes, and expanding pharmaceutical and specialty chemical industries

- The Gas-Based Flow Chemistry segment held the largest market revenue share in 2024, supported by its wide application in large-scale chemical synthesis, enhanced reaction safety, and efficiency in handling gaseous reagents. Industries increasingly prefer this technology for its scalability and ability to streamline continuous production

Report Scope and Middle East and Africa Flow Chemistry Market Segmentation

|

Attributes |

Middle East and Africa Flow Chemistry Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

Middle East and Africa

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Middle East and Africa Flow Chemistry Market Trends

“Shift Toward Continuous Manufacturing In Chemical And Pharmaceutical Production”

- The increasing shift toward continuous manufacturing is reshaping the flow chemistry landscape in the Middle East and Africa, as industries look to enhance safety, efficiency, and sustainability. Continuous processes allow precise reaction control, reduced waste generation, and scalability, making them highly attractive compared to traditional batch systems. This is particularly valuable for pharmaceutical and specialty chemical production where speed and quality are critical

- The rising demand for sustainable chemical practices is further boosting adoption. Flow reactors minimize energy consumption, reduce solvent usage, and support greener synthesis methods, aligning with global sustainability goals. Companies are leveraging these advantages to improve compliance with environmental regulations and reduce operational costs.

- Technological advancements such as automated reactors, modular systems, and digital monitoring tools are improving accessibility and flexibility. These innovations are encouraging both large-scale manufacturers and emerging players to integrate flow chemistry into their operations

- For instance, in 2024, a regional specialty chemicals firm announced the adoption of modular flow reactors for synthesizing fine chemicals, reporting faster production cycles, improved yield, and lower waste levels compared to batch methods. Such examples demonstrate how localized adoption is accelerating industrial modernization

- While continuous processes are becoming a cornerstone of modern chemical production, their success relies on investments in training, awareness, and infrastructure. Manufacturers must prioritize user-friendly technologies and localized solutions to fully harness the potential of flow chemistry across diverse industrial settings

Middle East and Africa Flow Chemistry Market Dynamics

Driver

“Growing Demand For Sustainable And Efficient Chemical Synthesis”

- Rising demand for sustainable production methods is pushing industries across the region to adopt flow chemistry as an alternative to batch processes. With growing global focus on reducing environmental footprints, continuous flow systems offer reduced emissions, higher yields, and safer handling of hazardous reactions. This has accelerated interest among chemical and pharmaceutical companies

- Efficiency gains are also a major driver, as continuous reactors enable faster production cycles, consistent product quality, and easy scalability. These benefits directly support the growing demand for cost-effective, high-quality chemicals and pharmaceuticals

- Governments and industry bodies are supporting advanced manufacturing technologies by promoting green chemistry initiatives and funding research collaborations. These initiatives are helping industries modernize their production while staying aligned with global sustainability commitments

- For instance, in 2023, a collaborative program was launched between research institutes and chemical manufacturers to pilot continuous flow technologies, demonstrating significant improvements in efficiency and safety over traditional processes

- While demand and institutional support are strong, widespread adoption requires addressing knowledge gaps and ensuring that small and medium-scale players can access and implement flow chemistry solutions effectively

Restraint/Challenge

“High Initial Investment And Limited Technical Expertise”

- The high upfront cost of flow reactors, automated systems, and associated infrastructure remains a barrier to adoption, particularly for smaller firms and emerging chemical producers. While long-term cost savings are significant, the initial financial outlay is restricting market penetration

- Limited availability of trained personnel capable of designing, operating, and maintaining advanced flow systems further slows adoption. Many companies continue to rely on traditional batch processes due to familiarity and lower training requirements

- Infrastructure limitations, especially in less industrialized regions, pose additional challenges. Access to advanced equipment, reagents, and technical services is not always guaranteed, slowing the integration of continuous processes

- For instance, in 2023, several small-scale chemical producers in North Africa reported delays in adopting flow reactors due to cost barriers and lack of technical expertise, highlighting the need for training programs and affordable modular solutions

- While technological advancements continue to make flow chemistry more accessible, solving cost and skills-related challenges is crucial. Stakeholders must focus on scalable solutions, partnerships, and training initiatives to unlock the full growth potential of the market

Middle East and Africa Flow Chemistry Market Scope

The market is segmented on the basis of technology, reactor type, and end-user.

- By Technology

On the basis of technology, the Middle East and Africa flow chemistry market is segmented into Gas-Based Flow Chemistry, Photochemistry-Based Flow Chemistry, and Microwave Irradiation-Based Flow Chemistry. The Gas-Based Flow Chemistry segment held the largest market revenue share in 2024, supported by its wide application in large-scale chemical synthesis, enhanced reaction safety, and efficiency in handling gaseous reagents. Industries increasingly prefer this technology for its scalability and ability to streamline continuous production.

The Photochemistry-Based Flow Chemistry segment is expected to witness the fastest growth rate from 2025 to 2032, driven by rising adoption in pharmaceutical and specialty chemical applications where controlled photo-induced reactions are required. Its advantages of precise reaction control, reduced by-products, and alignment with green chemistry principles are fueling strong demand across the region.

- By Reactor Type

On the basis of reactor type, the market is segmented into Continuous Flow Reactors, Continuous Stirred Tank Reactors (CSTR), Plug Flow Reactors (PFR), Micro Reactor Systems (MRT), and Microwave Systems. The Continuous Flow Reactors segment accounted for the largest revenue share in 2024, as they are widely used for high-throughput synthesis, cost efficiency, and consistent product quality. Their versatility across different chemical processes makes them a preferred choice for industrial-scale operations.

The Micro Reactor Systems (MRT) segment is expected to witness the fastest growth rate from 2025 to 2032, supported by their growing use in research and development, pharmaceutical innovation, and specialty chemical synthesis. MRTs enable precise reaction monitoring, efficient heat transfer, and rapid scalability, making them particularly attractive for high-value, small-batch production.

- By End-User

On the basis of end-user, the market is segmented into Pharmaceutical Biotechnology Companies, Chemical Industries, Food and Beverage Industries, Agriculture and Environmental Sector, Nutraceutical Firms, Academics and Research Institutes, and Analytical Laboratories. The Pharmaceutical Biotechnology Companies segment dominated the market in 2024, driven by rising demand for safer, faster, and cost-efficient drug manufacturing processes. The adoption of flow chemistry in this segment is strongly supported by the push for continuous production and regulatory compliance.

The Academics and Research Institutes segment is expected to witness the fastest growth rate from 2025 to 2032, as universities and research centers increasingly invest in advanced flow chemistry systems for experimental and training purposes. The focus on innovation, sustainable synthesis, and technology commercialization is accelerating demand within this category.

Middle East and Africa Flow Chemistry Market Regional Analysis

- Saudi Arabia dominated the Middle East and Africa flow chemistry market in 2024, supported by strong government initiatives to diversify industrial growth beyond oil and gas and significant investments in pharmaceutical and specialty chemical manufacturing

- The country’s advanced infrastructure, coupled with policies encouraging sustainable industrial practices, is accelerating adoption of continuous flow technologies across key sectors

South Africa Flow Chemistry Market Insight

South Africa is expected to witness the fastest growth rate from 2025 to 2032, driven by expanding pharmaceutical and specialty chemical industries, rising focus on green chemistry practices, and growing collaborations between academia and industry. Increasing investments in research infrastructure and cost-effective production solutions are expected to further strengthen the country’s growth trajectory.

Middle East and Africa Flow Chemistry Market Share

The Middle East and Africa flow chemistry industry is primarily led by well-established companies, including:

- Flowline Instruments LLC (U.A.E.)

- PetroFlow Petroleum Products (U.A.E.)

- Geo-Chem Middle East (U.A.E.)

- Emirates National Chemical Industries LLC (U.A.E.)

- Arkema Middle East DMCC (U.A.E.)

- LEWA NIKKISO Middle East FZE (U.A.E.)

- Evonik Gulf FZE (U.A.E.)

- SLB Emirates (U.A.E.)

- Corning Advanced-Flow Reactor Technology (U.A.E.)

- Beckman Coulter Life Sciences (U.A.E.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Middle East And Africa Flow Chemistry Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Middle East And Africa Flow Chemistry Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Middle East And Africa Flow Chemistry Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.