Middle East And Africa Glyoxal Market

Market Size in USD Million

CAGR :

%

USD

54.00 Million

USD

76.64 Million

2025

2033

USD

54.00 Million

USD

76.64 Million

2025

2033

| 2026 –2033 | |

| USD 54.00 Million | |

| USD 76.64 Million | |

|

|

|

|

Middle East and Africa Glyoxal Market Size

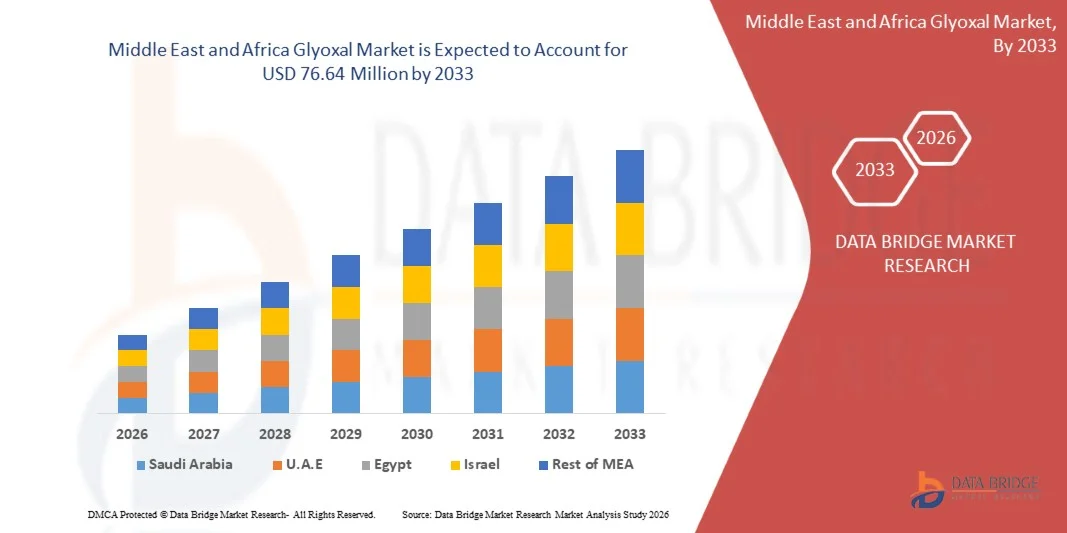

- The Middle East and Africa Glyoxal Market is expected to reach USD 76.64 million by 2033 from USD 54.00 million in 2025 growing with a CAGR of 4.5% in the forecast period of 2026 to 2033.

- The Middle East and Africa Glyoxal Market is witnessing steady growth driven by its expanding use across textiles, paper, leather, pharmaceuticals, agrochemicals, and oil & gas industries, where glyoxal is valued for its cross-linking, binding, and finishing properties.

- In addition, the growing demand for value-added chemical solutions, including customized glyoxal formulations for specific industrial processes and downstream integration within chemical supply chains, is reinforcing market maturity and supporting long-term growth across developed and emerging economies.

Middle East and Africa Glyoxal Market Analysis

- The Middle East and Africa Glyoxal Market serves diverse industries including textiles, paper, resins, pharmaceuticals, cosmetics, and water treatment. Demand is driven by its strong crosslinking properties and role as a key intermediate in specialty and performance chemical formulations.

- Rising textile finishing activities, increasing paper packaging consumption, and growing use of eco-friendly resins are major demand drivers. Expansion of pharmaceutical manufacturing and stricter wastewater treatment regulations further support sustained glyoxal consumption worldwide.

- The market features a mix of multinational chemical producers and regional manufacturers. Competition is based on product purity, application-specific grades, pricing, supply reliability, and compliance with environmental and safety regulations across key end-use industries.

- Saudi Arabia dominates the Middle East and Africa Glyoxal Market, supported by large-scale manufacturing capacity, low production costs, and abundant raw material availability. Strong downstream demand from textiles, resins, paper, and leather industries, along with an extensive chemical supply chain, further reinforces its leadership.

- The U.A.E Middle East and Africa Glyoxal Market is expected to grow at a CAGR of around 5.4% from 2026 to 2033, driven by rising demand from the textile and agrochemical industries and increasing use in resins and coatings for industrial applications. Expanding industrialization and urbanization in the region further fuel market growth.

- In 2025, the Industrial Grade segment is expected to dominate the Middle East and Africa Glyoxal Market with an 82.37% share due to its widespread use in manufacturing resins, adhesives, and paper treatment chemicals. The segment benefits from high demand in large-scale industrial applications and cost-effectiveness for bulk production, making it the preferred choice over other grades.

Report Scope and Middle East and Africa Glyoxal Market Segmentation

|

Attributes |

Middle East and Africa Glyoxal Market Insights |

|

Segments Covered |

|

|

Countries Covered |

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Middle East and Africa Glyoxal Market Trends

“Integration with smart manufacturing, warehouse processing, and e-commerce packaging ecosystems”

- Glyoxal is increasingly utilized in smart manufacturing environments for textile finishing, paper treatment, and resin applications, supporting consistent quality control, process optimization, and data-driven production decisions aligned with Industry 4.0 initiatives.

- In warehouse and processing facilities, glyoxal-based formulations aid in material stabilization, coating performance, and moisture resistance, improving handling efficiency, storage durability, and downstream processing reliability.

- The growing use of glyoxal in packaging adhesives, paper strengthening, and surface treatments supports the expansion of e-commerce by enhancing packaging integrity, load stability, and product protection across logistics networks.

For Instance,

- In January 2025, glyoxal-based chemical solutions were increasingly integrated into automated textile and paper processing lines, combined with advanced process controls and digital monitoring systems to improve efficiency, consistency, and sustainability across industrial operations, highlighting glyoxal’s role in next-generation manufacturing ecosystems.

- Recent industry developments indicate rising adoption of specialty aldehyde-based chemicals, including glyoxal, in high-performance packaging and industrial applications as e-commerce and logistics volumes grow, reinforcing its expanding role beyond traditional end-use sectors.

Middle East and Africa Glyoxal Market Dynamics

Driver

“Rising industrial modernization and performance-driven chemical application requirements”

- The Middle East and Africa industrial sector is witnessing accelerated adoption of glyoxal-based solutions driven by increasingly complex performance requirements across textiles, paper, resins, leather, and specialty chemical applications. Manufacturers are prioritizing glyoxal for its cross-linking, binding, and finishing properties that enhance product strength, durability, and functional performance. As industrial processes evolve toward higher efficiency and quality consistency, demand is growing for chemical formulations that support controlled reactions, reduced emissions, and improved end-product reliability.

- The expanding role of glyoxal within industrial modernization initiatives has created a dynamic environment for chemical producers to innovate, leading to advancements in formulation purity, application versatility, and process compatibility. In response to this demand-driven shift, manufacturers are investing in the development of customized glyoxal grades tailored for specific end-use requirements, including low-formaldehyde systems, specialty resins, and high-performance textile treatments.

- These innovations are largely driven by the operational needs of modern industries, which require adaptable chemical solutions capable of performing reliably under varied processing conditions and regulatory constraints. As industries continue to integrate glyoxal into advanced manufacturing and finishing workflows, this momentum not only influences supplier investment strategies but also reinforces glyoxal’s role as a critical intermediate in enhancing industrial productivity and material performance.

For Instances

- In September 2023, industry publications highlighted increased adoption of glyoxal in advanced textile finishing processes aimed at improving fabric strength and wrinkle resistance while meeting stricter environmental compliance standards.

- As of February 2024, chemical industry insights indicated that manufacturers across Middle East and Africa intensified the use of glyoxal-based resins and paper treatment solutions to support sustainable production practices and reduce reliance on higher-toxicity alternatives.

- In February 2025, regional industry developments across Asia-Pacific emphasized growing investments in specialty aldehyde production, including glyoxal, to meet rising demand from packaging, construction, and industrial manufacturing sectors focused on performance enhancement and regulatory alignment.

- The growing adoption of glyoxal across the global industrial sector underscores its increasing importance as a multifunctional chemical solution aligned with evolving performance, efficiency, and sustainability requirements. As industries continue to advance toward higher-quality outputs and more controlled manufacturing processes, glyoxal’s cross-linking, binding, and finishing capabilities position it as a critical enabler of enhanced material strength, durability, and functional consistency.

- Ongoing innovations in formulation purity and application-specific customization further reinforce its relevance across textiles, paper, resins, leather, and specialty chemicals. Supported by rising investments, regulatory alignment efforts, and expanding industrial use cases across major regions, glyoxal is expected to maintain a strategically significant role in driving industrial productivity and supporting the transition toward more sustainable and high-performance manufacturing practices.

Restraint/Challenge

“Lack of Harmonized Middle East and Africa Regulatory Frameworks for Chemical Manufacturing and Usage”

- The absence of harmonized Middle East and Africa regulations governing chemical manufacturing, handling, and end-use applications presents a notable challenge for the Middle East and Africa Glyoxal Market, as regulatory requirements differ significantly across countries and regions.

- Regulatory authorities apply varying standards related to chemical classification, permissible exposure limits, environmental compliance, labeling, transportation, and wastewater discharge. This regulatory fragmentation compels glyoxal manufacturers and downstream users to modify formulations, documentation, safety protocols, and compliance strategies for each market, increasing operational complexity, compliance costs, and time to market.

- As a result, companies face constraints in scaling glyoxal production and distribution Middle East and Africaly, particularly for cross-border trade and multinational supply chains serving textiles, paper, resins, and specialty chemical applications.

For Instances,

- In late 2025, regional environmental authorities in Asia and Middle East and Africa introduced differing compliance requirements for aldehyde-based chemicals, including glyoxal, with variations in emission thresholds and reporting obligations, illustrating regulatory inconsistencies that complicate standardized production and export strategies.

- In May 2025, national and local regulatory bodies in emerging markets enforced stricter chemical handling and transportation restrictions beyond existing central guidelines, creating temporary operational disruptions for glyoxal manufacturers and distributors who were required to obtain additional approvals and modify logistics workflows during the enforcement period.

- The lack of harmonized global regulatory frameworks continues to pose a structural challenge for the Global Middle East and Africa Glyoxal Market, limiting the ease of standardized production, distribution, and cross-border trade. Divergent regional requirements related to chemical classification, environmental compliance, handling, and transportation increase operational complexity and elevate compliance costs for manufacturers and downstream users.

- These regulatory inconsistencies not only slow market entry and scalability but also necessitate frequent adjustments to formulations, documentation, and logistics strategies across regions. As a result, regulatory fragmentation remains a key constraint on global market expansion, underscoring the need for greater alignment and transparency in chemical governance to support more efficient international supply chains and sustainable market growth.

Middle East and Africa Glyoxal Market Scope

The market is segmented on the basis of grade, purity, production process, packaging application, end-use chemicals and end-use industry

By Grade

Based on grade, the Middle East and Africa Glyoxal Market is primarily segmented into Industrial Grade and Pharmaceutical Grade.

By 2026, the Industrial Grade segment is projected to dominate the market, accounting for 82.29% of the total share. This dominance is attributed to its extensive applications across various industries, including textiles, paper processing, resins, leather treatment, and water treatment. The high-volume consumption of industrial-grade glyoxal is further supported by its cost-effectiveness and efficiency in large-scale operations. Additionally, the rapid expansion of industrial and manufacturing sectors in the Middle East and Africa region is driving strong and sustained demand. As a result, industrial-grade glyoxal is expected to remain the key growth driver within the regional market.

The Pharmaceutical Grade segment in the Middle East and Africa Glyoxal Market is expected to grow fastest from 2026 to 2033, driven by rising demand in pharmaceutical synthesis, stringent regulatory requirements for high-purity chemicals, and the expansion of advanced drug manufacturing and specialty applications. These factors boost the adoption of high-quality glyoxal in APIs and innovative drug formulations.

By Purity

On the basis of purity, the Middle East and Africa Glyoxal Market is segmented into 90%–99%, 40%–60%, and Others.

By 2026, the 40%–60% purity segment is expected to dominate the market, accounting for 73.25% of the total share. This segment’s prominence is attributed to its superior performance, higher reactivity, and suitability for advanced applications across pharmaceuticals, specialty resins, textiles, and cosmetics. Its consistent quality, along with adherence to stringent industry standards, further drives strong and sustained demand. Additionally, the balance between effectiveness and cost-efficiency makes this purity range highly preferred by manufacturers. As a result, the 40%–60% purity segment is projected to remain the primary contributor to growth in the Middle East and Africa Glyoxal Market.

The 90%-99% purity segment in the Middle East and Africa Glyoxal Market is expected to witness the fastest growth from 2026 to 2033, driven by its widespread use in pharmaceutical and specialty chemical applications that require high-purity glyoxal, along with increasing demand for advanced drug formulations and regulatory-compliant production processes.

By Production Process

On the basis of production process, the Middle East and Africa Glyoxal Market is segmented into Catalytic Oxidation of Ethylene Glycol, Oxidation of Acetylene, and Others.

By 2026, the Catalytic Oxidation of Ethylene Glycol segment is expected to dominate the market, accounting for 90.15% of the total share. This segment’s dominance is driven by its higher production efficiency, better yield control, and lower impurity levels compared to acetylene-based processes. Additionally, it offers improved safety and is more environmentally compliant, making it highly suitable for large-scale manufacturing. The cost-effectiveness and scalability of this method further reinforce its preference among manufacturers. As a result, the catalytic oxidation route is poised to remain the primary driver of growth in the Middle East and Africa Glyoxal Market.

The “Oxidation of Acetylene” production process segment in the Middle East and Africa Glyoxal Market is expected to witness the fastest growth from 2026 to 2033, driven by its ability to produce high-purity glyoxal suitable for pharmaceutical and specialty chemical applications, along with rising demand for advanced drug formulations and compliance with strict quality and regulatory standards.

By Packaging

On the basis of packaging, the Middle East and Africa Glyoxal Market is segmented into Drums, Composite IBC, Bulk, Jerrycans, and Bottles.

By 2026, the Drums segment is expected to dominate the market, accounting for 41.53% of the total share. This dominance is attributed to its versatility, ease of handling, and safe storage, particularly for small-quantity applications. Bottles are especially suitable for pharmaceuticals, cosmetics, and specialty chemical uses, where precision and safety are critical. Additionally, their wide availability and cost-effective production further drive strong adoption across industries. The convenience and reliability of bottle packaging make it a preferred choice for manufacturers and end-users alike.

The “Composite IBC” packaging segment in the Middle East and Africa Glyoxal Market is expected to witness the fastest growth from 2026 to 2033, driven by its efficiency in storing and transporting bulk chemicals, enhanced safety and chemical resistance, and increasing demand from pharmaceutical, specialty chemical, and industrial users who require reliable, large-capacity packaging solutions.

By Application

On the basis of packaging, the Middle East and Africa Glyoxal Market is segmented into Application Cross-Linking, Chemical Intermediates, Others.

By 2026, the Cross-Linking segment is expected to dominate the market, accounting for 66.19% of the total share. This dominance is attributed to its versatility, ease of handling, and safe storage, particularly for small-quantity applications. Bottles are especially suitable for pharmaceuticals, cosmetics, and specialty chemical uses, where precision and safety are critical. Additionally, their wide availability and cost-effective production further drive strong adoption across industries. The convenience and reliability of bottle packaging make it a preferred choice for manufacturers and end-users alike.

The Chemical Intermediates application segment in the Middle East and Africa Glyoxal Market is expected to be the fastest-growing segment from 2026 to 2033, driven by increasing demand for resins, polymers, and specialty chemicals, the expansion of the chemical manufacturing industry, and the use of glyoxal as a versatile cross-linking and reactive intermediate in industrial and specialty applications.

By End-Use Chemicals

On the basis of end-use chemicals, the Middle East and Africa Glyoxal Market is segmented into Dihydroxyethylene Urea (DHEU), 2-Imidazolidinone, Glyoxalated Polyacrylamide (GPAM), Glyoxylic Acid, Glyoxalated Starch, Glyoxal Phenol Resin, Glyoxal Urea Resin, Ethylene Glycol Diformate, Urea-Glyoxal Concentrate, Quinoxaline Derivatives, Methylol Glyoxal, Glyoxal-Bis(2-Hydroxyanil), Glyoxal Sodium Bisulfite, Quinoxaline, 2-Methylimidazole, Imidazole, Glycoluril, Allantoin, and Tetramethylol Acetylenediurea.

By 2026, the Dihydroxyethylene Urea (DHEU) segment is expected to dominate the market, accounting for 22.12% of the total share. Its dominance is driven by its wide applicability in textile finishing, paper treatment, and resin manufacturing. The segment benefits from high reactivity, consistent performance, and compatibility with various industrial processes. Additionally, growing demand for high-quality textiles and specialty chemical products in the Middle East and Africa region supports its strong market position. DHEU’s cost-effectiveness and efficiency further reinforce its preference among manufacturers and end-users.

The 2-Imidazolidinone end-use chemicals segment in the Middle East and Africa Glyoxal Market is expected to be the fastest-growing from 2026 to 2033, driven by its increasing use in pharmaceuticals, agrochemicals, and specialty chemical applications. Its growth is fueled by the rising demand for high-purity glyoxal as a key intermediate in synthesizing 2-Imidazolidinone for advanced formulations and regulatory-compliant chemical production.

By End-User

On the basis of end-user, the Middle East and Africa Glyoxal Market is segmented into Textile, Pulp and Paper, Leather, Paints and Coatings, Water Treatment, Pharmaceuticals, Household Products, Cosmetics and Personal Care, Packaging, Electrical and Electronics, Oil and Gas, and Others.

By 2026, the Textile segment is expected to dominate the market, accounting for 37.05% of the total share. This growth is driven by its widespread use in fabric finishing, wrinkle resistance, and crease-proof treatments. The increasing demand for durable and high-quality textiles, coupled with rapid expansion in the apparel and home furnishing industries, further supports market growth. Additionally, rising consumer preference for premium and long-lasting fabrics boosts the adoption of glyoxal-based solutions. As a result, the Textile segment is poised to remain the key contributor to the Middle East and Africa Glyoxal Market.

The Pulp and Paper end-user segment in the Middle East and Africa Glyoxal Market is expected to be the fastest-growing from 2026 to 2033, driven by the increasing demand for wet-strength resins and chemical additives that enhance paper durability and quality. Growth is supported by the expansion of the paper and packaging industry and the shift toward high-performance, sustainable paper products.

Middle East and Africa Glyoxal Market Insight

- Saudi Arabia dominates the regional market, driven by its robust petrochemical base, large-scale manufacturing capacity, and strong downstream demand. Ongoing investment in sustainable and high-purity chemical solutions underpins long-term regional market expansion.

- The Saudi Arabia Middle East and Africa Glyoxal Market is rapidly expanding, driven by large-scale chemical manufacturing capacity, strong demand from textiles, paper, construction chemicals, and agrochemicals, and supportive government policies. Technological advancements and cost-competitive production position China as a major Middle East and Africa glyoxal supplier with significant growth potential.

U.A.E Middle East and Africa Glyoxal Market Insight

The U.A.E Middle East and Africa Glyoxal Market is witnessing robust growth, supported by expanding textile and paper industries, rising chemical manufacturing activity, and increasing adoption of glyoxal in resins and specialty applications. Government initiatives promoting domestic chemical production and industrial growth continue to enhance market momentum.

Middle East and Africa Glyoxal Market Share

The Glyoxal is primarily led by well-established companies, including:

- Amzole India Pvt. Ltd (India)

- Asis Scientific Pty Ltd (Australia)

- Ataman Chemicals (India)

- BASF SE (Germany)

- Bidvest Chemical (South Africa)

- Bisley Asia (M) Sdn Bhd (Malaysia)

- Eastman Chemical Company (U.S.)

- Fluorochem Limited (U.K.)

- Fujifilm Wako Pure Chemical Corporation (Japan)

- Glentham Life Sciences Limited (U.K.)

- GetChem Co., Ltd. (China)

- Hanna Instruments Ltd (U.S.)

- Himedia Laboratories (India)

- Kanto Kagaku (Japan)

- Kemira Oyj (Finland)

- Merck KGaA (Germany)

- Meru Chem Pvt. Ltd (India)

- Muby Chemicals (India)

- Multichem Specialities Private Limited (India)

- Oakwood Products Inc. (U.S.)

- Otto Chemie Pvt. Ltd (India)

- Oxford Lab Fine Chem LLP (India)

- Santa Cruz Biotechnology Inc. (U.S.)

- Sasol (South Africa)

- Silver Fern Chemical, Inc. (U.S.)

- Thermo Fisher Scientific Inc. (U.S.)

- Univar Solutions LLC (U.S.)

- Weylchem International GmbH (Germany)

- Zhishang Chemical (China)

Latest Developments in Middle East and Africa Glyoxal Market

- In October 2025, Multichem Specialities Private Limited was recognized among the Top 10 Specialty Chemical Distributors 2025 by Industry Outlook Magazine, highlighting its quality, innovation, and dependable service in the specialty chemicals sector. In July 2025, the company also organized a successful blood donation drive in collaboration with Breach Candy Hospital Trust, engaging employees and community members to support healthcare needs.

- In February 2024, Multichem Specialities Private Limited participated in Vitafoods India, strengthening its presence in the nutraceuticals and specialty ingredients segment while engaging with customers and partners to showcase its expanding chemical portfolio.

- In October 2024, Otto Chemie Pvt. Ltd. expanded its portfolio of high-purity laboratory chemicals and reagents, enhancing its presence in pharmaceutical, research, and industrial sectors. The company also strengthened its distribution network and supply chain capabilities to meet growing demand across India and international markets.

- In July 2024, Otto Chemie Pvt. Ltd. organized a blood donation and health awareness drive in collaboration with local hospitals, reflecting the company’s commitment to community welfare and employee participation in social responsibility initiatives.

- In March 2025, Oxford Lab Fine Chem LLP implemented eco-friendly packaging solutions and optimized waste management practices in its production and distribution processes, reinforcing the company’s commitment to sustainable and responsible chemical manufacturing.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Middle East And Africa Glyoxal Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Middle East And Africa Glyoxal Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Middle East And Africa Glyoxal Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.