Middle East And Africa Passive Fire Protection Coating Market

Market Size in USD Thousand

CAGR :

%

USD

143,277.58 Thousand

USD

184,292.51 Thousand

2023

2031

USD

143,277.58 Thousand

USD

184,292.51 Thousand

2023

2031

| 2024 –2031 | |

| USD 143,277.58 Thousand | |

| USD 184,292.51 Thousand | |

|

|

|

|

Middle East Passive Fire Protection Coatings Market Analysis and Insights

The Middle East passive fire protection coatings market report provides details of market share, new developments, and the impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, products approvals, strategic decisions, product launches, and technological innovations in the market. To understand the analysis and the market scenario, contact us for an analyst brief, our team will help you create a revenue impact solution to achieve your desired goal.

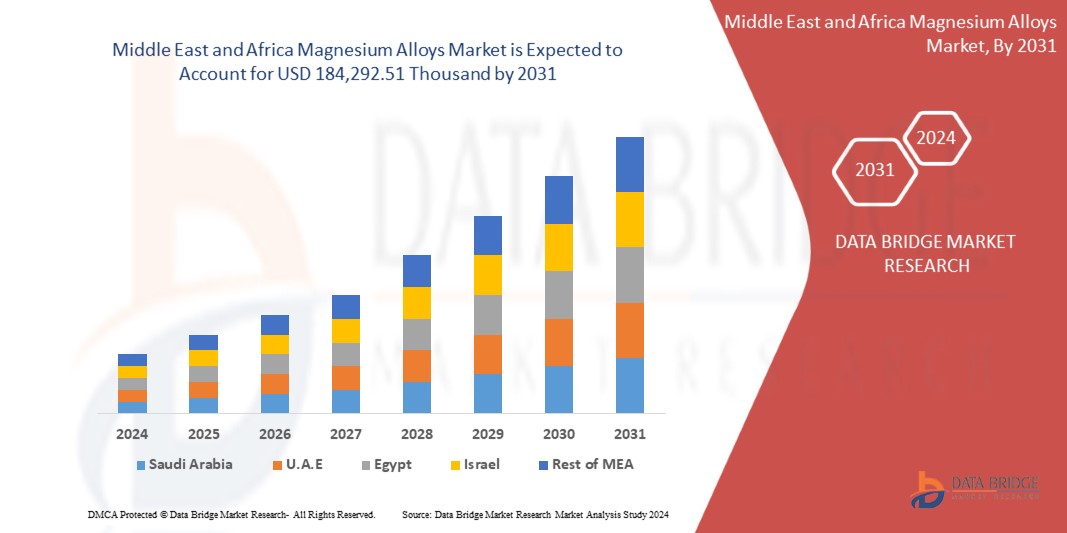

Data Bridge Market Research analyzes that Middle East passive fire protection coatings market is expected to reach USD 184,292.51 thousand by 2031 from USD 143,277.58 thousand in 2023, growing with a substantial CAGR of 3.4% in the forecast period of 2024 to 2031.

|

Report Metric |

Details |

|

Forecast Period |

2024 to 2031 |

|

Base Year |

2023 |

|

Historic Years |

2022 (Customizable to 2016 - 2021) |

|

Quantitative Units |

Revenue in USD Thousand and Volume in Tons |

|

Segments Covered |

Product Type (Cementitious Material and Intumescent Coating), Technology (Water-Based Protection Coating and Solvent-Based Protection Coating), End-Use (Building and Construction, Oil & Gas, Automotive, Aerospace & Defense, Electrical and Electronics, Textile, Furniture, and Others) |

|

Countries Covered |

Saudi Arabia, United Arab Emirates, Kuwait, Israel, Oman, Bahrain, Lebanon, Egypt, Rest of Middle East |

|

Market Players Covered |

3M, svt Group of Companies, Hempel A/S, The Sherwin-Williams Company, Hilti, Carboline, Akzo Nobel N.V., PPG Industries, Inc., Kansai Paint Co., Ltd., Etex Group, Isolatek International, GCP Applied Technologies Inc. (A Subsidiary of Saint-Gobain), Jotun, Sika AG, Arabian vermiculite industries, CHARCOAT PASSIVE FIRE PROTECTION, and Lanexis Enterprises (P) Ltd. among others |

Market Definition

Protection against fire coatings is made up of various fillers and flame retardants. It is utilized to keep fire flames from spreading quickly across the surface and to limit the amount of time that they are exposed to extreme heat. It also reduces the creation of gases that result from the combustion of materials. Passive fire protection (PFP) is components of a building or structure that slows or impedes the fire or smoke without system activation, and usually without movement. The instances of passive systems include floor-ceilings and roofs, fire doors, windows, and wall assemblies, fire-resistant coatings, and other fire and smoke control assemblies. Passive fire protection systems can include active components such as fire dampers.

Middle East Passive Fire Protection Coatings Market Dynamics

Drivers

- Rising Use of Passive Fire Protection Coatings in Various Industries

Passive fire protection systems are composed of tools and other engineered solutions that reduce fire occurrence or delay their spread in a facility for a certain period. It reduces the extent of damage, risk to lives, and gives people more time to vacate the establishment and ample time for emergency services to respond and act. Passive fire protection is commonly used in high rise buildings, houses, hotels, hospitals, industrial facilities, schools, warehouses, railways, car parks, railways, bridges, supermarkets, and on- and off-shore hydrocarbons. Passive fire protection coatings are increasingly important in the oil and gas industry. Applied to industrial oil and gas installations, the coatings expand to form an insulating layer of carbon char when exposed to high temperatures. This enables the steel to maintain its load-bearing capacity for up to four hours longer during a fire, giving people valuable time to escape the building and for firefighters to put the fire out.

- Increasing Demand for Water Based Fire Protection Coatings

The Middle East construction and infrastructure sectors are booming, creating a substantial demand for fire protection coatings. Water-based coatings offer cost-effective solutions due to their lower Volatile Organic Compound (VOCs) content and ease of application, making them economically viable for large-scale projects.

Water-based coatings have an increasing appeal due to their economic advantages. While water-based coatings may have a greater initial cost than solvent-based coatings, they provide long-term cost benefits due to their durability, ease of maintenance, and lower environmental effects. In the developing construction and infrastructure sectors of the Middle East, where large-scale projects are typical, the cost-effectiveness of water-based coatings appeals to developers and project managers.

Opportunities

- Technological Advancement in Oil and Gas Exploration Activities

Technological advancements in seismic imaging, geophysical surveys, and remote sensing techniques have enabled more precise and efficient oil and gas exploration. This has led to an increase in exploration activities in the Middle East, creating a higher demand for passive fire protection coatings to safeguard critical infrastructure in the oil and gas sector. Oil and gas exploration often takes place in harsh environments, including offshore drilling platforms and remote onshore locations. Advanced passive fire protection coatings are essential to mitigate the risk of fire hazards in these challenging conditions, ensuring the safety and integrity of structures.

Oil and gas exploration often takes place in harsh environments, including offshore drilling platforms and remote onshore locations. Advanced passive fire protection coatings are essential to mitigate the risk of fire hazards in these challenging conditions, ensuring the safety and integrity of structures. The incorporation of advanced materials and technologies in passive fire protection coatings enhances their durability and longevity. As exploration activities expand, there is a need for coatings that can withstand the harsh Middle Eastern climate and provide long-term protection against fire risks.

Restraints/Challenges

- Improper Installation of Passive Fire Protection Coating

Inadequate installation undermines the efficacy of passive fire protection coatings, reducing their ability to contain and prevent the spread of fires. In high-risk industries such as oil and gas, petrochemicals, and infrastructure, where severe fire safety regulations are vital, any errors in installation can have disastrous effects, including loss of life, property damage, and environmental risks. Such occurrences undermine trust in passive fire protection coatings and discourage potential customers from investing in these technologies, limiting market growth.

Furthermore, incorrect installation can result in noncompliance with regulatory requirements and building rules, exposing developers, contractors, and building owners to legal liability and penalties. Governments in the Middle East enforce stringent fire safety laws, which require the proper installation of passive fire protection coatings in specific areas. Failure to comply with these rules jeopardizes not only safety, but also corporate operations and project timetables, discouraging stakeholders from investing in passive fire protection coatings.

- Competition from Alternative Fire Protection Solutions

The availability of cheaper alternatives in the market are challenges for the market growth and eventually reduce the consumption of fire protective coatings. Fire protective coatings are comparatively costlier than other fire extinguisher (active fire protection coatings) products as these coatings are applied or sprayed which requires human resources as well as time thus making the coatings costlier. These systems involve the use of active measures, such as sprinklers, water mist systems, or gas-based suppression systems, to quickly detect and suppress fires. They are designed to actively combat and extinguish fires in their early stages. In contrast to passive solutions such as coatings, active suppression systems provide immediate and direct intervention. Construction materials with inherent fire-resistant properties are another alternative. These materials, such as fire-resistant gypsum boards, fire-retardant-treated wood, or concrete with fire-resistant additives, are integrated into the building's structure. They offer a passive approach by inherently resisting the spread of fire without the need for additional coatings.

Recent Development

- In February 2024, AkzoNobel concluded a significant capacity expansion at its Powder Coatings facility in Como, Italy. This expansion, involving a USD 21 million investment, is expected to enhance the company's ability to meet the growing demand for its products in Europe, the Middle East and Africa (EMEA). The completion of four new manufacturing lines, specifically two for automotive primers and two for architectural coatings, marks a substantial milestone in the project. Additionally, the incorporation of new bonding equipment lines further guarantees that the manufactured products not only meet but exceed industry standards, reinforcing AkzoNobel's commitment to delivering high-quality coatings to its customers in the EMEA region

- In December 2023, Hempel A/S announced the launch of HEET Dynamic, an innovative new coating software specially designed to make intumescent coating estimations on steel sections quicker, easier, and accurate for structural engineers and estimators. This will help the engineers to investigate the steel structures and other surfaces where fire-intumescent coatings are applied more accurately, making it a much-required tool. This will improve the company’s revenue eventually

Middle East Passive Fire Protection Coatings Market Scope

The Middle East passive fire protection coatings market is categorized based on product type, technology, and end-use. The growth amongst these segments will help you analyze major growth segments in the industries and provide the users with a valuable market overview and market insights to make strategic decisions to identify core market applications.

Product Type

- Intumescent Coating

- Cementitious Material

On the basis of product type, the market is segmented into intumescent coating and cementitious material.

Technology

- Solvent-Based Protection Coating

- Water-Based Protection Coating

On the basis of technology, the market is segmented into solvent-based protection coating and water-based protection coating.

End-Use

- Building and Construction

- Oil & Gas

- Automotive

- Aerospace & Defense

- Electrical and Electronics

- Textile

- Furniture

- Others

On the basis of end-use, the market is segmented into building & construction, oil & gas, automotive, aerospace & defense, electrical and electronics, textile, furniture, and others.

Middle East Passive Fire Protection Coatings Market: Regional Analysis/Insights

The Middle East passive fire protection coatings market is segmented on the basis of product type, technology, and end-use.

The countries covered in the Middle East passive fire protection coatings market are Saudi Arabia, United Arab Emirates, Kuwait, Israel, Oman, Bahrain, Lebanon, Egypt, and rest of Middle East.

Saudi Arabia is expected to dominate the market due to its booming construction sector, stringent fire safety regulations, and extensive investments in infrastructure projects. The country's large-scale developments, such as commercial complexes, industrial facilities, and residential buildings, drive significant demand for fire protection solutions.

The country section of the report also provides individual market-impacting factors and market regulation changes that impact the market's current and future trends. Data point downstream and upstream value chain analysis, technical trends, porter's five forces analysis, and case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of Middle East & Africa brands and their challenges faced due to large or scarce competition from local and domestic brands, the impact of domestic tariffs, and trade routes are considered while providing forecast analysis of the country data.

Middle East Passive Fire Protection Coatings Market : Competitive Landscape and Share Analysis

The Middle East passive fire protection coatings market competitive landscape provides details by competitors. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, production sites and facilities, company strengths and weaknesses, product launch, product trials pipelines, product approvals, patents, product width and breadth, application dominance, technology lifeline curve. The above data points provided are only related to the company’s focus on the Market.

Some of the major players operating in the Middle East passive fire protection coatings market are 3M, svt Group of Companies, Hempel A/S, The Sherwin-Williams Company, Hilti, Carboline, Akzo Nobel N.V., PPG Industries, Inc., Kansai Paint Co., Ltd., Etex Group, Isolatek International, GCP Applied Technologies Inc. (A Subsidiary of Saint-Gobain), Jotun, Sika AG, Arabian vermiculite industries, CHARCOAT PASSIVE FIRE PROTECTION, and Lanexis Enterprises (P) Ltd. among others.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET

1.4 LIMITATIONS

1.5 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 YEARS CONSIDERED FOR THE STUDY

2.3 CURRENCY AND PRICING

2.4 GEOGRAPHIC SCOPE

2.5 DBMR TRIPOD DATA VALIDATION MODEL

2.6 DBMR MARKET SWOT MODEL

2.7 TYPE LIFE LINE CURVE

2.8 MULTIVARIATE MODELING

2.9 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.1 DBMR MARKET POSITION GRID

2.11 MARKET END-USE COVERAGE GRID

2.12 DBMR MARKET CHALLENGE MATRIX

2.13 DBMR VENDOR SHARE ANALYSIS

2.14 SECONDARY SOURCES

2.15 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 PESTLE ANALYSIS

4.1.1 POLITICAL FACTORS

4.1.2 ECONOMIC FACTORS

4.1.3 SOCIAL FACTORS

4.1.4 TECHNOLOGICAL FACTORS

4.1.5 LEGAL FACTORS

4.1.6 ENVIRONMENTAL FACTORS

4.2 IMPORT EXPORT SCENARIO

4.3 PRODUCTION CONSUMPTION ANALYSIS

4.3.1 ESTIMATED PRODUCTION CONSUMPTION ANALYSIS

4.4 VENDOR SELECTION CRITERIA

4.5 SUPPLY CHAIN ANALYSIS

4.5.1 RAW MATERIAL PROCUREMENT

4.5.2 MANUFACTURING AND PACKING

4.5.3 MARKETING AND DISTRIBUTION

4.5.4 END USERS

4.6 TECHNOLOGICAL ADVANCEMENT BY MANUFACTURERS

4.7 RAW MATERIAL COVERAGE

4.7.1 RAW MATERIAL PRODUCTION COVERAGE

4.7.2 AMMONIUM POLYPHOSPHATE (APP)

4.7.3 CHLORINATED PARAFFIN 70% (SOLID CP)

4.7.4 EXPANDABLE GRAPHITE

4.7.5 MELAMINE

5 REGULATION COVERAGE

6 MARKET OVERVIEW

6.1 DRIVERS

6.1.1 RISING USE OF PASSIVE FIRE PROTECTION COATINGS IN VARIOUS INDUSTRIES

6.1.2 INCREASING DEMAND FOR WATER BASED FIRE PROTECTION COATINGS

6.1.3 GOVERNMENT REGULATIONS FAVORING THE FIRE PROTECTION COATINGS

6.2 RESTRAINTS

6.2.1 IMPROPER INSTALLATION OF PASSIVE FIRE PROTECTION COATING

6.2.2 USE OF HARMFUL CHEMICALS IN MANUFACTURING

6.3 OPPORTUNITIES

6.3.1 TECHNOLOGICAL ADVANCEMENT IN OIL AND GAS EXPLORATION ACTIVITIES

6.3.2 INCREASE IN RESEARCH AND DEVELOPMENT OF NEW PRODUCTS

6.4 CHALLENGES

6.4.1 COMPETITION FROM ALTERNATIVE FIRE PROTECTION SOLUTIONS

6.4.2 FAILURE IN DIAGNOSING FIREPROOFING

7 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE

7.1 OVERVIEW

7.2 INTUMESCENT COATING

7.3 CEMENTITIOUS MATERIAL

8 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY

8.1 OVERVIEW

8.2 SOLVENT-BASED PROTECTION COATING

8.3 WATER-BASED PROTECTION COATING

9 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE

9.1 OVERVIEW

9.2 BUILDING AND CONSTRUCTION

9.3 OIL & GAS

9.4 FURNITURE

9.5 AUTOMOTIVE

9.6 AEROSPACE & DEFENSE

9.7 ELECTRICAL AND ELECTRONICS

9.8 TEXTILE

9.9 OTHERS

10 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY COUNTRY

10.1 SAUDI ARABIA

10.2 UNITED ARAB EMIRATES

10.3 KUWAIT

10.4 ISRAEL

10.5 OMAN

10.6 BAHRAIN

10.7 LEBANON

10.8 EGYPT

10.9 REST OF MIDDLE EAST

11 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET-: COMPANY LANDSCAPE

11.1 COMPANY SHARE ANALYSIS: INTERNATIONAL VS MIDDLE EAST REGION

11.2 EXPANSION

11.3 COLLABORATION

11.4 CERTIFICATION

11.5 CERTIFICATION

11.6 ALLIANCE

11.7 PRODUCT LAUNCH

11.8 COMMITMENT

11.9 ACQUISITION

12 SWOT ANALYSIS

13 COMPANY PROFILES

13.1 GCP APPLIED TECHNOLOGIES INC.

13.1.1 COMPANY SNAPSHOT

13.1.2 PRODUCT PORTFOLIO

13.1.3 RECENT DEVELOPMENT

13.2 ETEX GROUP

13.2.1 COMPANY SNAPSHOT

13.2.2 PRODUCT PORTFOLIO

13.2.3 RECENT DEVELOPMENT

13.3 PPG INDUSTRIES, INC.

13.3.1 COMPANY SNAPSHOT

13.3.2 REVENUE ANALYSIS

13.3.3 PRODUCT PORTFOLIO

13.3.4 RECENT DEVELOPMENTS

13.4 THE SHERWIN-WILLIAMS COMPANY

13.4.1 COMPANY SNAPSHOT

13.4.2 REVENUE ANALYSIS

13.4.3 PRODUCT PORTFOLIO

13.4.4 RECENT DEVELOPMENTS

13.5 3M

13.5.1 COMPANY SNAPSHOT

13.5.2 REVENUE ANALYSIS

13.5.3 PRODUCT PORTFOLIO

13.5.4 RECENT DEVELOPMENT

13.6 AKZO NOBEL N.V.

13.6.1 COMPANY SNAPSHOT

13.6.2 REVENUE ANALYSIS

13.6.3 PRODUCT PORTFOLIO

13.6.4 RECENT DEVELOPMENTS

13.7 ARABIAN VERMICULITE INDUSTRIES

13.7.1 COMPANY SNAPSHOT

13.7.2 PRODUCT PORTFOLIO

13.7.3 RECENT DEVELOPMENT

13.8 CARBOLINE

13.8.1 COMPANY SNAPSHOT

13.8.2 PRODUCT PORTFOLIO

13.8.3 RECENT DEVELOPMENTS

13.9 CHAROAT PASSIVE FIRE PROTECTION

13.9.1 COMPANY SNAPSHOT

13.9.2 PRODUCT PORTFOLIO

13.9.3 RECENT DEVELOPMENT

13.1 HEMPEL A/S

13.10.1 COMPANY SNAPSHOT

13.10.2 REVENUE ANALYSIS

13.10.3 PRODUCT PORTFOLIO

13.10.4 RECENT DEVELOPMENTS

13.11 HILTI

13.11.1 COMPANY SNAPSHOT

13.11.2 REVENUE ANALYSIS

13.11.3 PRODUCT PORTFOLIO

13.11.4 RECENT DEVELOPMENT

13.12 ISOLATEK INTERNATIONAL

13.12.1 COMPANY SNAPSHOT

13.12.2 PRODUCT PORTFOLIO

13.12.3 RECENT DEVELOPMENT

13.13 JOTUN

13.13.1 COMPANY SNAPSHOT

13.13.2 REVENUE ANALYSIS

13.13.3 PRODUCT PORTFOLIO

13.13.4 RECENT DEVELOPMENTS

13.14 KANSAI PAINT CO., LTD.

13.14.1 COMPANY SNAPSHOT

13.14.2 REVENUE ANALYSIS

13.14.3 PRODUCT PORTFOLIO

13.14.4 RECENT DEVELOPMENTS

13.15 LANEXIS ENTERPRISES (P) LTD.

13.15.1 COMPANY SNAPSHOT

13.15.2 PRODUCT PORTFOLIO

13.15.3 RECENT DEVELOPMENT

13.16 SIKA AG

13.16.1 COMPANY SNAPSHOT

13.16.2 REVENUE ANALYSIS

13.16.3 PRODUCT PORTFOLIO

13.16.4 RECENT DEVELOPMENTS

13.17 SVT GROUP OF COMPANIES

13.17.1 COMPANY SNAPSHOT

13.17.2 PRODUCT PORTFOLIO

13.17.3 RECENT DEVELOPMENT

14 QUESTIONNAIRE

15 RELATED REPORTS

List of Table

TABLE 1 REGULATORY FRAMEWORK

TABLE 2 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 3 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

TABLE 4 MIDDLE EAST INTUMESCENT COATINGS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 5 MIDDLE EAST CEMENTITIOUS MATERIAL IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 6 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (USD THOUSAND)

TABLE 7 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (TONS)

TABLE 8 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD THOUSAND)

TABLE 9 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (TONS)

TABLE 10 MIDDLE EAST BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TYPE, 2022-2031 (USD THOUSAND)

TABLE 11 MIDDLE EAST BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 12 MIDDLE EAST OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY CATEGORY, 2022-2031 (USD THOUSAND)

TABLE 13 MIDDLE EAST OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 14 MIDDLE EAST FURNITURE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 15 MIDDLE EAST AUTOMOTIVE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 16 MIDDLE EAST AEROSPACE & DEFENSE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 17 MIDDLE EAST ELECTRICAL AND ELECTRONICS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 18 MIDDLE EAST TEXTILE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 19 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY COUNTRY, 2022-2031 (USD THOUSAND)

TABLE 20 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY COUNTRY, 2022-2031 (TONS)

TABLE 21 SAUDI ARABIA PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 22 SAUDI ARABIA PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

TABLE 23 SAUDI ARABIA INTUMESCENT COATINGS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 24 SAUDI ARABIA CEMENTITIOUS MATERIAL IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 25 SAUDI ARABIA PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (USD THOUSAND)

TABLE 26 SAUDI ARABIA PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (TONS)

TABLE 27 SAUDI ARABIA PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD THOUSAND)

TABLE 28 SAUDI ARABIA PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (TONS)

TABLE 29 SAUDI ARABIA BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TYPE, 2022-2031 (USD THOUSAND)

TABLE 30 SAUDI ARABIA BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 31 SAUDI ARABIA OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY CATEGORY, 2022-2031 (USD THOUSAND)

TABLE 32 SAUDI ARABIA OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 33 SAUDI ARABIA FURNITURE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 34 SAUDI ARABIA AUTOMOTIVE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 35 SAUDI ARABIA AEROSPACE & DEFENSE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 36 SAUDI ARABIA ELECTRICAL AND ELECTRONICS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 37 SAUDI ARABIA TEXTILE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 38 UNITED ARAB EMIRATES PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 39 UNITED ARAB EMIRATES PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

TABLE 40 UNITED ARAB EMIRATES INTUMESCENT COATINGS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 41 UNITED ARAB EMIRATES CEMENTITIOUS MATERIAL IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 42 UNITED ARAB EMIRATES PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (USD THOUSAND)

TABLE 43 UNITED ARAB EMIRATES PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (TONS)

TABLE 44 UNITED ARAB EMIRATES PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD THOUSAND)

TABLE 45 UNITED ARAB EMIRATES PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (TONS)

TABLE 46 UNITED ARAB EMIRATES BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TYPE, 2022-2031 (USD THOUSAND)

TABLE 47 UNITED ARAB EMIRATES BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 48 UNITED ARAB EMIRATES OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY CATEGORY, 2022-2031 (USD THOUSAND)

TABLE 49 UNITED ARAB EMIRATES OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 50 UNITED ARAB EMIRATES FURNITURE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 51 UNITED ARAB EMIRATES AUTOMOTIVE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 52 UNITED ARAB EMIRATES AEROSPACE & DEFENSE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 53 UNITED ARAB EMIRATES ELECTRICAL AND ELECTRONICS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 54 UNITED ARAB EMIRATES TEXTILE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 55 KUWAIT PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 56 KUWAIT PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

TABLE 57 KUWAIT INTUMESCENT COATINGS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 58 KUWAIT CEMENTITIOUS MATERIAL IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 59 KUWAIT PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (USD THOUSAND)

TABLE 60 KUWAIT PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (TONS)

TABLE 61 KUWAIT PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD THOUSAND)

TABLE 62 KUWAIT PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (TONS)

TABLE 63 KUWAIT BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TYPE, 2022-2031 (USD THOUSAND)

TABLE 64 KUWAIT BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 65 KUWAIT OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY CATEGORY, 2022-2031 (USD THOUSAND)

TABLE 66 KUWAIT OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 67 KUWAIT FURNITURE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 68 KUWAIT AUTOMOTIVE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 69 KUWAIT AEROSPACE & DEFENSE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 70 KUWAIT ELECTRICAL AND ELECTRONICS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 71 KUWAIT TEXTILE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 72 ISRAEL PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 73 ISRAEL PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

TABLE 74 ISRAEL INTUMESCENT COATINGS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 75 ISRAEL CEMENTITIOUS MATERIAL IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 76 ISRAEL PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (USD THOUSAND)

TABLE 77 ISRAEL PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (TONS)

TABLE 78 ISRAEL PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD THOUSAND)

TABLE 79 ISRAEL PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD TONS)

TABLE 80 ISRAEL BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TYPE, 2022-2031 (USD THOUSAND)

TABLE 81 ISRAEL BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 82 ISRAEL OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY CATEGORY, 2022-2031 (USD THOUSAND)

TABLE 83 ISRAEL OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 84 ISRAEL FURNITURE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 85 ISRAEL AUTOMOTIVE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 86 ISRAEL AEROSPACE & DEFENSE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 87 ISRAEL ELECTRICAL AND ELECTRONICS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 88 ISRAEL TEXTILE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 89 OMAN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 90 OMAN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

TABLE 91 OMAN INTUMESCENT COATINGS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 92 OMAN CEMENTITIOUS MATERIAL IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 93 OMAN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (USD THOUSAND)

TABLE 94 OMAN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (TONS)

TABLE 95 OMAN PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD THOUSAND)

TABLE 96 OMAN PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (TONS)

TABLE 97 OMAN BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TYPE, 2022-2031 (USD THOUSAND)

TABLE 98 OMAN BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 99 OMAN OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY CATEGORY, 2022-2031 (USD THOUSAND)

TABLE 100 OMAN OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 101 OMAN FURNITURE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 102 OMAN AUTOMOTIVE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 103 OMAN AEROSPACE & DEFENSE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 104 OMAN ELECTRICAL AND ELECTRONICS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 105 OMAN TEXTILE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 106 BAHRAIN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 107 BAHRAIN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

TABLE 108 BAHRAIN INTUMESCENT COATINGS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 109 BAHRAIN CEMENTITIOUS MATERIAL IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 110 BAHRAIN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (USD THOUSAND)

TABLE 111 BAHRAIN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (TONS)

TABLE 112 BAHRAIN PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD THOUSAND)

TABLE 113 BAHRAIN PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (TONS)

TABLE 114 BAHRAIN BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TYPE, 2022-2031 (USD THOUSAND)

TABLE 115 BAHRAIN BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 116 BAHRAIN OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY CATEGORY, 2022-2031 (USD THOUSAND)

TABLE 117 BAHRAIN OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 118 BAHRAIN FURNITURE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 119 BAHRAIN AUTOMOTIVE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 120 BAHRAIN AEROSPACE & DEFENSE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 121 BAHRAIN ELECTRICAL AND ELECTRONICS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 122 BAHRAIN TEXTILE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 123 LEBANON PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 124 LEBANON PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

TABLE 125 LEBANON INTUMESCENT COATINGS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 126 LEBANON CEMENTITIOUS MATERIAL IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 127 LEBANON PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (USD THOUSAND)

TABLE 128 LEBANON PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (TONS)

TABLE 129 LEBANON PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD THOUSAND)

TABLE 130 LEBANON PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (TONS)

TABLE 131 LEBANON BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TYPE, 2022-2031 (USD THOUSAND)

TABLE 132 LEBANON BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 133 LEBANON OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY CATEGORY, 2022-2031 (USD THOUSAND)

TABLE 134 LEBANON OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 135 LEBANON FURNITURE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 136 LEBANON AUTOMOTIVE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 137 LEBANON AEROSPACE & DEFENSE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 138 LEBANON ELECTRICAL AND ELECTRONICS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 139 LEBANON TEXTILE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 140 EGYPT PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 141 EGYPT PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

TABLE 142 EGYPT INTUMESCENT COATINGS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 143 EGYPT CEMENTITIOUS MATERIAL IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 144 EGYPT PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (USD THOUSAND)

TABLE 145 EGYPT PASSIVE FIRE PROTECTION COATINGS MARKET, BY TECHNOLOGY, 2022-2031 (TONS)

TABLE 146 EGYPT PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (USD THOUSAND)

TABLE 147 EGYPT PASSIVE FIRE PROTECTION COATINGS MARKET, BY END-USE, 2022-2031 (TONS)

TABLE 148 EGYPT BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY TYPE, 2022-2031 (USD THOUSAND)

TABLE 149 EGYPT BUILDING AND CONSTRUCTION IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 150 EGYPT OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY CATEGORY, 2022-2031 (USD THOUSAND)

TABLE 151 EGYPT OIL & GAS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 152 EGYPT FURNITURE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 153 EGYPT AUTOMOTIVE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 154 EGYPT AEROSPACE & DEFENSE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 155 EGYPT ELECTRICAL AND ELECTRONICS IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 156 EGYPT TEXTILE IN PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 157 REST OF MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (USD THOUSAND)

TABLE 158 REST OF MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET, BY PRODUCT TYPE, 2022-2031 (TONS)

List of Figure

FIGURE 1 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET : SEGMENTATION

FIGURE 2 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: DATA VALIDATION MODEL

FIGURE 3 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: DROC ANALYSIS

FIGURE 4 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: REGIONAL VS COUNTRY MARKET ANALYSIS

FIGURE 5 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: COMPANY RESEARCH ANALYSIS

FIGURE 6 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: PRODUCT TYPE LIFE LINE CURVE

FIGURE 7 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: MULTIVARIATE MODELLING

FIGURE 8 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: INTERVIEW DEMOGRAPHICS

FIGURE 9 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: DBMR MARKET POSITION GRID

FIGURE 10 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: MARKET END-USE COVERAGE GRID

FIGURE 11 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: THE MARKET CHALLENGE MATRIX

FIGURE 12 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: DBMR VENDOR SHARE ANALYSIS

FIGURE 13 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: SEGMENTATION

FIGURE 14 INCREASING DEMAND FOR WATER BASED FIRE PROTECTION COATINGS IS DRIVING THE GROWTH OF THE MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET IN THE FORECAST PERIOD 2024 TO 2031

FIGURE 15 INTEUMESCENT COATING SEGMENT IS EXPECTED TO ACCOUNT FOR THE LARGEST SHARE OF THE MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET IN THE FORECAST PERIOD 2024 TO 2031

FIGURE 16 IMPORT EXPORT SCENARIO (USD THOUSAND)

FIGURE 17 VENDOR SELECTION CRITERIA

FIGURE 18 DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES OF MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET

FIGURE 19 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: BY PRODUCT TYPE, 2023

FIGURE 20 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: BY TECHNOLOGY, 2023

FIGURE 21 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: BY END-USE, 2023

FIGURE 22 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: SNAPSHOT (2023)

FIGURE 23 MIDDLE EAST PASSIVE FIRE PROTECTION COATINGS MARKET: COMPANY SHARE 2023 (%)

Middle East And Africa Passive Fire Protection Coating Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Middle East And Africa Passive Fire Protection Coating Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Middle East And Africa Passive Fire Protection Coating Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.