North America Composite Bearings Market

Market Size in USD Billion

CAGR :

%

USD

1.73 Billion

USD

2.85 Billion

2025

2033

USD

1.73 Billion

USD

2.85 Billion

2025

2033

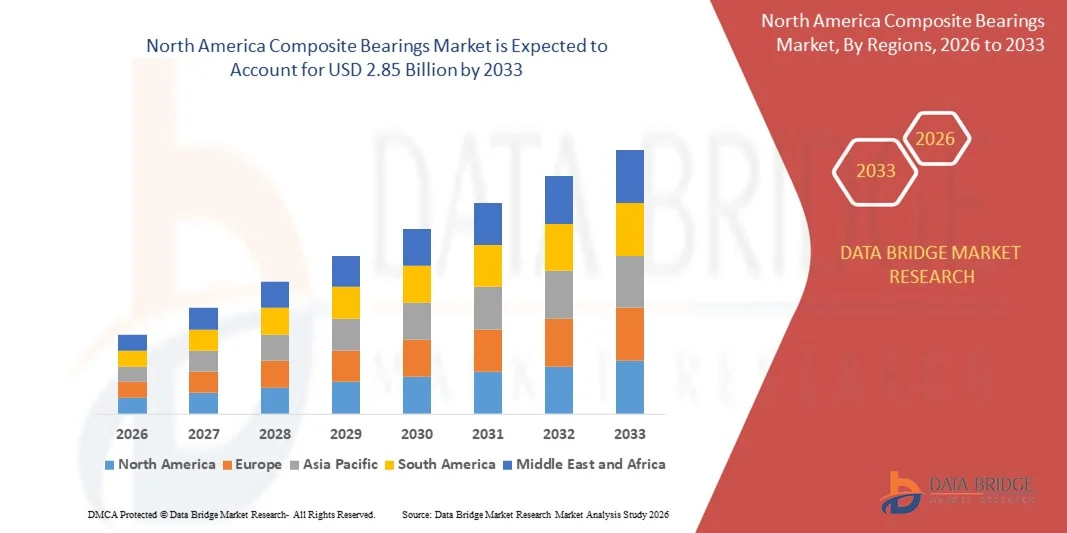

| 2026 –2033 | |

| USD 1.73 Billion | |

| USD 2.85 Billion | |

|

|

|

|

What is the North America Composite Bearings Market Size and Growth Rate?

- The North America composite bearings market size was valued at USD 1.73 billion in 2025 and is expected to reach USD 2.85 billion by 2033, at a CAGR of 6.4% during the forecast period

- Rising preference for lightweight components in various industrial domain acts as driver for the composite bearings market. High raw material and production cost is expected to restrain the composite bearings market in the forecast period

- Rapid industrialization in the emerging economies brings new opportunities for the composite bearings market. Attaining desired level of precision in designing and fabrication is challenging the composite bearings market

What are the Major Takeaways of Composite bearings Market?

- The rising adoption of lightweight, corrosion-resistant, and maintenance-free bearing solutions across automotive, aerospace, industrial machinery, and renewable energy applications is creating significant growth opportunities for the composite bearings market

- Manufacturers are facing challenges related to high material costs, complex manufacturing processes, and performance validation under extreme operating conditions, which may restrain market growth despite increasing demand

- U.S. dominated the North American composite bearings market with an estimated 45.6% revenue share in 2025, driven by widespread industrial adoption, strong automotive and machinery sectors, and high usage in construction, renewable energy, and heavy equipment applications

- Mexico is projected to register the fastest CAGR of 8.7% from 2026 to 2033, fueled by increasing adoption of composite bearings in automotive, construction, and industrial machinery applications

- The Fiber Matrix Composite segment dominated the market with an estimated 63.1% share in 2025, driven by its lightweight nature, excellent corrosion resistance, self-lubricating properties, and high wear resistance

Report Scope and Composite bearings Market Segmentation

|

Attributes |

Composite bearings Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Composite bearings Market?

Growing Shift Toward Lightweight, Maintenance-Free, and High-Performance Composite Bearings

- The composite bearings market is witnessing rising demand for lightweight, corrosion-resistant, and self-lubricating bearing solutions across automotive, aerospace, industrial machinery, and renewable energy applications

- Manufacturers are increasingly developing fiber-reinforced polymer, PTFE-lined, and metal-polymer composite bearings to improve wear resistance, load capacity, and operational lifespan

- Growing focus on maintenance reduction, energy efficiency, and equipment reliability is accelerating adoption of composite bearings in harsh and high-load operating environments

- For instance, companies such as SKF, Schaeffler, Trelleborg, GGB, and RBC Bearings are expanding their composite bearing portfolios for EVs, wind turbines, industrial automation, and heavy equipment

- Rising use of composite bearings in electric vehicles, robotics, aerospace systems, and fluid-handling equipment is driving sustained market expansion

- As industries prioritize durability, weight reduction, and lifecycle cost optimization, composite bearings will remain critical components in next-generation mechanical systems

What are the Key Drivers of Composite bearings Market?

- Increasing demand for maintenance-free and lubrication-free bearing solutions to reduce downtime and operating costs across industrial and automotive sectors

- For instance, during 2024–2025, leading manufacturers such as SKF, Schaeffler, and Trelleborg introduced advanced composite bearing solutions designed for high-load and extreme-temperature conditions

- Growing adoption of electric vehicles, wind energy systems, and automated manufacturing equipment is boosting demand for lightweight and high-performance bearings

- Advancements in material science, polymer engineering, and manufacturing techniques are enhancing bearing strength, wear resistance, and service life

- Rising emphasis on sustainability and energy efficiency is encouraging replacement of traditional metal bearings with composite alternatives

- Supported by industrial automation growth and infrastructure development, the Composite Bearings market is expected to witness steady long-term growth

Which Factor is Challenging the Growth of the Composite bearings Market?

- Higher material and manufacturing costs associated with advanced polymers, fibers, and precision fabrication can limit adoption in cost-sensitive applications

- During 2024–2025, volatility in raw material prices and supply-chain disruptions impacted production costs for composite bearing manufacturers

- Performance limitations under extreme shock loads or misalignment conditions may restrict usage in certain heavy-duty applications

- Limited awareness among small-scale manufacturers regarding long-term benefits and lifecycle cost advantages slows market penetration

- Competition from traditional metal bearings and low-cost alternatives creates pricing pressure

- To address these challenges, companies are focusing on cost optimization, application-specific designs, and customer education to expand adoption of composite bearings

How is the Composite bearings Market Segmented?

The market is segmented on the basis of product type, material, form, distribution channel, and application.

- By Product Type

On the basis of product type, the composite bearings market is segmented into Fiber Matrix Composite Bearings and Metal Matrix Composite Bearings. The Fiber Matrix Composite segment dominated the market with an estimated 63.1% share in 2025, driven by its lightweight nature, excellent corrosion resistance, self-lubricating properties, and high wear resistance. These bearings are widely used in automotive, aerospace, renewable energy, and industrial automation applications where weight reduction and maintenance-free operation are critical. Their superior vibration damping and noise reduction further enhance adoption across precision machinery.

The Metal Matrix Composite segment is expected to grow at the fastest CAGR from 2026 to 2033, supported by rising demand for bearings capable of withstanding high loads, elevated temperatures, and harsh operating environments. Increasing usage in heavy machinery, construction equipment, and oil & gas applications is accelerating growth. As industries demand higher durability and structural strength, metal matrix composite bearings are gaining traction globally.

- By Material

Based on material, the market is segmented into Poly Tetra Fluoro Ethylene (PTFE) Composite Bearings and Poly Oxy Methylene (POM) Composite Bearings. The PTFE Composite segment accounted for the largest share of approximately 58.7% in 2025, owing to its excellent self-lubricating characteristics, low friction coefficient, chemical resistance, and superior performance under dry-running conditions. PTFE composite bearings are extensively used in automotive, aerospace, hydraulic systems, and food processing machinery, where lubrication-free operation and cleanliness are essential.

The POM Composite segment is projected to register the fastest CAGR from 2026 to 2033, driven by its cost-effectiveness, high mechanical strength, dimensional stability, and ease of machining. Growing adoption in consumer equipment, agricultural machinery, and general industrial applications is supporting growth. As manufacturers seek balanced performance at competitive costs, POM composite bearings are expected to witness strong demand expansion.

- By Form

On the basis of form, the composite bearings market is segmented into Cylindrical Bushes, Flanged Bushes, Sliding Plates, Thrust Washers, and Flanged Washers. The Cylindrical Bushes segment dominated the market with a 36.9% share in 2025, due to their widespread usage across automotive suspension systems, construction machinery, hydraulic cylinders, and industrial equipment. Their simple design, high load-bearing capacity, and ease of installation make them the preferred choice across multiple industries.

The Sliding Plates segment is anticipated to grow at the fastest CAGR during 2026–2033, supported by increasing demand from structural engineering, bridges, renewable energy installations, and heavy-duty industrial applications. Sliding plates offer excellent load distribution, low friction, and long service life under oscillating movements. Thrust washers and flanged bushes are also witnessing steady growth due to rising demand for compact and application-specific bearing solutions.

- By Distribution Channel

Based on distribution channel, the market is segmented into Offline and Online channels. The Offline distribution channel dominated the market with an estimated 68.4% share in 2025, driven by strong reliance on direct supplier relationships, OEM partnerships, authorized distributors, and industrial procurement networks. End-users prefer offline channels for technical consultation, customized solutions, bulk purchasing, and assured product quality, especially in critical industrial applications.

The Online distribution channel is expected to grow at the fastest CAGR from 2026 to 2033, supported by increasing digitalization of industrial procurement, expanding B2B e-commerce platforms, and improved access to standardized composite bearing products. Small and mid-sized enterprises are increasingly adopting online purchasing due to competitive pricing, faster delivery, and wider product availability. As digital supply chains mature, online channels will play a growing role in market expansion.

- By Application

On the basis of application, the composite bearings market is segmented into Construction & Mining, Automotive, Aerospace, Agriculture, Marine, Renewable Energy, Food & Beverage, Gym Equipment, Oil & Gas, Hydraulic Industry, and Others. The Automotive segment dominated the market with a 31.5% share in 2025, driven by rising adoption in suspension systems, steering components, braking systems, and electric vehicles. Lightweight design, reduced maintenance, and improved fuel efficiency significantly support demand in this sector.

The Renewable Energy segment is projected to grow at the fastest CAGR from 2026 to 2033, supported by expanding wind and solar energy installations globally. Composite bearings are increasingly used in wind turbine pitch systems, yaw mechanisms, and solar tracking systems due to their durability and resistance to harsh environments. Growing investments in clean energy infrastructure continue to accelerate adoption across renewable applications.

Which Region Holds the Largest Share of the Composite bearings Market?

- U.S. dominated the North American composite bearings market with an estimated 45.6% revenue share in 2025, driven by widespread industrial adoption, strong automotive and machinery sectors, and high usage in construction, renewable energy, and heavy equipment applications. Rising demand for lightweight, maintenance-free, and high-performance composite bearings across key industries continues to reinforce the U.S.’s market leadership

- Increasing focus on energy efficiency, noise reduction, and durability in industrial, automotive, and aerospace applications is significantly boosting composite bearing adoption across the U.S. Strong manufacturing infrastructure, advanced R&D centers, and collaboration with OEMs further strengthen the regional market

Canada Composite Bearings Market Insight

In Canada, market growth is driven by automotive, construction, and renewable energy sectors, where composite bearings are extensively used in heavy machinery, wind turbines, and industrial equipment due to their wear resistance, low friction, and maintenance-free performance. Growing adoption of energy-efficient solutions, coupled with government incentives and industrial modernization programs, encourages market expansion. Collaborative efforts between manufacturers and local OEMs further accelerate adoption.

Mexico Composite Bearings Market Insight

Mexico is projected to register the fastest CAGR of 8.7% from 2026 to 2033, fueled by increasing adoption of composite bearings in automotive, construction, and industrial machinery applications. Rising investment in manufacturing, renewable energy projects, and infrastructure modernization is driving demand for fiber and metal matrix composite solutions. Export-oriented industrial growth, increasing EV adoption, and partnerships between local and international manufacturers further support long-term market expansion.

Which are the Top Companies in Composite bearings Market?

The composite bearings industry is primarily led by well-established companies, including:

- SKF (Sweden)

- Schaeffler AG (Germany)

- Trelleborg AB (Sweden)

- RBC Bearings Incorporated (U.S.)

- SGL Carbon (Germany)

- Polygon Company (U.S.)

- Huntsman International LLC (U.S.)

- HyComp LLC (U.S.)

- GGB (U.S.)

- Rexnord Corporation (U.S.)

- Tenneco Inc. (U.S.)

- Quality Pacific Manufacturing, Inc. (U.S.)

- FTL Technology (U.S.)

- Rheinmetall Automotive AG (Germany)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

North America Composite Bearings Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its North America Composite Bearings Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as North America Composite Bearings Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.