North America Flow Chemistry Market

Market Size in USD Million

CAGR :

%

USD

683.51 Million

USD

1,508.33 Million

2024

2032

USD

683.51 Million

USD

1,508.33 Million

2024

2032

| 2025 –2032 | |

| USD 683.51 Million | |

| USD 1,508.33 Million | |

|

|

|

|

North America Flow Chemistry Market Size

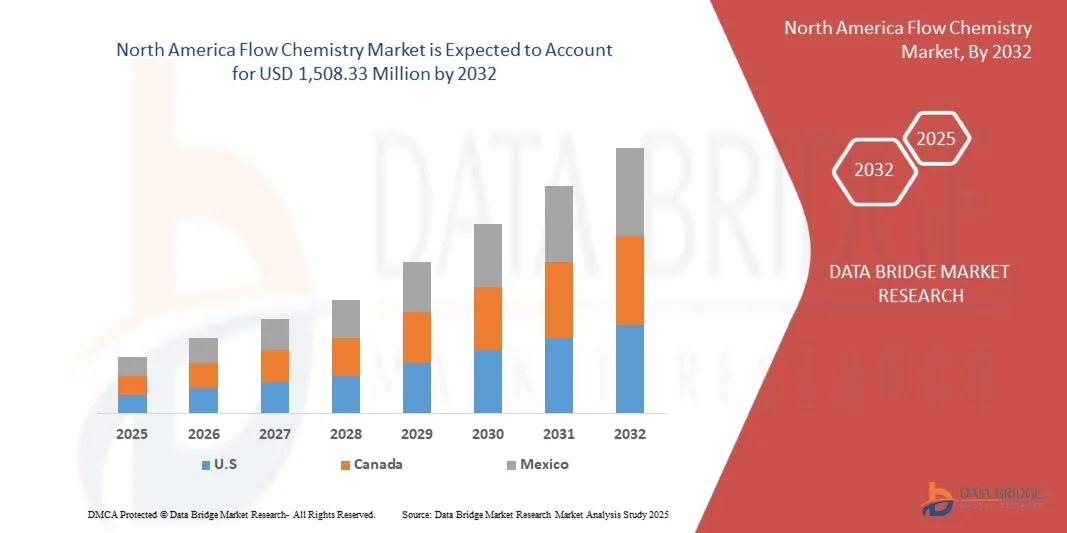

- The North America flow chemistry market size was valued at USD 683.51 million in 2024 and is projected to reach USD 1,508.33 million by 2032, growing at a CAGR of 10.40% during the forecast period

- The market expansion is primarily driven by increasing demand for continuous manufacturing processes across the pharmaceutical, chemical, and petrochemical industries, enabling improved efficiency, safety, and scalability

- In addition, advancements in microreactor technology and government initiatives promoting green chemistry are further propelling the adoption of flow chemistry, positioning it as a vital tool for modern industrial synthesis and sustainable production

North America Flow Chemistry Market Analysis

- The North America flow chemistry market is gaining momentum as a transformative approach in chemical manufacturing, offering continuous production, improved safety, and enhanced scalability, which are increasingly vital for pharmaceutical, petrochemical, and fine chemical industries.

- Growth in the region is primarily driven by rising demand for efficient and sustainable chemical processes, stringent environmental regulations, and growing investments in research and development across the pharmaceutical and specialty chemicals sectors.

- The U.S. dominated in the North America flow chemistry market with largest revenue share of 38.7% in 2024, attributed to its advanced manufacturing infrastructure, strong presence of major chemical and pharmaceutical companies, and early adoption of innovative processing technologies, particularly in the U.S., where industry players are leveraging automation and process intensification techniques.

- Mexico is expected to witness significant growth is further propelled by government support for green chemistry initiatives and a growing emphasis on reducing chemical waste and energy consumption.

- The continuous flow reactors segment held the largest market revenue share of 44.3% in 2024, due to their versatility, scalability, and ease of integration into existing manufacturing workflows

Report Scope and North America Flow Chemistry Market Segmentation

|

Attributes |

North America Flow Chemistry Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

North America Flow Chemistry Market Trends

“Process Optimization Through AI and Automation”

- A significant and accelerating trend in the North America Flow Chemistry Market is the integration of artificial intelligence (AI) and advanced automation systems to enhance real-time process monitoring, control, and optimization in continuous chemical production environments. This technological fusion is driving greater efficiency, scalability, and precision in both research and industrial applications.

- For Instance, companies like AM Technology and Vapourtec Ltd. are incorporating machine learning algorithms into their flow reactors, enabling predictive adjustments to temperature, pressure, and flow rates based on historical data and real-time inputs, significantly improving yield and reducing human error.

- AI integration allows for advanced data analytics and dynamic decision-making during chemical synthesis. Systems can now identify optimal reaction conditions, detect anomalies, and self-correct in real time. Some platforms even offer remote monitoring and cloud-based dashboards, enhancing accessibility and operational flexibility for lab and plant operators.

- Automated flow chemistry systems are also enabling faster scale-up from lab to pilot to production, while maintaining consistent product quality. This is particularly beneficial in pharmaceutical manufacturing, where precision, speed, and regulatory compliance are critical.

- Leading manufacturers such as Uniqsis Ltd. and Corning Incorporated are developing AI-enabled platforms with automated reagent feeding, inline analytics, and self-optimizing protocols, significantly reducing development cycles and operational costs.

- The demand for intelligent, automated flow chemistry solutions is growing rapidly in North America, driven by the need for sustainable, efficient, and high-throughput production systems, particularly in pharmaceuticals, fine chemicals, and materials science.

North America Flow Chemistry Market Dynamics

Driver

“Growing Demand Driven by Pharmaceutical Innovation and Process Efficiency”

- The increasing emphasis on pharmaceutical innovation, coupled with the growing need for efficient, scalable, and sustainable chemical processes, is a major driver for the rising adoption of flow chemistry in North America.

- For Instance, in early 2024, companies like Syrris and Chemtrix expanded their portfolio of continuous flow reactors tailored for pharmaceutical and fine chemical production, signaling strong market momentum. Such developments by leading players are expected to propel market growth during the forecast period.

- As pharmaceutical manufacturers prioritize faster drug development cycles and stricter regulatory compliance, flow chemistry offers advantages such as improved reaction control, higher product quality, and safer handling of hazardous materials, making it a compelling alternative to traditional batch processes.

- Moreover, the increasing adoption of automation and digital integration within chemical manufacturing plants further drives the need for continuous flow systems that can seamlessly interface with advanced monitoring and control technologies.

- The push for green chemistry and process intensification, along with cost savings from reduced waste and energy consumption, also support broader implementation of flow chemistry solutions in both pharmaceutical and specialty chemical industries. The trend towards modular and flexible production units is accelerating adoption, especially among small and mid-sized enterprises.

Restraint/Challenge

“High Initial Investment and Complexity of Integration”

- The relatively high capital expenditure required for setting up continuous flow chemistry systems, including specialized reactors and control infrastructure, poses a significant barrier for widespread adoption, especially among smaller manufacturers.

- Integration of flow chemistry into existing batch-oriented manufacturing processes can be complex and requires skilled personnel, which limits rapid deployment and scalability.

- For instance, the need for trained operators and process development experts to optimize flow reactions has made some companies cautious about transitioning from traditional batch processes.

- Addressing these challenges through advancements in user-friendly system design, enhanced training programs, and collaborative partnerships between technology providers and end-users is crucial for accelerating market penetration.

- Although costs are expected to decline with technological maturation and broader acceptance, the initial investment and integration complexity remain critical concerns for many potential users in North America. Overcoming these hurdles by improving system modularity and offering flexible financing options will be essential for sustained growth in the flow chemistry market.

North America Flow Chemistry Market Scope

The flow chemistry market is segmented on the basis of technology, reactor type, and end-user.

• By Technology

The North America Flow Chemistry Market is segmented into gas-based flow chemistry, photochemistry-based flow chemistry, and microwave irradiation-based flow chemistry. In 2024, the gas-based flow chemistry segment dominated the market, accounting for the largest revenue share of approximately 47.5%, owing to its broad application in hazardous gas handling and efficient reaction control in pharmaceutical synthesis. Gas-based systems provide enhanced safety and improved reaction kinetics, making them highly favored in complex chemical processes.

The photochemistry-based flow chemistry segment is anticipated to register the fastest CAGR of 23.1% from 2025 to 2032. Its growth is driven by increasing demand for sustainable and green chemistry solutions, as photochemical reactions enable energy-efficient transformations using light as a clean energy source. Advances in LED technology and reactor design are further fueling adoption, particularly in pharmaceutical and fine chemical manufacturing.

• By Reactor Type

On the basis of reactor type, the market is segmented into continuous flow reactors, continuous stirred tank reactors (CSTR), plug flow reactors (PFR), and microwave systems. The continuous flow reactors segment held the largest market revenue share of 44.3% in 2024, due to their versatility, scalability, and ease of integration into existing manufacturing workflows. Continuous flow reactors enable precise control over reaction parameters, ensuring consistent product quality, which is critical in pharmaceutical and specialty chemical production.

The microwave systems segment is expected to witness the fastest growth rate at 22.5% CAGR through 2032, attributed to microwave-assisted flow chemistry’s ability to significantly accelerate reaction rates and reduce energy consumption. The integration of microwave irradiation in flow reactors presents new opportunities for process intensification and faster drug discovery cycles, enhancing overall market appeal.

• By End-User

The market is further segmented by end-user into pharmaceutical biotechnology companies, chemical industries, food and beverage industries, agriculture and environmental sectors, nutraceutical firms, academics and research institutes, and analytical laboratories. The pharmaceutical biotechnology companies segment dominated in 2024 with the largest market revenue share of 51.7%, driven by the increasing need for rapid drug development, process optimization, and regulatory compliance in North America. Flow chemistry enables streamlined synthesis and scale-up, making it indispensable in pharmaceutical R&D and manufacturing.

The chemical industries segment is expected to record the fastest growth rate, at a CAGR of 20.9% from 2025 to 2032, fueled by rising demand for specialty chemicals, agrochemicals, and fine chemicals produced via continuous processes. Growing awareness of process safety, efficiency, and environmental benefits is encouraging broader adoption in the chemical manufacturing sector.

North America Flow Chemistry Market Regional Analysis

- The U.S. dominated the flow chemistry market with the largest revenue share of 38.7% in 2024, driven by strong pharmaceutical and biotech industry presence, coupled with increasing demand for efficient and scalable chemical synthesis methods.

- Companies and research institutions in the region highly prioritize process intensification, safety, and sustainability, which flow chemistry enables through continuous processing and improved reaction control.

- This widespread adoption is further supported by significant R&D investments, advanced technological infrastructure, and stringent regulatory standards encouraging innovative manufacturing approaches, establishing flow chemistry as a preferred choice for pharmaceutical development, specialty chemicals, and fine chemical production across North America.

Canada Flow Chemistry Market Insight

The Canada flow chemistry market is anticipated to grow at a steady CAGR throughout the forecast period, supported by growing pharmaceutical manufacturing capabilities and increasing focus on sustainable chemical processes. Government initiatives aimed at reducing environmental impact, alongside rising R&D activities in academic and research institutions, are key drivers. The adoption of flow chemistry in specialty chemical production and fine chemicals is expanding, with companies seeking to improve efficiency and safety. The market is also bolstered by Canada’s investment in advanced manufacturing and digital integration technologies.

Mexico Flow Chemistry Market Insight

The Mexico flow chemistry market is expected to witness significant growth, driven by expanding pharmaceutical and chemical manufacturing sectors catering to North American and global demand. Increasing foreign direct investment and the establishment of new manufacturing facilities are enhancing market prospects. Mexico’s strategic location and trade agreements promote the adoption of innovative continuous processing technologies like flow chemistry. Additionally, growing awareness of process optimization and cost efficiency among manufacturers is encouraging the shift from traditional batch processes to flow chemistry solutions.

North America Flow Chemistry Market Share

The Flow Chemistry industry is primarily led by well-established companies, including:

- AM Technology (U.K.)

- Asahi Glassplant Inc. (Japan)

- METTLER TOLEDO (Switzerland)

- Vapourtec Ltd. (U.K.)

- ThalesNano Inc. (U.S.)

- H.E.L. Group (U.K.)

- Uniqsis Ltd. (U.K.)

- Ehrfeld Mikrotechnik BTS (Germany)

- Future Chemistry Holding BV (Netherlands)

- Corning Incorporated (U.S.)

- Parr Instrument Company (U.S.)

- Amar Equipment Pvt. Ltd. (India)

- FABEX ENGINEERING PVT. LTD. (India)

- Dalton Pharma Services (Canada)

What are the Recent Developments in North America Flow Chemistry Market?

- In April 2023, Syrris Ltd., a leading flow chemistry technology provider, launched its latest modular flow reactor system designed to optimize pharmaceutical synthesis processes. This innovation emphasizes Syrris’ commitment to enhancing reaction efficiency and scalability, addressing the complex needs of pharmaceutical manufacturers in North America. By combining flexibility with automation, the new system supports faster drug development cycles, reinforcing Syrris’ position in the rapidly expanding North America Flow Chemistry Market.

- In March 2023, Chemtrix BV, a prominent continuous flow technology company, introduced an advanced microreactor platform specifically tailored for fine chemical and specialty manufacturing. The platform enables precise control over reaction parameters, improving safety and product quality in commercial environments. This development reflects Chemtrix’s focus on delivering innovative solutions that meet growing industrial demands for continuous processing, highlighting the company’s leadership in North America’s evolving flow chemistry landscape.

- In March 2023, Parker Hannifin Corporation successfully partnered with a major U.S. biotech firm to implement integrated continuous flow systems for biologics manufacturing. The project demonstrated enhanced process reliability and reduced production times, showcasing Parker Hannifin’s expertise in applying flow chemistry to biopharmaceutical production. This collaboration underscores the increasing adoption of continuous processing technologies in North America’s life sciences sector, contributing to the region’s competitive manufacturing ecosystem.

- In February 2023, ThalesNano Inc., a developer of advanced flow chemistry equipment, announced a strategic alliance with several North American academic research institutions. The partnership aims to accelerate innovation by providing state-of-the-art continuous flow reactors for drug discovery and process development. This initiative highlights ThalesNano’s dedication to fostering collaboration and advancing research capabilities, driving growth in North America’s flow chemistry market.

- In January 2023, Ehrfeld Mikrotechnik BTS GmbH unveiled its latest continuous stirred tank reactor (CSTR) system at a major North American chemical engineering conference. The system, featuring enhanced automation and real-time monitoring, supports safer and more efficient chemical production at scale. Ehrfeld’s introduction of this technology emphasizes the company’s commitment to advancing process intensification and sustainability within North America’s flow chemistry industry, offering manufacturers improved operational control and flexibility.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

North America Flow Chemistry Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its North America Flow Chemistry Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as North America Flow Chemistry Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.