North America Rotomolding Products Market Analysis and Size

The North America rotomolding products market is being driven by the growth in the popularity of athletics and water sports. In addition, improvement in the shipbuilding industry is an important driver for the Asia-Pacific rotomolding products market. Moreover, the demand for rotomolding is increasing and manufacturers are now more focused and involved in the new product launch, promotions, awards, certification, and event participation in the market. However, excessive energy consumption and government regulations are expected to pose a challenge to market growth which may restrain the market growth.

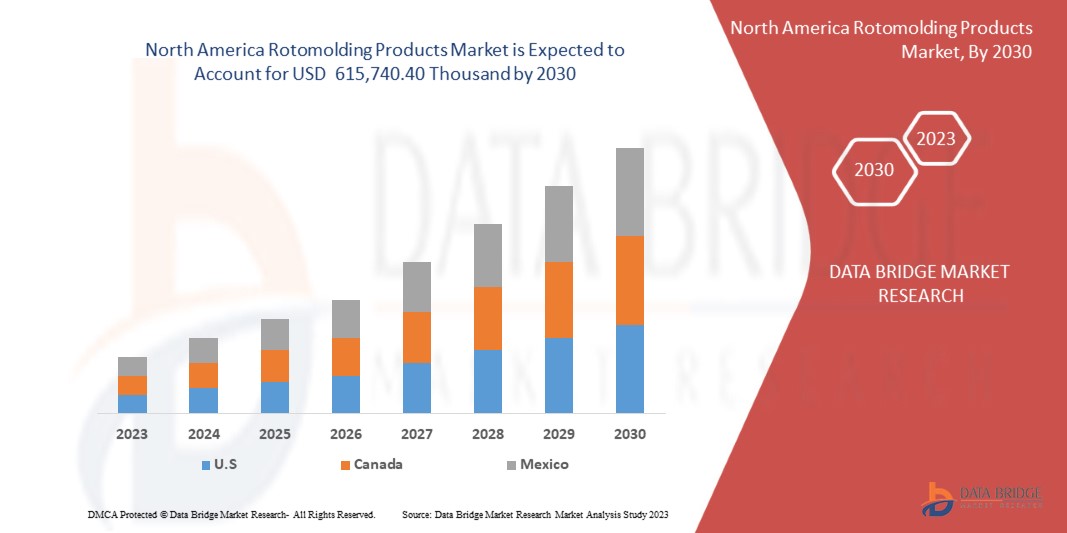

Data Bridge Market Research analyses that the North America rotomolding products market is expected to reach the value of USD 615,740.40 thousand by 2030, at a CAGR of 5.8% during the forecast period.

|

Report Metric |

Details |

|

Forecast Period |

2023 to 2030 |

|

Base Year |

2022 |

|

Historic Years |

2021 (Customizable to 2015 - 2020) |

|

Quantitative Units |

Revenue in Thousand, Volumes in Units, and Pricing in USD |

|

Segments Covered |

Product (Polycarbonate, Polyethylene, Polyurethane, PVC, Nylon, Polypropylene, and Others), Machining (Clamshell Machine, Shuttle Machine, Vertical or Rotational Machine, Carousel Machine, Swing Arm Machine, and Others), Application (Packaging, Agriculture, Industrial, Building & Construction, Consumer Goods, Automotive, Furniture, Marine, and Others) |

|

Countries Covered |

U.S., Canada, and Mexico |

|

Market Players Covered |

Rotoplast S.A.S., K. K. Nag Pvt. Ltd, FIBERTECH PLASTICS, Top Rotomolding Technology Co., Ltd., Yantai Fangda Rotational Molding Co., Ltd, Rotovia, Carris Pipes & Tubes Private Limited, Starplast S.r.l., PartnerPlast, ROTOMADE, Comos Corporation Co., Ltd, Rototek Limited, Tank Holding Corp., Sherman Roto Tank, Dutchland Plastics, Ocean Plastic Intertrade Co., Ltd., Ningbo Fly Plastic Co., Ltd., Changzhou Treering Plastics Co., ltd, and Myers Industries among others |

Market Definition

Rotomolding is a production process to form hollow parts of limitless size. This is a cost-effective method to produce large plastic parts. Resins are added into a mold that’s heated and rotated slowly, both vertically and horizontally. The simultaneous heating and rotation distribute and fuses the resin on the inner surfaces of the mold. The result is a product that contains seamless parts with a uniform wall thickness with more material in corners to absorb shocks and stresses where they occur most.

North America Rotomolding Products Market Dynamics

This section deals with understanding the market drivers, advantages, opportunities, restraints, and challenges. All of this is discussed in detail below:

Drivers:

- Rising acceptance of rotomolded products such as containers and pallets in material handling and packaging applications

Material handling and packaging is among the five interconnected logistical roles that contribute significantly to logistics. The transportation, storage, control, and protection of materials, products, and packaged items during the manufacturing, distribution, and disposal processes are all part of material handling. Packaging serves a crucial purpose in enclosing materials and goods for distribution and transportation. They are important to improve customer service, minimize costs, and lower the chance of accidents and damage. The products manufactured through rotomolding technology offer affordable, safe, and durable solutions for material handling and packaging applications in various industries. They too have a high load bearing capacity because of their seamless, one-part design. Rotationally molded components are also a better alternative to conventional steel parts. Rotational molding is the ideal process for producing parts and components that may be utilized for collecting, storing, or moving nearly any substance due to its lower weight, improved corrosion resistance, and joint-free manufacture.

- Positive outlook toward the construction sector

The construction sector is associated with the building, repair, renovation, and maintenance of infrastructures. The construction industry contributes to the nation's socioeconomic development and economic growth. The construction industry generates activity and employment in other areas of the economy such as manufacturing, logistics, trade, and financial services. Population growth, growing urbanization, housing market, and infrastructure development are the key drivers of the construction industry.

The construction industry has the potential to be a major driving force in the expansion of rotomolded products. Rotomolded products have a wide range of applications in building construction projects such as water storage tanks and septic tanks among others. Moreover, products such as barricades and traffic cones that are used in the construction of roads and highways are also manufactured through rotomolding technology. Such products are durable, corrosion resistant, and require low maintenance which makes them ideal for infrastructure applications. Moreover, due to the light weight of products such as barricades and traffic cones, they are easy to carry which leads to lower fuel costs for the end user. In addition to it, they are easy to transport and relocate when compared to other products made from materials such as metal. The growing focus on developing efficient and long-lasting infrastructure adds up to the application growth of rotomolded products in the construction sector.

RESTRAINTS/ CHALLENGES

- Limitation regarding the processing of other materials namely metals and ceramics

Rotomolding technology is used to process thermoplastic polymeric materials like polyethylene and polypropylene. Moreover, the raw material used in the formation of rotomolding products be easily converted from granules to fine powder and should have high thermal stability. This limits the material selection to only poly-based resins in the formation of rotomolded products. The high thermal stability requirement leads to the high cost of raw materials and the expense of grinding material into powder to rise.

Although rotomolding offers various advantages when plastic based products are processed, however, it faces restraints while processing other materials such as metals and ceramics. They have high melting points compared to polymers, therefore offering a disadvantage because metal and ceramics require high temperatures. Ceramics and metals too have high structural strength and weight bearing capability that is less seen in rotomolded plastics. The metals and ceramics too have high heat resistance and thermal conductivity, therefore used in industrial applications where heat and thermal resistant properties are required. Hence, the inability to process materials such as metals and ceramics through rotomolding technology limits the growth of the Asia-Pacific rotomolding products market.

- Stringent rules and regulations aimed for polymers processing

There are various stringent rules and regulations imposed by various government organizations and international authorities related to the polymers that are used in the rotomolding process. These rules, regulations, and standards are made so that the industries follow them to ensure the health and safety of workers and consumers. A few of the regulations related to the polymers used for the production of rotomolding products are as follows:

OPPORTUNITIES

- Possibility of inclusion of new printing and labeling technologies

Over time, new label demands from customers and changing market dynamics will influence the choice of printed label type and new label technological developments. The packaging industry and its customers are constantly working to reduce the weight of product packaging, either by employing smaller rigid containers made of metal, glass, or plastic or by transitioning to flexible plastic formats. Labeling is essential for the manufacturing process. Labels can be used for product identification, warehouse labeling, and tracking things along the supply chain. Labels also help to boost consumer satisfaction by providing correct information about a product or service. Manufacturers ensure that end users, such as customers, may make educated purchasing decisions by properly identifying a product or service with labels.

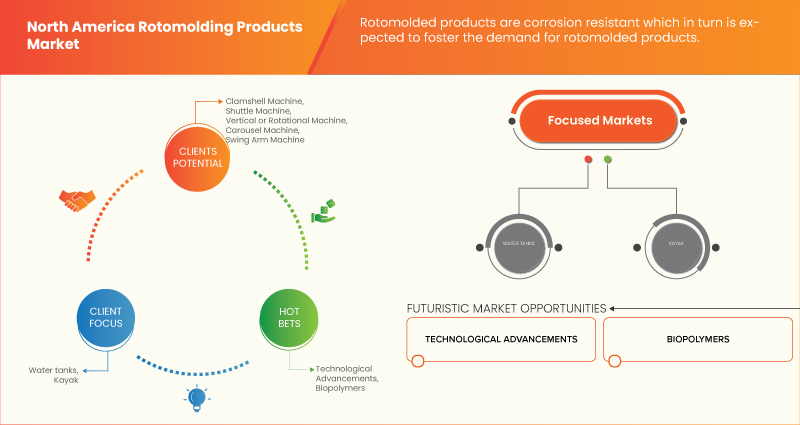

- Increasing Access to Bio-Based Polymers

Bio-based polymers are polymers that are produced from sustainable resources such as agricultural waste, plant-based feedstock, or biodegradable materials. They have numerous environmental benefits that consist of low usage of fossil fuels, less production of plastic waste, and a low carbon footprint. The use of such polymers will also help to overcome regulations set up by the government authorities over polymers such as polyethylene and polypropylene. Moreover, consumers are getting aware of the side effects of plastics, therefore there has been an increase in consumer shift towards environmentally friendly polymers.

North America Rotomolding Products Market Scope

The North America rotomolding products market is categorized into three notable segments, by product, machining, and application. The growth amongst these segments will help you analyze major growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Product

- Polyethylene

- Polypropylene

- PVC

- Polycarbonate

- Nylon

- Polyurethane

- Others

On the basis of product, the market is segmented into polycarbonate, polyethylene, elastomers, polyurethane, PVC, nylon, polypropylene, and others.

Machining

- Clamshell Machine

- Shuttle Machine

- Vertical or Rotational Machine

- Carousel Machine

- Swing Arm Machine

- Others

On the basis of the machining, the market is segmented into clamshell machine, shuttle machine, vertical or rotational machine, carousel machine, swing arm machine, and others.

Application

- Packaging

- Agriculture

- Industrial

- Building & Construction

- Consumer Goods

- Automotive

- Furniture

- Marine

- Others

On the basis of application, the market is segmented into packaging, agriculture, industrial, building & construction, consumer goods, automotive, furniture, marine, and others.

North America Rotomolding Products Market Regional Analysis/Insights

The North America rotomolding products market is analyzed and market size insights and trends are provided by country, product, machining, and application as referenced above.

The countries covered in the North America rotomolding products market report are U.S., Canada, and Mexico.

U.S. is expected to dominate the North America rotomolding products market due to the rise in the adoption of the molding technique because of its inexpensiveness as the molds do not have to withstand pressure and acts as one of the major factors driving the growth of the rotomolding market. However, the requirement of high cycle time and limited raw material selection is expected to restrict the growth of the market.

The country section of the report also provides individual market impacting factors and changes in market regulation that impact the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends, and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of North America brands and their challenges faced due to large or scarce competition from local and domestic brands, the impact of domestic tariffs, and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and North America Rotomolding Products Market Share Analysis

The North America rotomolding products market competitive landscape provides details by competitors. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, North America presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, and application dominance. The above data points provided are only related to the companies focus on the North America Rotomolding Products market.

Some of the major players operating in the North America rotomolding products market are Rotoplast S.A.S., K. K. Nag Pvt. Ltd, FIBERTECH PLASTICS, Top Rotomolding Technology Co., Ltd., Yantai Fangda Rotational Molding Co., Ltd, Rotovia, Carris Pipes & Tubes Private Limited, Starplast S.r.l., PartnerPlast, ROTOMADE, Comos Corporation Co., Ltd, Rototek Limited, Tank Holding Corp., Sherman Roto Tank, Dutchland Plastics, Ocean Plastic Intertrade Co., Ltd., Ningbo Fly Plastic Co., Ltd., Changzhou Treering Plastics Co., ltd, and Myers Industries among others.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW

1.4 LIMITATIONS

1.5 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 GEOGRAPHICAL SCOPE

2.3 YEARS CONSIDERED FOR THE STUDY

2.4 CURRENCY AND PRICING

2.5 DBMR TRIPOD DATA VALIDATION MODEL

2.6 MULTIVARIATE MODELLING

2.7 MANUFACTURING PROCESS LIFELINE CURVE

2.8 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.9 DBMR MARKET POSITION GRID

2.1 MARKET APPLICATION COVERAGE GRID

2.11 SECONDARY SOURCES

2.12 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 CASE STUDY: NORTH AMERICA ROTOMOLDING PRODUCTS MARKET

4.2 GROWTH POTENTIAL FOR ROTATIONAL MOLDING IN THE INTERMEDIATE BULK CONTAINERS MARKET

4.3 TENDANCE OF OEMS INTEGRATING ROTATIONAL MOLDING IN-HOUSE

5 MARKET OVERVIEW

5.1 DRIVERS

5.1.1 RISING ACCEPTANCE OF ROTOMOLDED PRODUCTS SUCH AS CONTAINERS AND PALLETS IN MATERIAL HANDLING AND PACKAGING APPLICATIONS

5.1.2 POSITIVE OUTLOOK TOWARDS THE CONSTRUCTION SECTOR

5.1.3 GROWTH IN THE POPULARITY OF ATHLETICS AND WATER SPORTS

5.1.4 IMPROVEMENT IN THE SHIPBUILDING INDUSTRY

5.1.5 FAVOURABLE ADOPTION SCENARIO IN VARIOUS SEGMENTS INCLUDING AGRICULTURE AND FOOD & BEVERAGE SEGMENTS

5.2 RESTRAINTS

5.2.1 LIMITATIONS REGARDING PROCESSING OF OTHER MATERIALS NAMELY METALS AND CERAMICS

5.2.2 SUBSTITUTIONAL THREAT FROM OTHER MOLDED MATERIALS

5.3 OPPORTUNITIES

5.3.1 POSSIBILITY OF INCLUSION OF NEW PRINTING AND LABELLING TECHNOLOGIES

5.3.2 INCREASING ACCESS TO BIO-BASED POLYMERS

5.4 CHALLENGES

5.4.1 STRINGENT RULES AND REGULATIONS AIMED AT POLYMERS PROCESSING

5.4.2 EXCESSIVE ENERGY CONSUMPTION

6 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET BY REGION

6.1 NORTH AMERICA

7 COMPANY LANDSCAPE

7.1 COMPANY SHARE ANALYSIS: NORTH AMERICA

8 COMPANY PROFILE

8.1 MYERS INDUSTRIES

8.1.1 COMPANY SNAPSHOT

8.1.2 REVENUE ANALYSIS

8.1.3 COMPANY SHARE ANALYSIS

8.1.4 PRODUCT PORTFOLIO

8.1.5 RECENT DEVELOPMENTS

8.2 TANK HOLDING CORP.

8.2.1 COMPANY SNAPSHOT

8.2.2 COMPANY SHARE ANALYSIS

8.2.3 PRODUCT PORTFOLIO

8.2.4 RECENT DEVELOPMENT

8.3 DUTCHLAND PLASTICS

8.3.1 COMPANY SNAPSHOT

8.3.2 COMPANY SHARE ANALYSIS

8.3.3 PRODUCT PORTFOLIO

8.3.4 RECENT DEVELOPMENTS

8.4 ROTOVIA.

8.4.1 COMPANY SNAPSHOT

8.4.2 COMPANY SHARE ANALYSIS

8.4.3 PRODUCT PORTFOLIO

8.4.4 RECENT DEVELOPMENT

8.5 COMOS CORPORATION CO., LTD

8.5.1 COMPANY SNAPSHOT

8.5.2 COMPANY SHARE ANALYSIS

8.5.3 PRODUCT PORTFOLIO

8.5.4 RECENT DEVELOPMENT

8.6 CARRIS PIPES & TUBES PRIVATE LIMITED

8.6.1 COMPANY SNAPSHOT

8.6.2 PRODUCT PORTFOLIO

8.6.3 RECENT DEVELOPMENT

8.7 CHANGZHOU TREEING PLASTICS CO., LTD

8.7.1 COMPANY SNAPSHOT

8.7.2 PRODUCT PORTFOLIO

8.7.3 RECENT DEVELOPMENT

8.8 FIBERTECH PLASTICS

8.8.1 COMPANY SNAPSHOT

8.8.2 PRODUCT PORTFOLIO

8.8.3 RECENT DEVELOPMENT

8.9 K.K NAG PVT. LTD

8.9.1 COMPANY SNAPSHOT

8.9.2 PRODUCT PORTFOLIO

8.9.3 RECENT DEVELOPMENT

8.1 NINGBO FLY CO., LTD.

8.10.1 COMPANY SNAPSHOT

8.10.2 PRODUCT PORTFOLIO

8.10.3 RECENT DEVELOPMENT

8.11 OCEAN PLASTIC INTERTRADE CO., LTD.

8.11.1 COMPANY SNAPSHOT

8.11.2 PRODUCT PORTFOLIO

8.11.3 RECENT DEVELOPMENT

8.12 PARTNERPLAST

8.12.1 COMPANY SNAPSHOT

8.12.2 PRODUCT PORTFOLIO

8.12.3 RECENT DEVELOPMENT

8.13 ROTOMADE

8.13.1 COMPANY SNAPSHOT

8.13.2 PRODUCT PORTFOLIO

8.13.3 RECENT DEVELOPMENT

8.14 ROTOPLAST S.A.S

8.14.1 COMPANY SNAPSHOT

8.14.2 PRODUCT PORTFOLIO

8.14.3 RECENT DEVELOPMENT

8.15 ROTOTEK LIMITED

8.15.1 COMPANY SNAPSHOT

8.15.2 PRODUCT PORTFOLIO

8.15.3 RECENT DEVELOPMENT

8.16 SHERMAN ROTO TANK

8.16.1 COMPANY SNAPSHOT

8.16.2 PRODUCT PORTFOLIO

8.16.3 RECENT DEVELOPMENT

8.17 STARPLAST S.R.L.

8.17.1 COMPANY SNAPSHOT

8.17.2 PRODUCT PORTFOLIO

8.17.3 RECENT DEVELOPMENT

8.18 TOP ROTOMOLDING TECHNOLOGY CO., LTD.

8.18.1 COMPANY SNAPSHOT

8.18.2 PRODUCT PORTFOLIO

8.18.3 RECENT DEVELOPMENT

8.19 YANTAI FANGDA ROTATIONAL MOLDING CO., LTD

8.19.1 COMPANY SNAPSHOT

8.19.2 PRODUCT PORTFOLIO

8.19.3 RECENT DEVELOPMENT

9 QUESTIONNAIRE

10 RELATED REPORTS

List of Figure

FIGURE 1 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: SEGMENTATION

FIGURE 2 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: DATA TRIANGULATION

FIGURE 3 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: DROC ANALYSIS

FIGURE 4 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: REGIONAL VS COUNTRY MARKET ANALYSIS

FIGURE 5 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: COMPANY RESEARCH ANALYSIS

FIGURE 6 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: INTERVIEW DEMOGRAPHICS

FIGURE 7 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: DBMR MARKET POSITION GRID

FIGURE 8 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: MARKET APPLICATION COVERAGE GRID

FIGURE 9 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: SEGMENTATION

FIGURE 10 GROWTH IN THE POPULARITY OF ATHLETICS AND WATER SPORTS IS EXPECTED TO DRIVE THE NORTH AMERICA ROTOMOLDING PRODUCTS MARKET IN THE FORECAST PERIOD FROM 2023 TO 2030

FIGURE 11 THE POLYETHYLENE SEGMENT IS EXPECTED TO ACCOUNT FOR THE LARGEST SHARE OF THE NORTH AMERICA ROTOMOLDING PRODUCTS MARKET IN 2023 AND 2030

FIGURE 12 DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES OF THE NORTH AMERICA ROTOMOLDING PRODUCTS MARKET

FIGURE 13 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: SNAPSHOT (2022)

FIGURE 14 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: COUNTRY (2022)

FIGURE 15 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: BY COUNTRY (2023-2030)

FIGURE 16 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: BY COUNTRY (2022-2030)

FIGURE 17 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: BY PRODUCT (2023-2030)

FIGURE 18 NORTH AMERICA ROTOMOLDING PRODUCTS MARKET: COMPANY SHARE 2022 (%)

North America Rotomolding Products Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its North America Rotomolding Products Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as North America Rotomolding Products Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.