Global Metal Filament Market

市场规模(十亿美元)

CAGR :

%

USD

2.83 Billion

USD

3.82 Billion

2024

2032

USD

2.83 Billion

USD

3.82 Billion

2024

2032

| 2025 –2032 | |

| USD 2.83 Billion | |

| USD 3.82 Billion | |

|

|

|

|

全球金屬絲市場細分,依類型(不鏽鋼、銅、鋁等)、應用(工業、製造業等)-產業趨勢及 2032 年預測

金屬絲市場分析

受 3D 列印技術的進步以及各種工業應用對高性能材料的需求不斷增長的推動,金屬長絲市場正在經歷顯著增長。金屬絲由金屬粉末與熱塑性材料結合而成,無需傳統的金屬加工工藝即可列印金屬零件。這項創新已應用於航空航太、汽車、醫療保健和消費電子等行業,這些行業對輕質、耐用和客製化設計的組件的需求很高。金屬長絲市場的一個關鍵進步是開發更易於獲取且更具成本效益的長絲,這使得金屬 3D 列印可用於更廣泛的行業。此外,混合長絲和複合材料(例如不銹鋼和銅注入長絲)的引入使得產品設計和材料特性更加靈活。工業 4.0 技術的日益普及也推動了市場的擴張,其中金屬 3D 列印在推動製造業生產力和創新方面發揮著至關重要的作用。隨著各行各業繼續採用積層製造技術,金屬絲市場預計將持續成長,這得益於提高列印品質、材料特性和整體生產效率的創新。

金屬絲市場規模

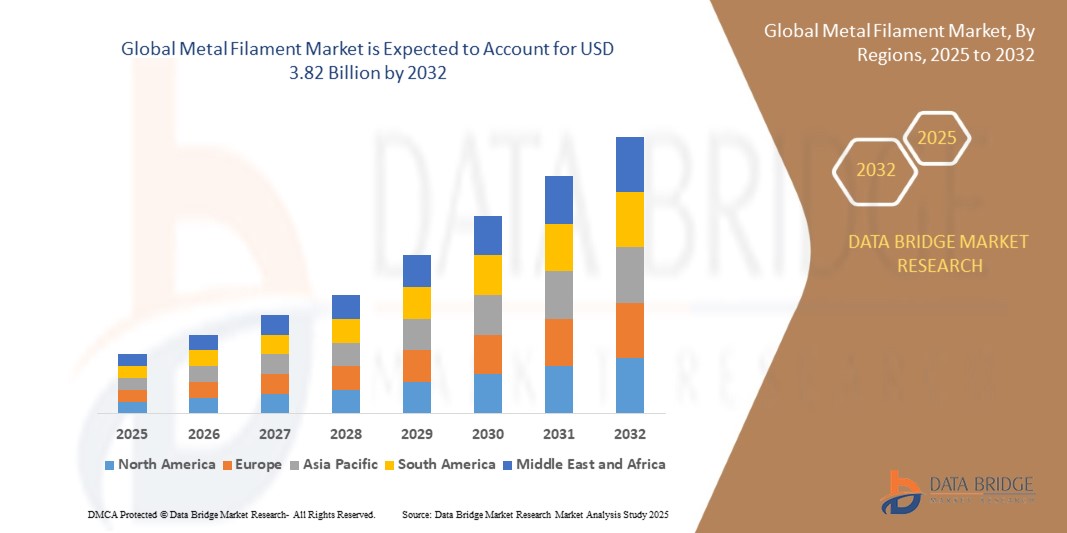

2024 年全球金屬長絲市場規模為 28.3 億美元,預計到 2032 年將達到 38.2 億美元,預測期內(2025 年至 2032 年)的複合年增長率為 6.60%。除了對市場價值、成長率、細分、地理覆蓋範圍和主要參與者等市場情景的洞察外,Data Bridge Market Research 整理的市場報告還包括深入的專家分析、定價分析、品牌份額分析、消費者調查、人口統計分析、供應鏈分析、價值鏈分析、原材料/消耗品概述、供應商選擇標準、PESTLE 分析、波特分析和監管框架

金屬絲市場趨勢

“混合和複合長絲的採用日益廣泛”

金屬長絲市場的一個主要趨勢是混合和複合長絲的採用日益增多,這種長絲將金屬粉末與碳纖維和陶瓷等其他材料結合在一起。這一發展使製造商能夠生產具有增強性能的零件,例如更高的強度、耐熱性和輕量化設計,使其成為航空航天和汽車等行業的理想選擇。例如,引入註入碳纖維的金屬絲可以製造出耐用且重量更輕的零件,從而提高汽車行業的燃油效率。隨著 3D 列印技術的進步,這些複合長絲變得越來越容易獲得,推動了它們在尋求突破設計和材料性能極限的行業中的應用。此外,使用這些材料列印複雜幾何形狀的能力為製造商提供了一種更靈活、更經濟的生產客製化零件的方法,從而促進了金屬長絲市場的持續成長。

報告範圍和金屬絲市場細分

|

屬性 |

金屬絲關鍵市場洞察 |

|

涵蓋的領域 |

|

|

覆蓋國家 |

北美洲的美國、加拿大和墨西哥、德國、法國、英國、荷蘭、瑞士、比利時、俄羅斯、義大利、西班牙、土耳其、歐洲其他地區、中國、日本、印度、韓國、新加坡、馬來西亞、澳洲、泰國、印尼、菲律賓、亞太地區 (APAC) 的其他地區、沙烏地阿拉伯、阿聯酋、南非、埃及、以色列、中東和非洲 (MEA) 的其他地區、其他地區的歐洲地區 |

|

主要市場參與者 |

BASF(德國)、colorFabb BV(荷蘭)、Protopasta(美國)、The Virtual Foundry Inc.(美國)、FormFutura(荷蘭)、Gizmo Dorks(美國)、Vastmind LLC。 (美國)、3D Platform(美國)、RD Mathis Company(美國)、Filaments(美國)、Ooznest Limited(英國)、Elmet Technologies(美國)、MakerBot Industries LLC(美國)、Fargo Additive Manufacturing Equipment 3D, LLC(美國)、Rhenium Alloys Inc.(美國)、Dick Systems, Inc. plc(英國)、通用電氣公司(美國)、CRS Holdings, LLC。 (美國)、Materialise(比利時)、voxeljet AG(德國)、Sandvik AB(瑞典)、EOS GmbH(德國)、ExOne(美國)和 Proto Labs(美國) |

|

市場機會 |

|

|

加值資料資訊集 |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework |

Metal Filament Market Definition

Metal filament refers to a type of 3D printing material that contains metal powder mixed with a binder or polymer to create a filament used in additive manufacturing. This filament is designed for use with 3D printers and allows users to produce parts and prototypes with metal-like properties. Once printed, the parts can be subjected to post-processing steps, such as sintering, to fully solidify and achieve the desired metal characteristics, including strength, conductivity, and durability.

Metal Filament Market Dynamics

Drivers

- Growing Demand for 3D Printing in Industrial Applications

The growing demand for 3D printing in industrial applications, particularly in sectors such as aerospace, automotive, and healthcare, is driving the metal filament market. As industries move towards additive manufacturing for both prototyping and the production of end-use parts, the need for metal filaments that offer superior strength, durability, and high-performance material properties has significantly increased. For instance, in aerospace, companies such as Boeing and Airbus use 3D printing with metal filaments to produce lightweight yet durable components for aircraft, improving fuel efficiency and reducing costs. In the automotive sector, manufacturers such as Ford and General Motors are utilizing metal 3D printing for producing custom parts and prototypes, enabling faster design iterations and enhanced performance. Similarly, in healthcare, metal filaments are employed for creating patient-specific implants and prosthetics that offer better compatibility and durability. The expanding use of metal filaments in these applications is fueling market growth, positioning them as a key driver in the rise of 3D printing across multiple industries.

- Rising Popularity Customization and Design Flexibility

Customization and design flexibility offered by metal filaments are driving growth in industries that require high-precision components, such as aerospace and medical device manufacturing. Metal filaments enable the creation of complex geometries that traditional manufacturing methods may not be able to achieve, allowing companies to design custom components that meet specific functional and aesthetic requirements. For instance, in the aerospace industry, companies such as GE Aviation are using metal 3D printing to produce lightweight, high-performance engine components with intricate designs that reduce weight and improve fuel efficiency. Similarly, in medical device manufacturing, metal filaments are used to create custom implants and prosthetics that perfectly fit a patient's anatomy, offering better outcomes and faster recovery times. The ability to produce such tailored solutions with metal filaments has made them increasingly attractive to industries focused on innovation, boosting their demand and establishing customization as a key driver in the metal filament market.

Opportunities

- Increasing Advancements in 3D Printing Technology

Advancements in 3D printing technology, including the development of improved printers and enhanced metal filament materials, have made metal 3D printing more accessible and cost-effective, creating significant market opportunities across various industries. For instance, new generation 3D printers, such as the ones from companies such as Stratasys and 3D Systems, are now capable of handling metal filaments with greater precision and efficiency, allowing for faster production times and reduced costs. Enhanced metal filaments, such as those offering improved strength and durability, have expanded the range of applications for metal 3D printing, from aerospace and automotive parts to medical implants and customized consumer goods. As the technology becomes more affordable and efficient, small to medium-sized businesses can now adopt metal 3D printing to produce high-quality components without the need for expensive tooling or molds. This has opened up new possibilities for rapid prototyping and on-demand production, positioning advancements in 3D printing technology as a key market opportunity in the metal filament sector.

- Rise of Metal 3D Printing in Manufacturing

隨著各行各業尋求高品質、高效、可擴展的大規模生產解決方案,金屬 3D 列印在製造業的興起極大地推動了對金屬長絲的需求。例如,通用電氣和波音等公司越來越多地將金屬 3D 列印技術融入其製造流程,以生產用於航空航天應用的複雜、輕巧且耐用的零件。採用這種方式可以讓製造商簡化生產、減少材料浪費、縮短交貨時間,同時保持高精度。金屬 3D 列印能夠創造出傳統製造方法難以實現或無法實現的複雜設計,這對於汽車、航空航太和工業機械等領域尤其具有吸引力。此外,向積層製造的轉變實現了按需生產,降低了庫存成本並提高了供應鏈效率。隨著越來越多的行業採用金屬 3D 列印進行大規模生產,對金屬絲日益增長的需求帶來了巨大的市場機遇,特別是對於能夠提供先進且經濟高效的材料的供應商而言。

限制/挑戰

- 生產成本高

高生產成本是金屬長絲市場面臨的重大挑戰,因為製造金屬長絲涉及複雜且資源密集的製程。生產用於 3D 列印的金屬絲需要專門的設備,例如擠壓機和高溫爐,以及金屬粉末或合金等高品質的原材料,這些原材料的成本可能很高。例如,鈦基長絲因其強度高、重量輕的特性而常用於航空航天應用,但由於鈦的成本高且製造長絲所需的工藝複雜,因此生產成本特別高。這些高昂的生產成本通常會轉嫁給消費者,從而限制了金屬絲的廣泛應用,尤其是對於小規模或個人用戶。與塑膠長絲等較便宜的替代品相比,高成本使得金屬長絲更難獲得,從而阻礙了市場的成長,特別是在成本效益至關重要的行業,例如消費品或小規模製造。

- 材料特性和一致性

材料特性和一致性對金屬長絲市場提出了重大挑戰,因為長絲品質的變化會影響 3D 列印物件的性能。實現直徑、合金成分和機械性能的均勻性至關重要,因為不一致會導致最終產品出現缺陷,例如薄弱點、黏合不當或尺寸不準確。例如,航空航太工業所使用的金屬絲必須符合強度、耐用性、耐熱性和耐腐蝕性的嚴格標準。金屬合金成分的細微變化都可能損害零件的結構完整性,從而導致關鍵應用出現故障。這些挑戰使得製造商難以維持不同批次間的品質一致性,尤其是在擴大生產規模時。不一致的金屬絲會增加生產成本,增加浪費,並可能導致客戶不滿意,最終限制金屬絲的廣泛應用,並阻礙依賴高精度的行業(如汽車和醫療保健)的發展。

本市場報告提供了最新發展、貿易法規、進出口分析、生產分析、價值鏈優化、市場份額、國內和本地化市場參與者的影響的詳細信息,分析了新興收入領域的機會、市場法規的變化、戰略市場增長分析、市場規模、類別市場增長、應用領域和主導地位、產品批准、產品發布、地理擴展、市場技術創新。要獲取更多市場信息,請聯繫 Data Bridge Market Research 獲取分析師簡報,我們的團隊將幫助您做出明智的市場決策,實現市場成長。

原材料短缺和運輸延誤的影響和當前市場情勢

Data Bridge Market Research 提供高水準的市場分析,並透過考慮原材料短缺和運輸延遲的影響和當前市場環境來提供資訊。這意味著評估策略可能性、制定有效的行動計劃並協助企業做出重要決策。

除了標準報告外,我們還提供對採購層面的深入分析,包括預測運輸延遲、按地區劃分的經銷商映射、商品分析、生產分析、價格映射趨勢、採購、類別績效分析、供應鏈風險管理解決方案、高級基準測試以及其他採購和戰略支援服務。

經濟放緩對產品定價和供應的預期影響

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Metal Filament Market Scope

The market is segmented on the basis of type and application. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Type

- Stainless Steel

- Copper

- Aluminum

- Others

Application

- Industrial

- Manufacturing

- Others

Metal Filament Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, type, and application as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia Pacific is projected to experience the highest compound annual growth rate (CAGR) in the Metal Filament market during the forecast period, driven by rapid advancements in manufacturing technologies, growing adoption of 3D printing in industrial applications, and increasing demand for customized and high-performance materials in countries such as China, Japan, and India. In addition, the region's expanding automotive, aerospace, and electronics industries are contributing to the surge in demand for metal filaments, as businesses seek to leverage these materials for more efficient and innovative production processes. This growth is further supported by significant investments in 3D printing infrastructure and the increasing availability of cost-effective metal filaments, making them accessible to a broader range of industries and applications.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Metal Filament Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Metal Filament Market Leaders Operating in the Market Are:

- BASF (Germany)

- colorFabb BV (Netherlands)

- Protopasta (U.S.)

- The Virtual Foundry Inc. (U.S.)

- FormFutura (Netherlands)

- Gizmo Dorks (U.S.)

- Vastmind LLC. (U.S.)

- 3D Platform (U.S.)

- RD Mathis Company (U.S.)

- Filaments (U.S.)

- Ooznest Limited (U.K.)

- Elmet Technologies (U.S.)

- MakerBot Industries LLC (U.S.)

- Fargo Additive Manufacturing Equipment 3D, LLC (U.S.)

- Rhenium Alloys Inc. (U.S.)

- 3D Systems, Inc (U.S.)

- Stratasys (U.S.)

- Renishaw plc (U.K.)

- General Electric Company (U.S.)

- CRS Holdings, LLC. (U.S.)

- Materialise (Belgium)

- voxeljet AG (Germany)

- Sandvik AB (Sweden)

- EOS GmbH (Germany)

- ExOne (U.S.)

- Proto Labs (U.S.)

Latest Developments in Metal Filament Market

- In December 2024, The Virtual Foundry (TVF), a leader in bound metal 3D printing filaments, launched its Universal Metal Expansion strategy, aimed at mainstreaming bound metal filament extrusion 3D printing. As part of this initiative, TVF signed a distribution agreement with Bambu Lab, a prominent high-speed 3D printer manufacturer

- In August 2024, Markforged Holding Corporation, a Germany-based industrial 3D printer manufacturer, introduced the FX10 Metal Kit, which expands the capabilities of the FX10 3D Printer to include metal printing using metal filaments and composite materials with continuous fiber reinforcement. The kit provides a fully integrated solution, delivering immediate value when implemented in manufacturing

- In June 2022, Ultimaker expanded its offerings with the Metal Expansion Kit, compatible with the Ultimaker S5, to make metal 3D printing more accessible and cost-effective. This kit removes bottlenecks in the metal printing process by equipping users with essential items, software, and knowledge for maximum efficiency

- In June 2021, France-based Nanovia launched two new extrusion-based 3D printing filaments, Nanovia Mt Inox 316L, a stainless steel 316L filament, and Nanovia Cr SiC, a ceramic silicon carbide filament

- In December 2020, Forward AM, the 3D printing division of BASF, introduced Ultrafuse 17-4 PH, a stainless steel filament made of metal powder within a polymer matrix. This material enables safe and cost-efficient metal printing on most standard FFF systems

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

研究方法

数据收集和基准年分析是使用具有大样本量的数据收集模块完成的。该阶段包括通过各种来源和策略获取市场信息或相关数据。它包括提前检查和规划从过去获得的所有数据。它同样包括检查不同信息源中出现的信息不一致。使用市场统计和连贯模型分析和估计市场数据。此外,市场份额分析和关键趋势分析是市场报告中的主要成功因素。要了解更多信息,请请求分析师致电或下拉您的询问。

DBMR 研究团队使用的关键研究方法是数据三角测量,其中包括数据挖掘、数据变量对市场影响的分析和主要(行业专家)验证。数据模型包括供应商定位网格、市场时间线分析、市场概览和指南、公司定位网格、专利分析、定价分析、公司市场份额分析、测量标准、全球与区域和供应商份额分析。要了解有关研究方法的更多信息,请向我们的行业专家咨询。

可定制

Data Bridge Market Research 是高级形成性研究领域的领导者。我们为向现有和新客户提供符合其目标的数据和分析而感到自豪。报告可定制,包括目标品牌的价格趋势分析、了解其他国家的市场(索取国家列表)、临床试验结果数据、文献综述、翻新市场和产品基础分析。目标竞争对手的市场分析可以从基于技术的分析到市场组合策略进行分析。我们可以按照您所需的格式和数据样式添加您需要的任意数量的竞争对手数据。我们的分析师团队还可以为您提供原始 Excel 文件数据透视表(事实手册)中的数据,或者可以帮助您根据报告中的数据集创建演示文稿。