Global Metal Finishing Chemicals Market

市场规模(十亿美元)

CAGR :

%

USD

10.70 Billion

USD

16.36 Billion

2024

2032

USD

10.70 Billion

USD

16.36 Billion

2024

2032

| 2025 –2032 | |

| USD 10.70 Billion | |

| USD 16.36 Billion | |

|

|

|

|

Global Metal Finishing Chemicals Market Segmentation, By Type (Plating Chemicals, Proprietary Chemicals, Cleaning Chemicals, Conversion Coating Chemicals), Process (Electroplating, Plating, Anodizing, Carbonizing, Polishing, Thermal Or Plasma Spray Coating, Others), Material (Zinc, Nickel, Chromium, Aluminum, Copper, Precious Metals, Others), End-Use Industry (Automotive, Electrical & Electronics, Industrial Machinery, Aerospace & Defence, Construction, Others)- Industry Trends and Forecast to 2032

Metal Finishing Chemicals Market Size

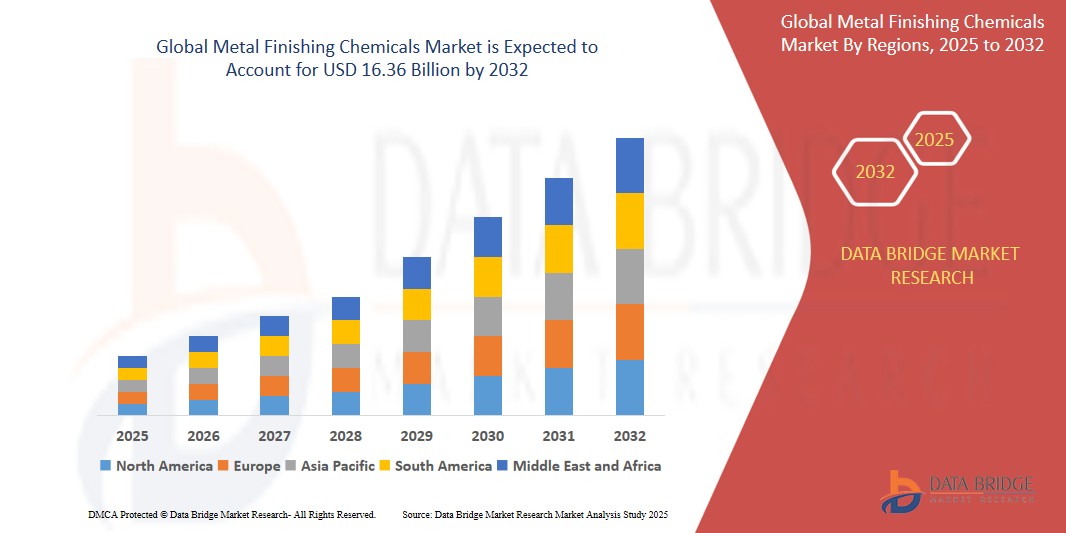

- The global Metal Finishing Chemicals market was valued atUSD 10.70 billion in 2024 and is expected to reachUSD 16.36 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at aCAGR of5.45%, primarily driven by the growing number of applications from automotive industry.

- This growth is driven by factors such as the rise in the usages of chemicals in aerospace maintenance, repair and overhauls.

Metal Finishing Chemicals Market Analysis

- Metal Finishing Chemicals are essential materials used to improve the surface properties of metal components, providing corrosion resistance, enhancing appearance, and ensuring durability across industries like automotive, aerospace, electronics, and construction. They are vital for processes such as electroplating, anodizing, and polishing.

- The demand for these chemicals is significantly driven by the rising need for high-performance and corrosion-resistant materials, especially in automotive lightweighting and the growing electronics sector. Over half of the global demand is fueled by industries pushing for enhanced surface functionality and environmental compliance, particularly in automotive manufacturing and consumer electronics.

- The Asia-Pacific region stands out as one of the dominant regions for Metal Finishing Chemicals, driven by rapid industrialization, a booming automotive sector, and increasing manufacturing activities across countries like China, India, and Japan.

- For instance, China leads the global electroplating and surface treatment market, with strong government support for expanding manufacturing capabilities and stringent environmental regulations encouraging the use of advanced metal finishing technologies.

- Globally, Metal Finishing Chemicals rank as one of the most crucial chemical categories in surface engineering, second only to industrial coatings, and play a pivotal role in enhancing the longevity, aesthetics, and functionality of critical metal components across multiple industries.

Report Scope and Metal Finishing Chemicals Market Segmentation

|

Attributes |

Metal Finishing Chemicals Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

• DOW (U.S.) • NOF CORPORATION (Japan) • ELEMENTIS PLC (United Kingdom) • Atotech (Germany) • Chemetall GmbH (Germany) • Coral (India) • Houghton International Inc. (U.S.) • McGean-Rohco Inc. (U.S.) • A Brite Company (U.S.) • COVENTYA International (France) • C.Uyemura & CO., LTD. (Japan) • Grauer & Weil (India) Limited (India) • Henkel Adhesives Technologies India Private Limited (India) • Industrial Metal Finishing, Inc. (U.S.) • Metal Finishing Technologies, LLC (U.S.) • Quaker Chemical Corporation (U.S.) • RASCHIG GmbH (Germany) • Wuhan Jadechem International Trade Co., Ltd. (China) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Metal Finishing Chemicals Market Trends

“Shift Towards Eco-friendly and Sustainable Metal Finishing Solutions”

- One prominent trend in the global Metal Finishing Chemicals market is the increasing shift toward eco-friendly and sustainable solutions.

- This trend is driven by rising environmental regulations and the growing demand for green manufacturing practices across industries such as automotive, aerospace, and electronics.

- For instance, chromium-free coatings and water-based chemicals are becoming more popular due to their lower environmental impact and regulatory compliance. These sustainable options help manufacturers reduce their carbon footprint and align with global sustainability goals.

- In addition, the development of biodegradable and non-toxic chemicals is providing an opportunity for companies to meet stricter environmental standards while offering high-performance results.

- This trend is reshaping the metal finishing landscape, driving the demand for more sustainable practices and leading to increased market growth for eco-friendly chemicals.

Metal Finishing Chemicals Market Dynamics

Driver

“Increasing Demand for High-Performance Materials in Manufacturing”

- The growing demand for high-performance materials in industries such as automotive, aerospace, and electronics is significantly driving the need for advanced Metal Finishing Chemicals.

- As industries strive for lighter, stronger, and more durable materials, the role of metal finishing chemicals becomes crucial in improving corrosion resistance, surface hardness, and overall appearance.

- Automotive manufacturers, for example, are pushing for materials that reduce weight while maintaining strength and durability, which in turn demands advanced coating solutions.

- Additionally, the aerospace sector requires finishing solutions that can withstand extreme temperatures and environments, further increasing demand for specialized metal finishing chemicals.

For instance,

- In July 2024, according to the International Energy Agency (IEA), the global automotive industry's focus on electric vehicle production is driving the need for lighter metal components. This, in turn, boosts the demand for advanced surface treatment solutions, including coatings and electroplating, to improve the durability and performance of metals.

- In June 2023, the aerospace sector reported a surge in demand for high-quality, corrosion-resistant materials that are critical for maintaining the safety and efficiency of aircraft, a trend that directly impacts the demand for metal finishing chemicals.

Opportunity

“Growth of Eco-friendly and Sustainable Finishing Solutions”

- As global environmental regulations tighten and industries seek sustainable manufacturing processes, there is a significant opportunity for the development and adoption of eco-friendly metal finishing chemicals.

- Manufacturers are increasingly focusing on solutions that are water-based, biodegradable, and chromium-free, which are not only safer for the environment but also align with green certifications and regulatory requirements.

- The automotive and electronics industries, in particular, are looking for alternatives to toxic chemicals like hexavalent chromium, which has led to the rise of eco-friendly coatings and non-toxic finishing agents.

For instance,

- In July 2023, the European Union introduced stricter regulations on hazardous chemicals in manufacturing processes, leading to a shift toward sustainable and eco-friendly alternatives in surface treatments. This regulatory shift creates significant opportunities for companies to innovate in sustainable metal finishing chemicals.

- In December 2022, automotive manufacturers in the U.S. announced their commitment to reducing environmental impact, pushing for increased use of water-based and environmentally friendly finishing chemicals in vehicle production.

Restraint/Challenge

“High Production Costs and Regulatory Compliance”

- The production of advanced metal finishing chemicals involves high research and development costs, especially when creating eco-friendly or specialized chemical formulations.

- Compliance with increasingly stringent environmental regulations also adds to operational costs for manufacturers, particularly those producing chromium-free, biodegradable, or low-VOC products.

- These factors can increase the final cost of metal finishing chemicals, limiting their adoption, particularly in cost-sensitive industries or regions with less developed regulatory standards.

For instance,

- In August 2024, a report by Chemical Engineering News highlighted that the production of eco-friendly metal finishing chemicals is 20-30% more expensive than conventional chemical alternatives, which could impact the price competitiveness of manufacturers in markets with low cost tolerance.

Metal Finishing Chemicals Market Scope

The market is segmented on the basis Type, Process, Material, End-Use Industry,

|

Segmentation |

Sub-Segmentation |

|

By Type |

|

|

By Process |

|

|

By End-Use Industry

|

|

|

By Material |

|

Metal Finishing Chemicals Market Regional Analysis

“North America is the Dominant Region in the Metal Finishing Chemicals Market”

- North America dominates the Metal Finishing Chemicals market, driven by advanced manufacturing capabilities, technological innovations, and a robust industrial base, particularly in industries such as automotive, aerospace, and electronics.

- The U.S. holds a significant market share due to the high demand for high-performance materials that require specialized metal finishing treatments, such as coatings for corrosion resistance, surface hardening, and aesthetic enhancement.

- The region’s strong regulatory framework and emphasis on advanced manufacturing processes, along with a significant presence of leading metal finishing chemical producers, contribute to the market’s dominance.

- Additionally, the growing emphasis on sustainability and eco-friendly chemical alternatives in the U.S. and Canada is further driving the demand for innovative metal finishing solutions.

- The automotive industry’s push for lightweight, durable materials and the aerospace sector’s need for corrosion-resistant finishes are significant factors fueling the region’s dominance in the global market.

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- The Asia-Pacific (APAC) region is expected to witness the highest growth rate in the Metal Finishing Chemicals market, fueled by rapid industrialization, growing manufacturing sectors, and increasing demand for high-quality materials in the automotive, electronics, and consumer goods industries.

- China and India are emerging as key markets, driven by their large manufacturing bases and growing adoption of high-performance materials in sectors like automotive and electronics.

- China, being a global manufacturing hub, demands advanced surface treatment chemicals to meet the high standards required for precision components in industries such as automotive and electronics. The increasing push for sustainable practices in Chinese manufacturing is further contributing to the market’s growth.

- Japan, with its advanced manufacturing technologies and strong industrial base in electronics and automotive, is a crucial market for specialized metal finishing chemicals. Japan continues to adopt innovative metal finishing solutions, particularly those that enhance corrosion resistance and surface durability in precision-engineered products.

- The growing demand for eco-friendly and sustainable chemical solutions across APAC, coupled with government initiatives promoting high-tech manufacturing, positions this region for continued market expansion in the coming years.

Metal Finishing Chemicals Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, Type dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- DOW (U.S.)

- NOF CORPORATION (Japan)

- ELEMENTIS PLC (United Kingdom)

- Atotech (Germany)

- Chemetall GmbH (Germany)

- Coral (India)

- Houghton International Inc. (U.S.)

- McGean-Rohco Inc. (U.S.)

- A Brite Company (U.S.)

- COVENTYA International (France)

- C.Uyemura & CO., LTD. (Japan)

- Grauer & Weil (India) Limited (India)

- Henkel Adhesives Technologies India Private Limited (India)

- Industrial Metal Finishing, Inc. (U.S.)

- Metal Finishing Technologies, LLC (U.S.)

- Quaker Chemical Corporation (U.S.)

- RASCHIG GmbH (Germany)

- Wuhan Jadechem International Trade Co., Ltd. (China)

Latest Developments in Global Metal Finishing Chemicals Market

- In March 2025, Elementis PLC, a global leader in metal finishing chemicals, announced the launch of its new eco-friendly, chromium-free surface treatment solutions. These new formulations meet increasingly stringent environmental regulations while offering high-performance properties such as enhanced corrosion resistance and durability. The products are aimed at the automotive and aerospace industries, where the demand for sustainable and high-performance materials is growing rapidly.

- In December 2024, Atotech revealed its new line of high-efficiency plating chemicals designed for the electronics industry. The new products enable faster processing times and improved adhesion properties, making them ideal for the production of microelectronics and semiconductors. This launch is in response to the increasing demand for advanced materials in the smart device and automotive electronics markets, where precision and reliability are critical.

- In November 2024, Chemetall GmbH announced the introduction of a new environmentally friendly coating system for automotive and aerospace applications. The system is designed to reduce energy consumption and the environmental impact during the finishing process. It aligns with global sustainability efforts and offers improved resistance to corrosion and wear, further strengthening the company’s position as a leader in sustainable metal finishing solutions.

- In October 2024, Houghton International Inc. unveiled a new range of cutting-edge lubrication chemicals for industrial metalworking applications. These chemicals, designed for high-performance machinery and metal forming processes, offer superior cooling and lubrication properties, extending the lifespan of industrial tools while increasing overall manufacturing efficiency.

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

研究方法

数据收集和基准年分析是使用具有大样本量的数据收集模块完成的。该阶段包括通过各种来源和策略获取市场信息或相关数据。它包括提前检查和规划从过去获得的所有数据。它同样包括检查不同信息源中出现的信息不一致。使用市场统计和连贯模型分析和估计市场数据。此外,市场份额分析和关键趋势分析是市场报告中的主要成功因素。要了解更多信息,请请求分析师致电或下拉您的询问。

DBMR 研究团队使用的关键研究方法是数据三角测量,其中包括数据挖掘、数据变量对市场影响的分析和主要(行业专家)验证。数据模型包括供应商定位网格、市场时间线分析、市场概览和指南、公司定位网格、专利分析、定价分析、公司市场份额分析、测量标准、全球与区域和供应商份额分析。要了解有关研究方法的更多信息,请向我们的行业专家咨询。

可定制

Data Bridge Market Research 是高级形成性研究领域的领导者。我们为向现有和新客户提供符合其目标的数据和分析而感到自豪。报告可定制,包括目标品牌的价格趋势分析、了解其他国家的市场(索取国家列表)、临床试验结果数据、文献综述、翻新市场和产品基础分析。目标竞争对手的市场分析可以从基于技术的分析到市场组合策略进行分析。我们可以按照您所需的格式和数据样式添加您需要的任意数量的竞争对手数据。我们的分析师团队还可以为您提供原始 Excel 文件数据透视表(事实手册)中的数据,或者可以帮助您根据报告中的数据集创建演示文稿。