The global automotive landscape is undergoing a fundamental structural transformation, characterized by the dual trends of electrification and component miniaturization. As Internal Combustion Engine (ICE) vehicles give way to Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs), the demand for traditional, bulky engine components is being replaced by a need for smaller, high-precision, and multifunctional metal parts. Metal Injection Molding (MIM) has emerged as the critical enabler for this shift, as it allow for the production of intricate geometries in materials like 316L and 17-4PH that would be prohibitively expensive to machine. The drive for "lightweighting" to extend EV battery range, coupled with the miniaturization of sensors for Advanced Driver-Assistance Systems (ADAS), has directly catalyzed the consumption of specialized MIM powders and feedstocks. The upward trajectory in vehicle electrification—marked by a shift from mass-produced simple parts to high-value, miniaturized assemblies—has solidified the role of 316L and 17-4PH powders in the automotive supply chain. These materials have thus emerged as a critical component in the global MIM feedstock market, enabling the creation of the high-strength, lightweight, and complex hardware necessary for the next generation of autonomous and electric mobility

Access Full Report @ https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-powders-and-feedstock-market

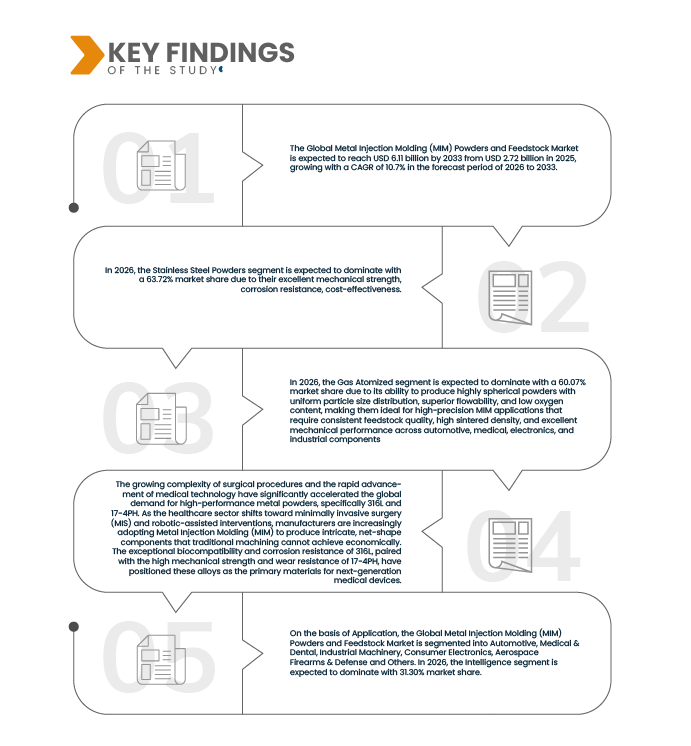

Data Bridge market research analyzes that Global Metal Injection Molding (MIM) Powders and Feedstock Market is expected to reach USD 6.11 billion by 2033 from USD 2.71 billion in 2025, growing with a substantial CAGR of 10.7% in the forecast period of 2025 to 2033.

Key Findings of the Study

Increasing Demand for Titanium and Specialty Alloy Feedstocks in High Value Applications

The global Metal Injection Molding (MIM) powders and feedstock market is increasingly benefiting from rising demand for titanium and specialty alloy feedstocks driven by high‑value applications in medical, aerospace, and defense sectors. Titanium alloys are prized for their high strength‑to‑weight ratio, corrosion resistance, and biocompatibility, making them ideal for demanding applications such as orthopedic and dental implants, surgical instruments, and lightweight structural components in aircraft and spacecraft. MIM processes that utilize titanium and other engineered specialty alloys enable manufacturers to produce complex, near‑net‑shape parts with high precision and minimal waste — capabilities that are increasingly sought by OEMs focused on performance, reliability, and innovation. As suppliers expand their titanium and specialty alloy offerings, the availability of tailored feedstock supports broader adoption in applications where performance characteristics directly influence product value and safety.

For instances,

- In 2025, Advanced Powder Products (APP) outlined that its titanium MIM feedstock is engineered for applications requiring biocompatibility and lightweight performance such as medical devices, surgical implants, and aerospace components, showcasing supplier positioning of titanium alloys for high‑value end uses.

- In 2025, Advanced Powder Products’ medical division highlighted that ISO 13485‑certified MIM components made from medical‑grade alloys, including titanium, support dental, surgical, and implantable applications, indicating specialized alloy demand in regulated healthcare markets.

The growing emphasis on titanium and specialty alloy feedstocks represents a significant opportunity for the global MIM powders and feedstock market. Regulatory approvals, such as those from the FDA and adherence to standards like ASTM F136 and ISO 5832‑3, validate the suitability of these materials for high‑value applications in medical, aerospace, and defense sectors. Suppliers capable of providing certified, high‑performance titanium and specialty alloys are well-positioned to meet rising OEM demand for complex, precise, and reliable components, driving market expansion and reinforcing the strategic importance of advanced MIM feedstocks

Report Scope and Market Segmentation

|

Report Metric

|

Details

|

|

Forecast Period

|

2026 to 2033

|

|

Base Year

|

2025

|

|

Historic Years

|

2024 (Customizable to 2018-2023)

|

|

Quantitative Units

|

Revenue in USD billion

|

|

Segments Covered

|

By Material type (Stainless Steel Powders, Low Alloy Steel Powders,

Nickel & Cobalt based Powders, Titanium Powders and Others), By

Production Method (Gas Atomized, Water Atomized, Mechanical Alloying

and Other Methods (Plasma, Ultrasonic)), By Application (Automotive,

Medical & Dental, Industrial Machinery, Consumer Electronics,

Aerospace, Firearms & Defense and Others), By End User (Electronics &

Electrical, Automotive OEMs, Medical Devices, Industrial Equipment,

Defense & Aerospace and Others), By Distribution Channel (Direct sales,

Distributors)

|

|

Countries Covered

|

North America

Europe

Asia-Pacific

Middle East And Africa

South America

|

|

Market Players Covered

|

|

|

Data Points Covered in the Report

|

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include Porter’s five forces analysis, challenges and barriers, comparative analysis/benchmarking, analysis on capex & opex, for metal powder production capacity of 20,000 tonne/year, costing analysis, raw material coverage, supply chain analysis, technological advancement, value chain analysis, innovation tracker and strategic analysis, product category-wise key players, tariffs & impact on the market, regulation coverage.

|

Segment Analysis

The Global Metal Injection Molding (MIM) Powders and Feedstock Market is segmented into five notable segments based on the material type, Production method, application, end user and distribution channel

- On the basis of Material type, the Global Metal Injection Molding (MIM) Powders and Feedstock Market is segmented into Stainless Steel Powders, Low Alloy Steel Powders, Nickel & Cobalt based Powders, Titanium Powders and Others.

In 2026, the Stainless Steel Powders segment is expected to dominate the market

In 2026, the Stainless Steel Powders segment is expected to dominate the global Metal Injection Molding (MIM) Powders and Feedstock market share of 63.72% due to to its excellent balance of mechanical strength, corrosion resistance, and costeffectiveness, along with its wide adoption across automotive, medical, consumer electronics, and industrial machinery applications. The material’s compatibility with high-volume MIM processing and consistent sintering behavior further supports its dominant market position.

- On the basis of Production Method, the Global Metal Injection Molding (MIM) Powders and Feedstock Market is segmented into Gas Atomized, Water Atomized, Mechanical Alloying and Other Methods (Plasma, Ultrasonic).

In 2026, the Gas Atomized segment is expected to dominate the market

In 2026, Gas Atomized segment is expected to dominate the global Metal Injection Molding (MIM) Powders and Feedstock market share of 60.07% due to their superior powder sphericity, controlled particle size distribution, and enhanced flowability, which are critical for achieving high-density, defect-free MIM components. The increasing demand for precision parts with tight tolerances in automotive, medical, and aerospace applications continues to drive the adoption of gas atomized powders.

- On the basis of Application, the Global Metal Injection Molding (MIM) Powders and Feedstock Market is segmented into Automotive, Medical & Dental, Industrial Machinery, Consumer Electronics, Aerospace, Firearms & Defense and Others.

- On the basis of End user, the Global Metal Injection Molding (MIM) Powders and Feedstock Market is segmented into Electronics & Electrical, Automotive OEMs, Medical Devices, Industrial Equipment, Defense & Aerospace and Others.

- On the basis of Distribution channel, the Global Metal Injection Molding (MIM) Powders and Feedstock Market is segmented into Direct Sales and Distributors.

Major Players

Linde PLC (U.K.), BASF (Germany), Epson Atmix Corporation (Japan), Sandvik AB (Sweden), AMETEK Inc. (U.S.) among others.

Latest Developments in Global Metal Injection Molding (MIM) Powders and Feedstock Market

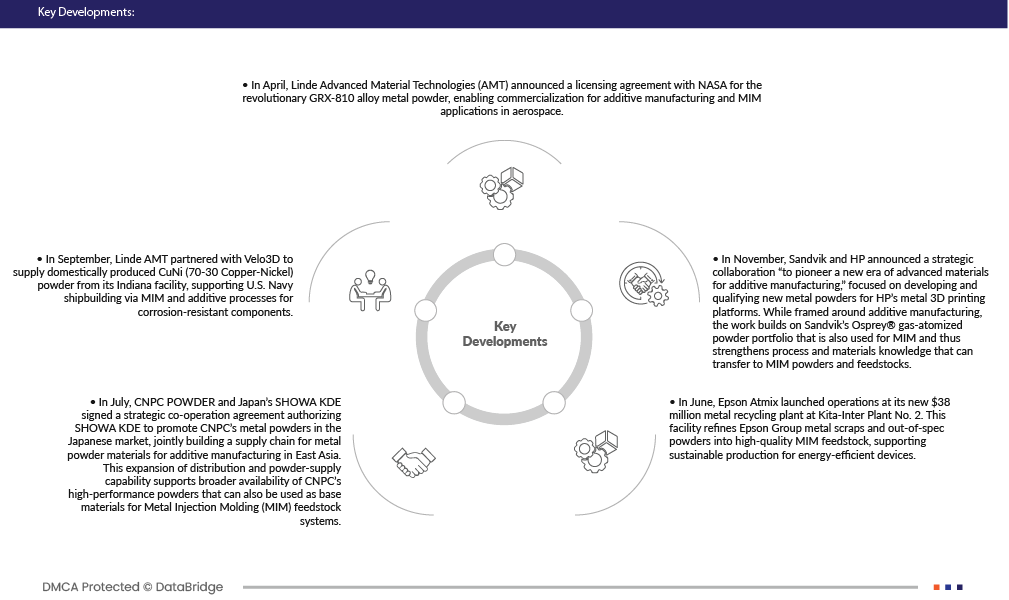

- In June 2025, Epson Atmix launched operations at its new $38 million metal recycling plant at Kita-Inter Plant No. 2. This facility refines Epson Group metal scraps and out-of-spec powders into high-quality MIM feedstock, supporting sustainable production for energy-efficient devices.

- In February 2025, BASF launched Catamold motion 8620, a new low-alloy feedstock using pre-alloyed gas-atomized powders for enhanced MIM performance in structural applications.

- In April 2024, Linde Advanced Material Technologies (AMT) announced a licensing agreement with NASA for the revolutionary GRX-810 alloy metal powder, enabling commercialization for additive manufacturing and MIM applications in aerospace.

- In November 2023, Sandvik and HP announced a strategic collaboration “to pioneer a new era of advanced materials for additive manufacturing,” focused on developing and qualifying new metal powders for HP’s metal 3D printing platforms. While framed around additive manufacturing, the work builds on Sandvik’s Osprey® gas‑atomized powder portfolio that is also used for MIM and thus strengthens process and materials knowledge that can transfer to MIM powders and feedstocks.

- In February 2023, Carpenter Additive expanded AM powder manufacturing capacity across global facilities including Torshälla (Sweden), Athens (Alabama), and Liverpool (England) to meet rising demand for MIM-grade powders in aerospace, medical, and energy sectors.

As per Data Bridge Market Research analysis:

Geographically, the country covered in the Global Metal Injection Molding (MIM) Powders and Feedstock Market are North America, Europe, Asia-Pacific, South America, Middle East & Africa. North America is sub-segmented into the U.S., Canada and Mexico. Europe Market is sub-segmented into Germany, Italy, France, U.K., Netherlands, Spain, Switzerland, Russia and Rest of Europe. Asia-Pacific Market is sub-segmented into China, Japan, South Korea, India, Australia, Singapore, Thailand, Indonesia, Malaysia, Philippines, New Zealand and Rest of Asia-Pacific. South America Market is sub-segmented into Brazil, Argentina, Colombia, Chile, Bolivia and Rest of South America. Middle East and Africa Market is sub-segmented into Saudi Arabia, United Arab Emirates, Israel, South Africa, Egypt and Rest of Middle East & Africa.

Asia-Pacific is the dominating country in Global Metal Injection Molding (MIM) Powders and Feedstock Market

Asia-Pacific is the Global Metal Injection Molding (MIM) Powders and Feedstock Market, driven by its strong manufacturing ecosystem, particularly in China, Japan, South Korea, and emerging hubs such as India and Southeast Asia. The region benefits from high demand from automotive (including EVs), consumer electronics, and medical devices, coupled with cost-competitive production, skilled labor availability, and rapid industrialization. Supportive government initiatives and continuous advancements in powder metallurgy and binder technologies further reinforce Asia-Pacific’s leadership in the global MIM value chain.

Asia-Pacific is expected to be the fastest growing country in Global Metal Injection Molding (MIM) Powders and Feedstock Market

Asia-Pacific is expected to be the fastest-growing region in the global Metal Injection Molding (MIM) powders and feedstock market, driven by rapid expansion of automotive and EV manufacturing, rising electronics production, and increasing adoption of MIM in medical devices. Growth is further supported by strong industrialization in China, India, and Southeast Asia, cost-efficient manufacturing capabilities, and government initiatives promoting advanced manufacturing and localized supply chains.

For more detailed information about the Global Metal Injection Molding (MIM) Powders and Feedstock Market report, click here – https://www.databridgemarketresearch.com/reports/global-metal-injection-molding-mim-powders-and-feedstock-market