Global Surface Mount Technology Market

시장 규모 (USD 10억)

연평균 성장률 :

%

USD

1,982.52 Million

USD

3,969.90 Million

2024

2032

USD

1,982.52 Million

USD

3,969.90 Million

2024

2032

| 2025 –2032 | |

| USD 1,982.52 Million | |

| USD 3,969.90 Million | |

|

|

|

|

Global Surface Mount Technology Market Segmentation, By Component (Passive Surface-Mount Devices, Transistor & Diodes, Integrated Circuits) Service (Design, Test and Prototype, Supply Chain Services, Manufacturing, Aftermarket Services), Equipment (Inspection Equipment, Placement Equipment, Soldering Equipment, Screen Printing Equipment, Cleaning Equipment, Repair and Rework Equipment), Application (Consumer Electronics, Telecommunication, Aerospace & Defense, Automotive, Medical, Industrial, Energy and Power Systems) - Industry Trends and Forecast to 2032

Surface Mount Technology Market Size

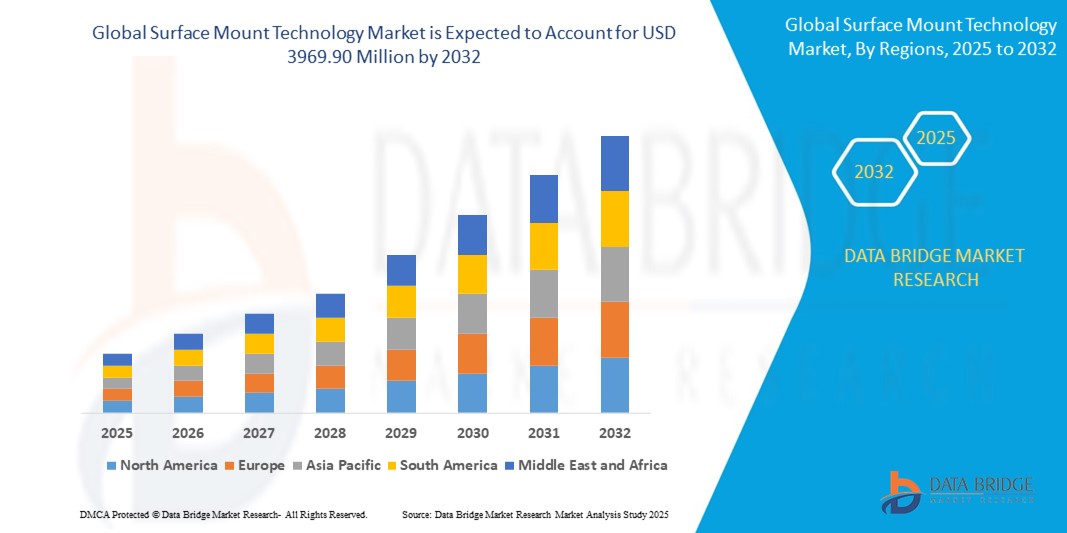

- The Global Surface Mount Technology Market was valued atUSD 1,982.52 Million in 2024and is expected to reachUSD 3,969.90 Million by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at aCAGR of 9.16%,primarily driven by the continuous advancements in miniaturization and automation across the electronics manufacturing sector.

- This growth is supported by factors such as the rising demand for compact, high-performance electronic devices, the increasing penetration of consumer electronics, and rapid technological innovations in assembly techniques and components.

Surface Mount Technology Market Analysis

- Surface mount technology (SMT) has become an essential method in the electronics manufacturing sector, enabling the placement of electronic components directly onto the surface ofprinted circuit boards (PCBs)with high precision and efficiency. It is fundamental for the production of a wide range of electronic devices, includingsmartphones, computers, automotive electronics, and medical devices.

- The demand for SMT is significantly fueled by the growing need for compact, lightweight, and high-performance electronics. Over half of the global demand is driven by sectors such asconsumer electronics and automotive manufacturing, where the miniaturization and reliability of components are critical to product innovation.

- North Americastands out as one of the dominant regions in the Surface Mount Technology market, supported by its advanced manufacturing infrastructure, strong presence of leading electronics companies, and rapid adoption of emerging technologies such as 5G, electric vehicles, and IoT devices.

- For instance, theUnited Stateshas seen a steady increase in investments in advanced electronics manufacturing facilities, with a focus onautomation, robotics, and high-precision SMT equipmentto meet the rising demand for next-generation electronic products.

- Globally, surface mount technology ranks as one of the most crucial techniques in modern electronics manufacturing, following through-hole technology, and plays a pivotal role in enhancing production efficiency, reducing manufacturing costs, and improving the performance of electronic devices.

Report Scope and Surface Mount Technology Market Segmentation

|

Attributes |

Surface Mount Technology Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Surface Mount Technology Market Trends

“increase in the manufacturing of electronic hardware devices”

- The continuous rise in the mass production of electronic hardware devices is a key factor fueling the growth of theGlobal Surface Mount Technology Market.

- As industries such asconsumer electronics, automotive, aerospace, and medical devices expand, the demand for efficient, high-volume manufacturing solutions like SMT becomes critical to meet production targets and maintain quality standards.

- Surface mount technology enables fasterassembly processes, higher component density, and cost-efficient production, which are essential for scaling up electronic hardware manufacturing operations.

- This demand is further amplified by the global push toward digitalization and smart technologies across various sectors.

For instance:

- According to a report byIPC Internationalin 2024, global electronic hardware production is expected to grow at aCAGR of 8%between 2024 and 2028, with surface mount assembly lines accounting for nearly70%of all PCB manufacturing during the period.

- Additionally, theConsumer Technology Association (CTA) reported that in 2024, sales of electronic devices like smart home gadgets and wearables surged by over10%,heavily relying on SMT processes for compact and efficient device manufacturing.

Surface Mount Technology Market Dynamics

Driver

“Increasing Demand for Miniaturized Consumer Electronics”

- The rapid rise in the demand for miniaturized consumer electronics products is significantly driving the growth of theGlobal Surface Mount Technology Market.

- As devices likesmartphones, tablets, wearables, and other compact gadgetsbecome more sophisticated, there is an increasing need for efficient and precise electronic component assembly, which SMT enables.

- In addition, the manufacturing of electronic hardware devices in large quantities requires technologies that ensurespeed, accuracy, and scalability, all of which are provided by surface mount technology.

- The growing electronic industry, especially in sectors likeautomotive, telecommunication, and medical devices,further propels the adoption of SMT solutions to meet high-performance and miniaturization requirements.

For instance:

- According to a report byIPC Internationalpublished in October 2024, global production of miniaturized electronics increased by nearly12% annuallyover the past three years, with smartphones, wearables, and IoT devices being the major contributors, heavily relying on surface mount technology for compact designs.

- This trend is expected to continue as innovation in electronic device functionality and compactness accelerates.

Opportunity

“Rising Adoption of Surface Mount Technology in Electric Vehicles and LED Lighting”

- The increasing global adoption of electric vehicles (EVs) presents a substantial growth opportunity for theSurface Mount Technology Market.

- EVs require a complex network of electronic components forbattery management, safety systems, and autonomous driving features, all of which benefit from the efficiency and reliability of SMT.

- Moreover, the rising demandfor LED lighting systemsin automotive, industrial, and residential sectors is boosting the application of SMT, as LED assemblies heavily rely on surface-mounted components for compact and efficient designs.

For instance:

- According to theInternational Energy Agency (IEA)2024 report, global EV sales surpassed14 million units, and the demand for PCB assembly technologies like SMT grew proportionally to support increased EV electronic requirements.

- Similarly, a 2024 report byLEDinsidehighlighted that the global LED lighting market size is projected to exceedUSD 96 billionby 2027, with surface mount LEDs being the dominant technology in lighting designs.

- The growing integration of biometrics and security features into consumer electronics and medical devices is also expected to create new avenues for market expansion during the forecast period.

Restraint/Challenge

“High Initial Investment Costs and Thermal Management Challenges”

- The substantial initial investment required for setting up advanced SMT production lines, includinghigh-precision machinery and automated systems, poses a significant challenge, particularly for small and medium-sized enterprises (SMEs).

- SMT equipment such asreflow ovens, automated optical inspection (AOI) machines, and surface mount pick-and-place systemscan be extremely expensive, creating a financial burden for companies with limited budgets.

- Moreover, the additional costs associated with training personnel, maintaining sophisticated machines, and regularly upgrading systems to stay competitive add to the overall operational expenditure.

For instance:

- According to a November 2024 analysisby Electronics Manufacturing Journal, the cost of a fully automated SMT production line can range fromUSD 400,000 to over USD 2 million,depending on the level of automation and precision required.

- In October 2024, a survey conducted by theGlobal Electronics Councilhighlighted that nearly45%of mid-sized electronics manufacturers cited high capital investment requirements as a major barrier to adopting next-generation SMT technologies.

- This financial constraint often leads smaller firms to delay upgrading their facilities or rely on less efficient manual assembly methods, thereby impacting market growth potential and slowing technological adoption rates in certain regions.

Surface Mount Technology Market Scope

Surface mount technology market is segmented on the basis of component, service, equipment and application.

|

Segmentation |

Sub-Segmentation |

|

By Component |

|

|

By Service |

|

|

By Equipment |

|

|

By Application |

|

Surface Mount Technology Market Regional Analysis

“Asia-Pacific is the Dominant Region in the Surface Mount Technology Market”

- Asia-Pacific dominates theSurface Mount Technology Market, driven by the strong presence of advanced manufacturing facilities, rapid adoption of automation in electronic assembly, and robust technological advancements.

- Chinaholds a significant share due to the growing demand for miniaturized electronic devices, advancements in telecommunication technologies, and increasing use of SMT inautomotive and industrial applications.

- The presence of major semiconductor and electronics manufacturers, coupled with heavy investments in R&D activities to enhance production efficiency and product quality, further supports the market growth.

- In addition, the rising trend ofsmart manufacturing and Industry 4.0 initiatives, along with increasing demand for high-performance consumer electronics, is fueling the expansion of the Surface Mount Technology market across the region.

“Europe is Projected to Register the Highest Growth Rate”

- The Europe region is expected to register the highest growth rate in the Surface Mount Technology Market, fueled by the boomingelectronics industry, expanding industrialization, and growing demand for advanced consumer electronics.

- Countries such asGermany, France, Spain, U.K.are emerging as key markets due to the increasing production and export of electronic devices and rising investments in manufacturing technologies.

- Germany, with its strong emphasis on precision manufacturing and innovation, remains a crucial market for SMT, leading in the adoption of high-end assembly technologies to support theautomotive, electronics, and telecommunication sectors.

- Germany and U.K.,with their large manufacturing bases and supportive government initiatives for domestic production, are experiencing rapid growth in SMT adoption. The increasing presence of global electronics manufacturers and continuous technological advancements further contribute to the market’s expansion in the region.

Surface Mount Technology Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- ASM Assembly Systems GmbH & Co. KG(Germany)

- YXLON International(Germany)

- Viscom AG(Germany)

- Universal Instruments Corporation(United States)

- Teradyne Inc.(United States)

- Saki Corporation(Japan)

- Panasonic Corporation (Japan)

- Orbotech Ltd.(Israel)

- OMRON Corporation(Japan)

- Nordson Corporation(United States)

- Nikon Metrology Inc.(Japan)

- Naprotek, Inc. (United States)

- Mycronic(Sweden)

- Kulicke & Soffa Industries Inc. (United States)

- KOHYOUNG TECHNOLOGY Inc. (South Korea)

- JUKI CORPORATION(Japan)

- Illinois Tool Works Inc.(United States)

- GLENBROOK TECHNOLOGIES(United States)

- FUJI Corporation(Japan)

- Electro Scientific Industries, Inc.(United States)

- Yamaha Motor Co., Ltd.(Japan)

Latest Developments in Global Surface Mount Technology Market

- In January 2025,ASMPT Limited, a leading provider of surface mount technology equipment, announced the launch of its newSIPLACE CA2 system, designed to enhance the integration of chip assembly and SMT placement. This next-generation platform improves efficiency by allowing multiple production steps to be performed in a single machine, reducing operational costs and improving throughput for electronics manufacturers globally.

- In October 2024,Panasonic Corporationunveiled its latest generation of high-speed placement machines at the Productronica exhibition. The new equipment features enhancedAI-based optimization software, capable of predictive maintenance, real-time defect detection, and automated line balancing. These innovations aim to improve production yields and line efficiency in complex PCB assembly environments.

- In September 2024,Yamaha Motor Co., Ltd.introduced itsstate-of-the-art YRM20DL SMT machineat SEMICON Taiwan 2024. This dual-lane modular system is built for high-mix, high-volume production and leverages advanced motion control technology, reducing placement time and increasing precision, crucial for next-gen electronic device manufacturing.

- In September 2024,Nordson Corporationannounced the commercial release of itsASYMTEK Select Coat® SL-1040 conformal coating system. With upgraded automation and inspection capabilities, this system supports manufacturers' push towards Industry 4.0, offering closed-loop process controls and smart analytics to minimize coating defects and maximize productivity in electronic assembly lines.

SKU-

세계 최초의 시장 정보 클라우드 보고서에 온라인으로 접속하세요

- 대화형 데이터 분석 대시보드

- 높은 성장 잠재력 기회를 위한 회사 분석 대시보드

- 사용자 정의 및 질의를 위한 리서치 분석가 액세스

- 대화형 대시보드를 통한 경쟁자 분석

- 최신 뉴스, 업데이트 및 추세 분석

- 포괄적인 경쟁자 추적을 위한 벤치마크 분석의 힘 활용

연구 방법론

데이터 수집 및 기준 연도 분석은 대규모 샘플 크기의 데이터 수집 모듈을 사용하여 수행됩니다. 이 단계에는 다양한 소스와 전략을 통해 시장 정보 또는 관련 데이터를 얻는 것이 포함됩니다. 여기에는 과거에 수집한 모든 데이터를 미리 검토하고 계획하는 것이 포함됩니다. 또한 다양한 정보 소스에서 발견되는 정보 불일치를 검토하는 것도 포함됩니다. 시장 데이터는 시장 통계 및 일관된 모델을 사용하여 분석하고 추정합니다. 또한 시장 점유율 분석 및 주요 추세 분석은 시장 보고서의 주요 성공 요인입니다. 자세한 내용은 분석가에게 전화를 요청하거나 문의 사항을 드롭하세요.

DBMR 연구팀에서 사용하는 주요 연구 방법론은 데이터 마이닝, 시장에 대한 데이터 변수의 영향 분석 및 주요(산업 전문가) 검증을 포함하는 데이터 삼각 측량입니다. 데이터 모델에는 공급업체 포지셔닝 그리드, 시장 타임라인 분석, 시장 개요 및 가이드, 회사 포지셔닝 그리드, 특허 분석, 가격 분석, 회사 시장 점유율 분석, 측정 기준, 글로벌 대 지역 및 공급업체 점유율 분석이 포함됩니다. 연구 방법론에 대해 자세히 알아보려면 문의를 통해 업계 전문가에게 문의하세요.

사용자 정의 가능

Data Bridge Market Research는 고급 형성 연구 분야의 선두 주자입니다. 저희는 기존 및 신규 고객에게 목표에 맞는 데이터와 분석을 제공하는 데 자부심을 느낍니다. 보고서는 추가 국가에 대한 시장 이해(국가 목록 요청), 임상 시험 결과 데이터, 문헌 검토, 재생 시장 및 제품 기반 분석을 포함하도록 사용자 정의할 수 있습니다. 기술 기반 분석에서 시장 포트폴리오 전략에 이르기까지 타겟 경쟁업체의 시장 분석을 분석할 수 있습니다. 귀하가 원하는 형식과 데이터 스타일로 필요한 만큼 많은 경쟁자를 추가할 수 있습니다. 저희 분석가 팀은 또한 원시 엑셀 파일 피벗 테이블(팩트북)로 데이터를 제공하거나 보고서에서 사용 가능한 데이터 세트에서 프레젠테이션을 만드는 데 도움을 줄 수 있습니다.