Global Automotive Adhesives Market

Market Size in USD Billion

CAGR :

%

USD

33.12 Billion

USD

61.30 Billion

2024

2032

USD

33.12 Billion

USD

61.30 Billion

2024

2032

| 2025 –2032 | |

| USD 33.12 Billion | |

| USD 61.30 Billion | |

|

|

|

Automotive Adhesives Market Analysis

The automotive adhesives market is experiencing significant growth, driven by increasing demand for lightweight and fuel-efficient vehicles, advancements in adhesive technologies, and stringent government regulations on emissions. Automakers are shifting from traditional welding and mechanical fastening to high-performance adhesives to enhance vehicle structural integrity, crash resistance, and durability. The rise of electric vehicles (EVs) has further accelerated the adoption of specialized adhesives designed to improve thermal management, battery pack assembly, and vibration resistance.

Technological advancements such as smart adhesives with self-healing properties, nanotechnology-based adhesives, and bio-based adhesive formulations are revolutionizing the market. For instance, Henkel’s Loctite TLB 9300 APSi, launched in 2023, enhances EV battery system performance and safety. Similarly, Bostik’s Born2Bond engineering adhesives offer precise bonding solutions for automotive electronics and interior applications.

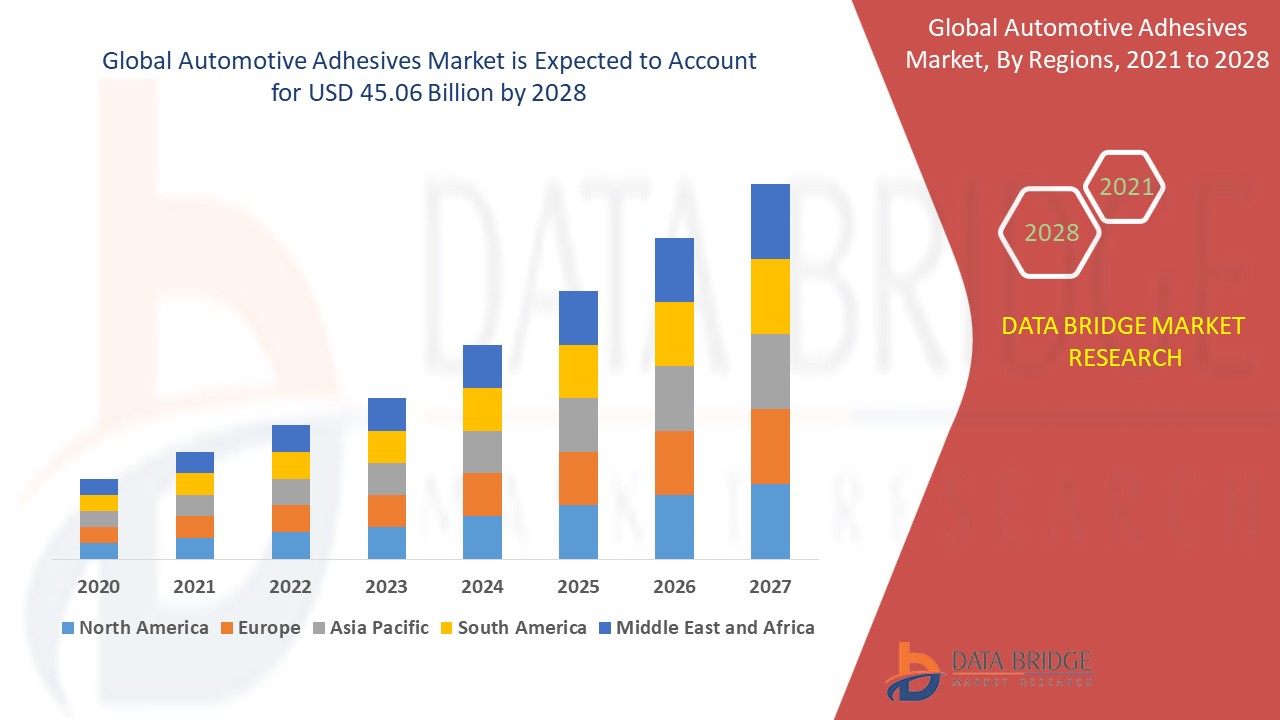

The Asia-Pacific region dominates the market due to the growing automotive production in China, India, and Japan, while North America and Europe witness steady growth due to high RandD investments and regulatory compliance. As the industry advances, automotive adhesives will play a pivotal role in vehicle design, safety, and sustainability.

Automotive Adhesives Market Size

The global automotive adhesives market size was valued at USD 33.12 billion in 2024 and is projected to reach USD 61.30 billion by 2032, with a CAGR of 8.00% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Automotive Adhesives Market Trends

“Growing Adoption of Structural Adhesives for Lightweight Vehicle Manufacturing”

The automotive adhesives market is witnessing a major trend in the adoption of structural adhesives for lightweight vehicle manufacturing, aimed at enhancing fuel efficiency and reducing carbon emissions. Automakers are increasingly replacing welding and mechanical fasteners with high-performance adhesives to bond multi-material structures such as aluminum, carbon fiber, and high-strength steel, a shift accelerated by the rise of electric vehicles (EVs) where weight reduction is crucial for extending battery range. For instance, BMW’s i-Series and Tesla’s Model 3 extensively use advanced structural adhesives to improve chassis strength without adding weight, while Henkel’s epoxy-based adhesives offer thermal stability and crash resistance for EV battery pack assembly. With stricter automotive regulations pushing for sustainability and efficiency, manufacturers are investing in next-generation adhesives with improved bonding strength, durability, and eco-friendly formulations, making them an essential component of modern vehicle design and performance.

Report Scope and Automotive Adhesives Market Segmentation

|

Attributes |

Automotive Adhesives Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

3M (U.S.), Bostik (France), Ashland (U.S.), BASF (Germany), Bemis Associates Inc. (U.S.), DuPont (U.S.), Covestro AG (Germany), EMS-CHEMIE HOLDING AG (Switzerland), H.B. Fuller Company (U.S.), Henkel AG and Co. KGaA (Germany), Huntsman International LLC. (U.S.), Illinois Tool Works Inc. (U.S.), Permatex (U.S.), Parker Hannifin Corp (U.S.), Nitto Denko Corporation (Japan), RPM International Inc. (U.S.), Dow (U.S.), ThreeBond International (Japan), and Wacker Chemie AG (Germany) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Automotive Adhesives Market Definition

Automotive adhesives are high-performance bonding materials used in vehicle manufacturing to join various components, enhance structural integrity, and improve safety, durability, and efficiency. These adhesives replace traditional welding, riveting, and mechanical fasteners, enabling the use of lightweight materials such as aluminum, carbon fiber, and composites, which help reduce vehicle weight and enhance fuel efficiency.

Automotive Adhesives Market Dynamics

Drivers

- Growing Demand for Lightweight and Fuel-Efficient Vehicles

The increasing focus on fuel efficiency and emission reduction has accelerated the adoption of lightweight materials in automotive manufacturing. Traditional welding and mechanical fasteners add unnecessary weight to vehicles, leading manufacturers to replace them with high-performance adhesives that offer strong, durable bonding for materials such as aluminum, composites, and carbon fiber. The use of adhesives not only enhances structural integrity but also significantly reduces vehicle weight, leading to improved fuel efficiency and lower emissions. For instance, BMW’s i-Series and Tesla’s Model 3 incorporate structural adhesives in their designs, optimizing lightweight construction without compromising strength. This shift is a key market driver, as automakers globally strive to meet stringent emission regulations and improve vehicle performance while enhancing crash safety and durability.

- Rising Adoption of Electric Vehicles (EVs)

The surging demand for electric vehicles (EVs) has created a need for high-performance adhesives in battery pack assembly, structural bonding, and thermal management. Unlike conventional vehicles, EVs require lightweight materials to extend battery range and energy efficiency. Adhesives help eliminate excess weight while providing excellent heat dissipation, vibration resistance, and structural strength crucial factors in EV safety and performance. A prime instance is Henkel’s Loctite TLB 9300 APSi, a thermally conductive adhesive designed to improve battery system efficiency, heat management, and structural integrity in EVs. As automakers continue to expand their EV production, the demand for advanced adhesive solutions is rising, making this a key driver of the automotive adhesives market.

Opportunities

- Increasing Stringent Environmental and Safety Regulations

Global regulatory bodies such as the EPA, Euro NCAP, and NHTSA are enforcing stricter fuel efficiency and emission standards, compelling automakers to adopt sustainable and low-VOC (volatile organic compound) adhesives. These regulations aim to reduce carbon footprints, promote recyclability, and enhance vehicle safety. As a result, automakers are shifting from traditional welding and mechanical fasteners to structural adhesives, which provide lighter, stronger, and more durable bonding solutions while complying with environmental laws. In addition, adhesives play a critical role in improving crash resistance and passenger safety. For instance, Ford’s aluminum-intensive F-150 utilizes structural adhesives to enhance body strength, impact absorption, and energy dissipation during collisions, ensuring compliance with modern safety standards. This regulatory shift presents a major market opportunity, as manufacturers increasingly invest in eco-friendly adhesive solutions to meet evolving global standards.

- Increasing Advancements in Adhesive Technologies

Continuous innovations in epoxy, polyurethane, acrylic, and silicone-based adhesives are transforming automotive manufacturing by enhancing bonding strength, flexibility, and thermal stability. The latest adhesive solutions are designed to withstand extreme temperatures, harsh environmental conditions, and high mechanical stress, making them ideal for next-generation vehicle production. In addition, the integration of smart adhesives with self-healing properties, temperature adaptability, and conductivity features is driving significant market growth. These advancements support the development of lightweight structures and electronic components, which are essential for modern electric and autonomous vehicles. A notable instance is Bostik’s Born2Bond™ engineering adhesives, which offer high-precision bonding solutions for automotive electronics and lightweight materials. The increasing adoption of these advanced adhesives in EVs, connected cars, and high-performance vehicles is a key market opportunity, as automakers seek cutting-edge adhesive technologies to enhance vehicle efficiency and durability.

Restraints/Challenges

- Durability and Long-Term Performance Concerns

Automotive adhesives face challenges related to durability, long-term performance, and resistance to environmental factors. Exposure to extreme temperatures, humidity, chemicals, and mechanical stress can cause adhesive degradation, loss of bonding strength, and failure over time. This concern is particularly significant in electric vehicles (EVs) and high-performance automobiles, where adhesives must withstand intense heat from battery packs, rapid temperature fluctuations, and continuous vibrations. For instance, adhesive failure in an EV battery enclosure could compromise safety and performance, leading to higher warranty costs and recalls. As a result, manufacturers are under pressure to develop next-generation adhesives with enhanced heat resistance, moisture protection, and fatigue durability to ensure reliable long-term performance.

- High Initial Costs and Complex Implementation

The adoption of advanced automotive adhesives comes with high initial costs and complex implementation challenges, making it difficult for small and mid-sized manufacturers to integrate these solutions into their production processes. Unlike traditional welding and mechanical fasteners, structural adhesives require specialized application techniques, precise curing conditions, and material compatibility assessments. The need for advanced equipment, skilled labor, and quality control measures further increases operational expenses. For instance, OEMs using high-performance adhesives for lightweight vehicle structures must invest in specialized curing ovens, surface preparation processes, and automation systems, adding to production costs. This financial burden limits adoption in cost-sensitive markets, slowing overall market expansion.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions. Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Automotive Adhesives Market Scope

The market is segmented on the basis of resin type, technology, application, and vehicle type. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Resin Type

- Polyurethanes

- Epoxy

- Acrylics

- Silicone

- SMP (Silyl-Modified Polymers)

- Polyamide

- Others

Technology

- Hotmelt

- Solvent-Based

- Water-Based

- Pressure-Sensitive

- Others

Application

- Body in White

- Power Train

- Paint Shop

- Assembly

Vehicle Type

- Passenger Vehicles

- Light Commercial Vehicles

- Heavy Commercial Vehicles

Automotive Adhesives Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, resin type, technology, application, and vehicle type as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia-Pacific dominates the automotive adhesives market, driven by the increasing demand for high-performance adhesives in the automobile and transportation aftermarket. The region is witnessing rapid technological advancements in automotive adhesive formulations, enhancing vehicle durability, safety, and efficiency. In addition, the rising preference for lightweight vehicles to improve fuel efficiency and reduce carbon emissions is fueling market growth. Stringent environmental regulations and the growing adoption of electric vehicles (EVs) are further accelerating the demand for innovative adhesive solutions in the region.

North America is projected to experience the fastest compound annual growth rate (CAGR) in the automotive adhesives market during the forecast period. This growth is driven by increasing vehicle production, rising demand for lightweight and fuel-efficient vehicles, and advancements in adhesive technologies. In addition, stringent environmental regulations promoting sustainable and low-emission manufacturing processes are further boosting market expansion. The presence of key automotive manufacturers and ongoing research and development initiatives contribute to the region's rapid growth.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Automotive Adhesives Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Automotive Adhesives Market Leaders Operating in the Market Are:

- 3M (U.S.)

- Bostik (France)

- Ashland (U.S.)

- BASF (Germany)

- Bemis Associates Inc. (U.S.)

- DuPont (U.S.)

- Covestro AG (Germany)

- EMS-CHEMIE HOLDING AG (Switzerland)

- H.B. Fuller Company (U.S.)

- Henkel AG and Co. KGaA (Germany)

- Huntsman International LLC. (U.S.)

- Illinois Tool Works Inc. (U.S.)

- Permatex (U.S.)

- Parker Hannifin Corp (U.S.)

- Nitto Denko Corporation (Japan)

- RPM International Inc. (U.S.)

- Dow (U.S.)

- ThreeBond International (Japan)

- Wacker Chemie AG (Germany)

Latest Developments in Automotive Adhesives Market

- In May 2023, Henkel introduced Loctite TLB 9300 APSi, an injectable thermally conductive adhesive designed to enhance performance and safety in EV battery systems

- In January 2023, Saint-Gobain unveiled a new range of adhesives and sealants tailored for the automotive industry

- In May 2022, ITW Performance Polymers announced a distribution partnership with PREMA SA in Poland for its Devcon brand

- In April 2022, ITW Performance Polymers introduced Plexus MA8105, an adhesive featuring fast room-temperature curing, excellent mechanical properties, and broad adhesion compatibility

- In March 2022, Bostik signed a distribution agreement with DGE covering Europe, the Middle East, and Africa (EMEA) for its Born2Bond™ engineering adhesives, designed for precise bonding applications in sectors such as automotive, electronics, luxury packaging, medical devices, and MRO

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Automotive Adhesives Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Automotive Adhesives Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Automotive Adhesives Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.