Global Automotive Constant Velocity Joint Market

Market Size in USD Billion

CAGR :

%

USD

3.38 Billion

USD

5.11 Billion

2024

2032

USD

3.38 Billion

USD

5.11 Billion

2024

2032

| 2025 –2032 | |

| USD 3.38 Billion | |

| USD 5.11 Billion | |

|

|

|

Automotive Constant Velocity Joint Market Analysis

The automotive constant velocity joint market plays a crucial role in enabling smooth power transmission in vehicles by maintaining consistent rotational speed, especially in vehicles with independent suspension systems. As the demand for high-performance and fuel-efficient vehicles rises, the market for constant velocity joints has seen significant growth, driven by technological advancements, the increasing adoption of all-wheel-drive systems, and rising automotive production. The market is also propelled by the shift towards electric vehicles battery, which require specialized constant velocity joints to handle the unique powertrain configurations. Recent developments include innovations in lightweight, durable materials and the integration of advanced lubrication techniques, improving the efficiency and lifespan of constant velocity joints. Companies are focusing on product innovation and expanding their product portfolios to meet the evolving demands of the automotive industry. The market is highly competitive, with key players introducing advanced constant velocity joint designs to enhance vehicle handling, performance, and safety.

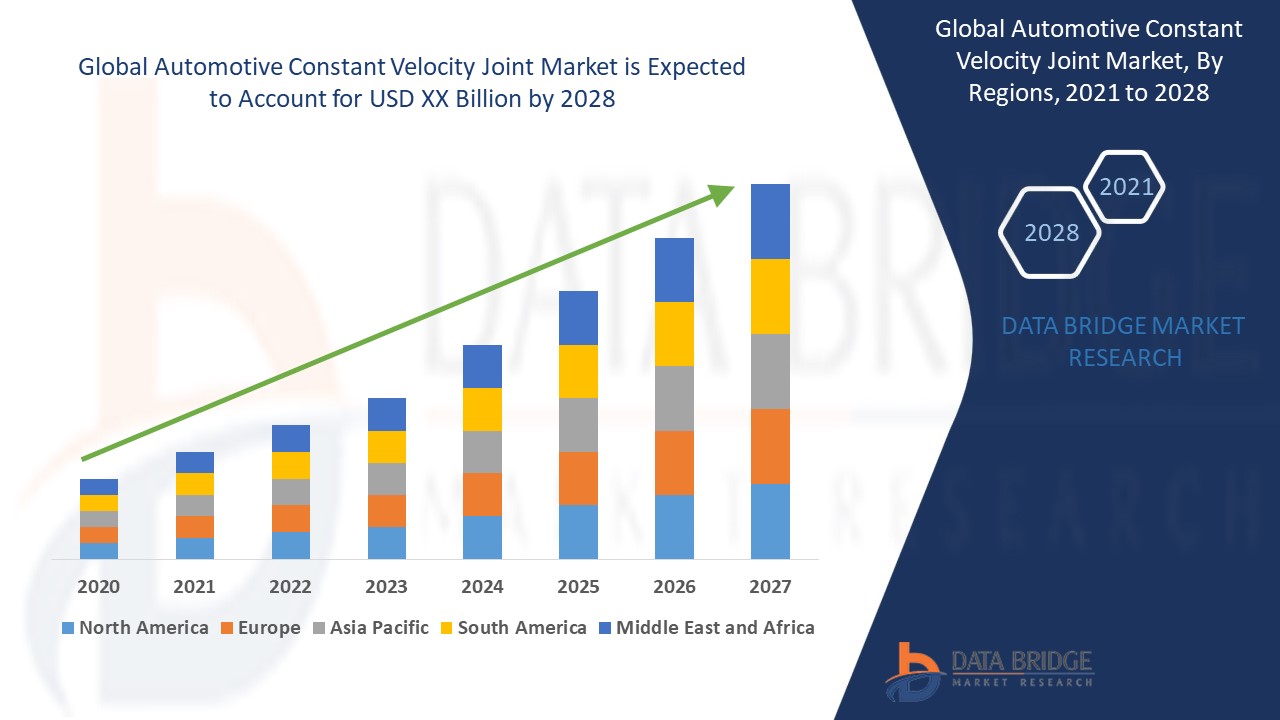

Automotive Constant Velocity Joint Market Size

The global automotive constant velocity joint market size was valued at USD 3.38 billion in 2024 and is projected to reach USD 5.11 billion by 2032, with a CAGR of 5.28% during the forecast period of 2025 to 2032. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

Automotive Constant Velocity Joint Market Trends

“Growing Popularity of All-Wheel-Drive Systems”

A key trend in the automotive constant velocity joint market is the rising adoption of all-wheel-drive systems in both passenger and commercial vehicles. All-wheel-drive systems require efficient power transmission to all wheels, ensuring optimal traction and stability across diverse driving conditions. As more consumers and manufacturers prioritize all-wheel-drive configurations for improved performance and safety, the demand for constant velocity joints is increasing. These joints play a crucial role in maintaining smooth power delivery and ensuring seamless operation, even when the wheels move at different speeds. The growing emphasis on vehicle performance, safety, and handling is driving the need for advanced constant velocity joints tailored to support all-wheel-drive systems, boosting market growth in this segment.

Report Scope and Automotive Constant Velocity Joint Market Segmentation

|

Attributes |

Automotive Constant Velocity Joint Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

GKN Automotive Limited (U.K.), IFA Holding GmbH (Germany), SKF (Sweden), NTN BEARING CORPORATION OF AMERICA (U.S.), Nexteer Automotive (U.S.), TAIZHOU HONGLI AUTOMOBILE PARTS CO., LTD. (China), NTN-SNR (France), C&U Americas (U.S.), Trelleborg AB (Sweden), American Axle & Manufacturing, Inc. (U.S.), Dana Limited (U.S.), DuPont (U.S.), GSP Automotive Group Wenzhou Co. Ltd. (China), Grandmark & Associates (India), Falga Srl (Italy), HYUNDAI WIA CORP. (South Korea), Neapco Holdings (U.S.), NTN Corporation (Japan) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Automotive Constant Velocity Joint Market Definition

An automotive constant velocity joint is a mechanical component used in vehicles to transmit power from the engine to the wheels while allowing for the changes in angle and distance that occur as the wheels move. It ensures that power is delivered smoothly and efficiently, even when the wheels are turning at different angles or speeds, such as when the vehicle turns corners or the suspension moves. Constant velocity joints are typically found in the drivetrain, particularly in vehicles with front-wheel drive, all-wheel drive, or four-wheel drive systems. They are designed to handle high torque and minimize power loss, contributing to improved vehicle performance, stability, and handling.

Automotive Constant Velocity Joint Market Dynamics

Drivers

- Growth in Electric Vehicle Production

As electric vehicles gain popularity, the demand for specialized constant velocity joints is significantly increasing. Unlike traditional internal combustion engine vehicles, electric vehicles generate higher torque and require more efficient power transmission systems to manage the unique powertrains sensor. Constant velocity joints in electric vehicles need to be designed to handle this higher torque while ensuring smooth power delivery and enhancing overall vehicle performance. This shift towards electric mobility, coupled with the need for advanced drivetrain components, is driving market expansion for constant velocity joints. Manufacturers are responding by developing more robust, efficient, and specialized joints to meet these demands, further fueling market growth.

- Improving Vehicle Performance and Safety Standards

As the automotive industry continues to prioritize better handling, safety, and stability, constant velocity joints have become essential in achieving these goals. These joints play a critical role in ensuring smooth and efficient power transmission, particularly in vehicles with complex suspension systems. By allowing the wheels to move at different angles and speeds without losing torque, constant velocity joints enhance vehicle stability and handling. This is especially important for modern vehicles that require precise power distribution and improved traction. As a result, the demand for high-performance constant velocity joints is rising, driving growth in the market.

Opportunities

- Increasing Demand for Lightweight Vehicles

The automotive industry's focus on reducing vehicle weight for improved fuel efficiency is creating significant opportunities for the constant velocity joint market. As automakers strive to meet regulatory standards and consumer demands for more fuel-efficient vehicles, there is an increasing push to incorporate lightweight materials in the production of components such as constant velocity joints. The use of advanced materials such as aluminum alloys and composites in these joints helps reduce overall vehicle weight and contributes to better performance and energy efficiency. This trend toward lightweight vehicle design is expected to drive the demand for more advanced and efficient constant velocity joints, fostering market growth.

- Technological Advancements in Powertrain Systems

Ongoing advancements in vehicle powertrain systems are creating substantial opportunities for the constant velocity joint market. As automakers continue to improve torque distribution and develop more efficient drivetrains, the need for high-performance constant velocity joints is growing. These advancements allow for smoother power delivery and enhanced vehicle handling, especially in complex systems such as all-wheel and four-wheel drive vehicles. The integration of new technologies such as hybrid and electric drivetrains further increases the demand for constant velocity joints that can handle higher torque and varying power demands. This shift towards more efficient powertrains is expected to drive innovation and growth in the constant velocity joint market.

Restraints/Challenges

- Complex Integration with Modern Drivetrains

Integrating constant velocity joints into new and evolving vehicle powertrain systems, especially electric and hybrid powertrains, presents a significant challenge in the automotive industry. These modern powertrains often feature varying torque characteristics, with electric motors delivering higher torque at lower speeds, which demands specialized constant velocity joints designed to handle these conditions. In addition, the design constraints of electric and hybrid vehicles, such as compact powertrains and unique suspension setups, further complicate the integration process. Manufacturers must develop innovative solutions to ensure that constant velocity joints can meet the specific performance and durability requirements of these advanced powertrain systems, making this a key challenge in the market.

- High Production Costs

The manufacturing of advanced constant velocity joints, particularly those made from specialized materials and designed for high-performance applications, poses a significant restraint in the automotive constant velocity joint market. The use of lightweight, high-strength materials such as titanium alloys or composites, which are necessary for optimal performance, increases production costs. In addition, the complex manufacturing processes required to ensure precision and durability in these joints further elevate costs. As a result, the high production expenses can limit the accessibility of advanced constant velocity joints, particularly for smaller automakers or in cost-sensitive vehicle segments, slowing overall market growth.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Automotive Constant Velocity Joint Market Scope

The market is segmented on the basis of joint type, vehicle type, and application. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Joint Type

- Tracta Joints

- Rzeppa Joints

- Double Coupling

- Thomson Coupling

Vehicle Type

- Passenger Cars

- Light Commercial Vehicles

- Heavy Commercial Vehicles

Application

- Commercial

- Logistics

- Defense

- Aviation

Automotive Constant Velocity Joint Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, joint type, vehicle type, and application as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America dominates the automotive constant velocity joint market, driven by rapid advancements in constant velocity joint technology and a robust manufacturing sector. The region's strong automotive industry fosters innovation, leading to the development of high-performance, efficient constant velocity joints. In addition, increasing demand for advanced drivetrains and automotive components contributes to the market's growth in North America.

Europe is the fastest growing region in the automotive constant velocity joint market between 2025 and 2032, driven by strong demand for passenger cars. The region’s robust automotive industry and shifting consumer preferences for advanced, fuel-efficient vehicles contribute to this growth. In addition, Europe’s focus on automotive innovation and sustainability is further propelling the market expansion.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Automotive Constant Velocity Joint Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Automotive Constant Velocity Joint Market Leaders Operating in the Market Are:

- GKN Automotive Limited (U.K.)

- IFA Holding GmbH (Germany)

- SKF (Sweden)

- NTN BEARING CORPORATION OF AMERICA (U.S.)

- Nexteer Automotive (U.S.)

- TAIZHOU HONGLI AUTOMOBILE PARTS CO., LTD. (China)

- NTN-SNR (France)

- C&U Americas (U.S.)

- Trelleborg AB (Sweden)

- American Axle & Manufacturing, Inc. (U.S.)

- Dana Limited (U.S.)

- DuPont (U.S.)

- GSP Automotive Group Wenzhou Co.ltd (China)

- Grandmark & Associates (India)

- Falga Srl (Italy)

- HYUNDAI WIA CORP. (South Korea)

- Neapco Holdings (U.S.)

- NTN Corporation (Japan)

Latest Developments in Automotive Constant Velocity Joint Market

- In April 2024, Hyundai WIA announced it was granted a patent for a new constant velocity joint designed for automobiles. The joint features a hub housing, bearing assembly, power transmission member, and a specialized boot with an innovative design. This boot is equipped with a lip that extends toward the knuckle, effectively preventing foreign contaminants from entering, while the precise measurements between the boot, knuckle, and bearing assembly optimize its protective efficiency

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.