Global Bead Winding Machine Market

Market Size in USD Million

CAGR :

%

USD

996.71 Million

USD

1,214.39 Million

2024

2032

USD

996.71 Million

USD

1,214.39 Million

2024

2032

| 2025 –2032 | |

| USD 996.71 Million | |

| USD 1,214.39 Million | |

|

|

|

|

What is the Global Bead Winding Machine Market Size and Growth Rate?

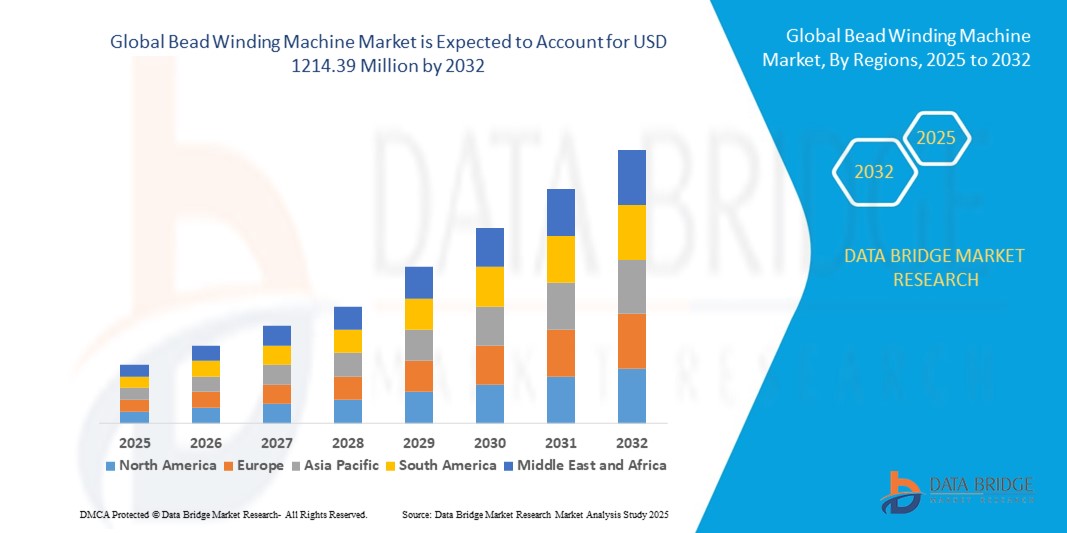

- The global bead winding machine market size was valued at USD 996.71 million in 2024 and is expected to reach USD 1214.39 million by 2032, at a CAGR of 2.50% during the forecast period

- A bead winding machine is a specialized device used in tire manufacturing to automate the process of winding steel wires around a tire's bead. It ensures precise and uniform winding, enhancing the tire's strength and durability. The machine contributes to efficient production in the tire industry by automating a critical component of the manufacturing process

What are the Major Takeaways of Bead Winding Machine Market?

- The rising consumer inclination towards high-performance tires, characterized by superior traction and durability, is propelling the need for advanced manufacturing processes. Bead winding machines play a pivotal role in meeting the precision and quality requirements of high-performance tire production

- Manufacturers are anticipated to embrace energy-efficient bead winding machines to optimize operational costs and align with stringent environmental regulations. This emphasis on energy efficiency reflects a broader industry commitment to sustainability and responsible manufacturing practices

- Asia-Pacific dominated the bead winding machine market with the largest revenue share of 40.78% in 2024, driven by the strong presence of tire manufacturing industries and rising adoption of automation in production lines

- Europe bead winding machine market is poised to grow at the fastest CAGR of 7.12% during 2025–2032, driven by the region’s push toward Industry 4.0 adoption, sustainability initiatives, and high demand for premium automotive tires

- The Automatic Bead segment dominated the bead winding machine market with the largest market revenue share of 41.5% in 2024, primarily due to its high efficiency, reduced manual intervention, and ability to produce consistent bead profiles with minimal errors

Report Scope and Bead Winding Machine Market Segmentation

|

Attributes |

Bead Winding Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Bead Winding Machine Market?

Automation and Digitalization for Higher Precision and Efficiency

- A major and fast-growing trend in the global bead winding machine market is the integration of advanced automation and digital monitoring technologies to improve efficiency, reduce downtime, and enhance production accuracy in tire manufacturing

- For instance, VMI Group has been focusing on developing fully automated bead winding systems with smart control units that allow continuous monitoring of winding quality, ensuring minimal material waste and consistent bead geometry. Similarly, Kobe Steel, Ltd. has been innovating its equipment to integrate IoT-based features that enable predictive maintenance

- Automation enables real-time process adjustments, reducing defects and improving tire durability, while digitalization allows factories to connect bead winding machines to central production management systems for better decision-making. The adoption of robotics is further enhancing productivity by reducing human intervention in repetitive processes

- This shift towards intelligent, automated, and connected bead winding solutions is reshaping production standards, allowing manufacturers to optimize cost efficiency, maintain consistent quality, and meet rising demand for advanced tires in the automotive industry

- Companies such as Cimcorp and Tianjin Saixiang Technology Co., Ltd. are actively introducing robotic and AI-powered solutions to provide tire manufacturers with faster cycle times and higher output

- The demand for automated bead winding machines is rapidly expanding across both developed and emerging markets, driven by the global push towards smart manufacturing and Industry 4.0 integration

What are the Key Drivers of Bead Winding Machine Market?

- The rising demand for passenger and commercial vehicles worldwide, coupled with the need for high-performance and durable tires, is a primary driver of bead winding machine adoption

- For instance, in March 2024, VMI Group launched its latest automated bead winding solution equipped with energy-efficient technology, designed to meet growing demand from global tire manufacturers. Such product developments by key players are expected to propel market expansion

- Tire manufacturers are under pressure to improve production efficiency, reduce waste, and ensure consistency in tire quality. Bead winding machines, with their precision-driven processes, offer significant improvements over conventional methods

- The global trend towards radial tires and advanced tire designs is also creating new opportunities, as bead winding machines are critical for handling complex bead configurations

- In addition, the adoption of Industry 4.0 and smart factory practices is driving investments in machines with IoT-enabled monitoring, predictive maintenance, and remote diagnostics, further accelerating market growth

- The growing emphasis on sustainability and energy efficiency in tire manufacturing is boosting the use of modern bead winding machines that minimize material wastage and optimize resource utilization

Which Factor is Challenging the Growth of the Bead Winding Machine Market?

- The high capital investment required for advanced bead winding machines poses a significant challenge for small and mid-sized tire manufacturers, limiting adoption in cost-sensitive regions

- For instance, while leading players such as Kobe Steel and Herbert Maschinenbau GmbH offer highly automated machines, their premium pricing often restricts accessibility for smaller companies in emerging economies

- Another key concern is the complexity of machine maintenance. Highly automated and digitally integrated machines require skilled technicians and regular servicing, creating additional operational costs for manufacturers

- Moreover, the shortage of skilled labor in developing regions often hinders the full-scale utilization of these advanced machines, impacting productivity

- Cybersecurity risks related to IoT-enabled machinery and data-sharing systems also pose potential threats, as tire manufacturers increasingly connect production equipment to central digital platforms

- While major players are working on offering cost-optimized models and providing training programs, overcoming cost barriers, skill gaps, and digital security issues remains crucial for wider adoption

How is the Bead Winding Machine Market Segmented?

The market is segmented on the basis of configuration and application.

- By Configuration

On the basis of configuration, the bead winding machine market is segmented into Single Bead, Multi-Spinder Bead, Automatic Bead, CNC Bead, and High-Speed Bead. The Automatic Bead segment dominated the bead winding machine market with the largest market revenue share of 41.5% in 2024, primarily due to its high efficiency, reduced manual intervention, and ability to produce consistent bead profiles with minimal errors. Manufacturers across the tire and rubber industries are increasingly adopting automatic bead winding machines to enhance productivity and reduce operational costs. These machines also allow for faster setup and integration with digital monitoring systems, making them ideal for mass production environments.

The CNC Bead segment is projected to witness the fastest CAGR from 2025 to 2032, fueled by rising demand for advanced automation, precision engineering, and customization capabilities. With industries shifting toward Industry 4.0, CNC bead winding machines are expected to gain rapid adoption in premium applications.

- By Application

On the basis of application, the bead winding machine market is segmented into Passenger Cars, Commercial Vehicles, Off-Road Vehicles, Industrial Machinery, and Agriculture Machinery. The Passenger Cars segment held the largest market revenue share of 47.8% in 2024, supported by the growing global automotive production, increasing consumer demand for high-performance tires, and rapid adoption of bead winding machines in tire manufacturing plants. Passenger cars require large-scale tire production, making them the biggest contributor to market revenue. The segment benefits further from rising vehicle ownership in emerging economies such as India and China.

The Commercial Vehicles segment is anticipated to witness the fastest CAGR from 2025 to 2032, driven by the increasing demand for heavy-duty tires, fleet expansion in logistics and transportation, and stricter safety regulations. The durability and strength requirements for commercial vehicle tires are expected to create sustained demand for bead winding machines tailored for larger, high-strength bead structures.

Which Region Holds the Largest Share of the Bead Winding Machine Market?

- Asia-Pacific dominated the bead winding machine market with the largest revenue share of 40.78% in 2024, driven by the strong presence of tire manufacturing industries and rising adoption of automation in production lines

- The region benefits from abundant raw material availability, cost-effective labor, and large-scale manufacturing facilities that boost the demand for bead winding machines in tire production

- Rapid industrialization, growing automotive demand, and expansion of leading tire manufacturers in the region further position Asia-Pacific as the global hub for bead winding machine adoption

China Bead Winding Machine Market Insight

China bead winding machine market captured the largest revenue share of 65% in 2024 within Asia-Pacific, supported by its dominance in tire manufacturing and large-scale automotive production. Local manufacturers are integrating advanced automation technologies to improve productivity and meet global demand. China’s government initiatives to strengthen domestic manufacturing and the country’s cost advantage in machine production are significantly driving market growth.

India Bead Winding Machine Market Insight

India bead winding machine market is projected to expand at a substantial CAGR throughout the forecast period, propelled by rapid automotive sector growth and rising foreign investments in tire production. Increasing demand for passenger and commercial vehicles, coupled with supportive government policies such as “Make in India,” is fueling adoption. Indian manufacturers are also focusing on upgrading production facilities with automated machinery, enhancing efficiency and competitiveness.

Japan Bead Winding Machine Market Insight

Japan bead winding machine market is anticipated to grow at a noteworthy CAGR, driven by its advanced manufacturing capabilities and strong focus on precision engineering. Japan’s tire industry emphasizes high-performance and eco-friendly solutions, creating demand for technologically advanced bead winding machines. Integration of smart manufacturing and robotics in production lines is further supporting the market’s evolution.

Which Region is the Fastest Growing Region in the Bead Winding Machine Market?

Europe bead winding machine market is poised to grow at the fastest CAGR of 7.12% during 2025–2032, driven by the region’s push toward Industry 4.0 adoption, sustainability initiatives, and high demand for premium automotive tires. Growing investments in automation, coupled with stringent EU regulations on safety and quality, are accelerating adoption. The presence of leading tire manufacturers in Germany, France, and Italy further boosts demand for advanced bead winding machines.

Germany Bead Winding Machine Market Insight

Germany bead winding machine market is gaining traction, backed by the country’s strong automotive industry and advanced engineering ecosystem. German tire manufacturers are heavily investing in digital manufacturing technologies and energy-efficient machinery. The market is witnessing increasing adoption of eco-friendly solutions, automation, and robotics integration, aligning with the country’s sustainability-driven industrial framework.

Which are the Top Companies in Bead Winding Machine Market?

The bead winding machine industry is primarily led by well-established companies, including:

- Bharaj Machineries Pvt Ltd (India)

- VMI Group (Finland)

- Kobe Steel, Ltd (Japan)

- Tianjin Saixiang Technology Co., Ltd (China)

- Herbert Maschinenbau GmbH & Co. KG (Germany)

- Cimcorp (Finland)

- Lorenz Pan AG (Switzerland)

- MEC A/S (Denmark)

- Strongman Group (Belgium)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Bead Winding Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Bead Winding Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Bead Winding Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.