Global Biocompatible Metal Electropolishing Solutions Market

Market Size in USD Million

CAGR :

%

USD

110.00 Million

USD

306.80 Million

2024

2032

USD

110.00 Million

USD

306.80 Million

2024

2032

| 2025 –2032 | |

| USD 110.00 Million | |

| USD 306.80 Million | |

|

|

|

|

Biocompatible Metal Electropolishing Solutions Market Size

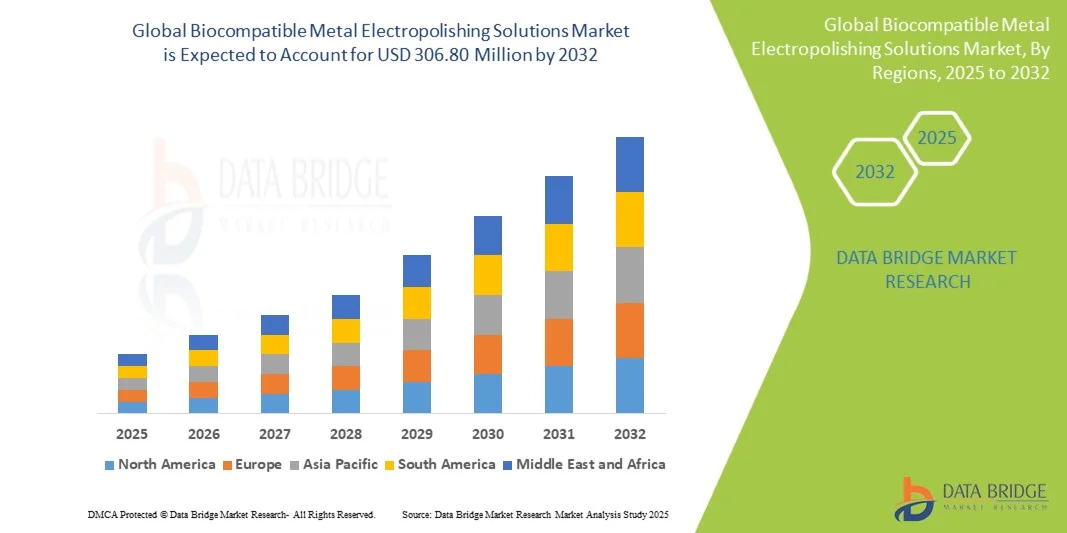

- The global biocompatible metal electropolishing solutions market size was valued at USD 110.00 million in 2024 and is expected to reach USD 306.80 million by 2032, at a CAGR of 13.68% during the forecast period

- The market expansion is primarily driven by the increasing demand for high-quality, corrosion-resistant, and contamination-free metal surfaces in medical, pharmaceutical, and implant manufacturing applications, where biocompatibility and precision are critical

- Moreover, ongoing advancements in surface finishing technologies, coupled with stringent regulatory standards for medical device cleanliness and performance, are promoting the adoption of biocompatible electropolishing solutions across multiple industries, thereby fueling significant market growth

Biocompatible Metal Electropolishing Solutions Market Analysis

- Biocompatible metal electropolishing solutions, used for producing ultra-smooth, corrosion-resistant, and contaminant-free metal surfaces, have become essential in medical device, implant, and pharmaceutical manufacturing, ensuring materials meet stringent cleanliness and biocompatibility standards for patient safety and regulatory compliance

- The rising demand for these solutions is primarily fueled by the growing production of medical implants and surgical instruments, increasing emphasis on surface finishing quality, and the broader adoption of advanced metal finishing technologies across healthcare and precision engineering sectors

- North America dominated the global biocompatible metal electropolishing solutions market with a revenue share of 38.9% in 2024, supported by the strong presence of medical device manufacturers, robust regulatory frameworks (FDA, ASTM), and early adoption of validated surface treatment technologies in the U.S. and Canada

- Asia-Pacific is projected to be the fastest-growing region during the forecast period, driven by rapid expansion of the medical device manufacturing industry, increasing investment in healthcare infrastructure, and rising outsourcing of precision finishing services to countries such as China, Japan, and India

- The stainless steel segment dominated the global biocompatible metal electropolishing solutions market with the largest market share of 46.8% in 2024, attributed to its extensive use in surgical tools, implants, and equipment components, along with the material’s superior compatibility with electropolishing processes that enhance biocompatibility and surface hygiene

Report Scope and Biocompatible Metal Electropolishing Solutions Market Segmentation

|

Attributes |

Biocompatible Metal Electropolishing Solutions Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Biocompatible Metal Electropolishing Solutions Market Trends

“Shift Towards Automated and Precision Surface Finishing”

- A significant and accelerating trend in the global biocompatible metal electropolishing solutions market is the growing adoption of automated and computer-controlled finishing systems, which enhance precision, repeatability, and safety in medical and pharmaceutical manufacturing

- For instance, automated rack and inline electropolishing systems from companies such as Metashell allow high-throughput processing of complex implants while maintaining biocompatibility standards

- Advanced process monitoring technologies are enabling real-time control of surface roughness, corrosion resistance, and cleanliness levels, improving product quality and reducing post-processing inspection needs

- The trend toward integrating digital monitoring and IoT-based process controls is reshaping expectations for quality assurance, regulatory compliance, and operational efficiency in high-precision industries

- Increasing focus on sustainable and eco-friendly electrolytes is influencing market trends, as manufacturers aim to reduce hazardous waste and environmental impact

- Rising integration with 3D-printed metal implants and components is driving demand for precise electropolishing solutions capable of handling complex geometries

Biocompatible Metal Electropolishing Solutions Market Dynamics

Driver

“Increasing Demand from Medical Device and Implant Manufacturing”

- The rising production of surgical instruments, implants, and medical devices requiring ultra-clean and corrosion-resistant surfaces is a significant driver for the global biocompatible metal electropolishing solutions market

- For instance, in 2024, Stryker expanded its implant finishing operations, incorporating validated electropolishing processes to meet stringent biocompatibility standards

- Stringent regulatory requirements, including FDA and ISO standards for surface cleanliness and biocompatibility, are further accelerating the adoption of specialized electropolishing solutions

- Growing outsourcing of precision metal finishing to specialized service providers is increasing market penetration, especially in emerging APAC medical manufacturing hubs

- For instance, electropolishing service providers in China and India are securing contracts with global OEMs for surgical instrument finishing, driving regional market growth

- Rising adoption of high-value implants and minimally invasive surgical tools requiring flawless surface finishes is further boosting demand for biocompatible electropolishing

- Increasing collaboration between chemical solution suppliers and OEMs to develop tailored formulations for specific metals and alloys is enhancing market growth

Restraint/Challenge

“High Cost and Regulatory Compliance Complexity”

- The high cost of advanced biocompatible electropolishing chemicals and automated systems, coupled with complex validation requirements, poses a key challenge for widespread adoption

- For instance, smaller medical device manufacturers may face budget constraints in implementing fully automated, FDA-compliant electropolishing lines

- Regulatory compliance hurdles, including documentation, cleaning validation, and process qualification, increase time-to-market and operational overheads

- Variability in substrate materials and part geometries can complicate process standardization, limiting scalability for some manufacturers

- Limited awareness and technical expertise regarding electropolishing process optimization among small-scale manufacturers can slow adoption

- For instance, improper handling of electrolytes or voltage settings can lead to substandard finishes, discouraging first-time users

- Environmental and disposal regulations related to hazardous electrolytes increase operational complexity and costs for manufacturers

Biocompatible Metal Electropolishing Solutions Market Scope

The market is segmented on the basis of electrolyte type, metal type, application, and process type.

- By Electrolyte Type

On the basis of electrolyte type, the global biocompatible metal electropolishing solutions market is segmented into phosphoric–sulfuric based, proprietary biocompatible formulations, and other chemistries. The Phosphoric–Sulfuric Based segment dominated the market with the largest revenue share in 2024, driven by its proven effectiveness in producing smooth, corrosion-resistant surfaces on stainless steel and titanium used in medical implants and surgical instruments. Manufacturers prefer this segment due to its cost-efficiency, established process protocols, and regulatory familiarity, which make it the go-to choice for high-volume production. The widespread availability of chemicals and technical expertise for phosphoric–sulfuric solutions further supports its market dominance. Its compatibility with both batch and continuous electropolishing systems allows manufacturers to achieve consistent results with minimal process variation.

The Proprietary Biocompatible Formulations segment is expected to witness the fastest growth during the forecast period, fueled by the increasing demand for customized surface finishes for complex medical implants and precision-engineered aerospace components. These formulations are engineered to meet strict biocompatibility standards while enhancing corrosion resistance and surface cleanliness. Rising adoption is also driven by OEMs seeking competitive differentiation through higher-value finishing solutions. Proprietary solutions often incorporate additives that optimize process efficiency and reduce cycle times, making them attractive for high-end applications.

- By Metal Type

On the basis of metal type, the global biocompatible metal electropolishing solutions market is segmented into stainless steel, titanium & alloys, aluminum, copper, and brass & nickel alloys. The Stainless Steel segment dominated the market with the largest share of 46.8% in 2024, owing to its extensive use in surgical tools, implants, and pharmaceutical equipment where biocompatibility and corrosion resistance are critical. Its favorable response to electropolishing processes enables ultra-smooth surfaces, reducing bacterial adhesion and improving sterilization outcomes. The segment benefits from a mature supply chain and extensive process knowledge among manufacturers. High-volume adoption in medical device manufacturing and food processing equipment reinforces its market leadership. Stainless steel also provides cost-effectiveness while meeting regulatory standards for both FDA and ISO certifications.

The Titanium & Alloys segment is expected to witness the fastest growth during the forecast period due to rising use in orthopedic implants, dental devices, and aerospace components requiring superior strength-to-weight ratios and exceptional corrosion resistance. Titanium’s compatibility with proprietary electropolishing solutions enhances biocompatibility and surface smoothness. Growth is also driven by the increasing prevalence of minimally invasive surgical procedures, which rely on precision-finished titanium implants. The segment benefits from innovations in additive manufacturing combined with specialized electropolishing processes.

- By Application

On the basis of application, the global biocompatible metal electropolishing solutions market is segmented into medical & pharmaceutical, aerospace & defense, semiconductor & electronics, automotive, food & beverage, and marine & others. The Medical & Pharmaceutical segment dominated the market with the largest revenue share in 2024, fueled by the rising production of surgical instruments, implants, and medical devices requiring highly polished, contamination-free surfaces. Strict regulatory requirements and biocompatibility standards in this sector make electropolishing solutions indispensable. The segment also benefits from growing healthcare infrastructure investments, especially in North America and Europe. Increasing outsourcing of metal finishing services to meet quality and compliance standards further reinforces its dominance.

The Aerospace & Defense segment is expected to witness the fastest growth during the forecast period, driven by the demand for corrosion-resistant, fatigue-resistant, and lightweight components in commercial and military aircraft. Precision electropolishing enhances performance and lifespan of aerospace alloys such as titanium and aluminum. Rising aerospace production in Asia-Pacific and modernization programs in North America contribute to strong growth. The need for specialized finishing for critical components, coupled with strict quality standards, is accelerating adoption in this segment.

- By Process Type

On the basis of process type, the global biocompatible metal electropolishing solutions market is segmented into batch electropolishing, continuous electropolishing, and manual vs automated systems. The Batch Electropolishing segment dominated the market with the largest share in 2024, owing to its flexibility and efficiency for small-to-medium volume production of medical instruments and implants. This process allows precise control over surface finish and uniformity, making it suitable for complex part geometries. Batch systems are also easier to validate for regulatory compliance, which is critical for FDA and ISO-certified manufacturing. Its cost-effectiveness and compatibility with standard electrolytes make it the preferred choice for many manufacturers.

The Continuous Electropolishing segment is expected to witness the fastest growth during the forecast period, driven by the increasing demand for high-volume, consistent-quality finishing in medical, aerospace, and automotive applications. Continuous systems reduce labor costs, improve throughput, and ensure uniform surface quality across multiple components. The growth is further supported by adoption of advanced process automation and monitoring technologies. Continuous electropolishing is especially attractive to OEMs and contract manufacturers aiming for scalable, high-precision production lines.

Biocompatible Metal Electropolishing Solutions Market Regional Analysis

- North America dominated the global biocompatible metal electropolishing solutions market with a revenue share of 38.9% in 2024, supported by the strong presence of medical device manufacturers, robust regulatory frameworks (FDA, ASTM), and early adoption of validated surface treatment technologies in the U.S. and Canada

- Manufacturers in the region prioritize high-quality, corrosion-resistant, and contamination-free metal surfaces for implants, surgical instruments, and precision equipment, ensuring compliance with FDA and ISO requirements

- This widespread adoption is further supported by advanced manufacturing infrastructure, skilled workforce, early adoption of automated electropolishing systems, and increasing investments in R&D for innovative surface finishing solutions, establishing North America as a key hub for both production and technological innovation in the sector

U.S. Biocompatible Metal Electropolishing Solutions Market Insight

The U.S. biocompatible metal electropolishing solutions market captured the largest revenue share of 82% in 2024 within North America, driven by the country’s strong medical device and implant manufacturing base. Manufacturers are increasingly prioritizing high-precision, corrosion-resistant, and biocompatible finishes to meet stringent FDA and ISO standards. The growing adoption of automated electropolishing systems and validated processes in hospitals, surgical instrument suppliers, and implant OEMs further propels market growth. Moreover, rising R&D investments in advanced surface finishing technologies and custom formulations are significantly contributing to the expansion of the U.S. market.

Europe Biocompatible Metal Electropolishing Solutions Market Insight

The Europe market is projected to expand at a substantial CAGR during the forecast period, primarily driven by strict regulatory requirements for medical devices and pharmaceutical equipment, as well as rising demand for high-quality, contamination-free metal surfaces. Increasing urbanization and the expansion of advanced healthcare infrastructure foster the adoption of biocompatible electropolishing solutions. European manufacturers are investing in automated and proprietary formulations to meet compliance standards and enhance operational efficiency. The market is experiencing strong growth across hospitals, implant manufacturers, and precision engineering companies, with solutions being incorporated into both new production lines and equipment retrofitting projects.

U.K. Biocompatible Metal Electropolishing Solutions Market Insight

The U.K. market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by rising medical device production and the need for enhanced surface quality and biocompatibility. Regulatory compliance with MHRA and ISO standards encourages manufacturers to adopt electropolishing solutions for surgical instruments and implants. The U.K.’s strong healthcare sector, coupled with advancements in automation and precision finishing, is expected to continue to stimulate market growth. Moreover, increasing outsourcing of polishing services to specialized providers enhances accessibility for smaller OEMs.

Germany Biocompatible Metal Electropolishing Solutions Market Insight

The Germany market is expected to expand at a considerable CAGR during the forecast period, fueled by growing awareness of high-quality surface finishing and stringent regulatory standards in medical, pharmaceutical, and aerospace sectors. Germany’s well-developed infrastructure and focus on innovation promote the adoption of automated electropolishing solutions and proprietary chemical formulations. Integration with precision manufacturing and quality assurance systems is becoming increasingly prevalent, with a strong preference for reproducible, validated processes aligning with local industry expectations.

Asia-Pacific Biocompatible Metal Electropolishing Solutions Market Insight

The Asia-Pacific market is poised to grow at the fastest CAGR of 8% during the forecast period of 2025 to 2032, driven by increasing medical device production, rising healthcare investments, and rapid industrialization in countries such as China, Japan, and India. The region’s growing adoption of high-quality electropolishing solutions is supported by government initiatives promoting medical manufacturing and precision engineering. Furthermore, APAC is emerging as a hub for contract manufacturing of surgical instruments and implants, which is expanding the accessibility and affordability of electropolishing services and solutions across the region.

Japan Biocompatible Metal Electropolishing Solutions Market Insight

The Japan market is gaining momentum due to the country’s high-tech manufacturing culture, strong healthcare infrastructure, and demand for precision-finished implants and surgical tools. The adoption of electropolishing solutions is driven by stringent domestic regulations and a focus on process validation to ensure biocompatibility. Integration with advanced automation and IoT-enabled monitoring systems is fueling growth. Moreover, Japan’s aging population and increasing demand for minimally invasive medical devices are spurring the need for reliable and high-quality surface finishing solutions in both residential and commercial medical applications.

India Biocompatible Metal Electropolishing Solutions Market Insight

The India market accounted for the largest revenue share in Asia-Pacific in 2024, attributed to the country’s expanding medical device and surgical instrument manufacturing industry, rapid urbanization, and growing adoption of advanced finishing technologies. India is emerging as a key manufacturing hub for implants and precision equipment, with domestic and international OEMs increasingly outsourcing electropolishing services to the region. The push towards smart hospitals, affordable solutions, and the presence of specialized electropolishing service providers are key factors propelling market growth in India.

Biocompatible Metal Electropolishing Solutions Market Share

The biocompatible metal electropolishing solutions industry is primarily led by well-established companies, including:

- Able Electropolishing Co., Inc. (U.S.)

- Arrow Finishing, Inc. (U.S.)

- Control Electropolishing (U.S.)

- Delstar Metal Finishing, Inc. (U.S.)

- Electro-Max, Inc. (U.S.)

- Elkhorn Electropolish (U.S.)

- Mills Metal Finishing (U.S.)

- New England Electropolishing, (U.S.)

- Norman Noble, Inc. (U.S.)

- Precision Finishing, Inc. (U.S.)

- Rösler (Germany)

- Steven Douglas Corp. (U.S.)

- Techmetals, Inc. (U.S.)

- ActOn Finishing Ltd (U.K.)

- Best Technology (U.S.)

- Electrobright (U.S.)

- GPAINNOVA (Spain)

- Passivation Surface Finishing (India)

- Resonetics (U.S.)

- SEPTA Chemicals (India)

What are the Recent Developments in Biocompatible Metal Electropolishing Solutions Market?

- In August 2025, RBP Chemical Technology unveiled a novel electropolishing solution designed specifically for nitinol alloys at room temperature. This advancement enhances the biocompatibility and corrosion resistance of nitinol components used in medical devices, such as stents and guidewires, without the need for high-temperature processes

- In April 2025, Able Electropolishing highlighted how their electropolishing services improve the adhesion and uniformity of plating and coating processes. By eliminating surface defects, electropolishing ensures better performance and durability of metal parts used in various applications, including medical devices

- In February 2025, RBP Chemical Technology introduced specialized chemistries aimed at improving the surface quality of medical implants. These formulations focus on electropolishing and surface smoothing to achieve defect-free surfaces, thereby reducing bacterial adhesion and enhancing implant longevity

- In December 2024, a study published in the Royal Society of Chemistry's journal investigated the impact of electropolishing on Fe–Mn–C alloys, which are considered for biodegradable medical implants. The research demonstrated that electropolishing could enhance the surface properties of these alloys, making them more suitable for temporary implants that degrade within the body

- In January 2024, Able Electropolishing released a comprehensive guide addressing common metal surface issues. The guide emphasizes how electropolishing effectively resolves problems such as corrosion, burrs, and surface imperfections, thereby enhancing the performance and lifespan of critical metal components used in medical manufacturing

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.