Global Cement Kiln Co Processing Fuels Market

Market Size in USD Billion

CAGR :

%

USD

3.00 Billion

USD

4.37 Billion

2024

2032

USD

3.00 Billion

USD

4.37 Billion

2024

2032

| 2025 –2032 | |

| USD 3.00 Billion | |

| USD 4.37 Billion | |

|

|

|

Cement Kiln Co-Processing Fuels Market Size

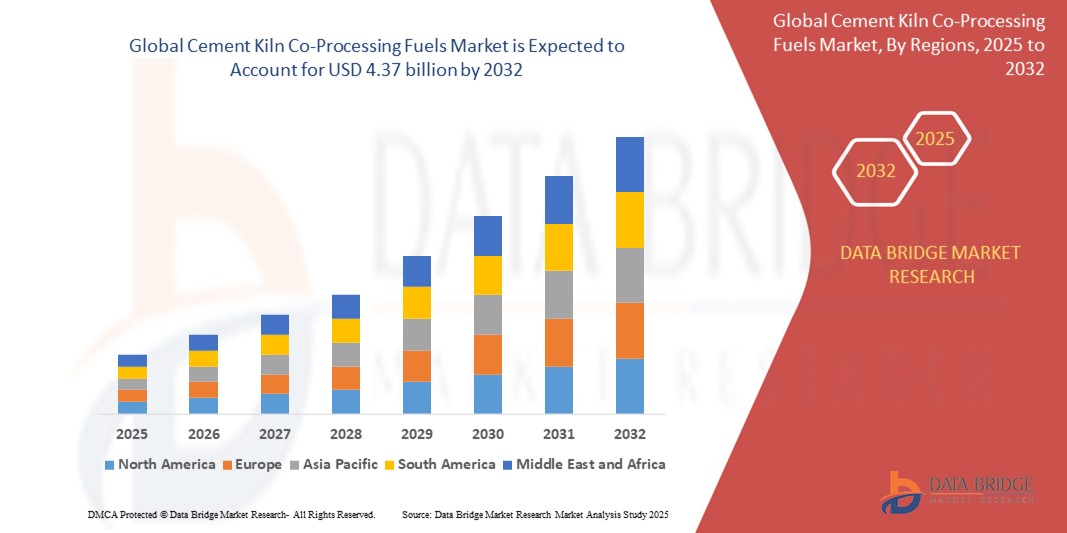

- The global cement kiln co-processing fuels market was valued at USD 3.00 billion in 2024 and is expected to reach USD 4.37 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 4.80%, primarily driven by growing need for sustainable and cost-effective waste management solutions

- This growth is driven by stringent environmental regulations aimed at reducing carbon emissions and the increasing adoption of alternative fuels such as refuse-derived fuel (RDF), biomass, and industrial waste in cement production

Cement Kiln Co-Processing Fuels Market Analysis

- The cement kiln co-processing fuels market is experiencing steady growth as the demand for alternative fuels in cement production rises. This market offers an efficient method of waste disposal while reducing reliance on traditional fossil fuels, benefiting both environmental and economic factors

- Factors driving the market include the increasing need for sustainable waste management solutions, stringent government regulations targeting carbon emissions, and the growing demand for circular economy practices within industries. Co-processing allows cement manufacturers to utilize waste products such as RDF, biomass, and industrial waste as substitutes for coal, lowering energy costs and reducing environmental impact

- Asia-Pacific is leading the market, driven by rapid industrialization, urbanization, and government-supported infrastructure projects. Countries such as China, India, and Japan are key players in adopting co-processing solutions due to their favorable regulations and increasing push for reducing emissions in cement production

- For instance, in 2024, the cement plant operated by Sociedad Boliviana de Cemento (Soboce) in Bolivia began a pilot program to co-process discarded electrical and electronic waste into alternative fuels, signaling growing innovation in the market

- The cement kiln co-processing fuels market is also evolving with trends such as the adoption of advanced technologies for efficient fuel handling, combustion optimization, and enhanced waste processing. As the demand for eco-friendly solutions continues, manufacturers are focused on expanding their waste recovery capabilities, aligning with global sustainability goals

Report Scope and Cement Kiln Co-Processing Fuels Market Segmentation

|

Attributes |

Cement Kiln Co-Processing Fuels Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Cement Kiln Co-Processing Fuels Market Trends

“Adoption of Waste-to-Energy Technologies”

- Cement Kiln Co-Processing Fuels companies are increasingly integrating waste-to-energy technologies to transform waste materials into valuable alternative fuels for cement production

- This technology helps in reducing landfill waste, minimizing carbon footprints, and addressing energy demands in cement manufacturing while contributing to the circular economy

- Advanced waste-to-energy solutions, such as gasification and pyrolysis, are being explored to improve the efficiency and cost-effectiveness of co-processing fuels

For instance,

- In May 2024, Suez Cement implemented a new waste-to-energy facility at its Helwan cement plant, significantly boosting its use of alternative fuels and reducing reliance on traditional energy sources

- As sustainability becomes a higher priority globally, waste-to-energy technologies are set to drive future growth in the cement kiln co-processing fuels market, aligning with broader environmental goals

Cement Kiln Co-Processing Fuels Market Dynamics

Driver

“Rising Environmental Regulations and Carbon Reduction Targets”

- Stricter environmental regulations and global commitments to reducing carbon emissions are encouraging cement manufacturers to adopt alternative fuels, reducing their reliance on fossil fuels

- Cement Kiln Co-Processing Fuels are seen as a crucial solution in reducing emissions in cement production by utilizing waste materials instead of coal and other traditional fuels

- Governments worldwide are offering incentives and support to cement producers to adopt more sustainable practices, including co-processing, to help meet their carbon reduction targets

For instance,

- In June 2024, the European Union introduced stricter carbon emissions targets for cement producers, leading several companies to accelerate their adoption of co-processing technologies

- With tightening regulations, the cement kiln co-processing fuels market is expected to see significant growth as industries seek solutions that help meet environmental compliance and carbon reduction goals

Opportunity

“Expansion in Developing Markets”

- Developing economies are investing heavily in infrastructure development, offering a significant opportunity for cement kiln co-processing fuels adoption in these regions

- As these markets grow, there is a rising need for sustainable construction practices and waste management solutions, making co-processing a viable and eco-friendly alternative

- The increasing demand for affordable housing, commercial, and industrial buildings in regions such as Africa, Latin America, and Asia presents a lucrative market for co-processing solutions

For instance,

- In August 2024, the African Development Bank announced a new initiative to support infrastructure projects in Sub-Saharan Africa, which will include the use of sustainable materials such as co-processed fuels in cement manufacturing

- As developing regions continue to expand, cement kiln co-processing fuels will play an integral role in building sustainable infrastructure and meeting environmental goals

Restraint/Challenge

“High Initial Investment Costs”

- Although cement kiln co-processing fuels offer long-term benefits, the initial investment required for setting up co-processing facilities can be substantial

- High capital costs, particularly for technologies such as waste handling and processing equipment, can pose a barrier for smaller cement producers looking to enter the market

- Financial constraints and the long payback periods of these investments may deter some manufacturers, especially in cost-sensitive markets

For instance,

- In July 2024, Lafarge reported delays in its planned expansion of co-processing facilities in South Asia due to high upfront investment requirements

- Addressing the challenge of high initial investment costs will require financial incentives, subsidies, or partnerships to facilitate wider adoption of cement kiln co-processing fuels across the industry

Cement Kiln Co-Processing Fuels Market Scope

The market is segmented on the basis of source type, fuel type, and application.

|

Segmentation |

Sub-Segmentation |

|

By Source Type |

|

|

By Fuel Type |

|

|

By Application |

|

Cement Kiln Co-Processing Fuels Market Regional Analysis

“Asia-Pacific is the Dominant Region in the Cement Kiln Co-Processing Fuels Market”

- Rapid industrialization and urban development across countries such as China, India, and Indonesia are significantly driving the demand for cement, thereby boosting the use of co-processing fuels in cement kilns

- Government regulations and sustainability initiatives in the region are encouraging the adoption of alternative fuels, reducing reliance on fossil fuels and cutting down carbon emissions

- Strong waste generation infrastructure and rising focus on circular economy models are enabling efficient waste collection and conversion into energy-rich fuels for cement production

- Asia-Pacific has emerged as the dominant region in the cement kiln co-processing fuels Market, backed by its robust manufacturing base and progressive environmental policies

“Europe is projected to register the Highest Growth Rate”

- Stringent environmental regulations and EU climate policies are pushing cement manufacturers in Europe to adopt cleaner production methods, including alternative fuel co-processing in kilns

- Increased investments in waste-to-energy technologies and infrastructure are enabling efficient use of refuse-derived fuels, biomass, and industrial waste across European cement plants

- Collaborations between technology providers and cement producers are fostering innovation in fuel optimization, emissions control, and energy efficiency across the region

- Europe is projected to register the highest growth rate in the cement kiln co-processing fuels market, driven by its proactive regulatory environment and commitment to sustainability

Cement Kiln Co-Processing Fuels Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Energesman (Turkey)

- BEUMER Group (Germany)

- GEOCYCLE (Switzerland)

- Süreko A.S. (Turkey)

- Enva (U.K.)

- DCC plc (Ireland)

- Estre (Brazil)

- Komptech GmbH (Austria)

- Nameshift (Not Available)

- Averda (U.A.E.)

- Westeria GmbH (Germany)

- Veolia (France)

- Transwaste (U.K.)

- Mecore BV (Netherlands)

- Grupo Porcarellie (Spain)

- Paprec (France)

- Ron Hull (U.K.)

- Advetec (U.K.)

- Ciram (Italy)

- SUEZ (France)

Latest Developments in Global Cement Kiln Co-Processing Fuels Market

- In November 2024, ACC and Ambuja Cements announced the launch of two advanced facilities aimed at sustainable waste management—the Ambuja Marwar Pre-processing and Co-processing Facility and the ACC Jamul Co-processing Facility. Developed by their waste management division Geoclean, the Ambuja Marwar facility alone can process up to 220,000 tons of waste into alternative fuels. This milestone highlights their commitment to resource efficiency and environmental stewardship in the cement sector

- In October 2024, ABB signed a memorandum of understanding with U.K.-based climate tech firm Carbon Re to develop integrated digital solutions for cement decarbonisation. The partnership aims to enhance energy efficiency by up to 5% and boost alternative fuel usage by 50% by automating and optimizing kiln conditions. This collaboration signifies a progressive step toward smarter, greener cement production processes

- In September 2024, Bolivia’s Sociedad Boliviana de Cemento (Soboce) initiated a pilot project at its Viacha cement plant to co-process discarded electronic and electrical waste into alternative fuel. The initiative, conducted in collaboration with the Ministry of Environment and Water, involves repurposing 133 tons of material, including plastics with brominated flame retardants. This pilot reflects growing innovation in using complex waste streams to power cement production sustainably

- In August 2023, GEOCYCLE, a subsidiary of the HOLCIM Group, expanded its waste-processing capabilities for cement kiln fuel through a closed-loop recycling system. This move is intended to reduce both emissions and logistical costs by keeping waste management operations localized. The expansion reinforces HOLCIM’s commitment to circular economy principles and carbon footprint reduction

- In June 2023, Suez Cement invested USD 16 million to upgrade its facilities for alternative fuel usage across its Helwan, Kattameya, and Suez cement plants. In addition, the company allocated USD 60 million to dust control and USD 25 million to building a waste heat recovery (WHR) plant at Helwan. These cumulative investments underline Suez Cement’s strategy to achieve cleaner, more energy-efficient operations

- In December 2022, Heidelberg Materials reported reaching a fossil fuel substitution rate of over 60% in its European operations by leveraging alternative fuels such as refuse-derived fuel (RDF), biomass, and industrial waste. This milestone showcases Heidelberg's leadership in sustainable cement production and sets a benchmark for decarbonisation in the industry

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Cement Kiln Co Processing Fuels Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Cement Kiln Co Processing Fuels Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Cement Kiln Co Processing Fuels Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.