Global Cold Gas Spray Coating Market

Market Size in USD Billion

CAGR :

%

USD

1.17 Billion

USD

1.54 Billion

2024

2032

USD

1.17 Billion

USD

1.54 Billion

2024

2032

| 2025 –2032 | |

| USD 1.17 Billion | |

| USD 1.54 Billion | |

|

|

|

|

What is the Global Cold Gas Spray Coating Market Size and Growth Rate?

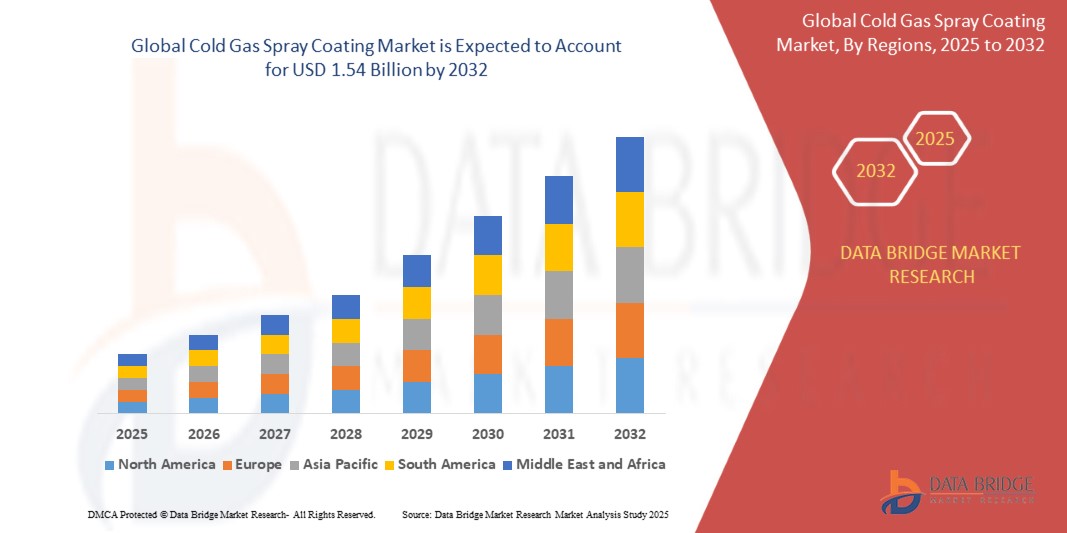

- The global cold gas spray coating market size was valued at USD 1.17 billion in 2024 and is expected to reach USD 1.54 billion by 2032, at a CAGR of 3.45% during the forecast period

- The cold gas spray coating market is experiencing robust growth due to its unique advantages and expanding applications across various industries. This coating technology is gaining traction because it enables the application of high-performance coatings with minimal thermal impact, preserving the integrity of the substrate. Its ability to create dense, strong coatings makes it ideal for applications requiring wear resistance, corrosion protection, and surface restoration

- Industries such as aerospace, automotive, and manufacturing are increasingly adopting cold gas spray coating to enhance the durability and longevity of components. The technology's advantages, including reduced oxidation and thermal stresses compared to traditional coating methods, further drive its adoption

What are the Major Takeaways of Cold Gas Spray Coating Market?

- Cold Gas Spray Coatings, offering electronic or digital access control for doors and gates, are increasingly vital components of modern home security and automation systems in both residential and commercial settings due to their enhanced convenience, remote access capabilities, and seamless integration with smart home ecosystems

- The escalating demand for cold gas spray coatings is primarily fueled by the widespread adoption of smart home technologies, growing security concerns among consumers, and a rising preference for the convenience of keyless entry

- North America dominated the cold gas spray coating market with the largest revenue share of 37.67% in 2024, driven by strong industrial demand across the aerospace, defense, automotive, and electronics sectors

- Asia-Pacific cold gas spray coating market is forecasted to grow at the fastest CAGR of 7.25% from 2025 to 2032, driven by rapid industrialization, increased adoption of surface engineering technologies, and growing investments in aerospace, defense, electronics, and automotive industries

- The High Pressure segment dominated the market with the largest market revenue share of 63.4% in 2024, owing to its ability to achieve higher particle velocities and stronger adhesion strength, making it ideal for structural repairs and demanding industrial applications such as aerospace and defense

Report Scope and Cold Gas Spray Coating Market Segmentation

|

Attributes |

Cold Gas Spray Coating Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Cold Gas Spray Coating Market?

“Adoption of Cold Gas Spray in Additive Manufacturing and Repair Applications”

- A key emerging trend in the cold gas spray coating market is its expanding use in additive manufacturing and component repair, particularly in aerospace, defense, and energy sectors. The ability to deposit coatings without melting feedstock materials makes cold spray ideal for structural repairs and restoring dimensional tolerances on high-value parts

- For instance, OC Oerlikon has been investing in cold spray systems for on-site repair of turbine components and aircraft engine parts, reducing downtime and extending component life. Similarly, Praxair Surface Technologies offers turnkey cold spray solutions for coating and additive manufacturing applications in industrial sectors

- Cold spray's solid-state process minimizes oxidation and thermal degradation, enabling high-strength bonding and preservation of material properties especially important for aluminum, titanium, and magnesium alloys

- The trend also aligns with sustainability goals by reducing material waste and energy consumption during manufacturing and repair, positioning cold spray as a green alternative to traditional thermal spray and welding methods

- Companies such as Wall Colmonoy are leveraging cold spray technology to offer custom engineered coatings and repairs in critical applications, including aviation, oil & gas, and power generation

- This growing demand for non-destructive, efficient, and cost-effective material restoration is set to significantly expand the role of cold gas spray technology across industries worldwide

What are the Key Drivers of Cold Gas Spray Coating Market?

- The increasing demand for corrosion-resistant and wear-resistant coatings in sectors such as automotive, aerospace, marine, and oil & gas is a major driver of the cold gas spray coating market. The technology is favored for its ability to apply dense, oxide-free coatings on temperature-sensitive materials

- For example, in February 2024, Saint-Gobain expanded its product line of wear-resistant coatings using advanced cold spray systems to meet rising demand in transportation and heavy industries

- Cold gas spray’s low heat input process enables its use on sensitive components, such as electronic enclosures and lightweight alloys, enhancing the performance and durability of structural and functional surfaces

- In addition, the rising focus on life-cycle cost reduction in industries is pushing OEMs and MRO service providers to adopt cold spray for extending the operational life of expensive machinery parts, reducing replacement frequency

- The method’s ability to apply thick, high-adhesion coatings with minimal distortion also supports its use in coating biomedical implants and thermal management systems in electronics

- Increased R&D investment and government support for advanced surface engineering technologies further boost the adoption of cold spray solutions in both industrial and defense applications

Which Factor is challenging the Growth of the Cold Gas Spray Coating Market?

- One of the major challenges in the cold gas spray coating market is the high capital cost and technical complexity associated with setting up cold spray systems. The equipment requires high-pressure gas handling, specialized nozzles, and robotic integration, making initial adoption difficult for small- and mid-sized manufacturers

- For instance, companies often require custom infrastructure and trained personnel to ensure accurate deposition, limiting its accessibility in developing regions or smaller production facilities

- Moreover, the limited material compatibility and geometric constraints of cold spray compared to other coating techniques pose challenges in coating intricate surfaces or harder substrates

- Another concern is the lack of standardized processes and qualification protocols, especially in aerospace and medical industries where reliability and repeatability are crucial

- Addressing these challenges requires scalable system design, extensive operator training, and standardization efforts to qualify cold spray coatings under stringent industry regulations

- Manufacturers such as GTV Wear Protection GmbH are focusing on compact, modular cold spray systems and application-specific nozzles to reduce cost barriers and expand market reach

- Overcoming these hurdles through technological innovation, cost optimization, and process standardization is critical for the long-term scalability of cold spray coatings

How is the Cold Gas Spray Coating Market Segmented?

The market is segmented on the basis of type of technology and end user.

• By Type of Technology

On the basis of type of technology, the cold gas spray coating market is segmented into High Pressure and Low Pressure. The High Pressure segment dominated the market with the largest market revenue share of 63.4% in 2024, owing to its ability to achieve higher particle velocities and stronger adhesion strength, making it ideal for structural repairs and demanding industrial applications such as aerospace and defense. This technology is widely adopted in applications where dense, thick coatings are required for corrosion protection and dimensional restoration.

The Low Pressure segment is anticipated to witness the fastest growth rate from 2025 to 2032, supported by its lower cost, compact equipment, and suitability for delicate substrates or less intensive coating applications. It is gaining popularity among academic institutions, R&D facilities, and small-scale industrial operations, especially for prototype development and localized surface enhancements.

• By End-User

On the basis of end user, the cold gas spray coating market is segmented into Transportation, Electrical & Electronics, Oil & Gas, Utility, Medical, and Others. The Transportation segment held the largest market revenue share of 37.1% in 2024, driven by increasing use of cold spray coatings in aerospace, automotive, and rail industries for repairing high-value parts, extending lifecycle, and enhancing corrosion resistance. The non-thermal nature of cold spray makes it ideal for applying coatings on lightweight alloys and sensitive components used in this sector.

The Electrical & Electronics segment is expected to register the fastest CAGR from 2025 to 2032, fueled by the rising need for thermal management solutions, EMI shielding, and conductive coatings in microelectronics and power systems. As miniaturization trends continue, cold spray provides precise, damage-free coating solutions that are increasingly essential in next-generation devices.

Which Region Holds the Largest Share of the Cold Gas Spray Coating Market?

- North America dominated the cold gas spray coating market with the largest revenue share of 37.67% in 2024, driven by strong industrial demand across the aerospace, defense, automotive, and electronics sectors

- The region’s emphasis on component repair, corrosion resistance, and lightweight material preservation is significantly boosting the adoption of cold spray technologies

- The robust presence of major industry players, well-established R&D infrastructure, and growing investment in sustainable, non-thermal coating alternatives further support market leadership. In addition, rising military modernization programs and the push for extending the lifecycle of high-value components are increasing demand for cold gas spray systems

U.S. Cold Gas Spray Coating Market Insight

The U.S. cold gas spray coating market held the largest share within North America in 2024, propelled by its advanced aerospace and defense industries, increasing refurbishment of critical parts, and expanding infrastructure repair initiatives. The demand for non-oxidizing, heat-free coatings in sectors such as electronics, oil & gas, and transportation continues to drive technological adoption. Moreover, favorable government support for additive manufacturing and materials recovery enhances market prospects in the country.

Europe Cold Gas Spray Coating Market Insight

The Europe cold gas spray coating market is projected to expand at a substantial CAGR during the forecast period, driven by the region’s stringent environmental policies and increasing focus on energy-efficient, eco-friendly coating solutions. Growing usage in automotive, medical devices, and renewable energy sectors, combined with a mature manufacturing base and innovations in material engineering, are boosting demand. European nations are leveraging cold spray for repair applications in turbines, engines, and industrial equipment, with widespread adoption across Germany, France, and the U.K.

U.K. Cold Gas Spray Coating Market Insight

The U.K. market is anticipated to witness strong growth, owing to increased investments in advanced manufacturing technologies and refurbishment of defense and aerospace components. The country’s efforts to extend the usability of aging public infrastructure and rising adoption in the medical implants and electronics segments further support demand. In addition, innovation-driven institutions are contributing to advancements in portable cold spray systems.

Germany Cold Gas Spray Coating Market Insight

Germany is expected to record considerable market expansion due to its leadership in industrial automation, automotive production, and sustainable manufacturing. The demand for cold spray in engine block repairs, corrosion-resistant coatings, and tool restoration is accelerating. Germany's focus on reducing carbon emissions and increasing material recovery from damaged components aligns well with the cold gas spray technology’s capabilities.

Which Region is the Fastest Growing Region in the Cold Gas Spray Coating Market?

Asia-Pacific cold gas spray coating market is forecasted to grow at the fastest CAGR of 7.25% from 2025 to 2032, driven by rapid industrialization, increased adoption of surface engineering technologies, and growing investments in aerospace, defense, electronics, and automotive industries. Countries such as China, Japan, India, and South Korea are leading the surge due to rising demand for efficient repair techniques and protective coatings. The region’s shift toward localized production, coupled with government initiatives to boost advanced manufacturing and reduce environmental impact, is fostering the uptake of cold gas spray solutions.

Japan Cold Gas Spray Coating Market Insight

Japan is witnessing growing adoption due to its technology-forward industrial base, focus on precision manufacturing, and need for lightweight material protection in robotics and electronics. The market is further supported by aging infrastructure requiring non-invasive repair methods and high demand for recyclable, damage-free coatings in medical and aerospace applications.

China Cold Gas Spray Coating Market Insight

China held the largest revenue share in Asia-Pacific in 2024, bolstered by its expansive manufacturing sector, growing export of coated components, and increasing focus on military and aviation modernization. Strategic investments in research labs, universities, and defense contracts are fueling the development of domestic cold spray technologies, while local players offer cost-effective systems for repair, restoration, and additive manufacturing use cases.

Which are the Top Companies in Cold Gas Spray Coating Market?

The cold gas spray coating industry is primarily led by well-established companies, including:

- Praxair Technology, Inc. (U.S.)

- HC Starck Tungsten GmbH (Germany)

- Wall Colmonoy (U.S.)

- Saint-Gobain (France)

- Fujimi Incorporated (Japan)

- OC Oerlikon Management AG (Switzerland)

- GTV Wear Protection GmbH (Germany)

- Medicoat AG (Switzerland)

- TOCALO Co., Ltd. (Japan)

- Höganäs AB (Sweden)

- CASTOLIN EUTECTIC (Germany)

- Powder Alloy Corp (U.S.)

- DURUM Wear Protection GmbH (Germany)

What are the Recent Developments in Global Cold Gas Spray Coating Market?

- In March 2023, Linde, a leading industrial gases and engineering company, launched Linspray Connect, a cutting-edge gas delivery system specifically designed for Cold Spray Additive Manufacturing (CSAM). Developed in collaboration with Impact Innovations (Germany), this system is tailored to enhance the reliability, precision, and safety of the cold spray process. This advancement highlights Linde's focus on innovation in high-performance surface engineering

- In March 2023, Oerlikon completed the acquisition of German firm Riri, strengthening its coating solutions portfolio. The deal aims to integrate their respective technological expertise and R&D efforts to diversify and improve their global product offerings. This acquisition is expected to reinforce Oerlikon’s leadership in advanced surface technologies

- In November 2021, EWI announced the establishment of a Center of Excellence at its Buffalo facility, scheduled to launch in early 2022. The center was conceived to unlock the full potential of cold spray technology, focusing on making it more reliable, cost-effective, and repeatable. This move emphasizes EWI's commitment to advancing cold spray into scalable industrial applications

- In January 2021, a merger between Hannecard and ASB Industries led to the formation of Hannecard Roller Coatings, Inc., laying the groundwork for future expansion. This strategic collaboration combined the strengths of both companies in roller coating technologies. The merger marked a foundational step in broadening their global footprint in thermal spray coatings

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Cold Gas Spray Coating Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Cold Gas Spray Coating Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Cold Gas Spray Coating Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.