Global Composite Bearings Market

Market Size in USD Billion

CAGR :

%

USD

5.50 Billion

USD

8.96 Billion

2024

2032

USD

5.50 Billion

USD

8.96 Billion

2024

2032

| 2025 –2032 | |

| USD 5.50 Billion | |

| USD 8.96 Billion | |

|

|

|

|

Composite Bearings Market Size

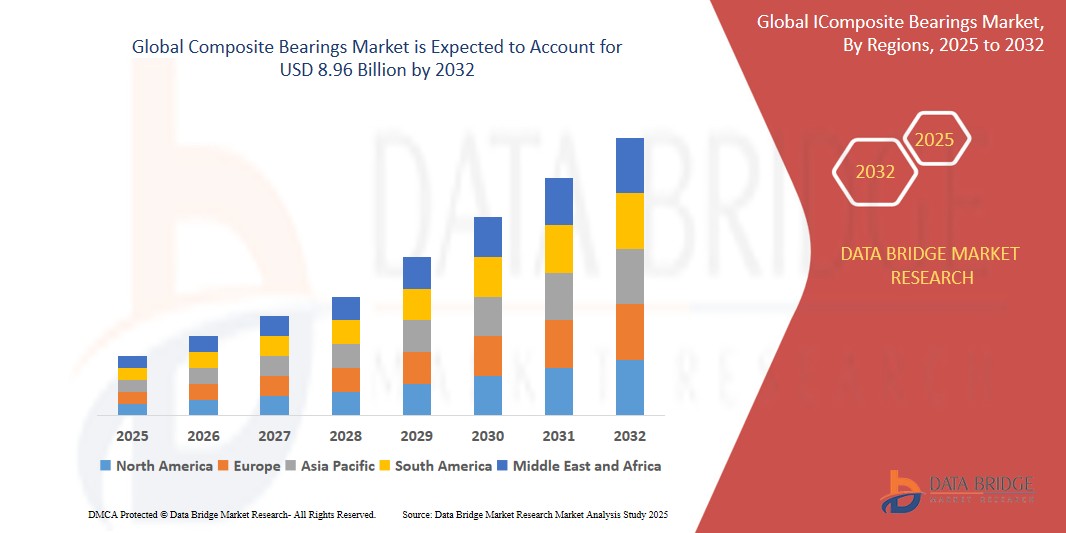

- The global composite bearings market size was valued at USD 5.50 billion in 2024 and is expected to reach USD 8.96 billion by 2032, at a CAGR of 6.30% during the forecast period

- This growth is driven by continual research and development drives and urbanization and infrastructure development

Composite Bearings Market Analysis

- Composite bearings are critical materials used across a wide range of industries including electronics, medical devices, automotive, aerospace, and energy, due to their superior thermal resistance, electrical insulation, biocompatibility, and mechanical strength

- The demand for these materials is significantly driven by technological advancements, the rise in electric vehicle production, and growing adoption in semiconductor and medical applications

- North America is expected to dominate the composite bearings market with the largest market share of 29.11%, driven by a strong industrial base, robust R&D investments, and a high concentration of leading market players in sectors such as aerospace, defense, and healthcare

- Asia-Pacific is expected to dominate the composite bearings market, driven by the region’s strong presence in manufacturing, automotive production, and industrial machinery sectors

- The cylindrical bushes segment is expected to dominate the market with the largest market share of 40.31% due to their widespread application in reducing vibrations and noise in engines, particularly within the automotive and renewable energy sectors. Their versatility and effectiveness in various mechanical systems make them a preferred choice across multiple industries

Report Scope and Composite Bearings Market Segmentation

|

Attributes |

Composite Bearings Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Composite Bearings Market Trends

“Integration of Composite Bearings in Industrial Automation”

- A rising trend in the composite bearings market is their growing integration into industrial automation systems, including robotic arms, conveyors, and actuators, due to their low friction, high wear resistance, and maintenance-free operation

- Composite bearings enhance operational uptime by reducing the need for lubrication and resisting corrosion in harsh industrial environments

- This is especially valuable in sectors such as food processing, pharmaceuticals, and packaging, where cleanliness and precision are critical

- For instance, in January 2024, igus GmbH introduced a new series of tribologically optimized composite bearings tailored for automated machinery and cleanroom environments

- As factories increasingly embrace automation, the demand for durable and self-lubricating bearing materials is expected to rise significantly across global manufacturing hubs

Composite Bearings Market Dynamics

Driver

“Growing Demand in Agriculture and Construction Equipment”

- The need for reliable, maintenance-free components in off-road machinery is driving the demand for composite bearings across agriculture and construction sector

- Composite bearings offer vibration damping, dirt resistance, and extended service life under high loads and challenging condition

- With increasing mechanization and smart farming techniques, equipment manufacturers are turning to composite bearings to reduce total ownership costs

- For instance, in 2023, Trelleborg Sealing Solutions launched new composite bushing solutions for hydraulic cylinders used in tractors and excavators

- This growing equipment modernization is fueling long-term growth in the composite bearings market, particularly in developing economies

Opportunity

“Aerospace Advancements Creating Niche Applications”

- Composite bearings are gaining momentum in aerospace applications due to their lightweight nature, ability to withstand extreme temperatures, and excellent fatigue performance

- Used in critical systems such as landing gear, flight controls, and engine components, these bearings help reduce aircraft weight and improve fuel efficiency

- As the aviation sector recovers and new aircraft programs focus on lightweight composite structures, the adoption of advanced bearings is expected to surge

- For instance, in April 2024, RBC Bearings Incorporated received FAA approval for its aerospace-grade composite bearing systems used in narrow-body aircraft assemblies

- This trend opens up high-margin growth avenues for composite bearing manufacturers focused on aerospace-grade certifications

Restraint/Challenge

“Limited Standardization and High Testing Requirements”

- One of the challenges in the composite bearings market is the lack of standardization in performance metrics across regions and industries, which complicates material selection and supplier qualification

- In industries such as aerospace and defense, rigorous validation and long test cycles delay commercialization, especially for newer composite materials

- Companies often face hurdles in scaling production due to these regulatory and compliance constraints

- For instance, a 2023 report by SAE International noted that composite bearings used in aviation must undergo over 1,000 hours of load-fatigue and thermal cycling tests before being certified for flight applications

- Such stringent requirements pose barriers to entry for small players and slow the pace of innovation and product rollout

Composite Bearings Market Scope

The market is segmented on the basis of product type, material, form, distribution channel and application.

|

Segmentation |

Sub-Segmentation |

|

By Product Type |

|

|

By Material |

|

|

By Form |

|

|

By Distribution Channel

|

|

|

By Application

|

|

In 2025, the metal matrix is projected to dominate the market with a largest share in product type segment

The metal matrix segment is expected to dominate the composite bearings market, due to its superior operational sturdiness, elevated strength in severe environments, and economical cost, which enable extensive employment across various end-use industries.

The cylindrical bushes is expected to account for the largest share during the forecast period in form segment

In 2025, the cylindrical bushes segment is expected to dominate the market with the largest market share of 40.31% due to their widespread application in reducing vibrations and noise in engines, particularly within the automotive and renewable energy sectors. Their versatility and effectiveness in various mechanical systems make them a preferred choice across multiple industries.

Composite Bearings Market Regional Analysis

“Asia-Pacific Holds the Largest Share in the Composite Bearings Market”

- Asia-Pacific is expected to dominate the composite bearings market, driven by the region’s strong presence in manufacturing, automotive production, and industrial machinery sectors

- China, Japan, and South Korea are leading contributors, benefiting from large-scale production facilities, rising demand for lightweight and maintenance-free bearings, and the integration of composite materials in high-load applications

- Government initiatives promoting industrial automation, energy efficiency, and the use of durable, low-friction components in heavy machinery and transport systems are accelerating regional growth

- A surge in construction activities, marine infrastructure, and demand from renewable energy projects further strengthens Asia-Pacific’s leadership in the global market

“North America is Projected to Register the Highest CAGR in the Composite Bearings Market”

- North America is expected to witness the highest growth rate in the composite bearings market, driven by increased adoption of composite bearings in aerospace, defense, and healthcare sectors due to their corrosion resistance and high performance in extreme environments

- The U.S. leads the regional market due to rising investments in infrastructure modernization, electric vehicle components, and medical devices using polymer-based bearing technologies

- Strong R&D infrastructure, growing focus on lightweight and eco-friendly materials, and strategic collaborations between OEMs and material scientists are advancing innovation in composite bearing applications

- The region’s push toward sustainability and energy-efficient equipment continues to create lucrative opportunities for market players in high-performance bearing solutions

Composite Bearings Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Polygon Company (India)

- Schaeffler AG (Germany)

- Huntsman International LLC (U.S.)

- GGB (U.S.)

- SGL Carbon (Germany)

- Columbia Industrial Products (U.S.)

- Regal Rexnord Corporation (U.S.)

- Tenneco Inc. (U.S.)

- Spaulding Composites, Inc. (U.S.)

- TIODIZE Co., Inc. (U.S.)

- Trelleborg AB (Sweden)

- Kor-Pak (U.S.)

- RBC Bearings Incorporated (U.S.)

- TriStar Plastics Corp. (U.S.)

- SKF (Sweden)

- Quality Pacific Manufacturing, Inc. (U.S.)

- FTL Technology (India)

- Technoslide (South Africa)

- Rheinmetall AG (Germany)

Latest Developments in Global Composite Bearings Market

- In October 2024, SKF Automotive announced the launch of its new Hub Bearing Unit (HBU) wheel bearing, which integrates two types of rolling bearings into a single unit, combining ball and tapered roller elements for enhanced performance

- In September 2024, DICA launched its Engineered Steel and Composite Crane Pads, designed with alternating solid composite timbers and steel I-beams bolted together to ensure maximum load distribution in heavy-duty operations

- In December 2023, Trelleborg Sealing Solutions advanced composite innovation with the release of Orkot C620, an ultra-low friction bearing material offering five times the compressive strength of traditional Orkot products, specifically tailored for offshore and marine applications

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Composite Bearings Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Composite Bearings Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Composite Bearings Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.