Global Computer Aided Manufacturing Market

Market Size in USD Billion

CAGR :

%

USD

3.73 Billion

USD

6.89 Billion

2024

2032

USD

3.73 Billion

USD

6.89 Billion

2024

2032

| 2025 –2032 | |

| USD 3.73 Billion | |

| USD 6.89 Billion | |

|

|

|

|

Computer Aided Manufacturing Market Size

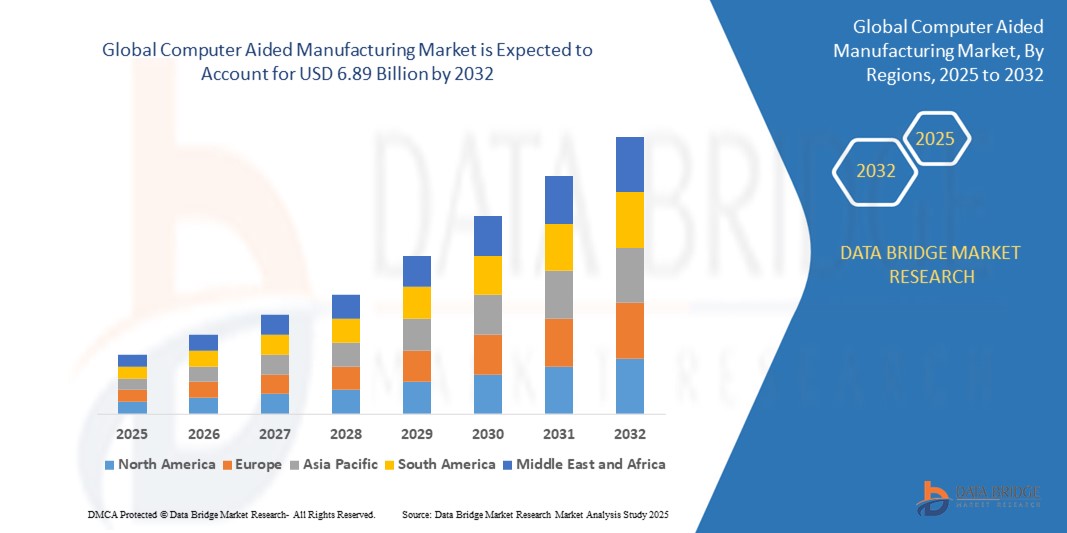

- The global computer aided manufacturing market size was valued at USD 3.73 billion in 2024 and is expected to reach USD 6.89 billion by 2032, at a CAGR of 7.98% during the forecast period

- This growth is driven by factors such as the advancements in automation, increasing demand for precision manufacturing, the adoption of Industry 4.0 technologies, cost-efficiency, and the rising need for customization across industries

Computer Aided Manufacturing Market Analysis

- The computer-aided manufacturing market is experiencing steady growth, driven by the increasing demand for advanced manufacturing solutions across various industries. This growth is also supported by the growing adoption of automation technologies in manufacturing processes

- As manufacturing industries become more focused on improving efficiency, computer-aided manufacturing systems are being widely integrated. The shift towards smart factories and digital transformation is further pushing the market towards greater expansion

- North America is expected to dominate the computer aided manufacturing’s market due to its advanced manufacturing infrastructure, high adoption of automation technologies, and significant investments in R&D across key industries such as automotive, aerospace, and electronics

- Asia-Pacific is expected to be the fastest growing region in the computer aided manufacturing market during the forecast period due to rapid industrialization, increasing demand for automation, and significant investments in advanced manufacturing technologies

- Software segment is expected to dominate the market with a market share of 74.6% due to its role in enabling automation, improving precision, and streamlining production processes across various industries

Report Scope and Computer Aided Manufacturing Market Segmentation

|

Attributes |

Computer Aided Manufacturing Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Computer Aided Manufacturing Market Trends

“Increasing Integration of Artificial Intelligence in Manufacturing”

- The use of artificial intelligence in computer-aided manufacturing is transforming production processes by enabling real-time decision-making. AI is helping manufacturers improve production efficiency by optimizing designs and minimizing errors during the manufacturing process

- Companies such as Siemens and General Electric are already leveraging AI to enhance the capabilities of their manufacturing software, enabling predictive maintenance and smart automation. This trend is enhancing the ability of manufacturers to avoid downtime and reduce operational costs

- For instance, Siemens' AI-driven platform helps predict equipment failure before it occurs, preventing costly downtime

- AI-driven technologies are also improving the customization of products, allowing manufacturers to adapt to customer preferences more effectively. This trend is particularly notable in industries such as aerospace, where precision and tailored solutions are critical

- For instance, Boeing, which uses AI to tailor aircraft components based on specific customer needs

- Machine learning algorithms are being integrated into computer-aided manufacturing tools to analyze large datasets and predict potential bottlenecks. This integration is leading to a significant reduction in production delays and enhancing overall product quality

Computer Aided Manufacturing Market Dynamics

Driver

“Increasing Demand for Automation in Manufacturing Processes”

- One of the primary drivers of the computer-aided manufacturing market is the increasing demand for automation in manufacturing processes. Industries are pushing for higher efficiency, reduced production costs, and improved precision, making CAM systems indispensable in the process

- Automation, integrated with AI and machine learning, is revolutionizing product design and production.

- For instance, General Electric has integrated AI in its CAM systems to automate manufacturing processes, improving efficiency and reducing errors

- These systems enable quicker prototyping, improved quality control, and consistent production outcomes. The automotive industry, including companies such as Tesla, is heavily investing in CAM systems to optimize production lines and reduce human error while enhancing throughput

- The increasing complexity of modern products and demand for greater customization is contributing to the growth of CAM systems. Industries such as aerospace rely on CAM for precise manufacturing, as Boeing uses CAM technology to meet stringent design and customization requirements for its aircraft components

- CAM systems help streamline operations, reduce waste, and align with sustainability goals. This trend is visible in companies such as Siemens, which uses CAM to not only enhance production efficiency but also lower material waste, reflecting a broader shift toward more sustainable manufacturing practices

Opportunity

“Rapid Adoption of Industry 4.0 Technologies”

- A significant opportunity in the computer-aided manufacturing market lies in the rapid adoption of Industry 4.0 technologies, which include smart devices, IoT, and advanced data analytics. These technologies enable manufacturers to gather real-time data, which improves operational efficiency and product quality

- For instances, incorporating IoT into manufacturing processes allows for continuous monitoring and predictive maintenance, reducing breakdowns and enhancing machine lifespan.

- Companies such as Bosch have adopted IoT in their manufacturing plants to monitor equipment in real time, ensuring smoother operations and minimizing unexpected downtime

- The growing demand for customized production in consumer goods is driving the need for more adaptable manufacturing solutions. Industries such as fashion and medical devices are requiring highly tailored products, and CAM software can provide the flexibility to meet these demands

- As industries embrace digitalization, the potential for CAM technologies to help businesses deliver faster, more accurate, and cost-effective production is vast

- For instance, companies such as Adidas are using CAM to produce custom-designed footwear that caters to individual customer preferences, opening new opportunities in the market

Restraint/Challenge

“High Upfront Cost”

- A significant challenge facing the computer-aided manufacturing market is the high upfront cost associated with implementing CAM systems, particularly for small and medium-sized enterprises (SMEs). The initial investment in software, hardware, and skilled personnel can be prohibitively expensive, limiting adoption for many SMEs

- For instance, the cost barrier is especially difficult for smaller companies, as they may struggle to keep up with ongoing software upgrades and employee training. Many SMEs cannot afford to invest in the latest technology and may fall behind larger competitors who can continuously upgrade their systems

- The integration of CAM systems into existing manufacturing processes can be complex and time-consuming. Legacy systems often need significant modifications to be compatible with new CAM technologies, which can disrupt production and increase costs. This was seen in the automotive industry, where smaller manufacturers faced challenges when trying to integrate newer CAM technologies into their outdated equipment

- The steep learning curve for companies unfamiliar with advanced manufacturing technologies adds another layer of difficulty. Specialized training is required for employees, which can initially reduce productivity

- For instance, a company such as Volkswagen faced delays and initial productivity losses when implementing advanced CAM systems into its production process due to the need for extensive employee training

Computer Aided Manufacturing Market Scope

The market is segmented on the basis of components, organization size, deployment type, and industry vertical.

|

Segmentation |

Sub-Segmentation |

|

By Components |

|

|

By Organization Size |

|

|

By Deployment Type |

|

|

By Industry Vertical |

|

In 2025, the software is projected to dominate the market with a largest share in component segment

The software segment is expected to dominate the computer aided manufacturing market with the largest share of 74.6% in 2025 due to its critical role in enhancing manufacturing efficiency and precision. Software solutions in CAM provide powerful tools for design, simulation, and optimization, enabling manufacturers to create highly customized and complex products with minimal errors.

The on-premise is expected to account for the largest share during the forecast period in technology market

In 2025, the on-premise segment is expected to dominate the market with the largest market share of 64.5% due to its greater control over data security, customization, and integration with existing systems. On-premise solutions allow companies to store and manage their data internally, which is particularly important for industries with strict data security regulations, such as aerospace and defence.

Computer Aided Manufacturing Market Regional Analysis

“North America Holds the Largest Share in the Computer Aided Manufacturing Market”

- North American region is projected to dominate the computer-aided manufacturing market in 2025, holding the largest market share of 34.6%

- This dominance is driven by the high level of technological innovation, strong industrial sectors, and significant adoption of automation technologies in the region

- The U.S., in particular, is a major contributor, with a strong focus on precision manufacturing, automation, and the integration of Industry 4.0 technologies

- North America's automotive, aerospace, and defence industries are leading the adoption of computer-aided manufacturing solutions to enhance production efficiency and reduce operational costs

- The presence of key market players in the region, along with continuous investments in smart manufacturing technologies, supports the dominance of North America

- Government initiatives to support advanced manufacturing practices and technological innovation also drive the market growth in the region

“Asia-Pacific is Projected to Register the Highest CAGR in the Computer Aided Manufacturing Market”

- Asia-Pacific region is expected to be the fastest-growing market for computer-aided manufacturing in 2025

- This growth is fuelled by rapid industrialization, large-scale manufacturing activities, and the increasing demand for automation in countries such as China, Japan, and India

- Countries such as China and India are significantly investing in infrastructure and manufacturing technologies, driving the adoption of CAM solutions

- The push toward digital transformation and smart manufacturing in Asia-Pacific is a key factor in the region’s rapid market expansion

- With its large manufacturing base, the region continues to lead in the adoption of cost-efficient and advanced technologies to optimize production

- Government policies promoting automation and technological advancements further accelerate the growth of CAM solutions across the Asia-Pacific region

Computer Aided Manufacturing Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Autodesk Inc. (U.S.)

- Dassault Systèmes (France)

- Hexagon AB (Sweden)

- Siemens (Germany)

- 3D Systems, Inc. (U.S.)

- PTC (U.S.)

- HCL Technologies Limited (India)

- OPEN MIND Technologies AG (Germany)

- MecSoft Corporation (U.S.)

- SolidCAM GmbH (Germany)

- NTT DATA ENGINEERING SYSTEMS Corporation (Japan)

- BobCAD-CAM, Inc. (U.S.)

- ZWSOFT CO., LTD. (China)

- SmartCAMcnc. (U.S.)

- CNC Software, Inc. (U.S.)

- Cimatron (Israel)

- Camnetics, Inc. (U.S.)

- GRZ SOFTWARE (Germany)

- CASIO COMPUTER CO., LTD. (Japan)

- BenQ Asia Pacific Corporation (Taiwan)

- Dell Inc. (U.S.)

Latest Developments in Global Computer Aided Manufacturing Market

- In April 2024, ESI Group (France) and FAW-Volkswagen (China) TE announced a strategic partnership to advance intelligent simulation technology in the automotive industry. The collaboration focuses on establishing a localized automotive industry material database and driving innovation in intelligent simulation. A joint laboratory for material testing and simulation has been set up to enhance research and development efforts. This partnership aims to address challenges posed by China's automotive safety regulations and contribute to a cleaner, safer, and more productive future in automotive manufacturing

- In February 2024, Hexagon (Sweden) partnered with Augment Technologies (Australia) to integrate AI with mining operations. This collaboration combines Hexagon’s MinePlan Block Model Manager with Augment’s AI-powered Muckpile Block Model, enabling real-time, high-resolution data for ore extraction. The partnership aims to reduce ore loss and dilution, improving operational efficiency and profitability. By leveraging machine learning, this solution provides actionable insights to optimize mining processes

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.