Global Digital Textile Printing Market

Market Size in USD Billion

CAGR :

%

USD

3.07 Billion

USD

7.32 Billion

2024

2032

USD

3.07 Billion

USD

7.32 Billion

2024

2032

| 2025 –2032 | |

| USD 3.07 Billion | |

| USD 7.32 Billion | |

|

|

|

|

Digital Textile Printing Market Size

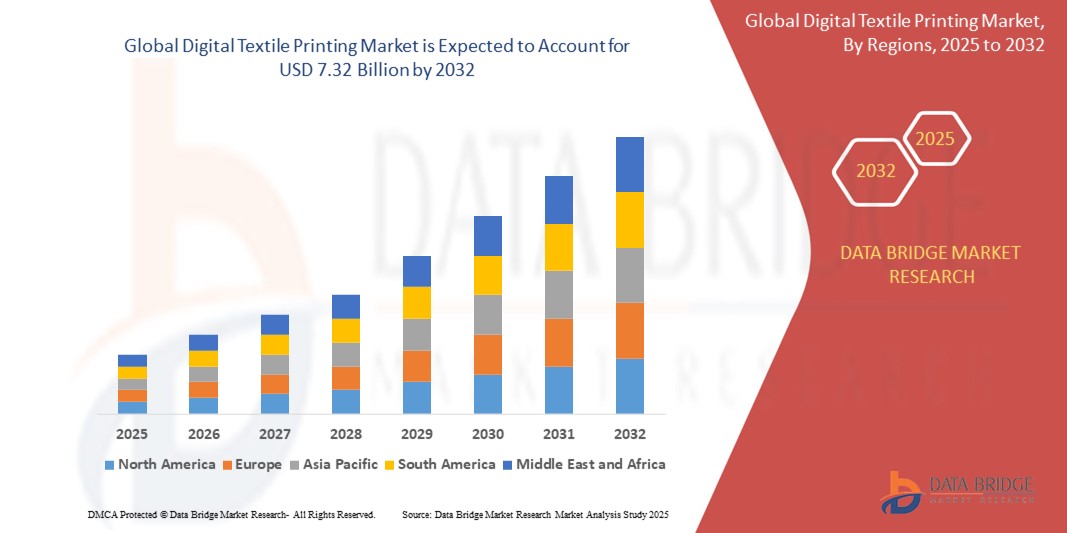

- The global digital textile printing market size was valued at USD 3.07 billion in 2024 and is expected to reach USD 7.32 billion by 2032, at a CAGR of 11.49% during the forecast period

- This growth is driven by factors such as rising demand for customization, growth in fast fashion and e-commerce, and increasing adoption of eco-friendly, sustainable printing methods

Digital Textile Printing Market Analysis

- Digital textile printing is a transformative technology that enables high-quality, on-demand printing directly onto fabrics, offering enhanced design flexibility, faster turnaround, and reduced environmental impact compared to traditional methods

- The digital textile printing market is witnessing robust growth, fueled by increasing demand for personalized and short-run textile production, advancements in printing technologies and ink formulations, and the rising shift toward sustainable, cost-efficient manufacturing in industries such as fashion, home décor, and soft signage

- Asia-Pacific is expected to dominate the digital textile printing market with a share of 33.1% due to large-scale textile production hubs, rising fashion consumption, and the growing adoption of sustainable, on-demand textile printing technologies

- North America is expected to be the fastest growing region in the digital textile printing market during the forecast period due to increasing demand for short-run, customized textile prints and rapid technological advancements in inkjet and dye-sublimation printing

- Clothing and apparel segment is expected to dominate the market with a market share of 54.5% due to rising demand for fast fashion, increasing consumer preference for customized and on-demand apparel, and the growing shift of manufacturers toward sustainable printing solutions. Digital textile printing enables quick turnaround times, reduced waste, and high-quality prints on a variety of fabrics, making it ideal for addressing dynamic fashion trends and small-batch production needs

Report Scope and Digital Textile Printing Market Segmentation

|

Attributes |

Digital Textile Printing Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Digital Textile Printing Market Trends

“Rising Demand for Customization”

- One prominent trend in the global digital textile printing market is the rising demand for customization

- This trend is driven by the evolving consumer preferences for unique designs, limited-edition apparel, and made-to-order fashion, particularly in sectors such as clothing, home décor, and promotional materials

- For instance, companies such as Spoonflower, Zazzle, and Printful are leveraging digital textile printing technologies to offer customizable fabric prints, personalized apparel, and on-demand home décor items tailored to individual customer specifications

- The demand for customized textiles is gaining momentum across both developed markets such as the U.S. and Western Europe, and emerging economies where online fashion and digital design tools are rapidly expanding

- As consumers continue to seek personalized and sustainable fashion options, the need for flexible, on-demand digital textile printing solutions is expected to remain a defining trend shaping the future of the market

Digital Textile Printing Market Dynamics

Driver

“Continuous Advancements in Digital Printing”

- Continuous advancements in digital printing technology are becoming significant drivers for the digital textile printing market, as manufacturers aim to improve print quality and reduce operational costs

- This shift is gaining momentum globally, with companies increasingly adopting faster, more efficient digital printers to meet demand for high-resolution, vibrant textile prints across fashion, home décor, and industrial applications

- As businesses strive to enhance production speed and minimize waste, there is growing emphasis on developing printers with automated workflows and versatile ink compatibility to handle diverse fabrics

- Companies are investing heavily in research and development to introduce innovative printheads, eco-friendly inks, and integrated software solutions that optimize efficiency and output quality

- Moreover, the rising need for sustainable and scalable textile production is amplifying the adoption of advanced digital printing technologies

For instance,

- Kornit Digital and EFI Reggiani are launching next-generation printers with improved speed and eco-friendly inks, while Mimaki is focusing on automation and user-friendly interfaces for small to medium enterprises

- Brother International is enhancing its direct-to-garment printing solutions with faster print cycles and advanced color management

- As digital printing innovations continue to evolve, the demand for high-performance, cost-effective digital textile printing solutions is expected to remain a primary growth driver in the market

Opportunity

“Innovation in Inks and Materials”

- Innovation in inks and materials presents a significant opportunity for the digital textile printing market, enabling higher print quality, expanded application range, and improved sustainability

- Industry players are capitalizing on this opportunity by developing advanced ink formulations, such as eco-friendly, pigment-based, and sublimation inks, that offer better color fastness, durability, and compatibility with diverse fabrics

- This opportunity aligns with the growing demand for sustainable textile production and high-performance materials that meet industry and consumer expectations for both aesthetics and environmental responsibility

For instance,

- Companies such as Sun Chemical and DIC Corporation are advancing eco-friendly ink technologies that reduce water usage and hazardous chemicals in the printing process

- EFI Reggiani is innovating with specialty inks designed for performance textiles used in sportswear, fashion, and technical applications

- As demand rises for sustainable and versatile textile printing solutions, especially in fashion, home décor, and industrial segments, the market is well-positioned to benefit from continued innovation in inks and materials that enhance print quality while reducing environmental impact

Restraint/Challenge

“Limited Fabric Compatibility”

- Limited fabric compatibility remains a significant challenge for the digital textile printing market, as not all printing technologies and inks work effectively across the wide variety of textile materials used in fashion, home décor, and industrial applications

- Manufacturers often face difficulties in achieving consistent print quality and color fastness on fabrics such as cotton, silk, polyester, and blends, which require different ink formulations and printing processes for optimal results

- This challenge is further complicated by the need to balance performance with sustainability, as eco-friendly inks may have restrictions on the types of fabrics they can be used with, limiting broader adoption

For instance,

- Companies such as Kornit Digital and EFI Reggiani are investing in R&D to expand fabric compatibility, but achieving universal applicability remains complex due to the diverse nature of textiles

- Without advancements in fabric-ink compatibility and standardized testing protocols, manufacturers may face production inefficiencies and quality issues, potentially slowing market growth and limiting the full potential of digital textile printing technologies

Digital Textile Printing Market Scope

The market is segmented on the basis of process type, printing process, ink type, and application.

|

Segmentation |

Sub-Segmentation |

|

By Process Type |

|

|

By Printing Process |

|

|

By Ink Type |

|

|

By Application |

|

In 2025, the clothing and apparel is projected to dominate the market with a largest share in application segment

The clothing and apparel segment is expected to dominate the digital textile printing market with the largest share of 54.5% in 2025 due to rising demand for fast fashion, increasing consumer preference for customized and on-demand apparel, and the growing shift of manufacturers toward sustainable printing solutions. Digital textile printing enables quick turnaround times, reduced waste, and high-quality prints on a variety of fabrics, making it ideal for addressing dynamic fashion trends and small-batch production needs.

The sublimation is expected to account for the largest share during the forecast period in ink type segment

In 2025, the sublimation segment is expected to dominate the market with the largest market share of 53.0% due to its superior print quality, vibrant color output, and strong demand in polyester-based applications such as sportswear, fashion apparel, and soft signage. Sublimation printing offers advantages such as high durability, wash resistance, and eco-friendliness, making it the preferred choice for high-volume and short-run digital textile printing, particularly in fast-paced and customization-driven markets.

Digital Textile Printing Market Regional Analysis

“Asia-Pacific Holds the Largest Share in the Digital textile printing Market”

- Asia-Pacific dominates the digital textile printing market with a share of 33.1%, driven by the large-scale textile production hubs, rising fashion consumption, and the growing adoption of sustainable, on-demand textile printing technologies

- China holds a significant share due to its vast textile manufacturing base, strong export capabilities, and increasing shift toward eco-friendly digital printing methods to meet global sustainability standards

- Regional dominance is reinforced by the presence of numerous fabric producers, rising investments in digital textile printing infrastructure, and expanding demand from apparel, home décor, and industrial textile segments

- The surge in fast fashion trends, customization demands, and cost-effective production solutions is expected to further strengthen Asia-Pacific's leadership in the digital textile printing market through 2032

“North America is Projected to Register the Highest CAGR in the Digital textile printing Market”

- North America is expected to witness the highest growth rate in the digital textile printing market, driven by increasing demand for short-run, customized textile prints and rapid technological advancements in inkjet and dye-sublimation printing

- U.S. holds a significant share due to its growing fashion-tech startups, focus on localized production, and the adoption of digital printing for personalized apparel, soft signage, and interior decor

- Market acceleration is also supported by a shift toward sustainable manufacturing practices, digital supply chains, and integration of advanced print-on-demand platforms

- With increasing consumer preference for customized and eco-conscious products, rising investments in digital print technologies, and expanding applications across various industries, North America is poised to be the fastest-growing region in the global digital textile printing market from 2025 to 2032

Digital Textile Printing Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Aeoon Technologies GmbH (Austria)

- ATPColor (Italy)

- Bordeaux Digital PrintInk Ltd. (Israel)

- DURST GROUP AG (Italy)

- Hollanders (Netherlands)

- Kornit Digital (Israel)

- SPGPrints (Netherlands)

- Brother International Corporation (Japan)

- Colorjet Group (India)

- d.gen (South Korea)

- Konica Minolta Business Solutions India Private Limited (Japan)

- Mimaki Engineering Co. Ltd. (Japan)

- Mutoh Holdings Co. Ltd. (Japan)

- Ricoh (Japan)

- Roland DG Corporation (Japan)

- Seiko Epson Corporation (Japan)

- DuPont (U.S.)

- Electronics For Imaging, Inc. (U.S.)

- Huntsman International LLC (U.S.)

- Marabu GmbH & Co. KG (Germany)

- Sawgrass Technologies (U.S.)

- Sensient Colors LLC (U.K.)

- Trendvision Technology (Zhuhai) Co., Ltd. (China)

Latest Developments in Global Digital Textile Printing Market

- In September 2024, Roland DG Corporation introduced the TY-300 direct-to-film production transfer printer, enhancing the digital textile printing market with superior image quality, high productivity, and cost efficiency. The printer’s ability to deliver vibrant colors and intricate details addresses the growing demand for high-quality apparel customization. Furthermore, its OEKO-TEX ECO PASSPORT-certified inks and powders reinforce market confidence by meeting stringent safety and environmental standards, appealing to sustainability-conscious consumers and manufacturers alike

- In April 2024, Epson America launched the SureColor F11070 and F11070H dye-sublimation printers, strengthening the industrial segment of the digital textile printing market. Designed for reliability, high throughput, and reduced total cost of ownership, these printers cater to large-scale print shops and web-to-print businesses seeking efficiency and scalability. Their user-friendly design and low maintenance requirements are expected to accelerate adoption, driving growth in industrial and commercial textile printing applications

- In January 2024, Agfa’s strategic partnership with EFI marks a significant development in the digital textile printing market by combining complementary technologies and expanding product offerings. The integration of EFI’s roll-to-roll system with Agfa’s hybrid inkjet printers provides customers with a more versatile and innovative portfolio, backed by robust service support. This collaboration enhances competitiveness and addresses diverse customer needs, thereby strengthening market presence and fostering greater adoption of advanced digital printing solutionsssss

- In August 2022, Roland DG Corporation, a leading manufacturer and distributor of advertising and signage inkjet printers and 3D manufacturing tools, announced the expansion of its operations. The company revealed plans to construct a new building at the factory in Samutsakhon, Thailand, which is managed by Roland Digital Group Thailand Ltd.

- In May 2022, Epson introduced the Monna Lisa 8000A direct-to-fabric printer to strengthen its presence in North America. The Monna Lisa 8000 (ML-8000) allows North American businesses to print locally on a wide variety of fabrics, accommodating both short runs and larger volume orders. Combining precision engineering with modern design, the ML-8000 offers the capability to print on a diverse range of fabric types

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Digital Textile Printing Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Digital Textile Printing Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Digital Textile Printing Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.