Global Elastomeric Coating Market

Market Size in USD Billion

CAGR :

%

USD

9.08 Billion

USD

23.73 Billion

2024

2032

USD

9.08 Billion

USD

23.73 Billion

2024

2032

| 2025 –2032 | |

| USD 9.08 Billion | |

| USD 23.73 Billion | |

|

|

|

|

What is the Global Elastomeric Coating Market Size and Growth Rate?

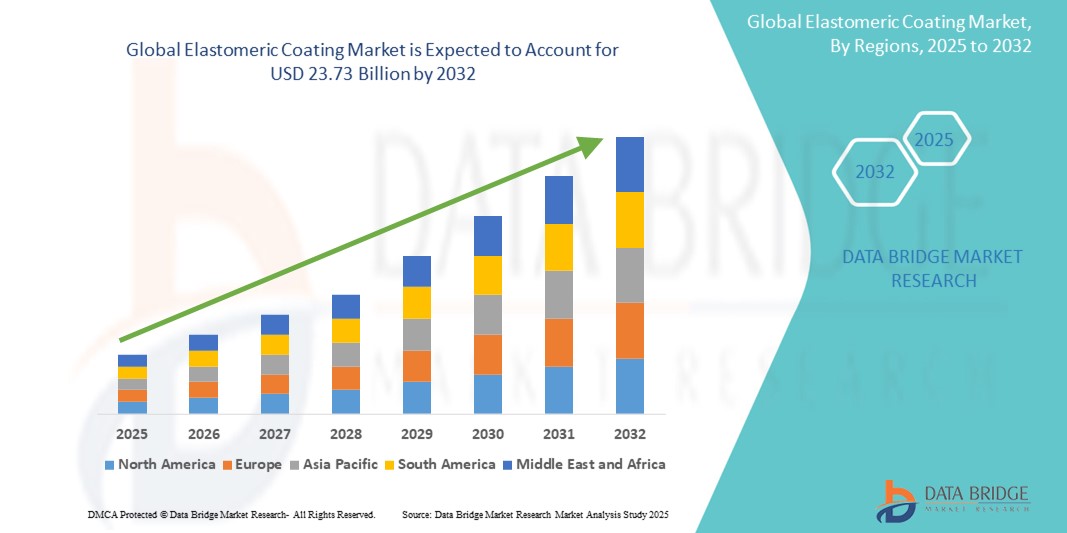

- The global elastomeric coating market size was valued at USD 9.08 billion in 2024 and is expected to reach USD 23.73 billion by 2032, at a CAGR of 12.75% during the forecast period

- The elastomeric coatings market is experiencing steady growth, driven by increasing demand from the construction, automotive, and industrial sectors. Elastomeric coatings are valued for their ability to provide protective, waterproof, and weather-resistant properties to various surfaces

- In the construction industry, elastomeric coatings are widely used for roof coatings, wall coatings, and waterproofing applications due to their durability and energy-efficient properties

What are the Major Takeaways of Elastomeric Coating Market?

- The automotive industry also contributes to the growth of the market, as these coatings are used for protecting automotive surfaces from corrosion, abrasion, and weathering. In addition, the industrial sector utilizes elastomeric coatings for corrosion protection, chemical resistance, and anti-slip properties

- Technological advancements, such as the progress in eco-friendly and sustainable elastomeric coatings, are also driving the market.

- North America dominated the elastomeric coating market with the largest revenue share of 44.31% in 2024, propelled by rising investments in infrastructure refurbishment and stringent environmental regulations

- Asia-Pacific elastomeric coating market is anticipated to grow at the fastest CAGR of 14.11% from 2025 to 2032, supported by rapid urbanization, infrastructure development, and industrialization across emerging economies

- The acrylic elastomeric coating segment dominated the market with the largest market revenue share of 36.7% in 2024, owing to its superior UV resistance, excellent flexibility, and cost-effectiveness

Report Scope and Elastomeric Coating Market Segmentation

|

Attributes |

Elastomeric Coating Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Elastomeric Coating Market?

“Sustainability and Energy Efficiency Driving Formulation Innovation”

- A major trend shaping the global elastomeric coating market is the shift towards eco-friendly, energy-efficient formulations. Rising environmental regulations and increasing demand for green building solutions are pushing manufacturers to develop coatings with low VOCs, solar reflectivity, and longer lifespans

- For instance, PPG Industries launched its solar reflective elastomeric roof coatings targeting commercial buildings to reduce cooling costs and carbon footprint. Similarly, Sherwin-Williams offers high-performance formulations with excellent thermal insulation and UV resistance for industrial applications

- Elastomeric coatings now often include cool roof technologies, offering energy savings by reflecting more sunlight and absorbing less heat. These coatings help maintain interior comfort, reducing dependency on air conditioning and supporting LEED certifications

- Innovation is also driven by demand for biobased ingredients, water-based systems, and recyclable packaging, aligning with sustainability goals of both manufacturers and end-users

- Companies such as BASF and Henry Company are investing in R&D for next-gen coatings that combine durability with eco-friendliness, targeting applications in both residential and commercial sectors

- As the global construction industry continues to prioritize sustainability, green elastomeric coatings are expected to see robust growth, especially in regions such as Europe and North America, where environmental compliance is stringent

What are the Key Drivers of Elastomeric Coating Market?

- The growing demand for weather-resistant coatings in the construction industry is a primary driver, especially in regions experiencing extreme climate conditions. Elastomeric coatings offer crack-bridging ability, UV stability, and waterproofing, making them ideal for exterior surfaces

- In March 2024, GAF introduced a new range of elastomeric wall coatings designed for high-humidity environments, improving mold and moisture resistance in both commercial and residential buildings

- The rapid expansion of the infrastructure and refurbishment sectors, especially in developing countries, is accelerating adoption. Aging structures require cost-effective surface protection solutions, and elastomeric coatings provide an excellent return on investment through extended service life and low maintenance costs

- In addition, rising awareness among end-users regarding energy savings and building sustainability certifications is increasing demand for coatings with reflective and insulative properties

- Government initiatives promoting energy-efficient building practices, coupled with rising consumer preference for durable and aesthetically pleasing finishes, are pushing market growth across sectors including residential, commercial, and industrial

Which Factor is challenging the Growth of the Elastomeric Coating Market?

- Despite strong growth prospects, the market faces challenges related to raw material volatility and high product costs. The dependence on petroleum-based polymers, such as acrylic and polyurethane, makes pricing highly susceptible to fluctuations in crude oil prices

- For instance, in late 2023, multiple manufacturers including Dow Chemical and 3M reported margin pressures due to rising costs of synthetic resins and additives used in elastomeric formulations

- In addition, while high-performance elastomeric coatings offer long-term benefits, their upfront costs remain higher than conventional paints, posing adoption hurdles in price-sensitive markets

- Another concern is the performance limitations of some water-based coatings under harsh conditions such as extreme heat, UV exposure, or industrial pollution, which can impact product longevity

- To overcome these barriers, companies are focusing on material innovation, such as hybrid polymers and nano-enhanced formulations, and investing in supply chain optimization to reduce costs. Improving product awareness and demonstrating long-term cost savings through lifecycle analysis will also be critical to increasing market acceptance, particularly in emerging economies

How is the Elastomeric Coating Market Segmented?

The market is segmented on the basis of type, technology, application, and end-use.

• By Type

On the basis of type, the elastomeric coating market is segmented into Acrylic Elastomeric Coating, Polyurethane Elastomeric Coating, Silicone Elastomeric Coating, Butyl Elastomeric Coating, Polysulfide, Vinyl Polymers, Epoxy, Polyurea, and Others. The Acrylic Elastomeric Coating segment dominated the market with the largest market revenue share of 36.7% in 2024, owing to its superior UV resistance, excellent flexibility, and cost-effectiveness. Acrylic coatings are widely used in residential and commercial construction projects due to their ease of application and long-lasting performance on exterior surfaces. Their water-based nature and environmental friendliness further contribute to their popularity among contractors and homeowners.

The polyurethane elastomeric coating segment is anticipated to witness the fastest growth rate from 2025 to 2032, driven by its high abrasion resistance, strong adhesion, and performance in harsh environments. Polyurethane coatings are increasingly adopted in industrial and commercial settings where durability and chemical resistance are key concerns.

• By Technology

On the basis of technology, the elastomeric coating market is segmented into Water-Borne Elastomeric Coating and Solvent-Borne Elastomeric Coating. The Water-Borne segment held the largest market share in 2024 due to growing regulatory support for low-VOC products and increased consumer preference for environmentally friendly solutions. These coatings offer easy cleanup, reduced odor, and compatibility with various substrates, making them suitable for residential and commercial use.

The Solvent-Borne segment is expected to register the fastest CAGR from 2025 to 2032, owing to its superior performance in extreme weather conditions and better film formation in high-humidity or low-temperature environments. Solvent-borne products are especially favored in industrial and infrastructure applications.

• By Application

On the basis of application, the market is segmented into Building and Construction, Wall Coating, Floor Coating/Horizontal Surface Coatings, Roof Coating, Bridges Coating, and Others. The Building and Construction segment accounted for the largest revenue share in 2024, driven by rising investments in infrastructure development and the growing demand for protective and decorative coatings in both new construction and renovation projects. Elastomeric coatings are extensively used to enhance structural longevity and surface aesthetics.

The Roof Coating segment is expected to witness the fastest growth rate from 2025 to 2032, supported by increasing awareness of energy efficiency and the role of reflective roof coatings in reducing cooling costs.

• By End-Use

On the basis of end-use, the market is segmented into Residential, Commercial, Industrial, and Others. The Residential segment dominated the market in 2024 with the highest revenue share, propelled by the rising trend of home improvement, increased spending on exterior home maintenance, and growing homeowner awareness of protective coatings' benefits.

The Commercial segment is projected to experience the fastest CAGR from 2025 to 2032, driven by expanding commercial real estate development and stringent building regulations demanding high-performance coatings for durability and aesthetics.

Which Region Holds the Largest Share of the Elastomeric Coating Maret?

- North America dominated the elastomeric coating market with the largest revenue share of 44.31% in 2024, propelled by rising investments in infrastructure refurbishment and stringent environmental regulations

- The region’s demand is driven by the product’s superior waterproofing, UV resistance, and energy-saving benefits, making it popular for roofing, wall coatings, and commercial structures

- High construction activity, awareness about green building standards, and the shift toward sustainable materials further contribute to the market’s growth across both residential and industrial sectors

U.S. Elastomeric Coating Market Insight

U.S. Elastomeric Coating market dominated North America’s revenue share in 2024, fueled by increasing renovations of aging infrastructure and the strong focus on eco-friendly building practices. The rising prevalence of energy-efficient structures, coupled with demand for low-VOC and long-lasting coatings, is boosting adoption. Furthermore, favorable government regulations and incentives promoting sustainable construction materials continue to drive market penetration in commercial, institutional, and residential applications.

Europe Elastomeric Coating Market Insight

Europe elastomeric coating market is expected to witness notable CAGR growth during the forecast period, driven by stringent environmental policies and rising investment in energy-efficient retrofits. Increasing awareness about moisture protection and façade preservation is accelerating product adoption. The construction of smart, sustainable buildings and restoration of heritage structures are also driving growth across the region. Countries such as Germany, France, and the U.K. are major contributors due to their progressive green building initiatives.

U.K. Elastomeric Coating Market Insight

U.K. elastomeric coating market is projected to grow significantly owing to rising demand for thermal insulation and waterproofing solutions. Urban expansion, coupled with rising rainfall frequency, has heightened the need for high-performance coatings. Government-backed energy-saving schemes and retrofitting programs are further encouraging product use in residential and public infrastructure, while consumer preference for low-maintenance, long-lasting coatings continues to rise.

Germany Elastomeric Coating Market Insight

Germany elastomeric coating market is poised for steady growth, backed by robust construction activity and increasing focus on climate-resilient architecture. The country’s commitment to environmental sustainability and innovation in building technologies fuels demand for durable, non-toxic coating solutions. Germany also exhibits high usage of elastomeric coatings in commercial and industrial structures, owing to its superior protection against thermal cycling, cracking, and damp conditions.

Which Region is the Fastest Growing in the Elastomeric Coating Market?

Asia-Pacific elastomeric coating market is anticipated to grow at the fastest CAGR of 14.11% from 2025 to 2032, supported by rapid urbanization, infrastructure development, and industrialization across emerging economies. Increased construction spending in China, India, and Southeast Asia, combined with favorable government policies, is boosting demand. Moreover, the regional shift toward sustainable construction materials, coupled with rising awareness of elastomeric coating benefits, is expanding the consumer base across residential, commercial, and public sectors.

Japan Elastomeric Coating Market Insight

Japan elastomeric coating market is advancing due to high building standards, seismic retrofitting needs, and demand for durable coatings in a humid climate. Japan’s emphasis on long-lasting, weather-resistant construction materials is driving market uptake. In addition, integration of eco-conscious coatings into modern architecture and smart buildings is supporting steady growth across both metropolitan and regional development projects.

China Elastomeric Coating Market Insight

The China elastomeric coating market secured the largest revenue share in Asia-Pacific in 2024, driven by rapid urban expansion, government investments in infrastructure, and widespread adoption of green building standards. The booming residential construction sector, alongside renovation of public infrastructure and rising middle-class demand for modern coatings, continues to fuel market growth. The availability of cost-effective domestic products and strategic government support are further enhancing market momentum.

Which are the Top Companies in Elastomeric Coating Market?

The Elastomeric Coating industry is primarily led by well-established companies, including:

- BASF SE (Germany)

- Dow (U.S.)

- CLARIANT (Switzerland)

- Nippon Paint Holdings Co., Ltd.(Japan)

- PPG Industries, Inc. (U.S.)

- The Sherwin-Williams Company (U.S.)

- Huntsman International LLC. (U.S.)

- MarvelVinyls (India)

- The VersaFlex Companies (U.S.)

- Axalta Coating Systems, LLC (U.S.)

- Pidilite Industries Ltd. (India)

- Valspar (U.S.)

- Rhino Linings Corporation. (U.S.)

- Nukote Coating Systems, Intl. (U.S.)

- Jotun (Norway)

- RODDA PAINT, CO. (U.S.)

- Constro Chem India Pvt. Ltd. (India)

- ELMET (U.S.)

- Aalberts Surface Technologies GmbH (Netherlands)

What are the Recent Developments in Global Elastomeric Coating Market?

- In December 2023, WEG company developed an innovative coating that promises significant benefits for offshore industries. Utilizing WrapX technology, the coating is based on high-performance elastomeric coatings, which effectively enhance the durability of the coated surface

- In April 2023, Gaco, a leading manufacturer of roofing systems, unveiled its latest product, GacoFlex A48, an acrylic elastomeric roof coating. This single-component coating is designed to be applied in a single pass application, offering the ability to apply up to 80 wet mils (5 gal/SQ). The elastomeric properties of the coating provide a long lifespan for roofs, improve their visual appearance, ensure strong adhesion, offer high tensile strength, and provide excellent reflectivity

- In April 2021, Nationwide Protective Coatings introduced PERMAKOTE Metal Roof Paint. PERMAKOTE metal roof paint is a bright white, matte finish, elastomeric acrylic, protective roof coating developed for use on metal roof systems. it is a water-based, high-performance solution with acrylic waterproofing technology

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Elastomeric Coating Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Elastomeric Coating Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Elastomeric Coating Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.