Global Food And Beverages Coding And Marking Equipment Market

Market Size in USD Billion

CAGR :

%

USD

3.46 Billion

USD

5.46 Billion

2024

2032

USD

3.46 Billion

USD

5.46 Billion

2024

2032

| 2025 –2032 | |

| USD 3.46 Billion | |

| USD 5.46 Billion | |

|

|

|

Food and Beverages Coding and Marking Equipment Market Analysis

The food and beverages coding and marking equipment market is experiencing significant growth due to increasing demand for product traceability, regulatory compliance, and brand differentiation. These technologies enable manufacturers to print critical information such as expiration dates, batch numbers, and ingredient lists on packaging, ensuring both safety and transparency. Strict regulations worldwide, especially in regions such as Europe and North America, require accurate and legible markings to meet food safety standards, driving the adoption of coding and marking solutions.

Recent advancements in the market include the development of high-speed inkjet printers, laser marking systems, and thermal transfer solutions, which enhance printing accuracy, speed, and durability. These innovations enable manufacturers to handle complex coding needs on various packaging types, including bottles, cans, and cartons. In addition, smart coding systems equipped with data-driven insights and connectivity are being integrated into production lines, providing enhanced tracking capabilities and operational efficiency.

As e-commerce and packaged food demand continue to grow, the market for food and beverages coding and marking equipment is expected to expand further. The evolving need for sustainable and eco-friendly solutions, along with continuous technological improvements, will shape the future of this industry.

Food and Beverages Coding and Marking Equipment Market Size

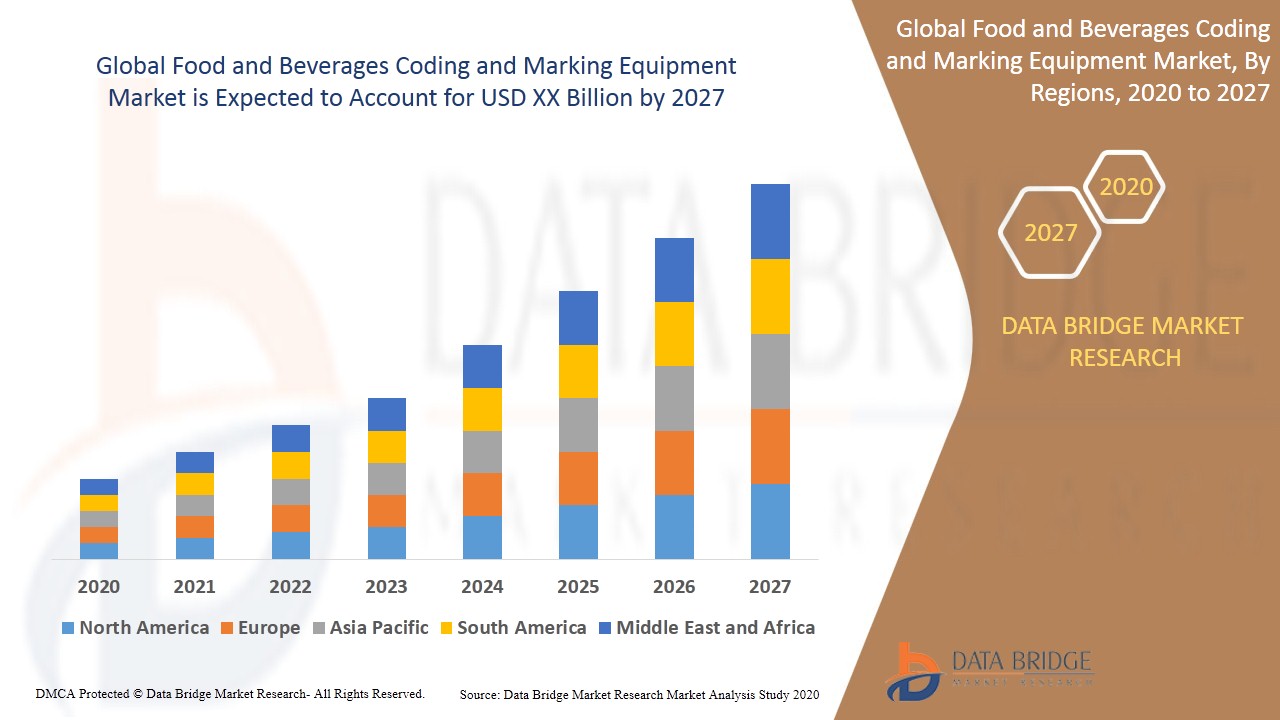

The food and beverages coding and marking equipment market size was valued at USD 3.46 billion in 2024 and is projected to reach USD 5.46 billion by 2032, with a CAGR of 5.87% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Food and Beverages Coding and Marking Equipment Market Trends

“Adoption of Laser Marking Technology”

The food and beverages coding and marking equipment market is witnessing a notable trend towards the adoption of laser marking technology, driven by its precision, speed, and eco-friendly benefits. Laser coding offers an effective solution for printing high-quality, durable marks on various packaging materials, including glass, plastic, and metal. For instance, Dover Corporation has been leveraging this technology to offer laser marking systems that provide clear and legible expiration dates, batch numbers, and brand logos without the need for consumables like ink. This trend is largely fueled by the rising demand for sustainability in packaging, as laser systems eliminate the use of chemicals and inks, reducing waste and promoting a cleaner production process. In addition, the increasing focus on traceability and compliance with stringent food safety regulations further accelerates the shift to laser marking, as it ensures the marks are permanent and resistant to tampering. This shift is expected to drive the growth of the food and beverages coding market, enhancing operational efficiency and environmental sustainability.

Report Scope and Food and Beverages Coding and Marking Equipment Segmentation

|

Attributes |

Food and Beverages Coding and Marking Equipment Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

Brother Industries, Ltd. (Japan), Danaher (U.S.), Dover Corporation (U.S.), Hitachi, Ltd. (Japan), ITW Diagraph GmbH (Germany), ID Technology, LLC. (U.S.), SATO Holdings Corporation (Japan), Durable Technologies (U.S.), Jantech Marking Equipment (Canada), Universal Labeling Systems (U.S.), and Superior Case Coding (U.S.) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Food and Beverages Coding and Marking Equipment Market Definition

Food and beverages coding and marking equipment refers to specialized machinery used to print vital information such as expiration dates, batch numbers, ingredient lists, and product identification codes on packaging materials. These systems ensure that food and beverage products meet regulatory standards, provide traceability, and facilitate consumer safety.

Food and Beverages Coding and Marking Equipment Market Dynamics

Drivers

- Rising Demand for Stringent Regulatory Requirements

Stringent regulatory requirements are a major driver of the food and beverage coding and marking equipment market, as governments around the world enforce strict labeling standards to ensure consumer safety. These regulations mandate the clear display of essential information, such as expiration dates, batch codes, ingredient lists, and nutritional facts, on packaging to maintain transparency and traceability. For instance, in the European Union, the Food Information to Consumers (FIC) regulation requires that food packaging include specific labeling details to protect consumer health and aid in product recall processes. As a result, manufacturers are increasingly investing in advanced coding and marking technologies, such as high-speed inkjet printers and laser marking systems, to meet these requirements. These technologies enable fast and accurate printing on diverse packaging materials while ensuring compliance with local and international food safety standards. This growing demand for compliance-driven solutions is significantly contributing to the expansion of the market for food and beverages coding and marking equipment.

- Growing Demand for Traceability

The growing demand for traceability is a key driver in the food and beverages coding and marking equipment market, as consumers and regulatory bodies increasingly require transparency throughout the product lifecycle. Traceability allows for the tracking of products from production to consumption, ensuring safety, quality, and accountability. For instance, the U.S. Food and Drug Administration (FDA) mandates that food products be traceable for the purpose of quick and efficient recalls in case of contamination. Coding and marking technologies, such as QR codes and RFID tags, play a crucial role in meeting these requirements by enabling manufacturers to track and trace products in real-time. By incorporating these solutions into their production lines, companies can provide detailed information on product origins, handling, and expiry, building consumer trust and enhancing food safety practices. As regulatory pressures around traceability continue to rise, the demand for advanced coding and marking equipment is expected to increase, driving market growth and innovation.

Opportunities

- Rising Growth of E-Commerce

The rising growth of e-commerce and the increasing demand for packaged food are creating a significant market opportunity for food and beverages coding and marking equipment. With more consumers turning to online shopping for food and beverage products, manufacturers must manage large volumes of packaging while maintaining efficiency, accuracy, and compliance. This shift is driving the need for advanced labeling and marking solutions capable of handling high-speed production and diverse packaging materials. For instance, companies such as Amazon and Walmart rely on efficient labeling systems to process thousands of packaged food products daily, ensuring accurate information such as expiration dates and batch numbers is printed clearly and consistently. As packaged food consumption continues to rise, coupled with the increasing popularity of online grocery shopping, the demand for robust coding and marking technologies that can meet these logistical challenges will further accelerate market growth, presenting an opportunity for innovation and investment in advanced equipment.

- Increasing Technological Advancements in Coding and Marking Systems

Technological advancements in coding and marking systems, such as laser marking, inkjet printing, and RFID tagging, present a significant market opportunity by enhancing speed, precision, and sustainability in packaging processes. These innovations enable manufacturers to meet the growing demand for high-quality, efficient labeling while reducing environmental impact. For instance, laser marking technology provides permanent, precise codes without the need for inks or solvents, offering a cleaner, more sustainable solution for marking food and beverage products. In addition, inkjet printing systems offer high-speed, flexible solutions for printing variable information on various substrates, while RFID tagging enhances traceability and inventory management. These technologies are increasingly being adopted by major companies such as Nestlé and Coca-Cola, who require reliable and eco-friendly marking systems to stay competitive in the market. As consumers demand more sustainable and efficient packaging solutions, these technological advancements create significant growth potential, driving innovation and investment in the food and beverages coding and marking equipment sector.

Restraints/Challenges

- High Initial Investment Costs

High initial investment costs are a significant market challenge for the food and beverage coding and marking equipment sector, particularly for smaller companies that may struggle with upfront expenses. High-quality systems, such as thermal inkjet printers or laser coders, often require substantial capital investment to purchase and install. For instance, a thermal inkjet printer might cost several thousand dollars, and a laser coding system can go even higher, especially with advanced features such as high-resolution capabilities or integration with automated production lines. Beyond the initial purchase, ongoing operational costs for consumables such as inks, ribbons, and solvents—coupled with maintenance costs to ensure optimal performance—further strain smaller businesses with limited budgets. For instance, thermal inkjet printers require regular ink refills, which can add hundreds or thousands of dollars annually to the total cost. These financial barriers may limit the ability of small enterprises to implement cutting-edge technology, forcing them to rely on older, less efficient systems. This market challenge can hinder small companies from scaling up, staying competitive, or adhering to increasingly stringent regulatory requirements, thus creating a competitive disadvantage in the industry.

- Counterfeit and Fraud Prevention

Counterfeit and fraud prevention has become a critical market challenge in the food and beverage coding and marking equipment industry, as the growing threat of counterfeit products puts both consumer safety and brand integrity at risk. To combat this, there is an increasing demand for more sophisticated coding and marking systems that include advanced anti-counterfeiting features such as QR codes, holograms, or hidden security markers that are difficult to replicate. For instance, brands such as Coca-Cola and Nestlé have adopted unique traceability systems, using specialized coding technologies to ensure product authenticity and safeguard against fraudulent copies entering the market. However, the integration of these advanced technologies comes at a high cost, both in terms of equipment and operational expenses. Manufacturers must invest in secure, high-tech systems that can apply complex codes quickly without compromising production speed or accuracy. These enhanced solutions raise overall production costs, and the need to constantly upgrade or improve security features adds financial pressure on companies. For smaller businesses or companies with tight margins, these additional costs can be a barrier, making it difficult to stay competitive while maintaining the required level of security. This growing demand for high-security systems directly ties into the broader market challenge of rising costs for advanced coding technologies.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an analyst brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions.

Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Food and Beverages Coding and Marking Equipment Market Scope

The market is segmented on the basis of technology, packaging code, and application. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Technology

- Continuous Inkjet

- Print and Apply Labeling Machine

- Piezoelectric Inkjet

- Thermal transfer Overprinting

- Laser Technology

- Valve inkjet

- Thermal Inkjet

Application

- Food Industry

- Beverage Industry

Packaging code

- Primary Packaging Code

- Secondary Packaging Code

Food and Beverages Coding and Marking Equipment Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, technology, packaging code, and application as referenced above.

The countries covered in the market report are U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia and New Zealand, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, United Arab Emirate, Saudi Arabia, Egypt, Israel, South Africa, Rest of Middle East and Africa

Europe dominates the food and beverages coding and marking equipment market, driven by the implementation of stringent regulations requiring accurate coding, labeling, and marking for food and beverage products. These regulations aim to enhance product traceability, ensure consumer safety, and comply with industry standards. The region’s focus on maintaining transparency and quality control has further fueled the adoption of advanced coding and marking technologies. This regulatory environment positions Europe as a key market for innovative solutions in the food and beverage sector.

Asia-Pacific is projected to experience the fastest growth rate in the food and beverages marking equipment market, driven by increasing demand across emerging economies. Factors such as rapid urbanization, expanding middle-class populations, and a surge in packaged food and beverage consumption contribute significantly to this growth. In addition, stricter regulatory frameworks for product labeling and traceability are pushing manufacturers to adopt advanced marking technologies. This robust demand positions Asia-Pacific as a critical market for the industry's expansion.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Food and Beverages Coding and Marking Equipment Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Food and Beverages Coding and Marking Equipment Market Leaders Operating in the Market Are:

- Brother Industries, Ltd. (Japan)

- Danaher (U.S.)

- Dover Corporation (U.S.)

- Hitachi, Ltd. (Japan)

- ITW Diagraph GmbH (Germany)

- ID Technology, LLC. (U.S.)

- SATO Holdings Corporation (Japan)

- Durable Technologies (U.S.)

- Jantech Marking Equipment (Canada)

- Universal Labeling Systems (U.S.)

- Superior Case Coding (U.S.)

Latest Developments in Food and Beverages Coding and Marking Equipment Market

- In September 2024, Domino Printing Sciences launched the K300, a compact monochrome inkjet printer, during Labelexpo Americas. Designed for high-speed variable data printing, it seamlessly integrates into existing production lines, enabling label customization with QR codes and batch details. The K300 will be showcased alongside Lake Image Systems’ code verification solution, catering to the growing demand for 2D codes in packaging

- In April 2024, Markem-Imaje introduced the MW2160P, a highly versatile opaque white ink for extruded materials such as PVC and rubber, compatible with the 9750+ CIJ printers. Offering excellent adhesion, durability, and resistance to bending and water, it is ideal for industrial applications. Dubbed the "Swiss Army Knife" of CIJ inks, it ensures superior print quality across diverse substrates

- In March 2023, Domino Printing Sciences unveiled the Ax350i, an advanced continuous inkjet (CIJ) printer optimized for high-speed manufacturing environments. This model features improved ink efficiency and reliable performance, making it suitable for industries such as food, beverage, and pharmaceuticals

- In February 2022, Hitachi launched the UX2, an upgraded version of its renowned CIJ printer. It features an enhanced user interface, expanded connectivity options, and environmentally friendly ink solutions. Its versatile design serves various industries, including food, cosmetics, and electronics

- In September 2021, Domino collaborated with Procter & Gamble (P&G), a U.S.-based multinational consumer goods company, to develop tactile-coded bottle designs for visually impaired individuals. This innovation allows users to easily identify personal care products by touch

- In July 2021, Koenig & Bauer Coding introduced the ICON 3, an entry-level marking laser. This cost-effective solution leverages laser technology to provide solvent-free, clean marking while eliminating the need for consumables, significantly reducing operating costs

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Food And Beverages Coding And Marking Equipment Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Food And Beverages Coding And Marking Equipment Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Food And Beverages Coding And Marking Equipment Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.