Global Industrial Machine Vision Market

Market Size in USD Billion

CAGR :

%

USD

11.29 Billion

USD

19.70 Billion

2024

2032

USD

11.29 Billion

USD

19.70 Billion

2024

2032

| 2025 –2032 | |

| USD 11.29 Billion | |

| USD 19.70 Billion | |

|

|

|

|

Industrial Machine Vision Market Size

- The global industrial machine vision market size was valued at USD 11.29 billion in 2024 and is expected to reach USD 19.70 billion by 2032, at a CAGR of 7.21% during the forecast period

- This growth is driven by factors such as the increasing adoption of automation across manufacturing industries, rising demand for quality inspection and defect detection, and technological advancements in machine learning and image processing

Industrial Machine Vision Market Analysis

- Industrial machine vision systems are critical technologies used in manufacturing environments for automated inspection, quality assurance, and robotic guidance, delivering precision and efficiency across various industries including automotive, electronics, pharmaceuticals, and food & beverage

- The demand for these systems is significantly driven by the rising need for automation, accuracy in defect detection, and advancements in AI-integrated imaging technologies

- Asia Pacific is expected to dominate the industrial machine vision market in 2025 with a market share of approximately 47.8% ,a strong presence of electronics and automotive manufacturers, and growing adoption of smart factory initiatives. Countries like China, Japan, India, and South Korea are major contributors

- Asia-Pacific is also projected to be one of the fastest-growing regions during the forecast period, fueled by government support for manufacturing automation, increasing labor costs, and rising investments in digital transformation across industrial sectors

- The automotive manufacturing segment is expected to dominate the industrial machine vision market with the largest share of 48.75% in 2025 due to its high demand for automation and quality control in production lines. As a critical component in modern automotive manufacturing, machine vision systems enhance precision in processes such as inspection, assembly, and part identification

Report Scope and Industrial Machine Vision Market Segmentation

|

Attributes |

Industrial Machine Vision Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

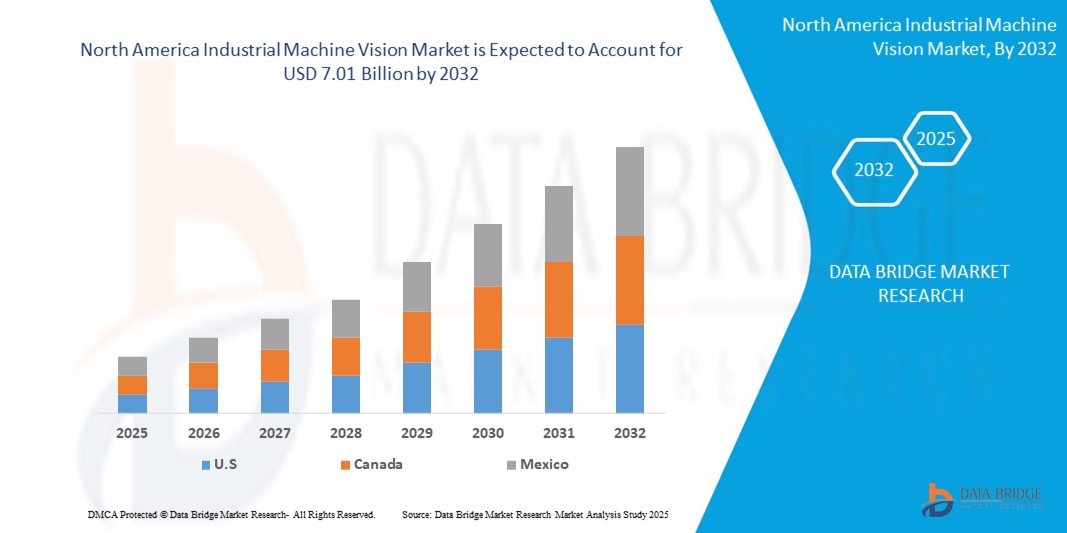

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Industrial Machine Vision Market Trends

“Integration of AI, Deep Learning and 3D Vision Systems in Industrial Automation”

- One prominent trend in the industrial machine vision market is the increasing integration of artificial intelligence (AI), deep learning algorithms, and 3D vision systems for real-time decision-making and precision automation in manufacturing processes

- These innovations significantly enhance machine vision performance by enabling systems to detect complex patterns, classify defects, and adapt to variable conditions that traditional rule-based systems may not handle effectively

- For instance, modern 3D vision technologies offer depth perception and volumetric analysis, enabling applications such as bin picking, robot guidance, and quality control of irregularly shaped objects with high accuracy

- These advancements are transforming the industrial automation landscape, reducing error rates, boosting production efficiency, and driving demand for smart vision systems in automotive, electronics, packaging, and logistics industries

Industrial Machine Vision Market Dynamics

Driver

“Growing Demand for Quality Inspection and Automation in Manufacturing”

- The rising emphasis on quality assurance, process optimization, and defect detection in modern manufacturing is significantly contributing to the increased demand for industrial machine vision systems

- As industries embrace automation, machine vision plays a critical role in enabling real-time inspection, precision measurement, and robotic guidance, ensuring consistency and reliability in production lines

- Industries such as automotive, electronics, pharmaceuticals, and food & beverage rely heavily on machine vision systems to meet stringent regulatory and quality standards

For instance,

- In October 2023, Cognex Corporation reported a surge in demand for vision systems in electronics and logistics sectors, driven by increasing consumer expectations for product reliability and fast order fulfillment

- As a result of this growing focus on automated quality control, there is a substantial increase in the adoption of industrial machine vision systems to enhance productivity, minimize errors, and reduce labor costs across global manufacturing ecosystems

Opportunity

“Advancing Industrial Machine Vision with Artificial Intelligence Integration”

- AI-powered industrial machine vision systems can enhance object detection, automation, and quality control in manufacturing processes, improving operational efficiency and precision

- AI algorithms can analyze real-time images to identify defects, monitor production lines, and track product quality, providing immediate feedback for manufacturers to address issues before they escalate

- AI-powered vision systems can also assist in predictive maintenance by analyzing equipment performance and identifying potential failures, reducing downtime and maintenance costs

For instance,

- In December 2024, a partnership between Siemens and an AI software company led to the integration of AI-powered industrial machine vision in Siemens’ manufacturing plants. The AI system provides real-time quality control by identifying defects on products and automatically adjusting production parameters to maintain consistent quality. This integration has resulted in a 15% increase in production efficiency and a 20% reduction in product defects

- The integration of AI in industrial machine vision systems can also lead to better resource utilization, faster production cycles, and reduced waste. By leveraging AI’s ability to analyze vast amounts of visual data, manufacturers can optimize production lines, reduce human error, and ensure better consistency in product quality

Restraint/Challenge

“High Equipment Costs Hindering Market Penetration”

- The high cost of industrial machine vision systems presents a significant barrier to their widespread adoption, particularly for small and medium-sized enterprises (SMEs) with limited budgets

- These advanced vision systems, which are essential for automating quality control and enhancing manufacturing processes, can range from tens of thousands to several hundred thousand dollars depending on the complexity and capabilities of the system

- The significant financial investment required for these systems can deter smaller companies from upgrading their equipment, leading to a reliance on manual inspection or outdated machine vision solutions

For instance,

- In October 2024, a report from the International Society of Automation (ISA) highlighted the challenge that small manufacturing companies face when considering the adoption of AI-powered industrial machine vision systems. The report emphasized that while large corporations can afford the high initial investment, many SMEs struggle with the cost of integrating AI-powered systems into their operations, slowing down the adoption rate across the sector

- As a result, this financial obstacle can lead to slower market growth and prevent broader adoption of advanced machine vision systems, particularly in cost-sensitive industries such as small-scale manufacturing or businesses in emerging markets

Industrial Machine Vision Market Scope

The market is segmented on the basis of component, product, type, deployment, applications, and end user.

|

Segmentation |

Sub-Segmentation |

|

By Component |

|

|

By Product |

|

|

By Type |

|

|

By Deployment |

|

|

By Applications |

|

|

By End-User |

|

In 2025, the automotive manufacturing segment is projected to dominate the market with the largest share in the end user segment

The automotive manufacturing segment is expected to dominate the industrial machine vision market with the largest share of 48.75% in 2025 due to its high demand for automation and quality control in production lines. As a critical component in modern automotive manufacturing, machine vision systems enhance precision in processes such as inspection, assembly, and part identification. The growing demand for vehicle safety features, coupled with advancements in machine vision technologies, drives the adoption of these systems in automotive production. Increased automation in automotive factories and the growing complexity of vehicle designs further contribute to the dominance of this segment in the industrial machine vision market.

The pattern recognition is expected to account for the largest share during the forecast period in application segments

In 2025, the pattern recognition segment is expected to dominate the industrial machine vision market with the largest market share of 50.62% due to its ability to enhance quality control, inspection, and automation in manufacturing processes. Pattern recognition systems are critical for identifying and classifying objects, defects, and anomalies in real-time, enabling manufacturers to maintain consistent product quality and optimize production efficiency. As industries demand higher levels of precision and speed, pattern recognition systems, especially in combination with AI and deep learning technologies, are driving market growth. The increasing complexity of products and the need for high-quality standards in sectors such as automotive, electronics, and pharmaceuticals further contribute to the dominance of pattern recognition-based machine vision systems in the market.

Industrial Machine Vision Market Regional Analysis

“Asia-Pacific Holds the Largest Share in the Industrial Machine Vision Market”

- Asia Pacific is expected to dominate the industrial machine vision market in 2025 with a market share of approximately 47.8%

- The region is driven by rapid industrialization, growing automation adoption, and demand for precision in manufacturing

- China holds approximately 45% of the industrial machine vision market in Asia-Pacific, supported by its large-scale manufacturing sector and high adoption of AI-powered machine vision systems

- The market benefits from substantial investments in smart manufacturing and government support for automation in industries like automotive, electronics, and semiconductors

- The increasing demand for defect detection, quality control, and production optimization in various industries further fuels market growth

- AI and robotics adoption in manufacturing plants is accelerating in Asia Pacific, contributing to the region's market dominance

“Asia-Pacific is Projected to Register the Highest CAGR in the Industrial Machine Vision Market”

- The Asia-Pacific region is expected to witness the highest growth rate in the industrial machine vision market, driven by rapid industrialization, rising automation demand, and increasing adoption of advanced machine vision systems

- Countries such as China, India, and Japan are emerging as key markets due to their strong manufacturing bases, high demand for precision in production, and significant investments in automation technologies

- China, with its large-scale manufacturing sector and focus on automation, continues to lead the market. The country’s growing adoption of AI-powered machine vision systems for quality control and production optimization is expected to contribute to its dominant share of 42.3% in 2025

- India and Japan, with their strong manufacturing industries and increasing emphasis on smart factory solutions, are also witnessing significant growth in the adoption of industrial machine vision. Japan, known for its advanced robotics and automation technologies, is projected to hold a substantial share in the market, while India is expected to see rapid growth due to increasing demand for automation in various industries, including automotive, electronics, and pharmaceuticals

- The market in Asia-Pacific benefits from increased government initiatives supporting automation and the growing presence of global industrial machine vision players. As a result, the region is set to experience the highest CAGR in the global industrial machine vision market, further contributing to its dominance

Industrial Machine Vision Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- KEYENCE CORPORATION (Japan)

- OMRON Corporation (Japan)

- Sony Semiconductor Solutions Corporation (Japan)

- Cognex Corporation (U.S.)

- SICK AG (U.S.)

- Teledyne FLIR LLC (U.S.)

- NATIONAL INSTRUMENTS CORP. (U.S.)

- BASLER AG (Germany)

- ISRA VISION (Germany)

- Intel Corporation (U.S.)

- Texas Instruments Incorporated (U.S.)

- Cadence Design Systems, Inc. (U.S.)

- Automatic Identification Systems (UK) Limited (U.K.)

- MV ASIA Infomatrix Pte Ltd (Singapore)

- Ceva Inc. (U.S.)

- Soda Vision (Singapore),

- The Imaging Source, LLC (U.S.)

- Kalypso: A Rockwell Automation Business (U.S.)

- Qualitas Technologies (India)

- Integro Technologies Corp. (U.S.)

Latest Developments in Global Industrial Machine Vision Market

- In July 2024, OMRON Corporation introduced a software update for its FH Vision System and FHV7 Smart Camera, integrating Digimarc decoding technology to enhance digital product identification. This update enables high-speed packaging verification using digital watermarks, achieving over 2,000 parts per minute. The integration improves detection accuracy, processing speed, camera flexibility, redundancy, and inspection capabilities, reinforcing OMRON’s commitment to innovation in industrial automation. Designed for consumer goods manufacturers, this advancement enhances quality assurance and efficiency in production

- In June 2024, SICK AG introduced the Inspector83x 2D vision sensor, a standalone solution for automated inspection tasks such as defect detection, sorting, and OCR/OCV. This advanced system processes up to 15 inspections per second, utilizing a combination of AI-enabled and rules-based algorithms. With AI training requiring only a few images, users can configure inspections directly on the device. The sensor features up to 5 MPixel resolution, built-in lighting, a quad-core CPU, dual-port Ethernet, C-mount lens threading, and external illumination support. It comes pre-installed with SICK Nova, the company’s configurable machine vision software

- In April 2024, Cognex Corporation introduced the In-Sight L38 3D Vision System, the world’s first AI-powered 3D vision system designed for fast deployment and reliable inspections in manufacturing automation. This system integrates AI, 2D, and 3D vision technologies, generating unique projection images that simplify training and uncover features invisible to traditional 2D imaging. With embedded AI tools, it enhances inspection accuracy, measurement precision, and operational efficiency, setting new standards in industrial automation

- In February 2024, OMRON Automation launched the TM S Series Collaborative Robots in India, designed to enhance factory efficiency in shared workspaces. These robots feature faster joints and expanded safety measures, enabling seamless collaboration between humans and machines. With advanced motion control, they improve precision, flexibility, and productivity across various industries, including logistics, consumer goods, and digital hardware. Their compact design allows easy integration into existing workflows, making automation more accessible

- In March 2023, KEYENCE CORPORATION launched the VS Series Vision System, designed to enhance industrial automation with advanced image processing, high-speed inspection, and user-friendly operation. This system improves quality control and efficiency in manufacturing environments, offering AI-powered and rule-based vision tools for precise inspections. Featuring optical zoom functionality, it allows flexible adjustments for various applications. The VS Series reflects Keyence’s commitment to cutting-edge vision technology for diverse industrial needs

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Industrial Machine Vision Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Industrial Machine Vision Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Industrial Machine Vision Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.