Global Industrial X Ray Market

Market Size in USD Billion

CAGR :

%

USD

3.37 Billion

USD

5.84 Billion

2024

2032

USD

3.37 Billion

USD

5.84 Billion

2024

2032

| 2025 –2032 | |

| USD 3.37 Billion | |

| USD 5.84 Billion | |

|

|

|

|

Industrial X-Ray Market Size

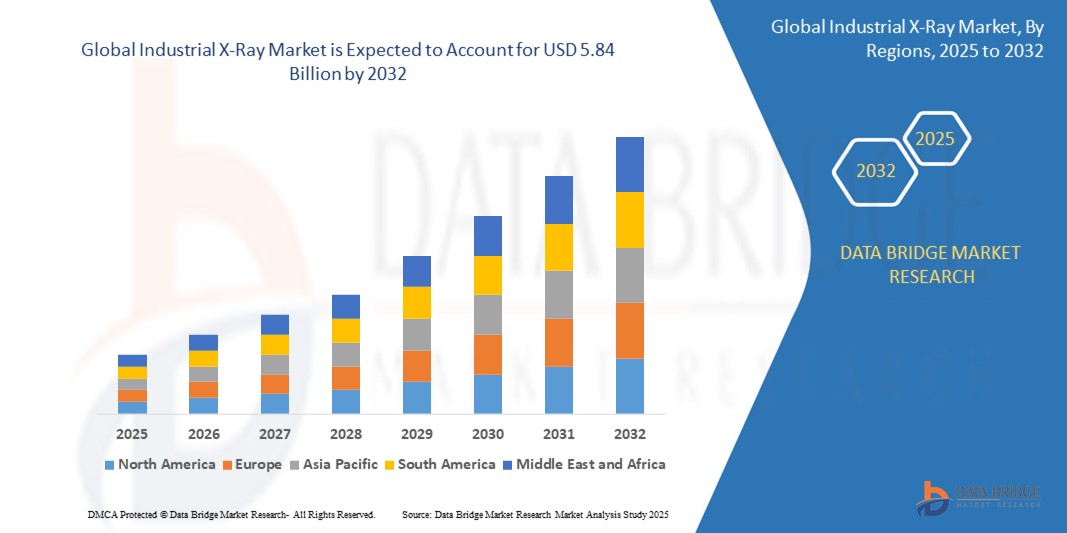

- The global Industrial X-Ray market was valued at USD 3.37 billion in 2024 and is expected to reach USD 5.84 billion by 2032

- During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 7.10%, primarily driven by the increasing demand for non-destructive testing and quality control in various industries

- This growth is driven by factors such as the advancements in X-ray technology, rising adoption of automated inspection systems, and the increasing need for safety and precision in manufacturing processes

Industrial X-Ray Market Analysis

- The global industrial x-ray market is experiencing significant growth due to the increasing demand for non-destructive testing and quality assurance across various industries such as automotive, aerospace, and manufacturing. These industries rely heavily on x-ray technology to ensure product safety, compliance with regulatory standards, and the overall quality of materials used

- The market is shifting towards more advanced and automated x-ray inspection systems. These systems not only improve the accuracy of inspections but also enhance operational efficiency, making them a popular choice in sectors where precision is critical

- Technological advancements in industrial x-ray equipment, such as the integration of artificial intelligence and machine learning algorithms, are enhancing the capabilities of x-ray systems. This includes improved image processing, better defect detection, and faster analysis, leading to better overall performance

- The demand for industrial x-ray solutions is also being influenced by the increasing trend of automation in manufacturing. Automated x-ray systems are becoming essential in ensuring the continuous inspection of products at high production rates, which is especially important for large-scale industries

- For Instance, in the automotive sector, advanced industrial x-ray systems are used to inspect critical components such as engine parts, ensuring that every part meets the required safety standards before being used in vehicle assembly lines. This contributes to maintaining the high standards expected in modern automotive manufacturing

Report Scope and Industrial X-Ray Market Segmentation

|

Attributes |

Industrial X-Ray Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Industrial X-Ray Market Trends

“Integration of Artificial Intelligence and Machine Learning”

- The incorporation of artificial intelligence and machine learning into industrial x-ray systems is revolutionizing non-destructive testing and quality control processes across various industries

- AI algorithms enhance the capability of x-ray systems to automatically identify and classify defects, reducing reliance on human interpretation and increasing inspection efficiency

- Machine learning models analyze data from x-ray inspections to predict equipment failures before they occur, allowing for proactive maintenance strategies that minimize downtime

- AI-driven analysis of x-ray images facilitates continuous improvement in manufacturing processes by identifying patterns and correlations that inform optimization efforts

- Advanced image processing techniques powered by AI provide clearer and more detailed images, leading to more accurate inspections and better decision-making

- The integration of AI enables real-time processing of x-ray images, allowing for immediate feedback and rapid adjustments during production, which is crucial for maintaining high-quality standards

- For instance, DeepTek.ai's CXR Analyzer, an AI-powered chest x-ray solution, received clearance from the U.S. Food and Drug Administration in October 2023, demonstrating the effectiveness of AI in enhancing medical imaging

Industrial X-Ray Market Dynamics

Driver

“Increasing Demand for Non-Destructive Testing (NDT)”

- The global industrial x-ray market is experiencing significant growth due to the rising demand for non-destructive testing (NDT) across various industries such as automotive, aerospace, and manufacturing

- NDT methods, including x-ray inspections, allow for the assessment of material integrity without causing damage, ensuring product quality and safety

- For instance, in the automotive sector, x-ray systems are utilized to inspect engine components for internal defects, ensuring optimal performance and safety standards

Opportunity

“Integration of Artificial Intelligence in Industrial Applications”

- The integration of artificial intelligence (AI) in industrial x-ray systems presents significant growth opportunities

- AI enhances image analysis, defect detection, and process optimization, leading to improved efficiency and accuracy in inspections

- Companies investing in AI-driven x-ray technologies can gain a competitive edge by offering advanced solutions that meet the evolving demands of industries

Restraint/Challenge

“Regulatory Compliance and Safety Concerns”

- Operating industrial x-ray systems involves navigating complex regulatory landscapes and addressing safety concerns related to radiation exposure

- Ensuring compliance with stringent safety standards requires continuous investment in training, equipment maintenance, and adherence to evolving regulations

- For Instance, the need for skilled operators to interpret x-ray images and manage radiation safety protocols can limit the widespread adoption of these systems

Industrial X-Ray Market Scope

The market is segmented on the basis imaging technique, application, modality, range, source, distribution channel, and product type

|

Segmentation |

Sub-Segmentation |

|

By Imaging Technique |

|

|

By Application |

|

|

By Modality |

|

|

By Range

|

|

|

By Source |

|

|

By Distribution Channel

|

|

|

By Product Type |

|

Industrial X-Ray Market Regional Analysis

“North America is the Dominant Region in the Industrial X-Ray Market”

- North America dominates the global industrial x-ray market due to the region’s advanced technological infrastructure and high adoption rate of industrial x-ray systems

- The U.S. is a major contributor, with strong demand across aerospace, automotive, and defense sectors where non-destructive testing (NDT) is critical

- Key market players such as General Electric and Carestream Health have their presence in the region, further promoting the growth of industrial x-ray systems

- Additionally, the high awareness of quality control standards and stringent regulatory policies favor the market growth in North America

- The U.S. government's focus on infrastructure development and manufacturing also fuels demand for advanced industrial x-ray equipment

“Asia-Pacific is Projected to Register the Highest Growth Rate”

- Asia-Pacific is the fastest-growing region in the global industrial x-ray market, driven by rapid industrialization and technological advancements

- Countries such as China, India, and Japan are key contributors, with high demand for industrial x-ray systems in automotive, aerospace, and manufacturing industries

- China’s growing manufacturing base and government initiatives for industrial automation significantly increase the demand for non-destructive testing and industrial x-ray technologies

- India, with its booming automotive and manufacturing sectors, is also a prominent market, while Japan leads in adopting cutting-edge technologies for quality control

- As Asia-Pacific becomes a major hub for semiconductor manufacturing, demand for x-ray inspection and testing systems is expected to continue its rapid expansion

Industrial X-Ray Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

The Major Market Leaders Operating in the Market Are:

- Teledyne Digital Imaging Inc. (Canada)

- ZEISS Group (Germany)

- FUJIFILM Corporation (Japan)

- GENERAL ELECTRIC (U.S.)

- Applus(Spain)

- Comet Group (Switzerland)

- Minebea Intec GmbH (Germany)

- Hamamatsu Photonics K.K. (Japan)

- Varex Imaging (U.S.)

- Hitachi High-Tech Analytical Science (U.K.)

- Carestream Health (U.S.)

- Nordson Corporation (U.S.)

- Rigaku Corporation (Japan)

- Shimadzu Corporation (Japan)

- Eastman Kodak Company (U.S.)

- Canon Electron Tubes & Devices Co., Ltd. (Japan)

- North Star Imaging Inc. (U.S.)

- Lohmann X-Ray GmbH (Germany)

- VJ X-Ray (U.S.)

- Ixar (U.S.)

Latest Developments in Global Industrial X-Ray Market

- In April 2024, Shimadzu acquired California X-ray Imaging Services, Inc. to enhance its direct sales of medical systems on the West Coast of the U.S.

- In March 2022, Konica Minolta, Inc. announced the launch of the AeroDR TX m01, a mobile X-ray system with wireless dynamic digital radiography capabilities, in Japan

- In November 2021, GE Healthcare received FDA clearance for its artificial intelligence (AI) algorithm to help healthcare professionals evaluate Endotracheal Tube (ETT) placements. The AI algorithms are installed in a mobile X-ray device for automated measurements, case prioritization, and quality control

- In March 2021, Philips announced a partnership with Lunit, a leading medical AI startup. Through this collaboration, Lunit’s INSIGHT CXR chest detection suite will be incorporated into Philips diagnostic X-ray suite to improve patient outcomes, improve the experience of patients and staff, and lower the cost of care

- In May 2021, the DRX-Compass X-ray System from Carestream Health was upgraded, giving healthcare facilities a new floor-mount option. This handy option provides cutting-edge technology and cost-effective medical imaging solutions to locations that cannot support an overhead tube crane

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.