Global Particulate Free Surgical Glove Coating Powders Market

Market Size in USD Million

CAGR :

%

USD

90.00 Million

USD

246.64 Million

2024

2032

USD

90.00 Million

USD

246.64 Million

2024

2032

| 2025 –2032 | |

| USD 90.00 Million | |

| USD 246.64 Million | |

|

|

|

|

Particulate-Free Surgical Glove Coating Powders Market Size

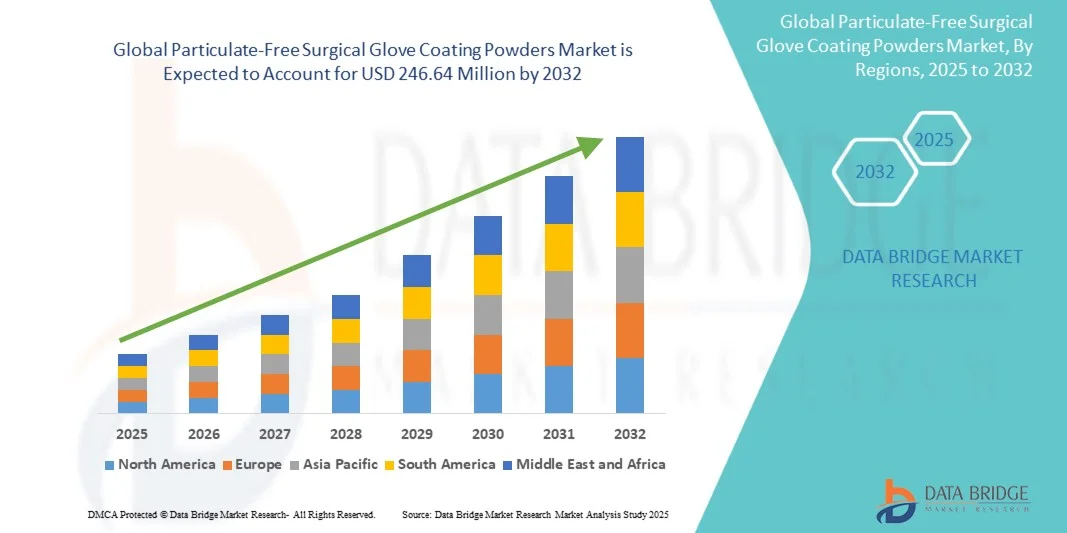

- The global particulate-free surgical glove coating powders market size was valued at USD 90.00 million in 2024 and is expected to reach USD 246.64 million by 2032, at a CAGR of 13.43% during the forecast period

- The market growth is largely fueled by the increasing transition from traditional powdered gloves to particulate-free alternatives, driven by stringent regulatory restrictions and rising awareness regarding surgical site contamination and patient safety

- Furthermore, growing demand for sterile, biocompatible, and user-friendly glove coatings in healthcare facilities is positioning particulate-free solutions as the preferred option for surgical glove manufacturers. These converging factors are accelerating adoption across the medical device industry, thereby significantly boosting the market’s growth

Particulate-Free Surgical Glove Coating Powders Market Analysis

- Particulate-free surgical glove coating powders, designed to enhance donning while eliminating risks associated with conventional powdered gloves, are becoming increasingly vital in modern surgical settings due to their role in reducing contamination, supporting sterility, and ensuring compliance with international safety standards

- The escalating demand for particulate-free coating powders is primarily fueled by regulatory bans on powdered medical gloves, rising awareness of surgical site infections, and the healthcare industry’s growing preference for safe, biocompatible, and user-friendly coating alternatives

- North America dominated the particulate-free surgical glove coating powders market with the largest revenue share of 31.7% in 2024, characterized by strict FDA regulations, high adoption of powder-free solutions, and a strong presence of leading glove manufacturers, with the U.S. witnessing significant growth in sterile and specialty surgical procedures that demand advanced glove coatings

- Asia-Pacific is expected to be the fastest-growing region in the global particulate-free surgical glove coating powders market during the forecast period due to the region’s role as a global hub for glove manufacturing, particularly in Malaysia, Thailand, and China, coupled with rising healthcare infrastructure investments and export-driven demand

- Latex segment dominated the particulate-free surgical glove coating powders market with the largest share of 42.5% in 2024, driven by its widespread use in surgical environments, cost-effectiveness, and compatibility with advanced coating technologies

Report Scope and Particulate-Free Surgical Glove Coating Powders Market Segmentation

|

Attributes |

Particulate-Free Surgical Glove Coating Powders Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Particulate-Free Surgical Glove Coating Powders Market Trends

“Rising Adoption of Sterile and Specialty Coatings”

- A significant and accelerating trend in the global particulate-free surgical glove coating powders market is the increasing adoption of sterile, low-particulate coatings for specialty surgical gloves, enhancing safety and compliance in operating rooms

- For instance, advanced polymer coating powders are now being used in ophthalmic and cardiovascular gloves to reduce contamination risks and improve glove donning performance

- Specialty coatings are engineered to minimize allergic reactions and maintain biocompatibility, catering to sensitive surgical environments and reducing postoperative complications

- The trend towards integrating particulate-free powders with innovative manufacturing processes enables higher consistency in coating thickness, improving glove quality and reliability

- This move towards safer, high-performance glove coatings is fundamentally reshaping healthcare expectations for infection control. Consequently, companies such as Top Glove Chemicals are developing next-generation powders with enhanced sterility and donning efficiency

- The demand for advanced particulate-free coatings is growing rapidly across hospitals, clinics, and glove manufacturing facilities, as manufacturers prioritize patient safety and regulatory compliance

Particulate-Free Surgical Glove Coating Powders Market Dynamics

Driver

“Regulatory Pressure and Patient Safety Concerns”

- The increasing regulatory restrictions on powdered gloves and rising awareness of surgical site infections are major drivers for the adoption of particulate-free coating powders

- For instance, in 2024, FDA and EU medical device updates reinforced the need for powder-free glove solutions, prompting manufacturers to shift production accordingly

- Healthcare facilities are increasingly implementing stringent protocols to reduce contamination, driving demand for low-particulate and biocompatible coatings

- The preference for gloves that enhance donning efficiency while maintaining sterility is making particulate-free coatings integral to modern surgical procedures

- Glove manufacturers are focusing on producing compliant, high-quality coated gloves to meet these regulations and cater to hospitals’ safety standards

- Rising investments in surgical infrastructure, especially in emerging markets, are driving demand for sterile gloves with particulate-free coatings

- Increasing awareness among surgeons and healthcare professionals about the health risks of powder-based gloves is pushing adoption of advanced coatings in routine procedures

Restraint/Challenge

“High Production Costs and Technical Compliance Hurdles”

- The relatively high cost of developing sterile, particulate-free coating powders compared to conventional powders poses a significant challenge for broader adoption

- For instance, specialty polymer coatings require advanced manufacturing processes and strict quality controls, increasing operational expenses for suppliers

- Achieving compliance with stringent medical standards such as ISO 13485 and ASTM for sterility and biocompatibility adds complexity and cost to production

- Smaller glove manufacturers may face difficulties in scaling up particulate-free production due to technical and financial limitations

- Overcoming these challenges through cost optimization, process innovation, and targeted R&D will be vital for broader adoption and sustained market growth

- Limited availability of raw materials for advanced coating powders can cause supply constraints, affecting timely production and delivery to glove manufacturers

- Inconsistent adoption across regions due to differences in regulatory enforcement and budget constraints may slow global market penetration for particulate-free coatings

Particulate-Free Surgical Glove Coating Powders Market Scope

The market is segmented on the basis of product type, coating, glove base material, application, and end user.

- By Product Type

On the basis of product type, the particulate-free surgical glove coating powders market is segmented into polymer coating powders, cornstarch derivatives, and other specialty lubricant powders. The polymer coating powders segment dominated the market with the largest revenue share in 2024, driven by its superior biocompatibility, consistent low particulate release, and enhanced glove donning performance. Manufacturers prefer polymer powders for sterile and specialty surgical gloves as they comply with FDA and ISO standards. These coatings reduce allergic reactions and minimize contamination risks, making them suitable for sensitive surgical procedures. They provide uniform coverage across latex, nitrile, and polyisoprene gloves, improving quality. Demand is particularly strong in North America and Europe, where powder-free regulations are stringent. Advanced polymer powders also allow customization for specialty surgical applications, reinforcing their dominance.

The cornstarch derivatives segment is anticipated to witness the fastest growth rate from 2025 to 2032, fueled by innovations in low-particulate engineered powders. These coatings offer an eco-friendly alternative while maintaining glove donning efficiency and sterility compliance. Rising demand in emerging markets, such as Asia-Pacific, is driven by cost-effectiveness and increasing awareness about infection control. Manufacturers are optimizing cornstarch derivatives to meet global regulatory standards while minimizing residual particles. Adoption is growing in general surgical and diagnostic lab gloves. Sustainable and biodegradable formulations further accelerate market growth in this segment.

- By Coating Type

On the basis of coating type, the particulate-free surgical glove coating powders market is segmented into polymer powder coating, chlorination, and polymer liquid coatings. Polymer powder coating dominated the market with the largest share in 2024, owing to its proven efficacy in reducing particulate contamination and maintaining glove surface uniformity. It is compatible with a wide range of glove materials and is preferred for sterile and high-risk surgical applications. Regulatory compliance with ISO and ASTM standards strengthens adoption among manufacturers. Polymer powder coatings improve grip, donning ease, and hypoallergenic performance. High demand is observed in North America and Europe due to hospital regulations and infection control priorities. Continuous technological improvements ensure consistency and quality, maintaining market leadership.

The chlorination segment is expected to witness the fastest growth rate from 2025 to 2032, driven by its chemical-based powder-free approach that eliminates physical powders. This method is gaining adoption in sensitive surgical and laboratory gloves. Chlorination reduces allergic reactions compared to traditional powders and meets stringent regulatory requirements. Manufacturers prefer chlorination for specialty gloves requiring ultra-low particulate levels. Emerging economies are gradually adopting chlorination processes for export compliance. Hybrid approaches combining chlorination and polymer coatings are accelerating growth in this segment.

- By Glove Base Material

On the basis of glove material, the particulate-free surgical glove coating powders market is segmented into latex, nitrile, polyisoprene, neoprene, and others. The latex glove segment dominated the market with the largest share of 42.5% in 2024, driven by long-standing use in surgical environments and cost-effectiveness. Polymer and specialty powders adhere well to latex, providing superior donning performance and sterility. Hospitals in North America and Europe widely use latex gloves, where powder-free adoption is high. Elasticity and tactile sensitivity make latex gloves ideal for both general and specialty surgical procedures. Compliance with regulatory standards and familiarity among healthcare professionals reinforce dominance. Despite the rise of nitrile and polyisoprene, latex remains the preferred choice in high-volume surgical applications.

The nitrile segment is expected to witness the fastest growth from 2025 to 2032 due to its hypoallergenic properties, durability, and increasing adoption in surgical and clinical settings. Nitrile is preferred in Asia-Pacific and emerging markets where latex allergies are a concern. Its compatibility with polymer and cornstarch-based coatings ensures effective particulate-free performance. Manufacturers are expanding nitrile production to meet growing hospital demand. Powder-free trends and infection control regulations further accelerate adoption. Awareness of latex allergies among healthcare professionals is a key growth driver for nitrile gloves.

- By Application

On the basis of application, the particulate-free surgical glove coating powders market is segmented into general surgery, specialty surgery, clinical & diagnostic labs, and pharmaceutical. The general surgery segment dominated the market in 2024 due to high procedural volumes and widespread glove usage. Hospitals prioritize sterile, powder-free gloves to maintain hygiene and prevent cross-contamination. Polymer and cornstarch-based coatings are widely used in general surgery gloves. North America and Europe drive demand due to strict regulatory frameworks. Consistent surgical volumes and replacement of traditional powdered gloves support dominance. General surgery remains the backbone segment for particulate-free coating powders.

The specialty surgery segment is anticipated to witness the fastest growth rate from 2025 to 2032. Specialty procedures, including ophthalmic, cardiovascular, and neurosurgery, demand ultra-low particulate gloves with high sterility standards. Advanced polymer and liquid coatings are increasingly used in specialty surgical gloves. Hospitals and surgical centers are investing in high-performance gloves for precision procedures. Growth is fueled by awareness of infection control and patient safety. Emerging markets are gradually adopting specialty gloves as healthcare infrastructure improves.

- By End User

On the basis of end user, the particulate-free surgical glove coating powders market is segmented into glove manufacturers, contract coaters, oems & private labelers, and healthcare systems. Glove manufacturers dominated the market with the largest share in 2024, as they are the primary buyers of coating powders for producing powder-free gloves. Polymer and cornstarch coatings are widely sourced to meet regulatory requirements. North America and Europe drive bulk demand due to established hospital networks. Manufacturers prefer reliable, compliant coating powders to maintain quality and sterility. Long-term supplier contracts reinforce dominance. Large-scale production facilities benefit from consistent demand and economies of scale.

Contract coaters are expected to witness the fastest growth rate from 2025 to 2032, due to increasing outsourcing of powder-free glove coating processes. They enable smaller glove manufacturers to adopt advanced coating technologies without investing in in-house facilities. Specialty glove demand drives growth. Asia-Pacific is a key region for contract coater expansion. The model allows faster market entry for glove brands. Adoption of contract coating services improves scalability and compliance with regulations.

Particulate-Free Surgical Glove Coating Powders Market Regional Analysis

- North America dominated the particulate-free surgical glove coating powders market with the largest revenue share of 31.7% in 2024, characterized by strict FDA regulations, high adoption of powder-free solutions, and a strong presence of leading glove manufacturers

- Hospitals and surgical centers in the U.S. and Canada highly prioritize sterile, low-particulate gloves, leading to widespread adoption of advanced polymer and specialty coating powders

- The region’s dominance is further supported by a mature healthcare infrastructure, high awareness among healthcare professionals about surgical site infection risks, and the presence of leading glove manufacturers and suppliers offering innovative powder-free solutions

U.S. Particulate-Free Surgical Glove Coating Powders Market Insight

The U.S. particulate-free surgical glove coating powders market captured the largest revenue share of 78% in 2024 within North America, fueled by stringent FDA regulations banning powdered gloves and the increasing emphasis on surgical safety. Hospitals and surgical centers are prioritizing sterile, low-particulate gloves to reduce infection risks and allergic reactions. The growing adoption of advanced polymer and specialty coating powders, coupled with high procedural volumes in general and specialty surgeries, further propels market growth. In addition, the shift toward nitrile and hypoallergenic gloves coated with particulate-free powders is accelerating. U.S. manufacturers are heavily investing in R&D for high-performance coatings, driving innovation in the market. The increasing awareness among healthcare professionals about glove quality and safety standards is also supporting consistent demand.

Europe Particulate-Free Surgical Glove Coating Powders Market Insight

The Europe market is projected to expand at a substantial CAGR throughout the forecast period, primarily driven by strict EU regulations restricting powdered gloves and increasing emphasis on infection control in hospitals. Rising urbanization and the adoption of advanced surgical procedures are fostering the use of sterile, low-particulate gloves. European healthcare providers value the enhanced safety, biocompatibility, and ease of donning offered by polymer and specialty coatings. The market is witnessing significant growth across general surgery, specialty surgery, and diagnostic lab applications. Manufacturers are innovating to meet compliance standards while catering to premium surgical glove segments. The increasing replacement of conventional powdered gloves in both new and established healthcare facilities is driving adoption.

U.K. Particulate-Free Surgical Glove Coating Powders Market Insight

The U.K. market is anticipated to grow at a noteworthy CAGR during the forecast period, driven by heightened awareness of surgical site infections and the shift toward safer, powder-free gloves. Healthcare providers and hospitals increasingly prefer gloves with polymer and cornstarch-based coatings for their consistent quality and sterility. Regulatory mandates banning powdered gloves, along with the adoption of advanced surgical procedures, are boosting demand. The U.K.’s robust healthcare infrastructure and high standards for patient safety further support growth. Hospitals and diagnostic labs are integrating powder-free gloves in routine surgical and clinical applications. Manufacturers are responding with R&D investments to provide compliant and high-performance coating solutions.

Germany Particulate-Free Surgical Glove Coating Powders Market Insight

The Germany market is expected to expand at a considerable CAGR during the forecast period, fueled by rising awareness of surgical safety, strict medical device regulations, and increasing demand for high-quality sterile gloves. Hospitals and surgical centers prioritize gloves with polymer or liquid coatings to reduce contamination risks and improve donning performance. The country’s emphasis on innovation and quality assurance promotes the adoption of advanced coating powders. Demand is particularly high in specialty surgeries requiring ultra-low particulate gloves. Manufacturers in Germany are investing in R&D to develop customized coating solutions that comply with European standards. Hospitals and labs increasingly rely on powder-free gloves for infection control and patient safety.

Asia-Pacific Particulate-Free Surgical Glove Coating Powders Market Insight

The Asia-Pacific market is poised to grow at the fastest CAGR during the forecast period of 2025 to 2032, driven by rising surgical volumes, increasing awareness of infection control, and expanding healthcare infrastructure in countries such as China, Japan, and India. Adoption of powder-free polymer and specialty coating powders is increasing in hospitals, clinics, and diagnostic labs. Government initiatives promoting healthcare quality, along with urbanization and rising disposable incomes, are supporting market growth. Emerging markets in APAC are investing in modern surgical centers requiring high-performance sterile gloves. Local manufacturers are expanding production of particulate-free coatings to meet both domestic and export demand. Increasing use of specialty surgical gloves in ophthalmic, cardiovascular, and neurosurgical procedures further accelerates adoption.

Japan Particulate-Free Surgical Glove Coating Powders Market Insight

The Japan market is gaining momentum due to high surgical volumes, an aging population, and increasing demand for safer, hypoallergenic gloves. Hospitals and surgical centers are prioritizing gloves with polymer and liquid coatings for ultra-low particulate levels. The adoption of specialty gloves in ophthalmic and cardiovascular surgeries is driving market expansion. Japanese healthcare providers value quality, precision, and compliance with strict local and international standards. R&D investments by glove manufacturers are fostering innovation in advanced coatings. Integration of powder-free gloves in both hospitals and diagnostic labs is becoming increasingly prevalent, supporting steady market growth.

India Particulate-Free Surgical Glove Coating Powders Market Insight

The India market accounted for the largest market revenue share in Asia-Pacific in 2024, driven by rapid urbanization, a growing middle class, and increasing healthcare infrastructure. Hospitals, clinics, and surgical centers are adopting polymer and cornstarch-coated gloves to meet international sterility standards. The push toward smart hospitals, along with the availability of affordable powder-free gloves, is propelling market growth. Local manufacturers and contract coaters are expanding production capacities to meet rising demand. Increasing awareness of infection control and allergic reactions from powdered gloves further supports adoption. Specialty surgical gloves for cardiovascular, ophthalmic, and neurosurgical procedures are increasingly used in India, accelerating market expansion.

Particulate-Free Surgical Glove Coating Powders Market Share

The particulate-free surgical glove coating powders industry is primarily led by well-established companies, including:

- Sempermed (Austria)

- ANSELL LTD (Australia)

- Molnlycke AB (Sweden)

- Medicom (Canada)

- Henry Schein One, LLC. (U.S.)

- Cardinal Health (U.S.)

- Medtronic (Ireland)

- Halyard Health (U.S.)

- ROMED Fasteners, Inc (Netherlands)

- Globus (U.K.)

- Stoe (India)

- Cleanroom Connection LLC (U.S.)

- Bull Products (U.K.)

- Creative Technology (U.S.)

- Surface Solutions Group (U.S.)

- Alpha Medthrift Scientific Co. (U.S.)

- Medispo Srl (Turkey)

What are the Recent Developments in Global Particulate-Free Surgical Glove Coating Powders Market?

- In August 2025, INTCO Medical announced a significant shift towards latex-free surgical gloves, responding to increasing demand and regulatory changes. This move aligns with the growing preference for powder-free and hypoallergenic gloves, positioning INTCO as a leader in the latex-free glove market. The company emphasizes the importance of durability and comfort in surgical gloves, aiming to meet the evolving needs of healthcare professionals

- In March 2024, Sempermed introduced the skySense gloves, a new addition to their surgical glove product line. These gloves are designed to offer enhanced protection and comfort, catering to the evolving needs of healthcare professionals. The skySense gloves are now available for order placement, reflecting Sempermed's commitment to advancing glove technology and meeting market demands

- In January 2024, ECO Medi Glove Sdn. Bhd. received FDA 510(k) clearance for their powder-free natural rubber latex surgical glove. This approval signifies that the glove meets the FDA's safety and effectiveness standards, ensuring its suitability for use in surgical procedures. The glove is designed to minimize the risk of allergic reactions associated with latex proteins, aligning with the industry's shift towards hypoallergenic options

- In July 2021, Cardinal Health launched the Protexis Latex Hydrogel surgical gloves, which are powder-free and made from natural rubber latex. These gloves include an exclusive hydrogel coating that enhances donning lubricity, making them easy to wear even when wet. The hydrogel coating provides a soft, comfortable fit, aiming to improve the overall user experience in surgical environments

- In July 2021, Ansell's Protexis Surgical Gloves Team announced a collaborative initiative with healthcare providers to improve the selection process for surgical gloves. The team offers guidance to clinicians in choosing the appropriate glove for various surgical procedures, focusing on factors such as material composition and coating technologies. This collaboration aims to ensure that healthcare professionals have access to gloves that meet specific procedural requirements and enhance safety and comfort during surgeries

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.