Global Progressing Cavity Pump Market

Market Size in USD Billion

CAGR :

%

USD

2.89 Billion

USD

4.40 Billion

2024

2032

USD

2.89 Billion

USD

4.40 Billion

2024

2032

| 2025 –2032 | |

| USD 2.89 Billion | |

| USD 4.40 Billion | |

|

|

|

|

Progressing Cavity Pump Market Analysis

The progressing cavity pump market has witnessed significant growth due to advancements in pump design and technology, which have led to increased reliability and efficiency. These pumps, known for their ability to handle a variety of fluids, including viscous, shear-sensitive, and abrasive substances, are widely used in industries such as oil and gas, wastewater treatment, food and beverage, and chemical processing. Technological improvements such as the integration of smart monitoring systems and enhanced materials have driven the development of pumps that offer better durability and lower maintenance costs. For instance, advancements in the use of wear-resistant and corrosion-resistant materials have improved the longevity of these pumps, enabling them to perform in harsh environments without frequent replacements. In addition, innovations in energy-efficient motor designs have further optimized energy consumption, which is a critical factor for many industries focused on reducing operational costs. The growing need for reliable pumping solutions in sectors such as biogas production and battery recycling is expected to drive the market. This market expansion is also supported by increasing infrastructure investments and industrial automation, which push the demand for high-performance, low-maintenance equipment.

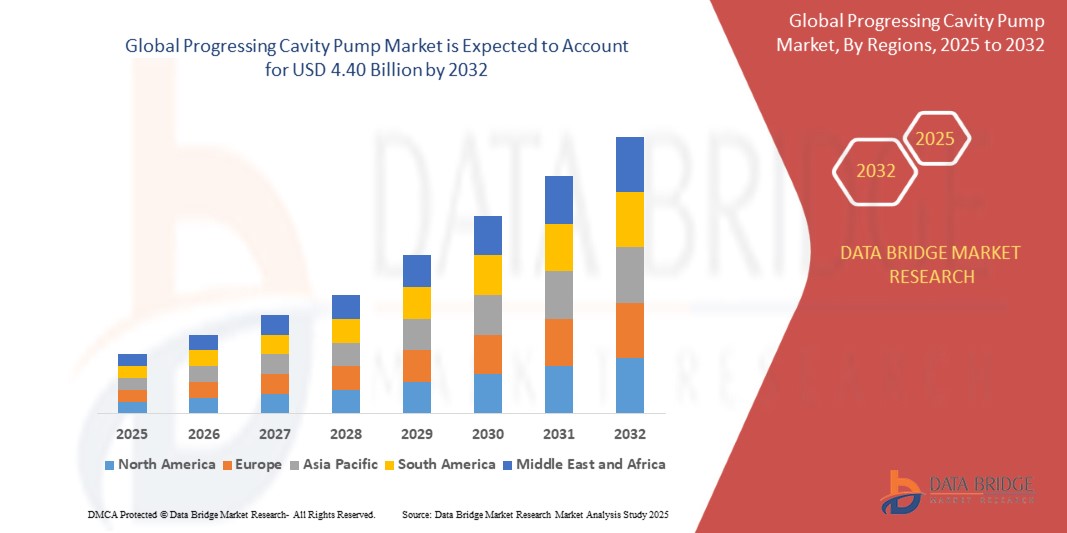

Progressing Cavity Pump Market Size

The global progressing cavity pump market size was valued at USD 2.89 billion in 2024 and is projected to reach USD 4.40 billion by 2032, with a CAGR of 5.40% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Progressing Cavity Pump Market Trends

“Increasing integration of IoT and smart technology”

A significant trend in the progressing cavity pump market is the increasing integration of IoT and smart technology for real-time monitoring and predictive maintenance. These advancements enhance the performance and reliability of pumps, reducing downtime and optimizing operations. For instance, manufacturers are now embedding sensors into the pumps to monitor key parameters such as pressure, temperature, and flow rates, enabling early detection of potential issues. This proactive approach extends the lifespan of the pumps and minimizes operational costs by preventing unexpected failures. The use of smart technology is especially prominent in sectors such as wastewater treatment and the oil and gas industry, where continuous and reliable operation is crucial. Companies such as NETZSCH and CIRCOR International are leading the way in incorporating these innovations, ensuring that pumps are more efficient, cost-effective, and adaptable to the demands of modern industrial applications. This trend is poised to drive further growth in the market.

Report Scope and Progressing Cavity Pump Market Segmentation

|

Attributes |

Progressing Cavity Pump Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

NETZSCH (Germany), Ingersoll Rand (U.S.), NOV (U.S.), CIRCOR International, Inc. (U.S.), ChampionX (U.S.), Xylem (U.S.), Sulzer Ltd (Switzerland), SLB (U.S.), WILO SE (Germany), Varisco (Italy), Delta PD Pumps (U.K.), Pumps Progressing Cavity (Italy), Roto Pumps Limited (India), INOXPA S.A.U. (Spain), German Legacy Pumps (Germany), Hangzhou Xinglong Pump Industry Co., Ltd. (China), Shanghai Pacific Pump Manufacturer (Group) Co., Ltd. (China), PSP PUMPS (India), Tapflo (Sweden), GEA Group Aktiengesellschaft (Germany), Fristam Pumpen KG (GmbH and Co.) (India), Atlas Copco UK Holdings (Sweden), HILGER and KERN GROUP (India), Risansi Industries Ltd. (India), Synopumps (India), and PUMPSQUARE SYSTEMS LLP (India) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Progressing Cavity Pump Market Definition

A progressing cavity pump is a type of positive displacement pump that moves fluid through a cylindrical chamber by using a rotating helical screw (the rotor) inside a stationary, shaped elastomer stator. The design creates a series of sealed cavities that progress as the rotor turns, enabling the pump to move fluid steadily and efficiently with minimal pulsation.

Progressing Cavity Pump Market Dynamics

Drivers

- Growing Demand for Wastewater Treatment Solutions

The growing demand for wastewater treatment solutions is driving the use of progressing cavity pumps, as these pumps are essential for efficiently managing and treating wastewater in various facilities. Their design allows them to handle thick, viscous, and abrasive fluids, making them ideal for applications such as sludge transfer and chemical dosing in wastewater plants. For instance, municipal water treatment facilities often face the challenge of processing high volumes of sewage and industrial waste; progressing cavity pumps excel in maintaining a steady flow, preventing blockages, and reducing downtime. In addition, with increasing urbanization and industrial activities leading to higher wastewater generation, municipalities and industries are investing in advanced treatment systems that incorporate these pumps. This trend is further bolstered by regulations and environmental standards that mandate effective wastewater treatment, reinforcing the need for reliable and efficient pump solutions. Thus, the demand for progressing cavity pumps continues to rise as they play a crucial role in sustainable water management practices.

- Rising Need for Efficient Industrial Processing

The rising need for efficient industrial processing in sectors such as food and beverage, chemicals, and oil and gas is driving the adoption of progressing cavity pumps. These pumps are particularly well-suited for handling viscous and shear-sensitive fluids due to their ability to maintain a consistent flow without altering the properties of the liquid. For instance, in the food and beverage industry, progressing cavity pumps are used for transferring ingredients such as chocolate, syrups, and sauces, where maintaining the integrity and texture of the product is crucial. Similarly, in the chemical industry, these pumps facilitate the transfer of polymers and other sensitive compounds, while in oil and gas, they are employed for handling crude oil and drilling fluids that require gentle pumping to avoid breaking down their composition. The reliable and efficient nature of progressing cavity pumps ensures minimal product degradation, reduced operational downtime, and lower maintenance costs, positioning them as a preferred solution for industries requiring high standards in fluid processing.

Opportunities

- Increasing Adoption of Progressing Cavity Pumps in Emerging Economies

The increasing adoption of progressing cavity pumps in emerging economies is driven by significant investments in infrastructure projects such as water treatment facilities and industrial processing plants. Developing regions such as Asia-Pacific and Latin America are prioritizing the expansion of clean water access and modernizing their industrial sectors, which has increased the demand for reliable pumping solutions. For instance, countries such as India and Brazil have been ramping up their efforts to build advanced wastewater treatment plants to tackle water scarcity and pollution. Progressing cavity pumps are highly valued in these projects due to their durability and capability to handle challenging fluids efficiently, making them an ideal choice for water and wastewater management systems. In addition, their application in industrial processing plants for the chemical, food, and beverage sectors further boosts market potential in these regions. This trend highlights the growth opportunity for manufacturers and suppliers looking to expand their presence in emerging markets.

- Increasing Demand for Energy Efficiency

Progressing cavity pumps are gaining recognition for their energy-efficient operation and minimal maintenance needs, making them a cost-effective solution for industries seeking long-term, sustainable pumping systems. These pumps operate with a consistent and low-energy consumption rate, which significantly reduces operational costs over time. For instance, in wastewater treatment plants, where pumps run continuously, energy savings can be substantial, contributing to lower operational expenses and reduced carbon footprints. The reduced frequency of maintenance also minimizes downtime, ensuring smooth operations and increased productivity. This feature is particularly appealing in sectors such as food processing and chemicals, where the reliability of equipment is critical for continuous production. As industries globally prioritize sustainable practices and cost management, the demand for energy-efficient and low-maintenance equipment such as progressing cavity pumps is expected to rise. This trend presents a significant market opportunity for manufacturers to promote these benefits and capture the attention of environmentally conscious and cost-driven businesses.

Restraints/Challenges

- High Initial Costs

High initial costs present a significant challenge for the progressing cavity pump market, as these pumps tend to be more expensive upfront compared to other pump types due to their intricate design and the specialized materials needed for manufacturing. For instance, industries in developing regions, such as small-scale wastewater treatment facilities or food processing plants, may find it difficult to justify the investment in progressing cavity pumps when cheaper alternatives such as centrifugal pumps are available, despite potential limitations in handling viscous or sludge-such as fluids. The higher purchase price can be a deterrent for budget-conscious industries that prioritize initial expenditure over long-term benefits, thus hindering the widespread adoption of progressing cavity pumps. This market challenge also requires manufacturers to explore cost-effective production methods, streamline their design processes, and offer financing or leasing options to make these pumps more accessible to a broader range of industries.

- Involved Maintenance and Wear

Maintenance and wear pose a significant challenge for the progressing cavity pump market, as these pumps' continuous rotating mechanism leads to gradual wear and tear on their components, requiring more frequent maintenance and replacement of parts. For instance, in industries such as wastewater treatment or oil extraction, where progressing cavity pumps are commonly used for their ability to handle viscous and abrasive fluids, the ongoing need for upkeep can lead to higher operational costs and downtime. These maintenance requirements can be particularly burdensome for industries with limited resources or smaller operators who may not have the infrastructure or budget for regular servicing. The cost and time associated with maintaining progressing cavity pumps can limit their appeal, making other, more low-maintenance pump types more attractive to cost-sensitive businesses, ultimately hampering the market growth.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions. Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Progressing Cavity Pump Market Scope

The market is segmented on the basis of product type, stage type, power, rating, pumping capacity, and end-user. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Product Type

- Dosing Pumps

- Flanged Pumps

- Hopper Pumps

- Food Grade Pumps

- Vertical Pumps

- Downhole Pumps

Stage Type

- Single Stage (90-PSI)

- Double Stage (180-PSI)

- Four Stage (360-PSI)

- Eight Stage (720-PSI)

Power Rating

- Up to 50 HP

- 51 to 150 HP

- Above 150 HP

Pumping Capacity

- Up to 500 GPM

- 501 to 1000 GPM

- Above 1000 GPM

End-User

- Oil and Gas

- Water and Wastewater Treatment

- Food and Beverage

- Food Waste

- Biogas

- Battery Recycling

- Chemicals and Petrochemicals

- Others

Progressing Cavity Pump Market Regional Analysis

The market is analysed and market size insights and trends are provided by country, product type, stage type, power, rating, pumping capacity, and end-user as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia-Pacific dominates the progressing cavity pump market due to the increasing demand for flexible plastic additives, which play a crucial role in enhancing the properties of plastic products. These modifiers enable the production of more durable and versatile plastics, driving their widespread use across industries. The region's robust automotive and industrial sectors further contribute to this growth, as polyamide (PA) blends are favored for their strength, durability, and lightweight characteristics. This trend highlights Asia-Pacific's significant position in the global market for Progressing Cavity Pump, driven by both manufacturing advancements and growing demand for high-performance materials.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Progressing Cavity Pump Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Progressing Cavity Pump Market Leaders Operating in the Market Are:

- NETZSCH (Germany)

- Ingersoll Rand (U.S.)

- NOV (U.S.)

- CIRCOR International, Inc. (U.S.)

- ChampionX (U.S.)

- Xylem (U.S.)

- Sulzer Ltd (Switzerland)

- SLB (U.S.)

- WILO SE (Germany)

- Varisco (Italy)

- Delta PD Pumps (U.K.)

- Pumps Progressing Cavity (Italy)

- Roto Pumps Limited (India)

- INOXPA S.A.U. (Spain)

- German Legacy Pumps (Germany)

- Hangzhou Xinglong Pump Industry Co., Ltd. (China)

- Shanghai Pacific Pump Manufacturer (Group) Co., Ltd. (China)

- PSP PUMPS (India)

- Tapflo (Sweden)

- GEA Group Aktiengesellschaft (Germany)

- Fristam Pumpen KG (GmbH & Co.) (India)

- Atlas Copco UK Holdings (Sweden)

- HILGER & KERN GROUP (India)

- Risansi Industries Ltd. (India)

- Synopumps (India)

- PUMPSQUARE SYSTEMS LLP (India)

Latest Developments in Progressing Cavity Pump Market

- In October 2024, NETZSCH unveiled an economical and hermetically sealed upgrade for its NEMO progressing cavity pumps, with this new design enhancing safety by preventing the release of toxic liquids and gases, while also offering cost savings as the sealing systems do not require maintenance

- In February 2023, Netzsch Pumps & Systems announced the expansion of its production and logistics in East Asia with a significant investment in a new production plant in Lanzhou, China, as part of the "Lanzhou New Plant" project, which will bolster production and logistics networks, reinforcing NETZSCH’s presence in the region and increasing annual pump production at the site

- In April 2022, NOV expanded the availability of its Low Flow Metering Range Pump, which is highly resistant to harsh chemicals and suitable for both continuous and intermittent dosing, with the pump being versatile and supporting a wide range of applications such as chemical injection for wastewater, chemical processing across various industries, and use in the pharmaceutical sector

- In February 2022, Atlas Copco announced the acquisition of Wangen Pumpen, a German manufacturer known for its progressive cavity pumps. This strategic move aims to enhance Atlas Copco’s presence in the wastewater treatment and process industries. Wangen Pumpen’s well-regarded products will be a significant addition to Atlas Copco's portfolio, enabling the company to reach a larger customer base and offer a more diverse range of pumping solutions

- In January 2022, NETZSCH commenced construction of a new production facility in Ribeirão Souto, Santa Catarina, Brazil, near its existing Pomerode site, with this new facility set to handle the full production of multi-screw pumps and also support the increase in production of other product lines, boosting the company's capabilities in South America

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Progressing Cavity Pump Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Progressing Cavity Pump Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Progressing Cavity Pump Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.