Global Roll Slitting Machine Market

Market Size in USD Billion

CAGR :

%

USD

1.31 Billion

USD

2.73 Billion

2024

2032

USD

1.31 Billion

USD

2.73 Billion

2024

2032

| 2025 –2032 | |

| USD 1.31 Billion | |

| USD 2.73 Billion | |

|

|

|

|

What is the Global Roll Slitting Machine Market Size and Growth Rate?

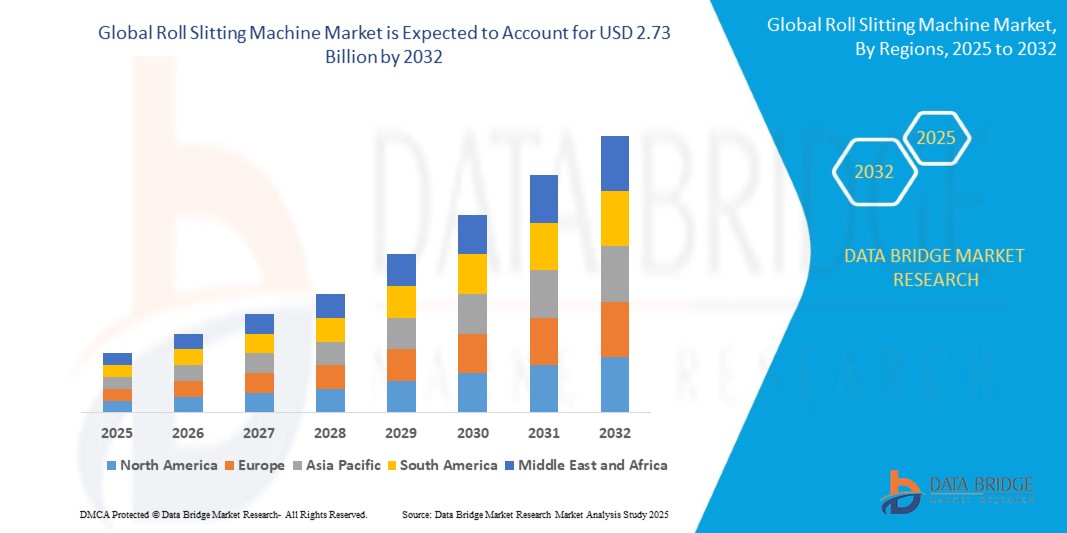

- The global roll slitting machine market size was valued at USD 1.31 billion in 2024 and is expected to reach USD 2.73 billion by 2032, at a CAGR of 9.60% during the forecast period

- The roll slitting machine refers to the collective industry involved in the manufacturing, distribution, and utilization of roll slitting machines. These machines are designed for precision cutting and slitting of various materials, such as paper, film, foil, textiles, and other flexible substrates, into narrower rolls

- The market encompasses the diverse range of roll slitting machines, including manual, semi-automatic, and fully automatic models, catering to the needs of industries such as packaging, printing, textiles, and converting. Key components include cutting blades, precision control systems, and automated features for efficient and accurate slitting

- The market is characterized by technological advancements, customization options, and a focus on sustainability, serving industries seeking precise and adaptable solutions for their production processes

What are the Major Takeaways of Roll Slitting Machine Market?

- Flexible packaging is becoming increasingly popular due to its advantages such as lightweight, durability, and printability. Roll slitting machines are essential for the production of flexible packaging material

- The e-commerce industry is growing rapidly, and this is driving the demand for roll slitting machines as more and more products are being packaged and shipped

- North America dominated the roll slitting machine market with the largest revenue share of 37.01% in 2024, fueled by increasing demand for packaging automation, advanced machinery, and the expansion of the e-commerce sector

- Asia-Pacific is projected to grow at the fastest CAGR of 7.21% from 2025 to 2032, driven by rapid industrialization, rising investments in manufacturing, and booming demand for flexible packaging materials

- The Slitter Rewinders segment dominated the market with the largest revenue share of 55.3% in 2024, owing to its widespread application in high-volume industries such as packaging, converting, and flexible materials

Report Scope and Roll Slitting Machine Market Segmentation

|

Attributes |

Roll Slitting Machine Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Roll Slitting Machine Market?

“Automation and AI-Enabled Precision Slitting”

- A major trend in the roll slitting machine market is the increasing integration of automation and artificial intelligence (AI) to enhance precision, reduce material waste, and improve overall operational efficiency

- Modern roll slitting systems now come equipped with AI-driven sensors and real-time monitoring software that automatically adjust blade pressure and alignment based on material thickness and tension variations, minimizing manual intervention

- For instance, Comexi has introduced slitting machines with intelligent web control systems that ensure high-speed and accurate cutting across various substrates, reducing setup time and operator dependency

- In addition, predictive maintenance features powered by AI help in identifying component wear or potential breakdowns before they occur, enhancing uptime and lowering long-term maintenance costs

- This transition toward intelligent, automated slitting systems is especially critical in packaging, label printing, and electronics industries where micro-level accuracy is essential.

- As manufacturers focus on higher productivity and sustainability, the adoption of smart slitting machines that reduce energy usage and material wastage is gaining rapid momentum globally

What are the Key Drivers of Roll Slitting Machine Market?

- The expanding flexible packaging industry, driven by food, pharmaceutical, and e-commerce sectors, is fueling the demand for advanced slitting machines that can handle various substrates such as plastic, paper, and foil efficiently

- In May 2024, Kampf Schneid- und Wickeltechnik GmbH & Co. KG launched its new “ConSlitter” series targeting high-speed, high-accuracy slitting with faster job changeovers, catering to increasing short-run production trends

- Manufacturers are increasingly adopting fully automated roll slitting machines to reduce human errors, improve quality control, and meet tighter tolerance requirements, especially in electronics and specialty films

- Further, the surge in eco-conscious manufacturing is pushing companies to invest in machines that optimize material usage, generate less waste, and support recyclable material processing, boosting the market

- Government incentives for modernization of industrial equipment in countries such as India and China are also providing a favorable backdrop for market growth

- Combined, these factors are propelling the global roll slitting machine market across printing, converting, automotive, and battery production applications

Which Factor is challenging the Growth of the Roll Slitting Machine Market?

- A key challenge is the high initial investment cost and technical complexity of advanced automated roll slitting systems, which limits adoption among small and medium enterprises (SMEs)

- For instance, SMEs in emerging regions often continue to rely on manual or semi-automatic slitting machines due to budget constraints and lack of skilled labor to operate high-end machinery

- In addition, integration with Industry 4.0 platforms and real-time analytics requires strong IT infrastructure and technical training, which are not always readily available in cost-sensitive markets

- Also, maintenance complexity of fully automated machines, including sensor calibration and software updates, adds to operational costs and may cause downtime if not properly managed

- Another barrier is the limited customization available for specific niche applications, such as ultra-thin film or composite materials, which require tailored cutting solutions

- Addressing these challenges with cost-effective entry-level automation, better training modules, and after-sales support will be crucial for expanding adoption across the global slitting machine ecosystem

How is the Roll Slitting Machine Market Segmented?

The market is segmented on the basis of type, material, slitter blade, operation, distribution channel, and industry.

• By Type

On the basis of type, the roll slitting machine market is segmented into Roll/Log Slitters and Slitter Rewinders. The Slitter Rewinders segment dominated the market with the largest revenue share of 55.3% in 2024, owing to its widespread application in high-volume industries such as packaging, converting, and flexible materials. These machines offer precise slitting combined with rewinding capabilities, making them highly efficient for roll-to-roll processing.

The Roll/Log Slitters segment is expected to witness the fastest growth rate of 19.8% from 2025 to 2032, driven by their increasing use in textile and label production where straight roll slitting is critical for wide materials. Their cost-effectiveness and simpler operation make them attractive to small and mid-sized enterprises.

• By Material

On the basis of material, the roll slitting machine market is segmented into Paper, Polymers, Foil, and Others. The Paper segment held the largest market revenue share in 2024, driven by strong demand from the publishing, printing, and packaging industries. Roll slitting is essential in processing large paper rolls into standardized sizes used in multiple commercial and industrial applications.

The Polymer segment is expected to grow at the fastest CAGR from 2025 to 2032, owing to the rapid expansion of flexible packaging, electronics films, and medical packaging. As polymer-based substrates become more complex, precision slitting becomes increasingly important for product quality and waste reduction.

• By Slitter Blade

On the basis of slitter blade, the market is segmented into Large Circular Blade and Fixed Band Blade. The Large Circular Blade segment accounted for the highest revenue share of 61.5% in 2024, driven by its high-speed operation, ability to cut thick materials, and adaptability to various substrates. It remains a staple across industrial-grade slitting applications.

The Fixed Band Blade segment is anticipated to witness the highest growth rate through 2032, owing to its minimal vibration, clean cuts, and suitability for delicate materials such as foils and specialty films. Its adoption is rising in industries where precision edges are essential, such as medical packaging and electronics.

• By Operation

On the basis of operation, the roll slitting machine market is segmented into Manual and Automatic. The Automatic segment dominated the market in 2024 with a revenue share of 67.9%, attributed to its increased use in large-scale manufacturing where speed, precision, and labor cost reduction are priorities. Automation also ensures consistency and minimizes operational downtime.

The Manual segment is projected to grow steadily in emerging markets, where low capital investment and simpler workflows make manual machines viable for small workshops and short-run production.

• By Distribution Channel

On the basis of distribution channel, the market is segmented into Direct Sales (OEM) and Indirect Sales. Direct Sales (OEM) held the majority market share of 58.6% in 2024, as most large industrial buyers prefer direct engagement with manufacturers for customization, training, and after-sales support. This channel also helps OEMs maintain tighter control over brand reputation and technical support.

The Indirect Sales segment is expected to witness rising demand due to the increasing reach of third-party distributors, e-commerce platforms, and regional dealers, especially in Asia-Pacific and Latin America.

• By Industry

On the basis of industry, the roll slitting machine market is segmented into Paper and Pulp, Textile, Packaging, and Others. The Packaging segment emerged as the largest contributor with a market share of 44.7% in 2024, owing to the explosive demand for custom-sized labels, films, and flexible packaging materials across food, healthcare, and consumer goods.

The Textile segment is projected to register the fastest CAGR from 2025 to 2032, propelled by increasing use of synthetic fabrics, nonwoven materials, and rising demand for high-speed slitting solutions in apparel and technical textiles.

Which Region Holds the Largest Share of the Roll Slitting Machine Market?

- North America dominated the roll slitting machine market with the largest revenue share of 37.01% in 2024, fueled by increasing demand for packaging automation, advanced machinery, and the expansion of the e-commerce sector

- The region benefits from well-established manufacturing sectors, high-speed industrial infrastructure, and significant investments in flexible packaging technologies

- The widespread adoption of roll slitting machines is also driven by the need for precision cutting in paper, plastic films, and metal foils, supporting both consumer goods and industrial applications

U.S. Roll Slitting Machine Market Insight

The U.S. roll slitting machine market held the largest share in North America in 2024, propelled by rising demand from the packaging, paper, and plastics industries. The adoption of advanced slitting systems offering automation, web tension control, and reduced downtime is growing. Increasing sustainability efforts and material efficiency requirements are also driving innovation, especially in sectors focused on recyclable and biodegradable materials.

Europe Roll Slitting Machine Market Insight

The Europe roll slitting machine market is anticipated to grow at a significant CAGR during the forecast period, driven by increasing demand for high-precision slitting technology and sustainability in material usage. Growth is further supported by strong industrial output in countries such as Germany, Italy, and the U.K., where advanced engineering and smart factory concepts are integrating automated slitting technologies into production lines.

U.K. Roll Slitting Machine Market Insight

The U.K. market is expected to grow steadily, fueled by a growing preference for compact, energy-efficient slitting machines suitable for small and medium-scale converters. Demand from pharmaceutical, labeling, and flexible packaging industries is on the rise, and domestic manufacturers are increasingly investing in advanced converting equipment that meets high quality and hygiene standards.

Germany Roll Slitting Machine Market Insight

The Germany market is expanding due to the country’s leadership in industrial automation and engineering excellence. German manufacturers are at the forefront of delivering high-speed, computer-controlled slitting machines with precision winding capabilities. The emphasis on Industries 4.0 and the integration of digital control systems continue to boost adoption across multiple manufacturing verticals.

Which Region is the Fastest Growing in the Roll Slitting Machine Market?

Asia-Pacific is projected to grow at the fastest CAGR of 7.21% from 2025 to 2032, driven by rapid industrialization, rising investments in manufacturing, and booming demand for flexible packaging materials. Key economies such as China, India, and Japan are investing in automation and high-efficiency slitting solutions to cater to domestic and global markets. Affordable labor, abundant raw materials, and government-backed industrial growth initiatives are boosting the region’s capacity to produce and adopt roll slitting technology at scale.

Japan Roll Slitting Machine Market Insight

The Japan market is gaining traction due to its high-quality packaging standards and demand for compact, high-precision machines. Japanese firms prioritize automation and space-saving machinery for sectors such as electronics, food, and cosmetics, where quality control and operational efficiency are critical.

China Roll Slitting Machine Market Insight

The China market captured the largest share in Asia-Pacific in 2024, led by strong domestic manufacturing capacity and growing exports. With local manufacturers producing competitively priced yet technologically advanced roll slitting systems, the country is becoming a key exporter of these machines, especially in flexible packaging, films, and battery components.

Which are the Top Companies in Roll Slitting Machine Market?

The roll slitting machine industry is primarily led by well-established companies, including:

- Atlas Converting (U.K.)

- Ashe Controls Private Limited (India)

- Comexi (Spain)

- Coeclerici SpA (Italy)

- Kampf Schneid- und Wickeltechnik GmbH & Co. KG (Germany)

- LIDEM Mechanical Constructions, S.L. (Spain)

- Parkland International (U.K.)

- RIBAMATIC (Spain)

- SOMA (Czech Republic)

- Kashif Saeed General Trading LLC (U.A.E.)

- H. R. (Paper) Machinery Private Limited (India)

- Orion Graphic Machinery (India)

- R. K. Label Printing Machinery Private Limited (India)

- Hariram Engineering (India)

- K M Trivedi Engineering Pvt. Ltd. (India)

- CMC Converting Machinery Cevenini Srl. (Italy)

- Ghezzi & Annoni (Italy)

- Kuen Yuh Machinery Engineering Co., Ltd. (Taiwan)

What are the Recent Developments in Global Roll Slitting Machine Market?

- In June 2024, Super Machine Works re-entered the Bangladesh market, offering advanced textile machinery such as Autoleveller Drawframes and Open-End Spinning machines, along with the new SC 1 Super Card carding machine. Represented by Rotation World in Dhaka, the company aims to boost automation while minimizing labor and power usage. This move is expected to enhance operational efficiency and support the region’s growing textile sector

- In April 2024, INVT unveiled its advanced automation and precision solutions for slitting machines in India, targeting enhanced performance in material conversion across industries. These upgraded slitter rewinders efficiently process large master rolls into narrower sizes, improving productivity and cost control. This innovation marks a strategic step towards smarter and more efficient industrial roll processing

- In August 2023, Comexi Group completed the USD 120 million acquisition of Spanish roll-to-roll printing equipment manufacturer Omet, a move designed to broaden Comexi’s product lineup by incorporating digital printing technologies. This acquisition solidifies Comexi’s leadership in the roll-to-roll printing and slitting segment worldwide

- In July 2023, Karlville Development Group launched a new range of multifunctional roll slitting machines, capable of slitting paper, film, and nonwovens for the converting industry. These machines address the need for high-speed, flexible slitting across multiple substrates. This launch is expected to drive versatility and precision in industrial roll conversion applications

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Roll Slitting Machine Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Roll Slitting Machine Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Roll Slitting Machine Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.