Global Slideway Oil Market

Market Size in USD Billion

CAGR :

%

USD

107.91 Billion

USD

158.22 Billion

2024

2032

USD

107.91 Billion

USD

158.22 Billion

2024

2032

| 2025 –2032 | |

| USD 107.91 Billion | |

| USD 158.22 Billion | |

|

|

|

|

What is the Global Slideway Oil Market Size and Growth Rate?

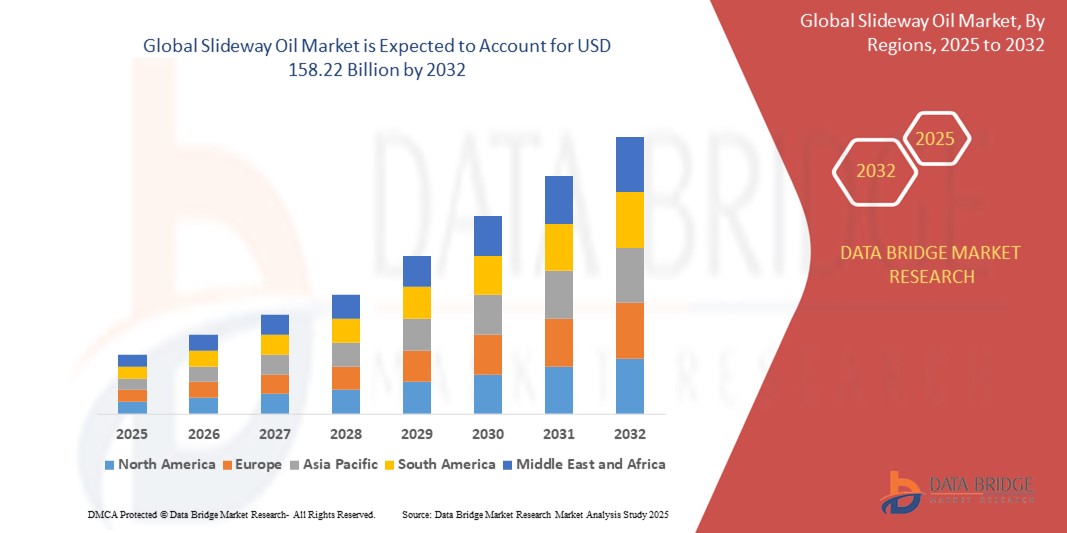

- The global slideway oil market size was valued at USD 107.91 billion in 2024 and is expected to reach USD 158.22 billion by 2032, at a CAGR of 4.90% during the forecast period

- The slideway oil market is witnessing steady growth, driven by the increasing demand for precision machinery across various industries such as automotive, aerospace, and manufacturing

- Slideway oils play a crucial role in ensuring the smooth operation of machine tools, which is essential for maintaining high productivity levels and reducing downtime in industrial operations

- The growth of automation and CNC (computer numerical control) machines further fuels the demand for high-quality lubricants such as slideway oils, as they help minimize wear and tear on critical moving parts

What are the Major Takeaways of Slideway Oil Market?

- The increasing emphasis on environmental sustainability is driving the development of biodegradable and eco-friendly slideway oils. As industries face mounting pressure to reduce their environmental impact, the demand for lubricants that meet stringent environmental regulations is growing

- These eco-friendly slideway oils are formulated to break down more easily in the environment, reducing the risk of pollution and minimizing the long-term ecological footprint of industrial operations

- North America dominated the slideway oil market with the largest revenue share of 40.5% in 2024, driven by the strong presence of advanced manufacturing industries, rising investments in precision machinery, and the growing emphasis on equipment efficiency and longevity

- Asia-Pacific slideway oil market is expected to grow at the fastest CAGR of 13.6% from 2025 to 2032, driven by rapid industrialization, growing machine tool demand, and technological advancements in emerging economies such as China, India, and Japan

- The ISO VG 68 segment dominated the slideway oil market with the largest revenue share of 39.5% in 2024, owing to its widespread use in machine tools and equipment requiring moderate viscosity for precise slideway movement

Report Scope and Slideway Oil Market Segmentation

|

Attributes |

Slideway Oil Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Slideway Oil Market?

“Enhanced Equipment Performance through Advanced Formulations”

- A significant and accelerating trend in the global slideway oil market is the development of advanced formulations designed to optimize machine tool performance and precision. Modern Slideway Oils incorporate superior friction modifiers, anti-wear additives, and tackifiers that minimize stick-slip, ensuring smooth, accurate movement of machine components

- For instance, products such as Shell Tonna S3 M and Mobil Vactra Oil Series are formulated to provide excellent friction control and film strength, enhancing slideway stability and operational precision in CNC machines and lathes

- New-generation slideway oils reduce chatter, improve machine accuracy, and extend component life, which is critical for industries where micron-level precision is essential. In addition, specialized additives help resist coolant washout, reducing oil consumption and maintenance needs

- Integration with automated lubrication systems is also gaining traction, enabling precise, programmable oil delivery to slideways, improving operational efficiency and reducing waste. This aligns with broader industry movements toward Industry 4.0 and smart manufacturing

- With manufacturers demanding greater machine uptime and part quality, companies such as FUCHS and TotalEnergies are introducing slideway oils with enhanced compatibility for various metalworking fluids, reducing downtime due to contamination issues

- The market is seeing rising demand for premium slideway oils in sectors such as aerospace, automotive, and precision engineering, where machinery performance directly impacts productivity and product quality

What are the Key Drivers of Slideway Oil Market?

- Growing investments in precision manufacturing and machine tools across sectors such as automotive, aerospace, and heavy engineering are major factors driving the slideway oil market. High-performance slideway oils are essential to maintain machine accuracy, reduce wear, and support smooth operation under demanding conditions

- For instance, in March 2024, FUCHS Group launched a new generation of slideway oils under the RENOLIN MR Series, focusing on superior friction control and compatibility with diverse coolants, enhancing overall machine efficiency

- The rise of CNC machines, coupled with the global push toward automation and Industry 4.0 integration, is fueling demand for slideway oils that support precise motion control and reduced machine downtime

- In addition, slideway oils contribute to reducing operational costs by minimizing component wear, lowering energy consumption, and extending equipment life key factors driving adoption in competitive manufacturing environments

- The market also benefits from stringent regulations promoting workplace safety and equipment reliability, where properly lubricated machine slideways reduce the risk of malfunction and accidents

Which Factor is challenging the Growth of the Slideway Oil Market?

- One of the primary challenges facing the slideway oil market is the growing emphasis on environmental sustainability and the rising demand for eco-friendly lubricants. Many conventional slideway oils contain mineral oil-based formulations that may pose environmental concerns related to disposal and leakage

- Regulatory pressures and end-user demand for biodegradable or low-toxicity alternatives are pushing manufacturers to innovate, but developing high-performance eco-friendly slideway oils that match traditional formulations remains technically complex and cost-intensive

- For instance, while some companies offer bio-based slideway oils, their higher cost and limited availability can deter adoption, especially among small to medium-sized machine shops with tight operating budgets

- Another challenge lies in the need for slideway oils to be compatible with various coolants and metalworking fluids used in the same machinery. Incompatibilities can lead to lubricant degradation, increased maintenance costs, and machine performance issues

- Overcoming these barriers requires continuous R&D investments in high-performance, sustainable slideway oils that deliver equivalent or superior performance while meeting environmental standards. Companies investing in such innovations, along with user education on lubricant selection and maintenance best practices, will be crucial to unlocking further market growth

How is the Slideway Oil Market Segmented?

The market is segmented on the basis of product, base oil, slideway orientation, end use industry, and application.

• By Product

On the basis of product, the slideway oil market is segmented into ISO VG 68, ISO VG 220, ISO VG 32, ISO VG 100, and Others. The ISO VG 68 segment dominated the Slideway Oil market with the largest revenue share of 39.5% in 2024, owing to its widespread use in machine tools and equipment requiring moderate viscosity for precise slideway movement. ISO VG 68 offers an optimal balance between friction reduction and lubrication performance, making it the preferred choice for a wide range of industrial applications.

The ISO VG 220 segment is anticipated to witness the fastest growth rate of 19.8% from 2025 to 2032, driven by the rising adoption of heavy-duty machinery and the need for higher viscosity oils that ensure robust film strength, especially in demanding applications such as large CNC machines and heavy presses.

• By Application

On the basis of application, the slideway oil market is segmented into Machinery and Equipment, Bearing, Steel Ball, and Other. The Machinery and Equipment segment accounted for the largest market revenue share of 46.7% in 2024, driven by the extensive use of Slideway Oils in precision machinery across industries such as automotive, aerospace, and manufacturing. Reliable lubrication enhances accuracy, reduces wear, and extends machine life, making it critical for operational efficiency.

The Bearing segment is expected to witness the fastest CAGR from 2025 to 2032, fueled by increasing demand for high-performance lubricants in bearings used within precision machine tools and industrial equipment, where minimal friction and smooth operation are essential.

• By Base Oil

On the basis of base oil, the slideway oil market is segmented into Mineral Oil Based and Synthetic Oil Based. The Mineral Oil Based segment dominated the market with the largest revenue share of 58.4% in 2024, attributed to its affordability, wide availability, and proven performance in general industrial applications. Mineral-based Slideway Oils remain the standard for many machine tool lubrication needs where extreme conditions are not prevalent.

The Synthetic Oil Based segment is expected to witness the fastest growth rate of 22.3% from 2025 to 2032, driven by its superior thermal stability, extended service life, and compatibility with high-precision, high-load machinery. Industries emphasizing precision and sustainability increasingly prefer synthetic options for reduced downtime and better operational efficiency.

• By Slideway Orientation

On the basis of slideway orientation, the slideway oil market is segmented into Horizontal Slideway Lubrication, Vertical Slideway Lubrication, and Inclined Slideway Lubrication. The Horizontal Slideway Lubrication segment held the largest market revenue share of 51.6% in 2024, driven by the dominance of horizontal machine tool setups, particularly in lathes, milling machines, and CNC equipment, where precision slideway lubrication is critical for operational accuracy.

The Vertical Slideway Lubrication segment is anticipated to witness the fastest CAGR from 2025 to 2032, as advancements in machine design and manufacturing processes drive the demand for vertical machinery requiring specialized lubrication to overcome gravitational challenges and ensure smooth, accurate movement.

• By End Use Industry

On the basis of end use industry, the slideway oil market is segmented into Automobile Industries, Construction Industries, Food and Beverages Industries, Plastic Industries, Mining Industries, and Others. The Automobile Industries segment dominated the market with the largest revenue share of 33.1% in 2024, owing to the extensive reliance on precision machinery for component manufacturing, assembly lines, and tool maintenance, where Slideway Oils play a critical role in ensuring production quality and efficiency.

The Mining Industries segment is projected to witness the fastest growth rate of 20.4% from 2025 to 2032, driven by the increasing mechanization of mining operations and the demand for durable lubrication solutions capable of withstanding harsh operating environments and heavy loads.

Which Region Holds the Largest Share of the Slideway Oil Market?

- North America dominated the slideway oil market with the largest revenue share of 40.5% in 2024, driven by the strong presence of advanced manufacturing industries, rising investments in precision machinery, and the growing emphasis on equipment efficiency and longevity

- The region’s widespread use of CNC machines, lathes, and milling equipment in automotive, aerospace, and metalworking industries significantly contributes to the demand for Slideway Oils, ensuring smooth machine operations and reducing wear

- High awareness of equipment maintenance, coupled with the region’s focus on productivity and advanced lubricants, makes slideway oils a critical component for enhancing machine tool performance across both small-scale workshops and large industrial plants

U.S. Slideway Oil Market Insight

U.S. slideway oil market captured the largest revenue share in 2024 within North America, supported by the country's leadership in precision manufacturing and technological advancements in industrial lubricants. The demand for slideway oils is propelled by the growing adoption of automated machining processes, smart factories, and predictive maintenance strategies. In addition, increased focus on high-quality production in industries such as automotive, aerospace, and defense continues to drive market growth, along with stringent standards for machinery performance and reliability.

Europe Slideway Oil Market Insight

Europe slideway oil market is expected to expand at a steady CAGR during the forecast period, driven by the region's well-established engineering, automotive, and machine tool industries. The demand for slideway oils is supported by Europe's emphasis on precision manufacturing, energy efficiency, and sustainability. Moreover, regulations promoting equipment longevity and reduced environmental impact are pushing manufacturers to adopt high-performance, eco-friendly Slideway Oils in both new equipment and retrofit projects.

U.K. Slideway Oil Market Insight

U.K. slideway oil market is anticipated to grow at a notable CAGR during the forecast period, fueled by ongoing investments in advanced manufacturing, metalworking, and aerospace industries. The country's focus on high-quality production standards, combined with efforts to reduce equipment downtime and maintenance costs, is encouraging the adoption of premium slideway oils. In addition, initiatives promoting innovation and smart factory technologies are expected to further support market growth.

Germany Slideway Oil Market Insight

Germany slideway oil market is poised to grow at a significant CAGR, supported by the country's reputation as a global hub for engineering excellence and precision manufacturing. With strong demand for CNC machines, machine tools, and industrial automation, slideway oils play a crucial role in maintaining machine performance and accuracy. Germany’s emphasis on technological innovation, sustainability, and machinery lifespan is also driving the uptake of advanced lubricant solutions tailored for high-performance industrial environments.

Which Region is the Fastest Growing Region in the Slideway Oil Market?

Asia-Pacific slideway oil market is expected to grow at the fastest CAGR of 13.6% from 2025 to 2032, driven by rapid industrialization, growing machine tool demand, and technological advancements in emerging economies such as China, India, and Japan. The region’s thriving manufacturing sector, especially in automotive, electronics, and metalworking, fuels the need for reliable slideway oils that enhance machinery performance and precision. Government initiatives promoting industrial development and the adoption of smart manufacturing solutions further contribute to market growth, as companies seek lubricants that optimize machine efficiency and reduce maintenance costs.

Japan Slideway Oil Market Insight

Japan slideway oil market is gaining momentum, driven by the country's leadership in robotics, automation, and high-precision manufacturing. Japanese industries emphasize machinery performance and operational efficiency, increasing demand for high-quality Slideway Oils that reduce wear and ensure consistent, precise movement in machine tools. The aging workforce also accelerates automation trends, requiring reliable lubricants to support advanced, automated systems in both industrial and workshop settings.

China Slideway Oil Market Insight

China slideway oil market accounted for the largest market revenue share in Asia-Pacific in 2024, supported by rapid industrial expansion, urbanization, and the country's strong position as a global manufacturing powerhouse. With increasing investments in advanced machinery, CNC equipment, and automation, the demand for Slideway Oils is rising across industries such as automotive, electronics, and heavy equipment. Domestic production, combined with the rising quality standards in Chinese manufacturing, continues to drive Slideway Oil market growth across both domestic and export-oriented sectors.

Which are the Top Companies in Slideway Oil Market?

The slideway oil industry is primarily led by well-established companies, including:

- Exxon Mobil Corporation (U.S.)

- Shell (Netherlands)

- Chevron Corporation (U.S.)

- Total Energies (France)

- BP p.l.c (U.K.)

- FUCHS (Germany)

- Phillips 66 Company (U.S.)

- Exol Lubricants Limited (U.K.)

- Witham Group (U.K.)

- Rymax Lubricants (Netherlands)

- Repsol (Spain)

- Cougar Lubricants International Ltd (U.K.)

- Schaeffer Manufacturing Co. (U.S.)

- Pennine Lubricants (U.K.)

- FRONTIER PERFORMANCE LUBRICANTS, INC. (U.S.)

- UNIL (Belgium)

What are the Recent Developments in Global Slideway Oil Market?

- In December 2023, LANXESS, a renowned specialty chemicals company, expanded its production capacity for sustainable light-colored sulfur carriers by several kilotons, catering to applications such as greases, metalworking fluids, slideway oils, and gear oils, reinforcing its commitment to supporting high-performance lubrication solutions for industrial needs

- In November 2022, Flexilube, a leading South African manufacturer of metalworking fluids, introduced a versatile lubricant that combines the functions of hydraulic, slideway, and gearbox oils, effectively helping machine shops reduce inventory complexity and streamline operations through product consolidation

- In January 2022, Niigata Machine Techno USA Inc. unveiled its HN800-V horizontal machining center (HMC), designed to deliver the precision of a high-speed jig borer at only a marginal cost increase compared to conventional HMCs, marking a breakthrough with its status as the world’s first machining center featuring hardened and ground inverted v-shaped slideways for superior accuracy and rigidity

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Slideway Oil Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Slideway Oil Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Slideway Oil Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.