Global Smart Pneumatic Actuator Market

Market Size in USD Billion

CAGR :

%

USD

2.37 Billion

USD

3.79 Billion

2024

2032

USD

2.37 Billion

USD

3.79 Billion

2024

2032

| 2025 –2032 | |

| USD 2.37 Billion | |

| USD 3.79 Billion | |

|

|

|

|

What is the Global Smart Pneumatic Actuator Market Size and Growth Rate?

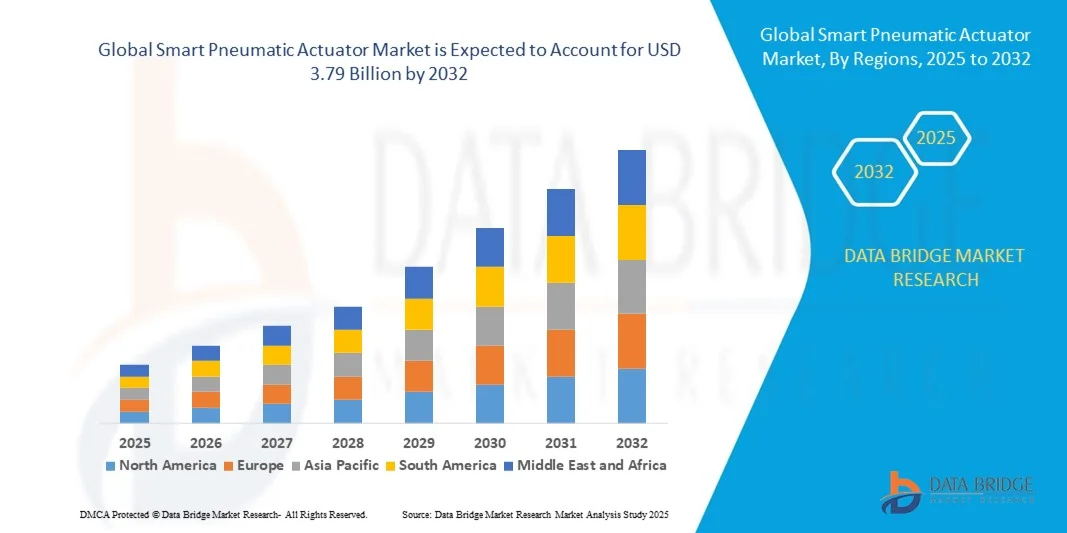

- The global smart pneumatic actuator market size was valued at USD 2.37 billion in 2024 and is expected to reach USD 3.79 billion by 2032, at a CAGR of 6.05% during the forecast period

- The growing demand for smart pneumatics due to remote monitoring capabilities, increasing penetration of digitization and internet of things, rising need for wireless infrastructure to maintain equipment in plants, growing awareness toward predictive maintenance, adoption of stringent environmental and safety regulations in energy industry are some of the major as well as important factors which will such asly to accelerate the growth of the smart pneumatic actuator market

What are the Major Takeaways of Smart Pneumatic Actuator Market?

- Increasing number of technological advancements with improved capabilities along with emergence of machine learning and artificial intelligence which will further contribute by generating immense opportunities that will led to the growth of the smart pneumatic actuator market in the above-mentioned projected timeframe

- Increasing need of high capital investment, lack of standardized certifications and government policies along with lack of common platform for Zigbee, Ethernet, and profibus which will such asly to act as market restraints factor for the growth of the smart pneumatic actuator in the above-mentioned forecasted period

- Asia-Pacific dominated the smart pneumatic actuator market with the largest revenue share of 42.25% in 2024, driven by rapid industrialization, urbanization, and growing adoption of automation technologies across multiple sectors, including energy, oil and gas, and manufacturing

- The North America Smart Pneumatic Actuator market is projected to grow at the fastest CAGR of 11.26 % from 2025 to 2032, driven by technological advancements, rising demand for industrial automation, and strong adoption across energy, automotive, and water treatment sectors

- The hardware segment dominated the market with a revenue share of 55% in 2024, driven by the widespread installation of physical actuators in industrial and commercial applications

Report Scope and Smart Pneumatic Actuator Market Segmentation

|

Attributes |

Smart Pneumatic Actuator Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Smart Pneumatic Actuator Market?

Integration of AI and Smart Control Systems for Enhanced Automation

- A major and accelerating trend in the global smart pneumatic actuator market is the integration of artificial intelligence (AI) and smart control technologies into actuator systems. These advancements allow actuators to operate with higher precision, predictive maintenance capabilities, and seamless integration with digital control platforms, enhancing industrial efficiency

- For instance, some AI-enabled smart actuators can autonomously adjust pressure and flow rates based on historical usage data, minimizing downtime and optimizing energy consumption. In addition, smart actuators with connectivity options support remote monitoring and control via industrial IoT platforms, streamlining operations across multiple sites

- AI integration enables predictive diagnostics, automatic fault detection, and adaptive control, allowing systems to respond to changing environmental or operational conditions. Voice-enabled interfaces and mobile app integrations further enhance real-time accessibility and operational convenience

- The seamless integration of smart pneumatic actuators with broader automation platforms facilitates centralized monitoring of complex systems, enabling companies to reduce manual intervention and improve operational efficiency

- This trend is reshaping expectations for industrial automation, with manufacturers increasingly prioritizing intelligent, connected, and self-regulating actuators. Companies such as Emerson and Parker Hannifin are actively developing AI-enabled actuator solutions with predictive capabilities and cloud-based control integration

- Demand for Smart Pneumatic Actuators with AI and automation integration is rising rapidly across industries such as automotive, manufacturing, and energy, as businesses seek operational efficiency, reliability, and cost reduction

What are the Key Drivers of Smart Pneumatic Actuator Market?

- The growing need for automation and precision control in industries is a key driver for smart pneumatic actuators. Advanced actuator systems are critical in optimizing processes, reducing energy consumption, and improving safety standards

- For instance, in 2024, Emerson Electric Co. introduced AI-enabled actuators that automatically adjust operations based on load and environmental conditions, enhancing efficiency in manufacturing and process industries. Such initiatives are expected to fuel market growth in the coming years

- Increasing industrial digitization and the adoption of Industry 4.0 technologies are driving the integration of smart actuators into production lines, enabling real-time data collection, predictive maintenance, and remote control functionalities

- Furthermore, industries are adopting Smart Pneumatic Actuators for reliability and safety, as these systems reduce human error, ensure consistent performance, and allow automated emergency shutdowns when needed

- The flexibility of these actuators for retrofitting into existing systems, combined with user-friendly control interfaces, remote monitoring, and predictive analytics, is encouraging widespread adoption across manufacturing, chemical, energy, and automotive sectors

Which Factor is Challenging the Growth of the Smart Pneumatic Actuator Market?

- High costs and technical complexity remain major barriers to adoption, particularly for small and medium-sized enterprises. Advanced smart pneumatic actuators with AI, connectivity, and cloud-based control require higher initial investments compared to conventional pneumatic systems

- Integration with industrial networks and IoT platforms introduces cybersecurity risks, as connected actuators can be vulnerable to hacking, data breaches, or operational disruptions if not properly secured

- Addressing these challenges requires manufacturers to implement robust encryption, secure authentication protocols, and regular software updates, building trust among industrial users. Companies such as Parker Hannifin and Emerson emphasize cybersecurity and reliability in their solutions

- Furthermore, some industries face a skills gap, as staff must be trained to operate and maintain advanced actuator systems. This challenge can slow adoption, especially in developing regions or traditional manufacturing environments

- Overcoming these barriers through cost reduction, improved training programs, and enhanced cybersecurity measures will be vital to sustain long-term market growth, making Smart Pneumatic Actuators a standard solution for industrial automation

How is the Smart Pneumatic Actuator Market Segmented?

The smart pneumatic actuator market is segmented on the basis of component and industry.

- By Component

On the basis of component, the smart pneumatic actuator market is segmented into hardware, software, and services. The hardware segment dominated the market with a revenue share of 55% in 2024, driven by the widespread installation of physical actuators in industrial and commercial applications. Hardware components, including pneumatic cylinders, valves, and actuators, are essential for precise motion control and process automation, making them the backbone of actuator systems. The strong demand is fueled by their durability, performance, and compatibility with smart control systems and IoT-enabled monitoring. Hardware upgrades and retrofits in existing industrial plants are also boosting market adoption.

The software segment is expected to witness the fastest CAGR of 22% from 2025 to 2032, driven by growing integration with AI, predictive maintenance tools, and digital twin platforms. Software enables centralized control, process optimization, and real-time monitoring, enhancing efficiency across manufacturing, energy, and water management industries.

- By Industry

On the basis of industry, the smart pneumatic actuator market is segmented into oil and gas, energy and power, water and wastewater, automotive, semiconductor, food and beverages, and others. The energy and power segment held the largest market revenue share of 32% in 2024, supported by the growing need for automation, reliability, and remote monitoring in power generation and distribution facilities. Smart actuators ensure precise valve control, enhance safety, and optimize energy consumption, making them indispensable in modern energy infrastructure.

The automotive industry segment is projected to witness the fastest CAGR of 21% from 2025 to 2032, driven by increased adoption of automated assembly lines, robotics integration, and electric vehicle manufacturing. Smart Pneumatic Actuators in automotive applications enhance production efficiency, reduce operational downtime, and support high-precision manufacturing standards, fueling market growth across global automotive hubs. Other sectors, including water treatment and food processing, are also increasingly adopting smart actuators for safety, efficiency, and compliance purposes.

Which Region Holds the Largest Share of the Smart Pneumatic Actuator Market?

- Asia-Pacific dominated the smart pneumatic actuator market with the largest revenue share of 42.25% in 2024, driven by rapid industrialization, urbanization, and growing adoption of automation technologies across multiple sectors, including energy, oil and gas, and manufacturing

- Consumers and industrial operators in the region highly value the reliability, efficiency, and precision offered by Smart Pneumatic Actuators, alongside the growing integration with IoT and digital control systems

- The widespread adoption is further supported by government initiatives promoting smart manufacturing, high infrastructure investments, and the presence of major actuator manufacturers in countries such as China, Japan, and India, establishing Smart Pneumatic Actuators as a preferred solution for industrial and commercial applications

China Smart Pneumatic Actuator Market Insight

The China smart pneumatic actuator market accounted for the largest revenue share in Asia-Pacific in 2024, fueled by rapid urbanization, increasing industrial automation, and strong domestic manufacturing capabilities. The adoption of smart actuators in factories, energy plants, and water treatment facilities is rising due to enhanced process efficiency, energy optimization, and IoT integration. China’s push towards smart cities and industrial digitization further supports market expansion.

Japan Smart Pneumatic Actuator Market Insight

The Japan market is gaining momentum due to its advanced manufacturing ecosystem, high-tech adoption, and emphasis on automation. Industrial sectors, including automotive and semiconductor manufacturing, are increasingly integrating Smart Pneumatic Actuators to improve precision, reliability, and productivity. Japan’s aging workforce is also accelerating demand for automated solutions that simplify industrial operations.

North America Smart Pneumatic Actuator Market Insight

The North America smart pneumatic actuator market is projected to grow at the fastest CAGR of 11.26 % from 2025 to 2032, driven by technological advancements, rising demand for industrial automation, and strong adoption across energy, automotive, and water treatment sectors. The presence of major actuator manufacturers, supportive government policies, and increasing investments in smart factory initiatives are accelerating market growth. The U.S. and Canada are key contributors, leveraging Industry 4.0 and IoT-enabled automation technologies.

U.S. Smart Pneumatic Actuator Market Insight

The U.S. market is a primary driver of North America’s growth, fueled by widespread adoption of advanced manufacturing technologies, energy automation, and smart infrastructure projects. Integration with predictive maintenance and AI-based monitoring systems is increasingly common across industrial facilities, further propelling market expansion.

Europe Smart Pneumatic Actuator Market Insight

The Europe market is expanding steadily, driven by stringent industrial safety regulations, demand for energy efficiency, and adoption of automation across manufacturing and utilities sectors. Countries such as Germany and the U.K. are experiencing growth in industrial and energy applications, with increasing investments in smart manufacturing and process optimization.

Which are the Top Companies in Smart Pneumatic Actuator Market?

The smart pneumatic actuator industry is primarily led by well-established companies, including:

- Emerson Electric Co. (U.S.)

- Parker Hannifin Corp (U.S.)

- Bimba Manufacturing Company (U.S.)

- Rotork (U.K.)

- Festo Corporation (Germany)

- Thomson Industries, Inc. (U.S.)

- BASSO Industry Corporation (Italy)

- Bosch Rexroth Ltd. (Germany)

- Chicago Pneumatic (U.S.)

- Delton Pneumatics (India)

- Eaton (U.S.)

- Gardner Denver (U.S.)

- Ingersoll-Rand plc (Ireland/U.S.)

- Jiffy Air Tool (U.S.)

- KRAMER ELECTRONICS INDIA PVT. LTD (India)

- Makita Corporation (Japan)

- by MANN+HUMMEL (Germany)

- MITSUBISHI HEAVY INDUSTRIES MACHINERY SYSTEMS, LTD. (Japan)

- Pepperl+Fuchs (India) Pvt. Ltd. (India)

- NINGBO SMART PNEUMATIC CO LTD (China)

- SMC Corporation of America (U.S.)

- Stanley Black & Decker, Inc. (U.S.)

- VAC-U-MAX (U.S.)

What are the Recent Developments in Global Smart Pneumatic Actuator Market?

- In June 2025, Rotork and Rockwell Automation collaborated to feature the Rotork IQ3 Pro electric actuator with EtherNet/IP connectivity in the Rockwell Automation Technology Partner Program, making it easier for engineers, system integrators, and end users to integrate Rotork’s actuator solutions into industrial automation projects, strengthening the accessibility of advanced actuator technologies

- In January 2025, SMC Corporation introduced the Rotary Actuators CRB/CDRB Series, available in double vane for sizes 10 to 40, featuring a compact body design with a built-in angle adjustment unit and auto switch unit, enhancing operational functionality and ease of use, thereby improving precision and efficiency in automated systems

- In November 2024, Curtiss-Wright Corporation expanded its range of Exlar electric actuators by launching hygienic actuators made with FDA-approved materials and finishes, designed for automation in the food & beverages, packaging, and pharmaceuticals industries, enabling customers to achieve hygienic certifications more cost-effectively while maintaining high operational standards

- In April 2024, Emerson Electric Co. launched the ASCO Series 148/149 safety valve and motorized actuator for industrial fuel oil burner recirculation and safety shutoff, designed to prevent overpressure, leaks, and system failures, providing a reliable and versatile solution for diverse combustion system applications and enhancing industrial safety protocols

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Smart Pneumatic Actuator Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Smart Pneumatic Actuator Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Smart Pneumatic Actuator Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.