Global Trivalent Chromium Finishing Market

Market Size in USD Million

CAGR :

%

USD

380.21 Million

USD

553.24 Million

2024

2032

USD

380.21 Million

USD

553.24 Million

2024

2032

| 2025 –2032 | |

| USD 380.21 Million | |

| USD 553.24 Million | |

|

|

|

|

What is the Global Trivalent Chromium Finishing Market Size and Growth Rate?

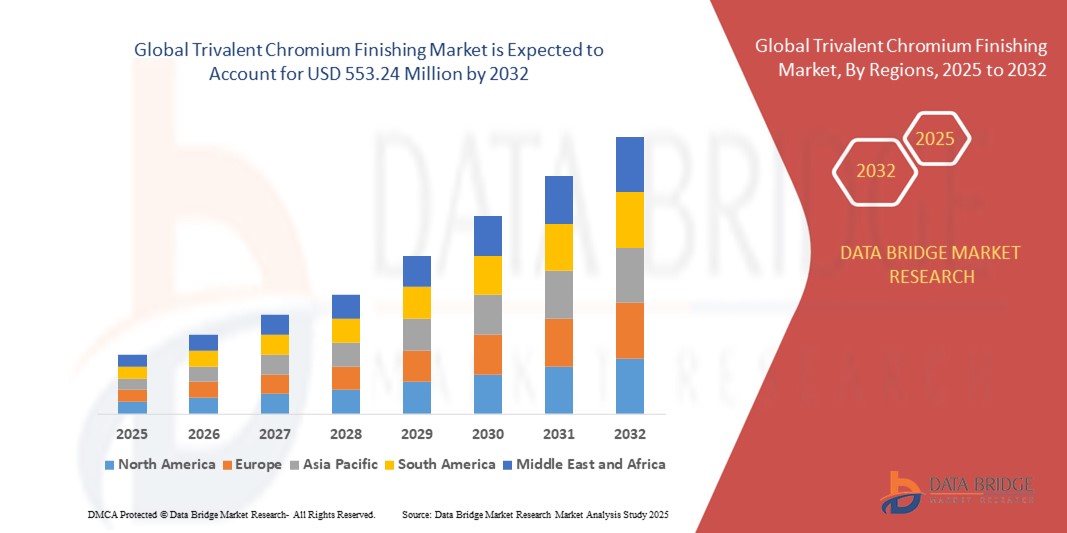

- The global trivalent chromium finishing market size was valued at USD 380.21 million in 2024 and is expected to reach USD 553.24 million by 2032, at a CAGR of 4.80% during the forecast period

- The growing number of applications from automotive industry is amongst the major factor influencing the growth of the market. The high growth of printed circuit board industry, rise in the usages of chemicals in aerospace maintenance, repair and overhauls, favorable policies of the government are also such asly to enhance the growth of the market in the forecast period

What are the Major Takeaways of Trivalent Chromium Finishing Market?

- Stringent environmental regulations mandating the reduction of hazardous hexavalent chromium usage have emerged as a pivotal driver for the global trivalent chromium finishing market. Trivalent chromium coatings serve as a sustainable alternative, aligning with regulatory frameworks focused on minimizing environmental impact

- The demand for trivalent chromium finishing is propelled, fostering a paradigm shift towards eco-friendly and compliant surface treatment solutions, as industries strive to comply with these regulations

- Asia-Pacific dominated the trivalent chromium finishing market with the largest revenue share of 42.3% in 2024, attributed to its booming industrial sector, rising environmental awareness, and supportive government regulations

- North America is projected to witness the fastest CAGR of 13.1% from 2025 to 2032, led by increasing environmental regulations and the shift toward sustainable industrial practices

- The Plating segment dominated the market with the largest market revenue share of 52.6% in 2024, attributed to its widespread use in both decorative and functional applications

Report Scope and Trivalent Chromium Finishing Market Segmentation

|

Attributes |

Trivalent Chromium Finishing Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Trivalent Chromium Finishing Market?

Shift Towards Environmentally Sustainable and Regulatory-Compliant Coatings

- A prominent trend shaping the trivalent chromium finishing market is the shift from hexavalent chromium to trivalent chromium processes, driven by stringent environmental regulations and rising demand for eco-friendly surface finishing. This transition aligns with the global push for sustainable manufacturing practices

- Unsuch as hexavalent chromium, which is known to be carcinogenic and environmentally hazardous, trivalent chromium offers comparable corrosion resistance and aesthetics with significantly reduced toxicity, making it an ideal alternative for industries aiming to meet REACH and RoHS compliance

- Automotive, aerospace, and consumer electronics manufacturers are actively adopting trivalent chromium to meet corporate sustainability goals and avoid regulatory penalties. For instance, Atotech has launched Tridur ZnNi H5.2, a hexavalent-free trivalent chromium passivate that meets demanding corrosion resistance requirements and EU directives

- The transition is also supported by advancements in chemistry and plating technologies, making trivalent-based processes more cost-effective and technically feasible across a wide range of substrates

- As green manufacturing becomes a global imperative, the adoption of trivalent chromium finishing is expected to increase steadily across end-use industries, replacing hazardous coatings and driving long-term growth in this segment

What are the Key Drivers of Trivalent Chromium Finishing Market?

- Growing environmental awareness and tightening regulations on hazardous substances are major drivers accelerating the shift from hexavalent to trivalent chromium finishing. Countries across Europe, North America, and parts of Asia are enforcing bans or restrictions on hexavalent chromium in industrial applications

- For instance, in March 2024, MacDermid Enthone Industrial Solutions expanded its portfolio of trivalent chromium solutions by introducing ENVIRAL CR 500, a decorative trivalent chromium plating process designed to replace legacy hexavalent systems

- Increasing demand for durable, aesthetic, and eco-safe coatings in automotive, electronics, and appliances is further pushing manufacturers to adopt trivalent chromium finishing as a superior alternative

- In addition, the trend towards lightweight metals such as aluminum and magnesium in vehicle manufacturing has amplified the need for advanced surface finishing that is both environmentally safe and corrosion-resistant

- Government initiatives promoting green technologies, coupled with incentives for sustainable production, are also supporting the adoption of trivalent chromium systems among metal finishing providers globally

Which Factor is challenging the Growth of the Trivalent Chromium Finishing Market?

- Despite its benefits, the higher cost and complexity of implementing trivalent chromium plating systems remain key challenges, especially for small-scale plating shops or manufacturers in cost-sensitive regions

- Establishing trivalent chromium lines often involves upgrading existing infrastructure, investing in new chemistry and equipment, and training personnel to manage the altered process parameters, which can be cost-prohibitive

- For instance, Chem Processing, Inc., while adopting trivalent chromium, cited the need for retooling and testing to match the performance of legacy hexavalent systems across various substrates

- Moreover, variability in appearance—particularly for decorative finishes—can make trivalent chromium less desirable for certain aesthetic-critical applications, such as luxury automotive trims or high-end consumer goods

- To overcome these challenges, manufacturers are investing in process optimization, while chemical suppliers focus on developing more adaptable trivalent chromium formulations that offer consistent appearance and performance across diverse applications

- Continued R&D investments, along with government-backed sustainability programs, will be crucial to address these barriers and unlock the full market potential of trivalent chromium finishing

How is the Trivalent Chromium Finishing Market Segmented?

The market is segmented on the basis of system, application, and end-use.

• By System

On the basis of system, the trivalent chromium finishing market is segmented into Plating, Conversion Coatings, and Passivation. The Plating segment dominated the market with the largest market revenue share of 52.6% in 2024, attributed to its widespread use in both decorative and functional applications. Plating offers superior corrosion resistance, improved wear protection, and an attractive finish, making it the preferred system for critical industries such as automotive and aerospace. Manufacturers continue to favor trivalent chromium plating over traditional hexavalent options due to its compliance with environmental regulations and improved worker safety.

The Conversion Coatings segment is expected to witness the fastest CAGR from 2025 to 2032, driven by growing demand in surface preparation and corrosion protection for components across industrial and hydraulic sectors. These coatings serve as a cost-effective solution for improving paint adhesion and offering a corrosion-resistant base layer.

- By Application

On the basis of application, the trivalent chromium finishing market is segmented into Decorative and Functional applications. The Decorative segment led the market in 2024 with the largest revenue share of 58.9%, driven by increasing demand from automotive trims, household fixtures, and electronic devices. Trivalent chromium coatings are increasingly favored in decorative applications due to their bright finish, durability, and non-toxic nature. The finish replicates the appearance of hexavalent chromium while offering an eco-friendlier profile, which is propelling its adoption across consumer-facing industries.

Meanwhile, the Functional segment is projected to experience the fastest growth rate during the forecast period, owing to its critical role in enhancing durability, wear resistance, and performance in harsh environments. The shift toward high-performance coatings in aerospace and heavy machinery is further fueling demand for functional trivalent chromium finishes.

- By End-Use

On the basis of end-use, the trivalent chromium finishing market is segmented into Automotive, Oil and Gas, Aerospace, Hydraulics and Heavy Machinery, and Others. The Automotive segment held the dominant market share of 38.4% in 2024, supported by the rising demand for lightweight, corrosion-resistant coatings in both interior and exterior vehicle components. Automotive manufacturers are rapidly shifting toward trivalent chromium finishing due to stringent emission and safety regulations as well as consumer demand for aesthetically appealing components.

The Aerospace segment is expected to register the highest CAGR from 2025 to 2032, driven by the need for precision coatings that offer high strength, reduced toxicity, and thermal resistance. As global air traffic and aircraft production rise, so does the demand for safer and sustainable surface finishing solutions.

Which Region Holds the Largest Share of the Trivalent Chromium Finishing Market?

- Asia-Pacific dominated the trivalent chromium finishing market with the largest revenue share of 42.3% in 2024, attributed to its booming industrial sector, rising environmental awareness, and supportive government regulations

- The increasing shift toward eco-friendly alternatives to hexavalent chromium, especially in automotive, electronics, and aerospace industries, is accelerating the adoption of trivalent chromium technologies across the region

- The presence of leading manufacturers and metal finishers, along with a cost-effective labor force and strong R&D investment, is solidifying Asia-Pacific’s lead in the global market

China Trivalent Chromium Finishing Market Insight

The China trivalent chromium finishing market captured the largest revenue share in Asia-Pacific in 2024 due to its rapid industrial expansion, stringent environmental policies, and growing investments in automotive and consumer electronics. The government’s push for sustainable manufacturing practices, along with growing export demand, is fostering a shift toward trivalent chromium finishing across sectors. Local players are also accelerating production of REACH- and RoHS-compliant coatings, further boosting the market.

Japan Trivalent Chromium Finishing Market Insight

The Japan market is experiencing steady growth driven by the country's emphasis on advanced manufacturing, precision engineering, and green technologies. Trivalent chromium finishing is gaining traction in automotive, robotics, and electronic components, where durability and environmental compliance are crucial. Japan’s strong focus on sustainability and technological innovation is supporting wider adoption across industrial applications, particularly for high-performance corrosion-resistant coatings.

India Trivalent Chromium Finishing Market Insight

India’s trivalent chromium finishing market is expanding rapidly, fueled by Make in India initiatives, foreign direct investments, and increasing demand in automotive and metal fabrication sectors. Environmental concerns and compliance with international standards are encouraging industries to replace traditional plating methods. The country’s push for industrial modernization, alongside growing awareness of worker safety and environmental health, is propelling the market forward.

Which Region is the Fastest Growing in the Trivalent Chromium Finishing Market?

North America is projected to witness the fastest CAGR of 13.1% from 2025 to 2032, led by increasing environmental regulations and the shift toward sustainable industrial practices. The adoption of trivalent chromium finishing is rapidly rising across automotive, aerospace, and medical device manufacturing, as companies strive to meet EPA guidelines and customer expectations for eco-friendly coatings. The region’s commitment to green chemistry, coupled with high R&D spending and demand for high-performance surface finishes, will continue to drive market growth.

U.S. Trivalent Chromium Finishing Market Insight

The U.S. market captured a significant share in 2024 within North America, spurred by regulatory compliance and increasing demand from the defense and aerospace sectors. Growing pressure to eliminate hexavalent chromium due to its carcinogenic nature is prompting a swift transition to trivalent alternatives. U.S.-based manufacturers are investing heavily in process modernization and eco-compliant coatings, ensuring sustained momentum over the forecast period.

Canada Trivalent Chromium Finishing Market Insight

The Canada market is experiencing healthy growth driven by the nation’s strong emphasis on sustainable manufacturing and adherence to REACH- and RoHS-compliant processes. With increasing demand in automotive, electronics, and infrastructure sectors, Canadian companies are actively investing in modern plating facilities and green technologies. Government-backed environmental initiatives and industrial development programs further support market expansion.

Mexico Trivalent Chromium Finishing Market Insight

Mexico’s trivalent chromium finishing market is growing steadily, supported by the country’s status as a manufacturing hub for automotive, aerospace, and electronics. International players setting up operations in Mexico are implementing environmentally friendly finishing technologies to comply with U.S. and European standards. The availability of skilled labor and strategic trade partnerships is enhancing the country’s market potential for trivalent chromium applications.

Which are the Top Companies in Trivalent Chromium Finishing Market?

The trivalent chromium finishing industry is primarily led by well-established companies, including:

- MacDermid, Inc. (U.S.)

- Ronatec C2C, Inc. (U.S.)

- Atotech (Germany)

- Chem Processing, Inc. (U.S.)

- Kakihara Industries Co., Ltd. (Japan)

- Sarrel (France)

- Columbia Chemical (U.S.)

What are the Recent Developments in Global Trivalent Chromium Finishing Market?

- In April 2025, Quaker Houghton announced the acquisition of Dipsol Chemicals Co., Ltd. for approximately USD 153 million, aiming to broaden its portfolio of advanced plating chemical solutions for automotive and industrial sectors. This strategic move reinforces Quaker Houghton’s foothold in the Asian market while integrating specialized trivalent chromium technologies into its offerings. This acquisition positions the company as a key player in environmentally sustainable surface finishing solutions

- In January 2025, Integer Holdings completed the acquisition of Precision Coating, a provider of surface functionality enhancement services for medical devices, thereby expanding its capabilities in specialized surface treatments, including trivalent chromium coatings for implants and surgical tools. The deal strengthens Integer’s position in the medical device manufacturing market with a focus on performance and safety

- In April 2023, according to an article published by Finishing and Coating, recent research has focused on improving the wear performance of trivalent chromium coatings, which is crucial for applications in aerospace and ground-based systems. Although traditional hexavalent chromium coatings are known for superior wear resistance, their toxic nature has prompted advancements in trivalent alternatives. This research highlights the industry's shift toward safer, high-performance coating technologies

- In May 2022, Atotech formed a business partnership with Schweitzer Engineering Laboratories, Inc., under which Atotech’s Uniplate equipment will be utilized at a newly established PCB manufacturing facility in Idaho, U.S. This collaboration supports advanced and environmentally friendly surface treatment processes in electronics manufacturing

- In March 2022, MacDermid, Inc. finalized the acquisition of Alent PLC, a division of Platform Specialty Products, and subsequently created a new division named Performance Solutions by integrating both business operations. This merger aimed to offer greater innovation and service across the global finishing supply chain. The integration enhances global service capabilities and strengthens product innovation in the trivalent chromium sector

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Trivalent Chromium Finishing Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Trivalent Chromium Finishing Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Trivalent Chromium Finishing Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.