Middle East And Africa Plastic Compounding Market

Market Size in USD Billion

CAGR :

%

USD

10.48 Billion

USD

14.98 Billion

2024

2032

USD

10.48 Billion

USD

14.98 Billion

2024

2032

| 2025 –2032 | |

| USD 10.48 Billion | |

| USD 14.98 Billion | |

|

|

|

|

Middle East and Africa Plastic Compounding Market Size

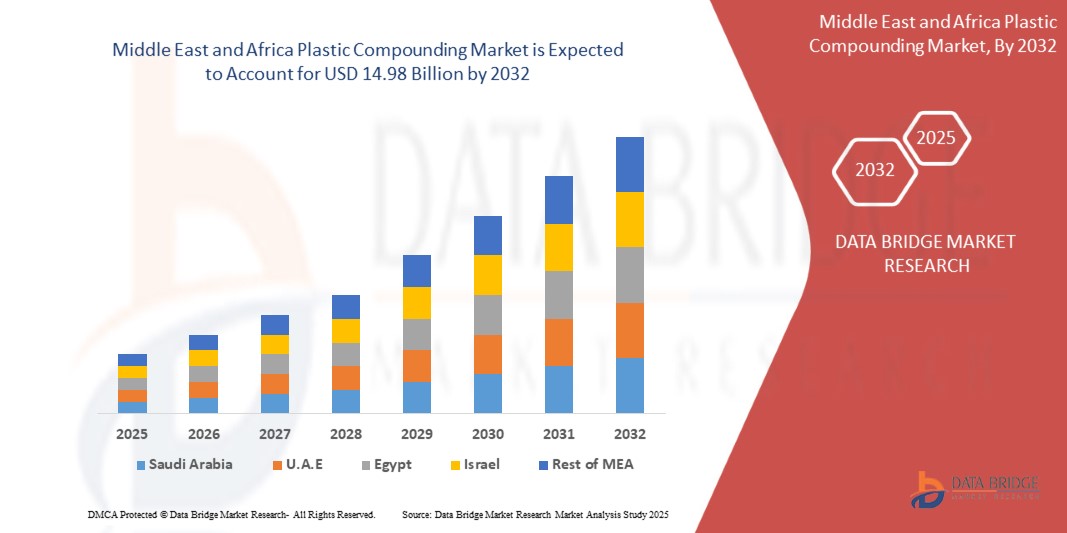

- The Middle East and Africa Plastic Compounding Market size was valued at USD 10.48 billion in 2024 and is expected to reach USD 14.98 billion by 2032, at a CAGR of 4.61% during the forecast period by Shift towards recyclable and biodegradable plastic compounds due to environmental regulations, advancements in compounding technologies improving product performance and cost-efficiency and supportive government policies and initiatives promoting the use of plastics in various industries

- Furthermore, the market is expected to growing use of bioplastics and sustainable compound alternatives, Surge in electric vehicle adoption requiring advanced polymers and Increasing demand for recyclable and circular plastic solutions

Middle East and Africa Plastic Compounding Market Analysis

- The global rise in the shift towards recyclable and biodegradable plastic compounds due to environmental regulations, advancements in compounding technologies improving product performance and cost-efficiency

- Key factors include the global rise in the shift towards recyclable and biodegradable plastic compounds due to environmental regulations, advancements in compounding technologies improving product performance and cost-efficiency, growing demand from energy transmission sectors, and increasing investments in grid modernization and cross-border infrastructure

- Saudi Arabia dominates the Middle East and Africa Plastic Compounding Market, holding the largest revenue share of 24.38% in 2024, attributed to its vast population base, growing prevalence of pelvic organ prolapse (POP) and urinary incontinence (UI), increasing health expenditure, and rapid adoption of innovative medical devices across tier-1 and tier-2 cities

- Saudi Arabia is projected to be the fastest-growing country in the market during the forecast period, driven by its widespread adoption for efficient, continuous compounding and growing demand for high-quality plastic compounds across various industries

- The thermoplastics segment is expected to dominate the Middle East and Africa Plastic Compounding Market, with a market share of 63.58% in 2025, owing to the by its widespread adoption for efficient, continuous compounding and growing demand for high-quality plastic compounds across various industries

Report Scope and Middle East and Africa Plastic Compounding Market Segmentation

|

Attributes |

Middle East and Africa Plastic Compounding Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

Middle East and Africa

|

|

Key Market Players |

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Middle East and Africa Plastic Compounding Market Trends

Surging Demand for High-Performance Plastics

- Demand for high-performance plastic compounds is growing rapidly—driven by rising urbanization, industrial activity, and the expanding use of electric vehicles and smart infrastructure. Advanced plastic compounds address these challenges by offering improved durability, energy efficiency, and enhanced product performance

- As countries focus on reducing carbon emissions and enhancing grid stability, there is a growing shift toward modernizing power infrastructure using innovative plastic compounds. This transition is critical for meeting increasing electricity demands while supporting cleaner and more efficient transmission systems

- Major industry players such as Covestro, LyondellBasell, and BASF are significantly increasing their R&D efforts to develop next-generation plastic compounds that are more sustainable, flexible, and high-performing, further driving innovation and market growth

- Advancements in plastic compounding technology—characterized by improved thermal stability, electrical insulation, and mechanical strength—are driving market growth. Leading manufacturers are actively developing specialized compounds to support large-scale renewable energy integration and enhance cross-regional energy infrastructure, fueling expansion in the global Middle East and Africa Plastic Compounding Market

Middle East and Africa Plastic Compounding Market Dynamics

Driver

Shift Towards Recyclable and Biodegradable Plastic Compounds Due to Environmental Regulations

- The rising global demand for sustainable materials—driven by stringent environmental regulations, increasing consumer awareness, and corporate sustainability goals—is placing immense pressure on traditional plastic production methods. To address this challenge, many manufacturers are accelerating investments in recyclable and biodegradable plastic compounds to reduce environmental impact and support circular economy initiatives. These developments are creating greener, more efficient, and future-ready material solutions, similar to how energy-efficient technologies optimize resource use.

- For instance, in 2024, several major chemical companies announced large-scale projects focused on expanding biodegradable plastic compounding capacities, aiming to meet growing demand from packaging, automotive, and consumer goods sectors. These initiatives focus on reducing plastic waste, enhancing recyclability, and complying with global regulatory frameworks such as the EU’s Circular Economy Action Plan.

- These investments are not only transforming material formulations but also enabling wider adoption of sustainable plastics across industries. Leading players such as BASF, Covestro, and LyondellBasell are heavily investing in R&D to develop next-generation bio-based and recyclable plastic compounds, ensuring enhanced performance and environmental compliance.

- Additionally, ongoing commitment by governments, private firms, and regulatory bodies is playing a pivotal role in promoting recyclable and biodegradable plastics as a critical component of global sustainability efforts. These initiatives are establishing eco-friendly plastic compounds as a key enabler of the circular economy and a major growth driver in the global Middle East and Africa Plastic Compounding Market.

Restraint/Challenge

Volatility in Raw Material Prices, Especially Petroleum-Based Feedstocks Like Polypropylene and Polyethylene

- The volatility in raw material prices, particularly petroleum-based feedstocks such as polypropylene and polyethylene, remains a significant restraint on the Middle East and Africa Plastic Compounding Market. Fluctuating prices impact production costs and profitability, creating uncertainty for manufacturers and end-users alike

- Furthermore, dependence on crude oil markets exposes the compounding industry to geopolitical tensions, supply chain disruptions, and changing trade policies, which can lead to sudden price spikes or shortages

- For instance, in early 2025, global crude oil price fluctuations caused polypropylene prices to vary by over 20% within months, directly affecting plastic compound manufacturers’ input costs and forcing adjustments in pricing strategies

- Additionally, alternative raw materials such as bio-based feedstocks, though promising, are currently limited by higher costs and scalability challenges, preventing full mitigation of petroleum price volatility

- This price instability poses challenges for long-term planning and investment in the plastic compounding sector, particularly for smaller manufacturers and regions with less financial resilience. Despite efforts to diversify raw material sources and improve supply chain flexibility, volatility in feedstock prices remains a key barrier to stable growth

Middle East and Africa Plastic Compounding Market Scope

The market is segmented on the basis of polymer type, filler type, manufacturing process, properties, and application.

- Polymer Type

On the basis of polymer type, the market is segmented into thermoplastics, thermosetting plastics, engineering plastics, bioplastics, and others. In 2025, the thermoplastics segment is expected to dominate the market with a market share of 63.58%, growing with the CAGR of 4.22% in the forecast period of 2025 to 2032 driven by growing demand for lightweight, durable materials across industries and increasing focus on recyclable and sustainable plastic compounds.

- Filler Type

On the basis of filler type, the market is segmented into mineral fillers, reinforcements, additives, and others. In 2025, the mineral fillers segment is expected to dominate the market with a market share of 50.75%, growing with the CAGR of 5.24% in the forecast period of 2025 to 2032 driven by growing demand for enhanced material properties, cost-efficiency, and increasing adoption in various industrial applications.

- Manufacturing Process

On the basis of manufacturing process, the market is segmented into extrusion, compaction / pressing, kneader / banbury mixing, injection molding based compounding, and others. In 2025, the extrusion segment is expected to dominate the market with a market share of 47.19%, growing with the CAGR of 4.90% in the forecast period of 2025 to 2032 driven by its widespread adoption for efficient, continuous compounding and growing demand for high-quality plastic compounds across various industries.

- Properties

On the basis of properties, the market is segmented into resistance, durability, flexibility, impact resistance, rigidity, and others. In 2025, the resistance segment is expected to dominate the market with a market share of 32.03%, growing with the CAGR of 5.10% in the forecast period of 2025 to 2032 driven by increasing demand for long-lasting and high-performance plastic compounds across automotive, construction, and consumer goods industries.

- Application

On the basis of application, the market is segmented into aerospace and defense, packaging, electrical and electronics, energy and power, building & construction, automotive, medical devices, furniture, and others. In 2025, the automotive segment is expected to dominate the market with a market share of 30.83%, growing with the CAGR of 3.67% in the forecast period of 2025 to 2032 driven by increasing demand for lightweight, durable, and recyclable plastic compounds to improve fuel efficiency and meet stringent environmental regulations.

Middle East and Africa Plastic Compounding Market Regional Analysis

- Middle East and Africa Plastic Compounding Market is expected to reach USD 14.98 billion by 2032, from USD 10.48 billion in 2024, growing at the CAGR of 4.61% in the forecast period of 2025 to 2032

- Middle East and Africa allocates a significant portion of its GDP to manufacturing and industrial development, ensuring robust funding for advanced materials and innovative plastic compounding technologies. In contrast, emerging markets are increasing their investments in plastic compounding driven by growing industrialization, urbanization, and rising demand for sustainable and high-performance materials. The availability of funding from both public and private sectors plays a crucial role in expanding production capacities and adoption of advanced plastic compounds globally

- In Middle East and Africa, advanced plastic compounding technologies are widely adopted and integrated into various industrial applications, supporting sectors such as automotive, aerospace, and electronics. In contrast, emerging markets with developing manufacturing infrastructure are experiencing rapid growth in demand for specialized plastic compounds, driven by expanding industrial bases and increasing healthcare, automotive, and packaging needs. As these healthcare and industrial systems become more centralized or privatized, it often leads to increased investment in cutting-edge plastic compounding technologies, which promotes market growth and accessibility

Saudi Arabia Middle East and Africa Plastic Compounding Market Insight

Saudi Arabia expected to register the CAGR of 5.86% from 2025 to 2032 in the Middle East and Africa region, driven by growing demand for enhanced material properties, cost-efficiency, and increasing adoption in various industrial applications.

Egypt Middle East and Africa Plastic Compounding Market Insight

Egypt is expected to register the CAGR of 4.51% from 2025 to 2032, driven by growing demand for lightweight, durable materials across industries and increasing focus on recyclable and sustainable plastic compounds.

Middle East and Africa Plastic Compounding Market Share

The Middle East and Africa Plastic Compounding Market is primarily led by well-established companies, including:

- LyondellBasell Industries Holdings B.V. (U.S.)

- BASF (Germany)

- Dow (U.S.)

- SABIC (Saudi Arabia)

- Covestro AG (Germany)

- LANXESS (Germany)

- Celanese Corporation (U.S.)

- Borealis GmbH (Austria)

- Mitsubishi Chemical Group Corporation (Japan)

- DuPont (U.S.)

- Avient Corporation (U.S.)

- Syensqo (Belgium)

- Arkema (France)

- Trinseo (U.S.)

- KANEKA CORPORATION (Japan)

- TORAY INDUSTRIES, INC. (Japan)

- SCG (Thailand)

- CLARIANT (Switzerland)

Latest Developments in Middle East and Africa Plastic Compounding Market

- In June 2025, Envalior, in collaboration with SENTImotion and Frencken Group, announced a product innovation involving a new gearbox concept for robot arms using Stanyl PA46 engineering plastic. This development enables 50% lighter and 50% more cost-effective gearboxes compared to metal alternatives, supporting large-scale production of lightweight, energy-efficient robots. The innovation significantly benefits Envalior by expanding its footprint in the robotics and mobility sectors, opening new growth opportunities in consumer and industrial automation

- In May 2024, Envalior announced its participation in the “Plastics in E&E Applications” SKZ conference, where it showcased product innovations including sustainable polyamide 6 compounds and a new halogen-free flame-retardant PBT (e.g., Pocan BFN4221Z). This development focuses on expanding Envalior’s engineering plastics portfolio with a higher proportion of sustainable raw materials, enabling customers to reduce their carbon footprint and reliance on fossil-based inputs. The highlighted materials offer enhanced mechanical performance and flame retardancy, positioning Envalior to better serve growing demand in E&E sectors such as electromobility, 5G, and autonomous systems while reinforcing its leadership in sustainable thermoplastics

- In July 2025, Arkema has launched Zenimid, a new brand name for its ultra-high-performance polyimide range, marking a strategic product development. This innovation enhances Arkema’s specialty materials portfolio by catering to high-demand sectors such as aerospace, electronics, and automotive. With exceptional thermal, mechanical, and chemical resistance, Zenimid supports the company’s growth in advanced applications. The launch reinforces Arkema’s market position in high-performance polymers

- In June 2025, Trinseo unveiled LIGOS A9615, a new acrylic adhesive tailored for the General Purpose Label (GPL) segment, launched on June 9, 2025, targeting film labels in the Southeast Asian market. This development represents a strategic product launch reinforcing Trinseo’s strength in adhesive innovation. The product’s key benefits include excellent aging resistance, clean removability with repositioning capability, and plasticizer resistance, enabling reliable adhesion even on curved PVC surfaces common in consumer goods and packaging applications

- In February 2025, Trinseo announced on February 27, 2025, the launch of the first transparent, dissolution‑recycled polystyrene (rPS) resin product in Middle East and Africa specifically approved for direct food contact, officially compliant with EU Regulation 2022/1616 This regulatory milestone followed extensive testing including a “Challenge Test” conducted with the Fraunhofer Institute to validate decontamination effectiveness and food‑safety compliance of the final resin.Produced at Trinseo’s Schkopau facility and containing approximately 30% recycled content, the new rPS resin offers a carbon footprint reduction of about 18% compared to virgin polystyrene . For Trinseo, this development represents a strategic sustainability advancement, enabling the company to meet growing demand for circular material solutions and support its customers’ recycled content targets

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW

1.4 LIMITATIONS

1.5 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 MARKETS COVERED

2.2 GEOGRAPHICAL SCOPE

2.3 YEARS CONSIDERED FOR THE STUDY

2.4 CURRENCY AND PRICING

2.5 DBMR TRIPOD DATA VALIDATION MODEL

2.6 MULTIVARIATE MODELING

2.7 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.8 DBMR MARKET POSITION GRID

2.9 MARKET APPLICATION COVERAGE GRID

2.1 SECONDARY SOURCES

2.11 ASSUMPTIONS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

4.1 PORTER’S FIVE FORCES ANALYSIS

4.1.1 THREAT OF NEW ENTRANTS

4.1.2 BARGAINING POWER OF SUPPLIERS

4.1.3 BARGAINING POWER OF BUYERS

4.1.4 THREAT OF SUBSTITUTES

4.1.5 INTERNAL COMPETITION

4.2 INNOVATION TRACKER AND STRATEGIC ANALYSIS

4.2.1 MAJOR DEALS AND STRATEGIC ALLIANCES ANALYSIS

4.2.1.1 JOINT VENTURES

4.2.1.2 MERGERS AND ACQUISITIONS

4.2.1.3 LICENSING AND PARTNERSHIP

4.2.1.4 TECHNOLOGY COLLABORATIONS

4.2.1.5 STRATEGIC DIVESTMENTS

4.2.2 NUMBER OF PRODUCTS IN DEVELOPMENT

4.2.3 STAGE OF DEVELOPMENT

4.2.4 TIMELINES AND MILESTONES

4.2.5 INNOVATION STRATEGIES AND METHODOLOGIES

4.2.6 RISK ASSESSMENT AND MITIGATION

4.2.7 FUTURE OUTLOOK

4.3 VALUE CHAIN ANALYSIS

4.4 IMPORT EXPORT SCENARIO

4.5 PRODUCTION CAPACITY FOR TOP MANUFACTURERS

4.6 BRAND OUTLOOK

4.7 CONSUMER BUYING BEHAVIOUR

4.8 DATA BASE OF COMPOUNDERS & THE EQUIPMENT THEY HAVE IN USE

4.9 PATENT ANALYSIS

4.9.1 PATENT QUALITY AND STRENGTH

4.9.2 PATENT FAMILIES

4.9.3 LICENSING AND COLLABORATIONS

4.9.4 REGION PATENT LANDSCAPE

4.9.5 IP STRATEGY AND MANAGEMENT

4.1 RAW MATERIAL COVERAGE

4.11 SUPPLY CHAIN ANALYSIS OF THE MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET

4.11.1 OVERVIEW

4.11.2 LOGISTIC COST SCENARIOS

4.11.3 IMPORTANCE OF LOGISTICS SERVICE PROVIDERS (LSPS)

4.12 TECHNOLOGICAL ADVANCEMENTS IN THE MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET

4.12.1 AI AND DIGITAL PROCESS OPTIMIZATION

4.12.2 ADVANCED EXTRUSION AND MATERIAL HANDLING TECHNOLOGIES

4.12.3 BIO-BASED AND FUNCTIONALIZED POLYMER COMPOUNDS

4.12.4 SMART AND RESPONSIVE COMPOUNDING SOLUTIONS

4.12.5 AUTOMATION AND INDUSTRY 4.0 IN COMPOUNDING OPERATIONS

4.12.6 SUSTAINABILITY AND CIRCULAR ECONOMY INNOVATIONS

4.12.7 DIGITAL CUSTOMER ENGAGEMENT AND FORMULATION PLATFORMS

4.13 VENDOR SELECTION CRITERIA

4.14 COMPANY EVALUATION QUADRANT

4.15 PRICING ANALYSIS

5 ROLE OF TARIFFS IN THE MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET

5.1 TARIFF LANDSCAPE: DUTIES ON POLYMERS, ADDITIVES, AND MACHINERY

5.2 IMPACT OF TARIFFS ON COST STRUCTURES AND SUPPLY CHAIN DYNAMICS

5.3 INFLUENCE OF TRADE AGREEMENTS AND REGULATORY POLICIES

5.4 MARKET TRENDS AMPLIFYING TARIFF IMPACTS

5.5 COMPETITIVE IMPLICATIONS FOR INDUSTRY PARTICIPANTS

5.6 CHALLENGES AND OPPORTUNITIES ARISING FROM TARIFFS

5.7 KEY COMPANIES AND TARIFF STRATEGY SNAPSHOT

6 REGULATION COVERAGE: MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET

7 MARKET OVERVIEW

7.1 DRIVERS

7.1.1 SHIFT TOWARDS RECYCLABLE AND BIODEGRADABLE PLASTIC COMPOUNDS DUE TO ENVIRONMENTAL REGULATIONS

7.1.2 ADVANCEMENTS IN COMPOUNDING TECHNOLOGIES IMPROVING PRODUCT PERFORMANCE AND COST-EFFICIENCY

7.1.3 DEVELOPMENT OF NANOCOMPOSITE PLASTICS OFFERING SUPERIOR MECHANICAL AND BARRIER PROPERTIES

7.1.4 INCREASED USE OF COMPOUNDED PLASTICS IN MEDICAL DEVICES DUE TO BIOCOMPATIBILITY AND STERILIZATION COMPATIBILITY

7.2 RESTRAINTS

7.2.1 VOLATILITY IN RAW MATERIAL PRICES, ESPECIALLY PETROLEUM-BASED FEEDSTOCKS LIKE POLYPROPYLENE AND POLYETHYLENE

7.2.2 COMPLEX RECYCLING PROCESSES AND LACK OF PROPER INFRASTRUCTURE FOR PLASTIC COMPOUND WASTE MANAGEMENT

7.3 OPPORTUNITIES

7.3.1 GROWING USE OF BIOPLASTICS AND SUSTAINABLE COMPOUND ALTERNATIVES

7.3.2 SURGE IN ELECTRIC VEHICLE ADOPTION REQUIRING ADVANCED POLYMERS

7.3.3 INCREASING DEMAND FOR RECYCLABLE AND CIRCULAR PLASTIC SOLUTIONS

7.4 CHALLENGES

7.4.1 PERFORMANCE LIMITATIONS OF SUSTAINABLE ALTERNATIVES

7.4.2 REGULATORY AND STANDARDS FRAGMENTATION ACROSS REGIONS

8 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE

8.1 OVERVIEW

8.2 THERMOPLASTICS

8.2.1 THERMOPLASTICS, BY TYPE

8.2.2 POLYETHYLENE (PE), BY TYPE

8.3 ENGINEERING PLASTICS

8.3.1 ENGINEERING PLASTICS, BY TYPE

8.4 THERMOSETTING PLASTICS

8.4.1 THERMOSETTING PLASTICS, BY TYPE

8.5 BIOPLASTICS

8.5.1 BIOPLASTICS, BY TYPE

8.6 OTHERS

9 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY FILLER TYPE

9.1 OVERVIEW

9.2 MINERAL FILLERS

9.2.1 MINERAL FILLERS, BY TYPE

9.3 REINFORCEMENTS

9.3.1 REINFORCEMENTS, BY TYPE

9.4 ADDITIVES

9.4.1 ADDITIVES, BY TYPE

9.5 OTHERS

10 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS

10.1 OVERVIEW

10.2 EXTRUSION

10.2.1 EXTRUSION, BY TYPE

10.2.2 EXTRUSION, BY PELLETIZING SYSTEM

10.3 INJECTION MOLDING BASED COMPOUNDING

10.3.1 INJECTION MOLDING BASED COMPOUNDING, BY PELLETIZING SYSTEM

10.4 COMPACTION/PRESSING

10.4.1 COMPACTION/PRESSING, BY PELLETIZING SYSTEM

10.5 KNEADER/BANBURY MIXING

10.5.1 KNEADER/BANBURY MIXING, BY PELLETIZING SYSTEM

10.6 OTHERS

11 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY PROPERTIES

11.1 OVERVIEW

11.2 RESISTANCE

11.3 DURABILITY

11.4 FLEXIBILITY

11.5 IMPACT RESISTANCE

11.6 RIGIDITY

11.7 OTHERS

12 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY APPLICATION

12.1 OVERVIEW

12.2 AUTOMOTIVE

12.2.1 AUTOMOTIVE, BY CATEGORY

12.2.1.1 INTERIOR COMPONENTS, BY TYPE

12.2.1.2 EXTERIOR BODY PARTS, BY TYPE

12.2.1.3 UNDER-THE-HOOD APPLICATIONS, BY TYPE

12.3 PACKAGING

12.3.1 PACKAGING, BY CATEGORY

12.3.1.1 FOOD & BEVERAGE PACKAGING, BY TYPE

12.3.1.2 INDUSTRIAL PACKAGING, BY TYPE

12.3.1.3 CONSUMER GOODS PACKAGING, BY TYPE

12.4 BUILDING & CONSTRUCTION

12.4.1 BUILDING & CONSTRUCTION, BY CATEGORY

12.5 ELECTRICAL & ELECTRONICS

12.5.1 ELECTRICAL & ELECTRONICS, BY CATEGORY

12.6 MEDICAL DEVICES

12.6.1 MEDICAL DEVICES, BY CATEGORY

12.7 FURNITURE

12.7.1 FURNITURE, BY CATEGORY

12.8 ENERGY AND POWER

12.8.1 ENERGY & POWER, BY CATEGORY

12.9 AEROSPACE AND DEFENSE

12.9.1 AEROSPACE AND DEFENSE, BY CATEGORY

12.1 OTHERS

13 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET BY COUNTRIES

13.1 MIDDLE EAST AND AFRICA

13.1.1 SAUDI ARABIA

13.1.2 EGYPT

13.1.3 U.A.E.

13.1.4 SOUTH AFRICA

13.1.5 ISRAEL

13.1.6 KUWAIT

13.1.7 OMAN

13.1.8 QATAR

13.1.9 BAHRAIN

13.1.10 REST OF MIDDLE EAST AND AFRICA

14 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: COMPANY LANDSCAPE

14.1 COMPANY SHARE ANALYSIS: MIDDLE EAST AND AFRICA

15 SWOT ANALYSIS

16 COMPANY PROFILES

16.1 SABIC

16.1.1 COMPANY SNAPSHOT

16.1.2 REVENUE ANALYSIS

16.1.3 COMPANY SHARE ANALYSIS

16.1.4 PRODUCT PORTFOLIO

16.1.5 RECENT DEVELOPMENT

16.2 LYONDELLBASELL INDUSTRIES HOLDINGS B.V.

16.2.1 COMPANY SNAPSHOT

16.2.2 REVENUE ANALYSIS

16.2.3 COMPANY SHARE ANALYSIS

16.2.4 PRODUCT PORTFOLIO

16.2.5 RECENT DEVELOPMENTS/NEWS

16.3 DOW

16.3.1 COMPANY SNAPSHOT

16.3.2 REVENUE ANALYSIS

16.3.3 COMPANY SHARE ANALYSIS

16.3.4 PRODUCT PORTFOLIO

16.3.5 RECENT DEVELOPMENT

16.4 DUPONT

16.4.1 COMPANY SNAPSHOT

16.4.2 REVENUE ANALYSIS

16.4.3 COMPANY SHARE ANALYSIS

16.4.4 PRODUCT PORTFOLIO

16.4.5 RECENT DEVELOPMENT

16.5 ARKEMA

16.5.1 COMPANY SNAPSHOT

16.5.2 REVENUE ANALYSIS

16.5.3 COMPANY SHARE ANALYSIS

16.5.4 PRODUCT PORTFOLIO

16.5.5 RECENT DEVELOPMENTS

16.6 ASAHI KASEI CORP.

16.6.1 COMPANY SNAPSHOT

16.6.2 REVENUE ANALYSIS

16.6.3 PRODUCT PORTFOLIO

16.6.4 RECENT DEVELOPMENT

16.7 AVIENT CORPORATION

16.7.1 COMPANY SNAPSHOT

16.7.2 REVENUE ANALYSIS

16.7.3 PRODUCT PORTFOLIO

16.7.4 RECENT DEVELOPMENT

16.8 BOREALIS GMBH

16.8.1 COMPANY SNAPSHOT

16.8.2 PRODUCT PORTFOLIO

16.8.3 RECENT DEVELOPMENT

16.9 BASF

16.9.1 COMPANY SNAPSHOT

16.9.2 REVENUE ANALYSIS

16.9.3 PRODUCT PORTFOLIO

16.9.4 RECENT DEVELOPMENT

16.1 CLEANESE CORPORATION

16.10.1 COMPANY SNAPSHOT

16.10.2 REVENUE ANALYSIS

16.10.3 PRODUCT PORTFOLIO

16.10.4 RECENT DEVELOPMENT

16.11 CHIMEI

16.11.1 COMPANY SNAPSHOT

16.11.2 REVENUE ANALYSIS

16.11.3 PRODUCT PORTFOLIO

16.11.4 RECENT DEVELOPMENT

16.12 CLARIANT

16.12.1 COMPANY SNAPSHOT

16.12.2 REVENUE ANALYSIS

16.12.3 PRODUCT PORTFOLIO

16.12.4 RECENT DEVELOPMENT

16.13 COVESTRO AG

16.13.1 COMPANY SNAPSHOT

16.13.2 REVENUE ANALYSIS

16.13.3 PRODUCT PORTFOLIO

16.13.4 RECENT DEVELOPMENT

16.14 DAICEL CORPORATION

16.14.1 COMPANY SNAPSHOT

16.14.2 REVENUE ANALYSIS

16.14.3 PRODUCT PORTFOLIO

16.14.4 RECENT DEVELOPMENTS

16.15 ENSINGER GMBH

16.15.1 COMPANY SNAPSHOT

16.15.2 PRODUCT PORTFOLIO

16.15.3 RECENT DEVELOPMENT

16.16 ENVALIOR

16.16.1 COMPANY SNAPSHOT

16.16.2 PRODUCT PORTFOLIO

16.16.3 RECENT DEVELOPMENTS

16.17 INEOS

16.17.1 COMPANY SNAPSHOT

16.17.2 PRODUCT PORTFOLIO

16.17.3 RECENT DEVELOPMENT

16.18 KANEKA CORPORATION

16.18.1 COMPANY SNAPSHOT

16.18.2 REVENUE ANALYSIS

16.18.3 PRODUCT PORTFOLIO

16.18.4 RECENT DEVELOPMENT

16.19 KINGFA SCI.&TECH. CO.,LTD.

16.19.1 COMPANY SNAPSHOT

16.19.2 REVENUE ANALYSIS

16.19.3 PRODUCT PORTFOLIO

16.19.4 RECENT DEVELOPMENT

16.2 LANXESS

16.20.1 COMPANY SNAPSHOT

16.20.2 REVENUE ANALYSIS

16.20.3 BUSINESS PORTFOLIO

16.20.4 RECENT DEVELOPMENT

16.21 LG CHEM

16.21.1 COMPANY SNAPSHOT

16.21.2 REVENUE ANALYSIS

16.21.3 PRODUCT PORTFOLIO

16.21.4 RECENT DEVELOPMENT

16.22 MITSUBISHI CHEMICAL GROUP CORPORATION.

16.22.1 COMPANY SNAPSHOT

16.22.2 REVENUE ANALYSIS

16.22.3 PRODUCT PORTFOLIO

16.22.4 RECENT DEVELOPMENT

16.23 MITSUI CHEMICALS, INC

16.23.1 COMPANY SNAPSHOT

16.23.2 REVENUE ANALYSIS

16.23.3 PRODUCT PORTFOLIO

16.23.4 RECENT DEVELOPMENT

16.24 RTP COMPANY

16.24.1 COMPANY SNAPSHOT

16.24.2 PRODUCT PORTFOLIO

16.24.3 RECENT DEVELOPMENT

16.25 SCG

16.25.1 COMPANY SNAPSHOT

16.25.2 REVENUE ANALYSIS

16.25.3 PRODUCT PORTFOLIO

16.25.4 RECENT DEVELOPMENT

16.26 SYENSQO

16.26.1 COMPANY SNAPSHOT

16.26.2 REVENUE ANALYSIS

16.26.3 PRODUCT PORTFOLIO

16.26.4 RECENT DEVELOPMENTS

16.27 TEKNOR APEX

16.27.1 COMPANY SNAPSHOT

16.27.2 PRODUCT PORTFOLIO

16.27.3 RECENT DEVELOPMENT

16.28 TORAY INDUSTRIES, INC.

16.28.1 COMPANY SNAPSHOT

16.28.2 REVENUE ANALYSIS

16.28.3 PRODUCT PORTFOLIO

16.28.4 RECENT DEVELOPMENT

16.29 TRINSEO

16.29.1 COMPANY SNAPSHOT

16.29.2 REVENUE ANALYSIS

16.29.3 SOLUTION PORTFOLIO

16.29.4 RECENT DEVELOPMENTS

16.3 WASHINGTON PENN

16.30.1 COMPANY SNAPSHOT

16.30.2 PRODUCT PORTFOLIO

16.30.3 RECENT DEVELOPMENT

17 QUESTIONNAIRE

18 RELATED REPORTS

List of Table

TABLE 1 STAGES OF VALUE CHAIN

TABLE 2 BRAND OUTLOOK: MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET

TABLE 3 CONSUMER BUYING BEHAVIOUR

TABLE 4 MIDDLE EAST AND AFRICA PLAYERS IN PLASTIC COMPOUNDING

TABLE 5 NUMBER OF PATENTS PER YEAR

TABLE 6 NUMBER OF PATENTS PER REGION/COUNTRY

TABLE 7 TOP PATENT APPLICANTS

TABLE 8 TARIFF EXPOSURE AND STRATEGIC RESPONSE BY COMPANY TYPE

TABLE 9 TARIFF EXPOSURE AND STRATEGIC RESPONSE OF KEY PLAYERS

TABLE 10 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 11 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 12 MIDDLE EAST AND AFRICA THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 13 MIDDLE EAST AND AFRICA THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 14 MIDDLE EAST AND AFRICA THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 15 MIDDLE EAST AND AFRICA POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 16 MIDDLE EAST AND AFRICA ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND )

TABLE 17 MIDDLE EAST AND AFRICA ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 18 MIDDLE EAST AND AFRICA ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 19 MIDDLE EAST AND AFRICA THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 20 MIDDLE EAST AND AFRICA THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 21 MIDDLE EAST AND AFRICA THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 22 MIDDLE EAST AND AFRICA BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 23 MIDDLE EAST AND AFRICA BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 24 MIDDLE EAST AND AFRICA BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 25 MIDDLE EAST AND AFRICA OTHERS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 26 MIDDLE EAST AND AFRICA OTHERS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 27 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY FILTER TYPE, 2018-2032 (USD THOUSAND)

TABLE 28 MIDDLE EAST AND AFRICA MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 29 MIDDLE EAST AND AFRICA MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 30 MIDDLE EAST AND AFRICA REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 31 MIDDLE EAST AND AFRICA REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 32 MIDDLE EAST AND AFRICA ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 33 MIDDLE EAST AND AFRICA ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 34 MIDDLE EAST AND AFRICA OTHERS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 35 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 36 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 37 MIDDLE EAST AND AFRICA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 38 MIDDLE EAST AND AFRICA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 39 MIDDLE EAST AND AFRICA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 40 MIDDLE EAST AND AFRICA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 41 MIDDLE EAST AND AFRICA INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 42 MIDDLE EAST AND AFRICA INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 43 MIDDLE EAST AND AFRICA INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 44 MIDDLE EAST AND AFRICA COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 45 MIDDLE EAST AND AFRICA COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 46 MIDDLE EAST AND AFRICA COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 47 MIDDLE EAST AND AFRICA KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 48 MIDDLE EAST AND AFRICA KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 49 MIDDLE EAST AND AFRICA KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 50 MIDDLE EAST AND AFRICA OTHERS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 51 MIDDLE EAST AND AFRICA OTHERS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 52 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 53 MIDDLE EAST AND AFRICA RESISTANCE IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 54 MIDDLE EAST AND AFRICA DURABILITY IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 55 MIDDLE EAST AND AFRICA FLEXIBILITY IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 56 MIDDLE EAST AND AFRICA IMPACT RESISTANCE IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 57 MIDDLE EAST AND AFRICA RIGIDITY IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 58 MIDDLE EAST AND AFRICA OTHERS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 59 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 60 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 61 MIDDLE EAST AND AFRICA AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 62 MIDDLE EAST AND AFRICA AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 63 MIDDLE EAST AND AFRICA AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 64 MIDDLE EAST AND AFRICA INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 65 MIDDLE EAST AND AFRICA EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 66 MIDDLE EAST AND AFRICA UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 67 MIDDLE EAST AND AFRICA PACKAGING IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 68 MIDDLE EAST AND AFRICA PACKAGING IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 69 MIDDLE EAST AND AFRICA PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 70 MIDDLE EAST AND AFRICA FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 71 MIDDLE EAST AND AFRICA INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 72 MIDDLE EAST AND AFRICA CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 73 MIDDLE EAST AND AFRICA BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 74 MIDDLE EAST AND AFRICA BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 75 MIDDLE EAST AND AFRICA BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 76 MIDDLE EAST AND AFRICA ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 77 MIDDLE EAST AND AFRICA ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 78 MIDDLE EAST AND AFRICA ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 79 MIDDLE EAST AND AFRICA MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 80 MIDDLE EAST AND AFRICA MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 81 MIDDLE EAST AND AFRICA MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 82 MIDDLE EAST AND AFRICA FURNITURE IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 83 MIDDLE EAST AND AFRICA FURNITURE IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 84 MIDDLE EAST AND AFRICA FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 85 MIDDLE EAST AND AFRICA ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 86 MIDDLE EAST AND AFRICA ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 87 MIDDLE EAST AND AFRICA ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 88 MIDDLE EAST AND AFRICA AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 89 MIDDLE EAST AND AFRICA AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 90 MIDDLE EAST AND AFRICA AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 91 MIDDLE EAST AND AFRICA OTHERS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (USD THOUSAND)

TABLE 92 MIDDLE EAST AND AFRICA OTHERS IN PLASTIC COMPOUNDING MARKET, BY REGION, 2018-2032 (KILO TONS)

TABLE 93 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY COUNTRY, 2018-2032 (USD THOUSAND)

TABLE 94 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY COUNTRY, 2018-2032 (KILO TONS)

TABLE 95 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 96 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 97 MIDDLE EAST AND AFRICA THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 98 MIDDLE EAST AND AFRICA POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 99 MIDDLE EAST AND AFRICA ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 100 MIDDLE EAST AND AFRICA THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 101 MIDDLE EAST AND AFRICA BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 102 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 103 MIDDLE EAST AND AFRICA MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 104 MIDDLE EAST AND AFRICA REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 105 MIDDLE EAST AND AFRICA ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 106 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 107 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 108 MIDDLE EAST AND AFRICA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 109 MIDDLE EAST AND AFRICA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 110 MIDDLE EAST AND AFRICA INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 111 MIDDLE EAST AND AFRICA COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 112 MIDDLE EAST AND AFRICA KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 113 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 114 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 115 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 116 MIDDLE EAST AND AFRICA AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 117 MIDDLE EAST AND AFRICA INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 118 MIDDLE EAST AND AFRICA EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 119 MIDDLE EAST AND AFRICA UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 120 MIDDLE EAST AND AFRICA PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 121 MIDDLE EAST AND AFRICA FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 122 MIDDLE EAST AND AFRICA INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 123 MIDDLE EAST AND AFRICA CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 124 MIDDLE EAST AND AFRICA BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 125 MIDDLE EAST AND AFRICA ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 126 MIDDLE EAST AND AFRICA MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 127 MIDDLE EAST AND AFRICA FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 128 MIDDLE EAST AND AFRICA ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 129 MIDDLE EAST AND AFRICA AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 130 SAUDI ARABIA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 131 SAUDI ARABIA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 132 SAUDI ARABIA THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 133 SAUDI ARABIA POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 134 SAUDI ARABIA ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 135 SAUDI ARABIA THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 136 SAUDI ARABIA BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 137 SAUDI ARABIA PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 138 SAUDI ARABIA MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 139 SAUDI ARABIA REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 140 SAUDI ARABIA ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 141 SAUDI ARABIA PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 142 SAUDI ARABIA PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 143 SAUDI ARABIA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 144 SAUDI ARABIA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 145 SAUDI ARABIA INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 146 SAUDI ARABIA COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 147 SAUDI ARABIA KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 148 SAUDI ARABIA PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 149 SAUDI ARABIA PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 150 SAUDI ARABIA PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 151 SAUDI ARABIA AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 152 SAUDI ARABIA INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 153 SAUDI ARABIA EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 154 SAUDI ARABIA UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 155 SAUDI ARABIA PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 156 SAUDI ARABIA FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 157 SAUDI ARABIA INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 158 SAUDI ARABIA CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 159 SAUDI ARABIA BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 160 SAUDI ARABIA ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 161 SAUDI ARABIA MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 162 SAUDI ARABIA FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 163 SAUDI ARABIA ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 164 SAUDI ARABIA AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 165 EGYPT PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 166 EGYPT PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 167 EGYPT THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 168 EGYPT POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 169 EGYPT ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 170 EGYPT THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 171 EGYPT BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 172 EGYPT PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 173 EGYPT MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 174 EGYPT REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 175 EGYPT ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 176 EGYPT PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 177 EGYPT PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 178 EGYPT EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 179 EGYPT EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 180 EGYPT INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 181 EGYPT COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 182 EGYPT KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 183 EGYPT PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 184 EGYPT PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 185 EGYPT PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 186 EGYPT AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 187 EGYPT INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 188 EGYPT EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 189 EGYPT UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 190 EGYPT PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 191 EGYPT FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 192 EGYPT INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 193 EGYPT CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 194 EGYPT BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 195 EGYPT ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 196 EGYPT MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 197 EGYPT FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 198 EGYPT ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 199 EGYPT AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 200 U.A.E. PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 201 U.A.E. PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 202 U.A.E. THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 203 U.A.E. POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 204 U.A.E. ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 205 U.A.E. THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 206 U.A.E. BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 207 U.A.E. PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 208 U.A.E. MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 209 U.A.E. REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 210 U.A.E. ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 211 U.A.E. PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 212 U.A.E. PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 213 U.A.E. EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 214 U.A.E. EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 215 U.A.E. INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 216 U.A.E. COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 217 U.A.E. KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 218 U.A.E. PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 219 U.A.E. PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 220 U.A.E. PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 221 U.A.E. AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 222 U.A.E. INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 223 U.A.E. EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 224 U.A.E. UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 225 U.A.E. PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 226 U.A.E. FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 227 U.A.E. INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 228 U.A.E. CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 229 U.A.E. BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 230 U.A.E. ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 231 U.A.E. MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 232 U.A.E. FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 233 U.A.E. ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 234 U.A.E. AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 235 SOUTH AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 236 SOUTH AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 237 SOUTH AFRICA THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 238 SOUTH AFRICA POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 239 SOUTH AFRICA ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 240 SOUTH AFRICA THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 241 SOUTH AFRICA BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 242 SOUTH AFRICA PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 243 SOUTH AFRICA MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 244 SOUTH AFRICA REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 245 SOUTH AFRICA ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 246 SOUTH AFRICA PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 247 SOUTH AFRICA PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 248 SOUTH AFRICA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 249 SOUTH AFRICA EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 250 SOUTH AFRICA INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 251 SOUTH AFRICA COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 252 SOUTH AFRICA KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 253 SOUTH AFRICA PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 254 SOUTH AFRICA PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 255 SOUTH AFRICA PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 256 SOUTH AFRICA AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 257 SOUTH AFRICA INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 258 SOUTH AFRICA EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 259 SOUTH AFRICA UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 260 SOUTH AFRICA PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 261 SOUTH AFRICA FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 262 SOUTH AFRICA INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 263 SOUTH AFRICA CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 264 SOUTH AFRICA BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 265 SOUTH AFRICA ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 266 SOUTH AFRICA MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 267 SOUTH AFRICA FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 268 SOUTH AFRICA ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 269 SOUTH AFRICA AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 270 ISRAEL PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 271 ISRAEL PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 272 ISRAEL THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 273 ISRAEL POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 274 ISRAEL ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 275 ISRAEL THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 276 ISRAEL BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 277 ISRAEL PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 278 ISRAEL MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 279 ISRAEL REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 280 ISRAEL ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 281 ISRAEL PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 282 ISRAEL PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 283 ISRAEL EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 284 ISRAEL EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 285 ISRAEL INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 286 ISRAEL COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 287 ISRAEL KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 288 ISRAEL PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 289 ISRAEL PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 290 ISRAEL PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 291 ISRAEL AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 292 ISRAEL INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 293 ISRAEL EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 294 ISRAEL UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 295 ISRAEL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 296 ISRAEL FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 297 ISRAEL INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 298 ISRAEL CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 299 ISRAEL BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 300 ISRAEL ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 301 ISRAEL MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 302 ISRAEL FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 303 ISRAEL ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 304 ISRAEL AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 305 KUWAIT PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 306 KUWAIT PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 307 KUWAIT THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 308 KUWAIT POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 309 KUWAIT ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 310 KUWAIT THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 311 KUWAIT BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 312 KUWAIT PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 313 KUWAIT MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 314 KUWAIT REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 315 KUWAIT ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 316 KUWAIT PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 317 KUWAIT PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 318 KUWAIT EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 319 KUWAIT EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 320 KUWAIT INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 321 KUWAIT COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 322 KUWAIT KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 323 KUWAIT PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 324 KUWAIT PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 325 KUWAIT PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 326 KUWAIT AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 327 KUWAIT INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 328 KUWAIT EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 329 KUWAIT UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 330 KUWAIT PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 331 KUWAIT FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 332 KUWAIT INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 333 KUWAIT CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 334 KUWAIT BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 335 KUWAIT ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 336 KUWAIT MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 337 KUWAIT FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 338 KUWAIT ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 339 KUWAIT AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 340 OMAN PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 341 OMAN PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 342 OMAN THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 343 OMAN POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 344 OMAN ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 345 OMAN THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 346 OMAN BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 347 OMAN PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 348 OMAN MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 349 OMAN REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 350 OMAN ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 351 OMAN PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 352 OMAN PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 353 OMAN EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 354 OMAN EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 355 OMAN INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 356 OMAN COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 357 OMAN KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 358 OMAN PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 359 OMAN PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 360 OMAN PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 361 OMAN AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 362 OMAN INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 363 OMAN EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 364 OMAN UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 365 OMAN PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 366 OMAN FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 367 OMAN INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 368 OMAN CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 369 OMAN BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 370 OMAN ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 371 OMAN MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 372 OMAN FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 373 OMAN ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 374 OMAN AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 375 QATAR PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 376 QATAR PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 377 ATAR THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 378 QATAR POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 379 QATAR ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 380 QATAR THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 381 QATAR BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 382 QATAR PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 383 QATAR MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 384 QATAR REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 385 QATAR ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 386 QATAR PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 387 QATAR PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 388 QATAR EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 389 QATAR EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 390 QATAR INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 391 QATAR COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 392 QATAR KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 393 QATAR PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 394 QATAR PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 395 QATAR PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 396 QATAR AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 397 QATAR INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 398 QATAR EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 399 QATAR UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 400 QATAR PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 401 QATAR FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 402 QATAR INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 403 QATAR CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 404 QATAR BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 405 QATAR ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 406 QATAR MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 407 QATAR FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 408 QATAR ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 409 QATAR AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 410 BAHRAIN PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 411 BAHRAIN PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

TABLE 412 BAHRAIN THERMOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 413 BAHRAIN POLYETHYLENE (PE) IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 414 BAHRAIN ENGINEERING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 415 BAHRAIN THERMOSETTING PLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 416 BAHRAIN BIOPLASTICS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 417 BAHRAIN PLASTIC COMPOUNDING MARKET, BY FILLER TYPE, 2018-2032 (USD THOUSAND)

TABLE 418 BAHRAIN MINERAL FILLERS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 419 BAHRAIN REINFORCEMENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 420 BAHRAIN ADDITIVES IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 421 BAHRAIN PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (USD THOUSAND)

TABLE 422 BAHRAIN PLASTIC COMPOUNDING MARKET, BY MANUFACTURING PROCESS, 2018-2032 (KILO TONS)

TABLE 423 BAHRAIN EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 424 BAHRAIN EXTRUSION IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 425 BAHRAIN INJECTION MOLDING BASED COMPOUNDING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 426 BAHRAIN COMPACTION/PRESSING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 427 BAHRAIN KNEADER/BANBURY MIXING IN PLASTIC COMPOUNDING MARKET, BY PELLETIZING SYSTEM, 2018-2032 (USD THOUSAND)

TABLE 428 BAHRAIN PLASTIC COMPOUNDING MARKET, BY PROPERTIES, 2018-2032 (USD THOUSAND)

TABLE 429 BAHRAIN PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (USD THOUSAND)

TABLE 430 BAHRAIN PLASTIC COMPOUNDING MARKET, BY APPLICATION, 2018-2032 (KILO TONS)

TABLE 431 BAHRAIN AUTOMOTIVE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 432 BAHRAIN INTERIOR COMPONENTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 433 BAHRAIN EXTERIOR BODY PARTS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 434 BAHRAIN UNDER-THE-HOOD APPLICATIONS IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 435 BAHRAIN PACKAGING IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 436 BAHRAIN FOOD & BEVERAGE PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 437 BAHRAIN INDUSTRIAL PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 438 BAHRAIN CONSUMER GOODS PACKAGING IN PLASTIC COMPOUNDING MARKET, BY TYPE, 2018-2032 (USD THOUSAND)

TABLE 439 BAHRAIN BUILDING & CONSTRUCTION IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 440 BAHRAIN ELECTRICAL & ELECTRONICS IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 441 BAHRAIN MEDICAL DEVICES IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 442 BAHRAIN FURNITURE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 443 BAHRAIN ENERGY AND POWER IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 444 BAHRAIN AEROSPACE AND DEFENSE IN PLASTIC COMPOUNDING MARKET, BY CATEGORY, 2018-2032 (USD THOUSAND)

TABLE 445 REST OF MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (USD THOUSAND)

TABLE 446 REST OF MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE, 2018-2032 (KILO TONS)

List of Figure

FIGURE 1 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET

FIGURE 2 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: DATA TRIANGULATION

FIGURE 3 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: DROC ANALYSIS

FIGURE 4 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: MIDDLE EAST AND AFRICA VS REGIONAL MARKET ANALYSIS

FIGURE 5 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: COMPANY RESEARCH ANALYSIS

FIGURE 6 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: MULTIVARIATE MODELLING

FIGURE 7 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: INTERVIEW DEMOGRAPHICS

FIGURE 8 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: DBMR MARKET POSITION GRID

FIGURE 9 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: MARKET APPLICATION COVERAGE GRID

FIGURE 10 EXECUTIVE SUMMARY

FIGURE 11 MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET: SEGMENTATION

FIGURE 12 FIVE SEGMENTS COMPRISE THE MIDDLE EAST AND AFRICA PLASTIC COMPOUNDING MARKET, BY POLYMER TYPE