Global Nickel Alloy Welding Consumables Market

시장 규모 (USD 10억)

연평균 성장률 :

%

USD

3.97 Billion

USD

6.23 Billion

2024

2032

USD

3.97 Billion

USD

6.23 Billion

2024

2032

| 2025 –2032 | |

| USD 3.97 Billion | |

| USD 6.23 Billion | |

|

|

|

|

Global Nickel Alloy Welding Consumables Market Segmentation, By Product Type (Stick Electrodes and Wires), Alloy Type (Monel Alloy, Inconel Alloy, and Others), Technology (Shielded Metal Arc Welding, Gas Metal Arc Welding, Gas Tungsten Arc Welding, Flux Cored Arc Welding, and Submerged Arc Welding), Application (Oil and Gas, Power, Construction, Marine, and Others) - Industry Trends and Forecast to 2032

Nickel Alloy Welding Consumables Market Analysis

In the nickel alloy welding consumables market, the latest method gaining traction is the use of advanced welding technologies, such as Laser Metal Deposition (LMD) and Electron Beam Welding (EBW). These technologies enable precise control of the welding process, ensuring stronger, more durable joints in high-performance applications such as aerospace, power generation, and marine industries. They allow for superior weld quality, reduced material waste, and better heat management, making them ideal for welding nickel-based alloys.

In addition, advancements in alloy formulations have resulted in consumables that offer better resistance to corrosion, high temperatures, and mechanical stress. For instance, the development of NiCr and Inconel-based filler materials has improved weld longevity in extreme environments.

The growing demand for these consumables is being driven by increased infrastructure development and the push for sustainable energy solutions. The aerospace and nuclear sectors are major contributors to market growth, given the high-performance needs for nickel alloys in these industries. The market is expected to grow as industries continue to prioritize materials that enhance operational efficiency, durability, and performance.

Nickel Alloy Welding Consumables Market Size

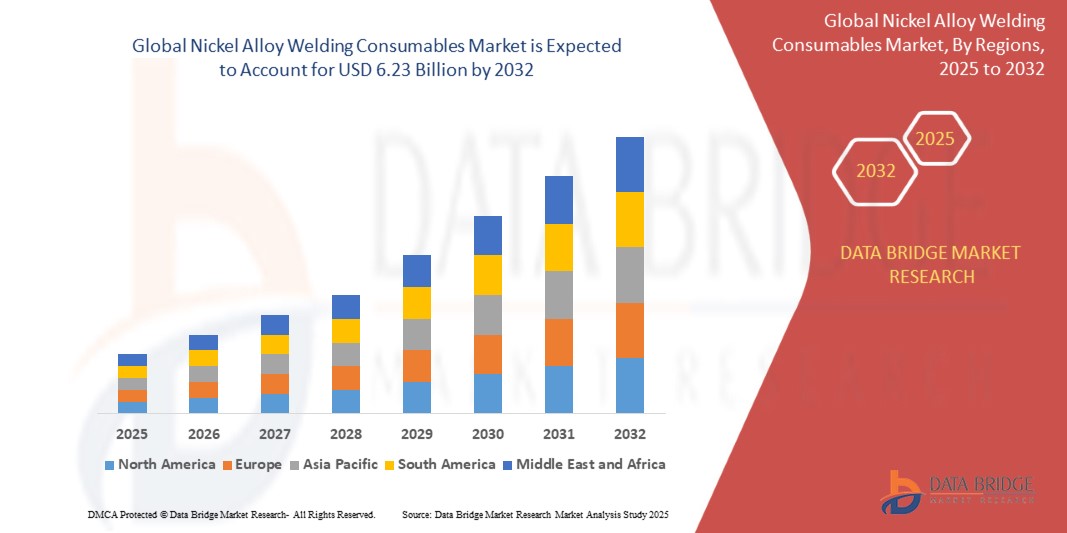

The global nickel alloy welding consumables market size was valued at USD 3.97 billion in 2024 and is projected to reach USD 6.23 billion by 2032, with a CAGR of 5.80% during the forecast period of 2025 to 2032. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework.

Nickel Alloy Welding Consumables Market Trends

“Increased Demand for High-Performance Materials in Aerospace and Energy Sectors”

One specific trend driving growth in the nickel alloy welding consumables market is the rising demand for high-performance materials in the aerospace and energy sectors. Nickel alloys are known for their excellent resistance to heat, corrosion, and wear, making them ideal for critical applications in these industries. For instance, companies such as General Electric and Rolls-Royce are increasingly using nickel alloy welding consumables for turbine engines, which operate under extreme conditions. This trend is further bolstered by the expansion of offshore oil and gas exploration, where nickel alloys are essential for welding in harsh environments. This growing demand for reliable and durable materials is significantly boosting the market.

Report Scope and Nickel Alloy Welding Consumables Market Segmentation

|

Attributes |

Nickel Alloy Welding Consumables Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

KOBE STEEL, LTD. (Japan), voestalpine Böhler Welding Group GmbH (Austria), Illinois Tool Works Inc. (U.S.), Ador Welding Limited (India), Arcos Industries, LLC (U.S.), Colfax Corporation (U.S.), The Lincoln Electric Company (U.S.), Sandvik AB (Sweden), Messer Investment Holding GmbH (Germany), Tianjin Bridge Welding Materials Group Co.,Ltd. (China), Precision Castparts Corp. (U.S.), ESAB (U.S.), Berkenhoff GmbH (Germany), COR-MET, Inc. (U.S.), and Linan Dayang Welding Material Co.,Ltd. (China) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include import export analysis, production capacity overview, production consumption analysis, price trend analysis, climate change scenario, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

Nickel Alloy Welding Consumables Market Definition

Nickel alloy welding consumables are materials used in the welding process that contain a high percentage of nickel and are designed to provide strong, corrosion-resistant welds. These consumables include nickel-based welding rods, wires, and electrodes, which are used to join components made of nickel alloys or materials exposed to high temperatures and corrosive environments. Nickel alloy consumables are often used in industries such as aerospace, chemical processing, and power generation, where durability and resistance to heat, stress, and chemicals are critical. They ensure structural integrity and extend the lifespan of welded joints in harsh operating conditions.

Nickel Alloy Welding Consumables Market Dynamics

Drivers

- Rise in Automotive Industry

The automotive sector's growing reliance on nickel alloys is a significant driver for the nickel alloy welding consumables market. Components such as exhaust systems, turbochargers, and catalytic converters, which require resistance to high temperatures and corrosion, are often made from nickel-based alloys. As automakers focus on producing more durable and efficient vehicles, especially with the shift toward electric vehicles (EVs) and hybrid vehicles, the demand for high-performance materials continues to increase. For instance, automakers such as Tesla and BMW use advanced nickel alloys in their exhaust systems, pushing the demand for specialized welding consumables. This trend ensures the growth of the welding consumables market in the automotive sector.

- Increased Focus on Infrastructure Development

The growing emphasis on infrastructure development, particularly in coastal and aggressive environments, is a key driver for the nickel alloy welding consumables market. Projects such as bridges, tunnels, and offshore structures require materials that can withstand extreme conditions such as high salinity and corrosion. Nickel alloys, known for their exceptional corrosion resistance and strength at elevated temperatures, are ideal for these applications. For instance, the construction of the Hong Kong-Zhuhai-Macau Bridge, one of the longest sea-crossing bridges, relied heavily on the use of nickel alloys for structural integrity and long-lasting performance. This growing demand for durable, corrosion-resistant materials in infrastructure is fueling the need for specialized welding consumables.

Opportunities

- Power Generation Sector Expansion

The power generation sector’s growth, particularly in nuclear and renewable energy, presents significant opportunities for the nickel alloy welding consumables market. Nickel alloys are essential in power plants due to their resistance to high temperatures, corrosion, and pressure. In nuclear plants, these alloys are used for components such as reactor cores, which require precision welding for safety and durability. Similarly, renewable energy sectors, such as wind and solar, use nickel alloys for turbines and energy storage systems. For instance, General Electric utilizes nickel alloy welding in the construction of gas turbines. As these industries expand globally, the demand for high-performance welding consumables will continue to rise.

- Rising Investment in High-Temperature Manufacturing

The growing investment in high-temperature manufacturing across sectors such as power generation and aerospace is creating significant opportunities for the nickel alloy welding consumables market. These industries require materials capable of withstanding extreme heat and pressure, which nickel alloys offer due to their superior thermal stability. For instance, in the aerospace industry, components such as turbine blades and engine parts need to endure high operational temperatures, pushing the demand for welding consumables that can ensure strong, durable joints. Similarly, power plants, particularly those in renewable energy or nuclear sectors, require corrosion-resistant and heat-resistant alloys, which further fuels the need for advanced welding consumables to meet these rigorous demands.

Restraints/Challenges

- High Cost of Nickel Alloys

The high cost of nickel alloys significantly hinders the growth of the welding consumables market. Nickel alloys are inherently expensive, and this increases the cost of welding consumables, making them less attractive to industries with tight budgets, such as automotive and construction. In price-sensitive sectors, the high material cost can lead to escalated overall production expenses, limiting widespread adoption. Companies may seek cheaper alternatives, further dampening demand for nickel-based welding consumables. This financial barrier may cause manufacturers to reconsider their use of nickel alloys, opting for more cost-effective options, which, in turn, restricts the market potential for nickel alloy welding consumables.

- Limited Availability of Raw Materials

The limited availability of raw materials significantly hampers the nickel alloy welding consumables market. High-quality nickel alloys are sourced from a few global suppliers, and their supply is often subject to market fluctuations, geopolitical issues, or mining challenges. This creates volatility in prices and can lead to shortages, causing disruptions in the production and availability of welding consumables. Such supply chain instability often results in production delays, further escalating costs for manufacturers and end-users. Industries dependent on these materials face difficulties in securing timely and cost-effective supplies, which limits the growth and scalability of the nickel alloy welding consumables market.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Impact and Current Market Scenario of Raw Material Shortage and Shipping Delays

Data Bridge Market Research offers a high-level analysis of the market and delivers information by keeping in account the impact and current market environment of raw material shortage and shipping delays. This translates into assessing strategic possibilities, creating effective action plans, and assisting businesses in making important decisions. Apart from the standard report, we also offer in-depth analysis of the procurement level from forecasted shipping delays, distributor mapping by region, commodity analysis, production analysis, price mapping trends, sourcing, category performance analysis, supply chain risk management solutions, advanced benchmarking, and other services for procurement and strategic support.

Expected Impact of Economic Slowdown on the Pricing and Availability of Products

When economic activity slows, industries begin to suffer. The forecasted effects of the economic downturn on the pricing and accessibility of the products are taken into account in the market insight reports and intelligence services provided by DBMR. With this, our clients can typically keep one step ahead of their competitors, project their sales and revenue, and estimate their profit and loss expenditures.

Nickel Alloy Welding Consumables Market Scope

The market is segmented on the basis of product type, alloy type, technology, and application. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Product Type

- Stick Electrodes

- Wires

Alloy Type

- Monel Alloy

- Inconel Alloy

- Others

Technology

- Shielded Metal Arc Welding

- Gas Metal Arc Welding

- Gas Tungsten Arc Welding

- Flux Cored Arc Welding

- Submerged Arc Welding

Application

- Oil and Gas

- Power

- Construction

- Marine

- Others

Nickel Alloy Welding Consumables Market Regional Analysis

The market is analysed and market size insights and trends are provided by product type, alloy type, technology, and application as referenced above.

The countries covered in the market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Asia-Pacific is expected to dominate the nickel alloy welding consumables market due to rapid industrialization and infrastructure development. Countries such as China, India, Japan, and South Korea are seeing significant growth in manufacturing sectors, along with increased investments in aerospace, automotive, and oil and gas industries, driving the demand for these consumables.

North America is expected to show significant growth in the nickel alloy welding consumables market, driven by favorable government initiatives promoting domestic manufacturing and technological advancements in welding processes. These factors contribute to the region becoming a key hub for market players and stakeholders, boosting demand for high-performance welding consumables.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Nickel Alloy Welding Consumables Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Nickel Alloy Welding Consumables Market Leaders Operating in the Market Are:

- KOBE STEEL, LTD. (Japan)

- voestalpine Böhler Welding Group GmbH (Austria)

- Illinois Tool Works Inc. (U.S.)

- Ador Welding Limited (India)

- Arcos Industries, LLC (U.S.)

- Colfax Corporation (U.S.)

- The Lincoln Electric Company (U.S.)

- Sandvik AB (Sweden)

- Messer Investment Holding GmbH (Germany)

- Tianjin Bridge Welding Materials Group Co.,Ltd. (China)

- Precision Castparts Corp. (U.S.)

- ESAB (U.S.)

- Berkenhoff GmbH (Germany)

- COR-MET, Inc. (U.S.)

- Linan Dayang Welding Material Co.,Ltd. (China)

Latest Developments in Nickel Alloy Welding Consumables Market

- In November 2021, Lincoln Electric, a prominent leader in welding and cutting solutions, announced the acquisition of Overstreet-Hughes Company, Inc. This strategic acquisition aimed to boost Lincoln Electric’s presence in the automation sector by integrating Overstreet-Hughes' expertise in robotic welding systems and automation technology. The move allowed Lincoln Electric to diversify its automation solutions, thereby strengthening its capabilities to serve various industries. This acquisition highlights Lincoln Electric’s commitment to driving innovation and solidifies its position as a trusted global partner for welding and cutting solutions

SKU-

세계 최초의 시장 정보 클라우드 보고서에 온라인으로 접속하세요

- 대화형 데이터 분석 대시보드

- 높은 성장 잠재력 기회를 위한 회사 분석 대시보드

- 사용자 정의 및 질의를 위한 리서치 분석가 액세스

- 대화형 대시보드를 통한 경쟁자 분석

- 최신 뉴스, 업데이트 및 추세 분석

- 포괄적인 경쟁자 추적을 위한 벤치마크 분석의 힘 활용

연구 방법론

데이터 수집 및 기준 연도 분석은 대규모 샘플 크기의 데이터 수집 모듈을 사용하여 수행됩니다. 이 단계에는 다양한 소스와 전략을 통해 시장 정보 또는 관련 데이터를 얻는 것이 포함됩니다. 여기에는 과거에 수집한 모든 데이터를 미리 검토하고 계획하는 것이 포함됩니다. 또한 다양한 정보 소스에서 발견되는 정보 불일치를 검토하는 것도 포함됩니다. 시장 데이터는 시장 통계 및 일관된 모델을 사용하여 분석하고 추정합니다. 또한 시장 점유율 분석 및 주요 추세 분석은 시장 보고서의 주요 성공 요인입니다. 자세한 내용은 분석가에게 전화를 요청하거나 문의 사항을 드롭하세요.

DBMR 연구팀에서 사용하는 주요 연구 방법론은 데이터 마이닝, 시장에 대한 데이터 변수의 영향 분석 및 주요(산업 전문가) 검증을 포함하는 데이터 삼각 측량입니다. 데이터 모델에는 공급업체 포지셔닝 그리드, 시장 타임라인 분석, 시장 개요 및 가이드, 회사 포지셔닝 그리드, 특허 분석, 가격 분석, 회사 시장 점유율 분석, 측정 기준, 글로벌 대 지역 및 공급업체 점유율 분석이 포함됩니다. 연구 방법론에 대해 자세히 알아보려면 문의를 통해 업계 전문가에게 문의하세요.

사용자 정의 가능

Data Bridge Market Research는 고급 형성 연구 분야의 선두 주자입니다. 저희는 기존 및 신규 고객에게 목표에 맞는 데이터와 분석을 제공하는 데 자부심을 느낍니다. 보고서는 추가 국가에 대한 시장 이해(국가 목록 요청), 임상 시험 결과 데이터, 문헌 검토, 재생 시장 및 제품 기반 분석을 포함하도록 사용자 정의할 수 있습니다. 기술 기반 분석에서 시장 포트폴리오 전략에 이르기까지 타겟 경쟁업체의 시장 분석을 분석할 수 있습니다. 귀하가 원하는 형식과 데이터 스타일로 필요한 만큼 많은 경쟁자를 추가할 수 있습니다. 저희 분석가 팀은 또한 원시 엑셀 파일 피벗 테이블(팩트북)로 데이터를 제공하거나 보고서에서 사용 가능한 데이터 세트에서 프레젠테이션을 만드는 데 도움을 줄 수 있습니다.