Global Industrial Maintenance Management Software Market

Market Size in USD Billion

CAGR :

%

USD

13.50 Billion

USD

32.95 Billion

2024

2032

USD

13.50 Billion

USD

32.95 Billion

2024

2032

| 2025 –2032 | |

| USD 13.50 Billion | |

| USD 32.95 Billion | |

|

|

|

Industrial Maintenance Management Software Market Analysis

The industrial maintenance management software market is experiencing significant growth, driven by the increasing need for efficient asset management, predictive maintenance, and automation in industrial operations. Industries such as manufacturing, energy, oil & gas, and transportation are rapidly adopting Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) solutions to enhance equipment reliability, minimize downtime, and reduce maintenance costs. Advancements in AI-driven predictive maintenance, IoT-enabled real-time monitoring, and cloud-based maintenance solutions are transforming the market, allowing organizations to transition from reactive to proactive maintenance strategies. AI-powered analytics and machine learning algorithms are improving failure prediction accuracy, while digital twins and augmented reality (AR)-based maintenance are enabling remote troubleshooting and real-time diagnostics. The integration of mobile applications and remote access capabilities is further streamlining workflow management, enhancing productivity, and ensuring compliance with industry regulations. With the rise of Industry 4.0, companies are increasingly investing in smart maintenance solutions to optimize asset lifecycle management. As industries move toward automation and data-driven decision-making, the demand for advanced Industrial Maintenance Management Software is expected to surge, shaping the future of industrial maintenance.

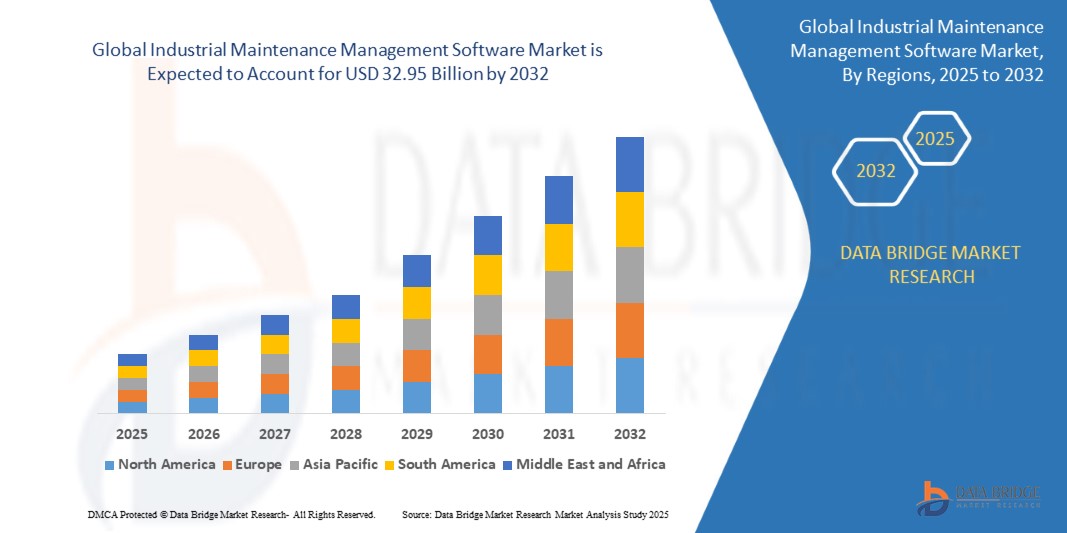

Industrial Maintenance Management Software Market Size

The global industrial maintenance management software market size was valued at USD 13.50 billion in 2024 and is projected to reach USD 32.95 billion by 2032, with a CAGR of 11.80% during the forecast period of 2025 to 2032. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

Industrial Maintenance Management Software Market Trends

“Integration of AI-Driven Predictive Maintenance”

One of the key trends in the industrial maintenance management software market is the integration of AI-driven predictive maintenance to enhance operational efficiency and reduce unplanned downtime. Industries are increasingly leveraging machine learning algorithms and IoT-enabled sensors to monitor equipment health in real time and predict potential failures before they occur. For instance, in the automotive manufacturing sector, companies such as Tesla and BMW use AI-powered maintenance solutions to track machinery performance, optimize repair schedules, and minimize production disruptions. In addition, the adoption of cloud-based maintenance management software (CMMS) is enabling remote monitoring and seamless data integration across multiple facilities. With the rise of Industry 4.0, businesses are shifting from reactive maintenance models to data-driven, predictive strategies, ensuring higher asset reliability and cost efficiency. This trend is particularly crucial in energy and utilities, where AI-enhanced maintenance is helping to optimize grid performance and prevent costly outages, driving market growth.

Report Scope and Industrial Maintenance Management Software Market Segmentation

|

Attributes |

Industrial Maintenance Management Software Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America |

|

Key Market Players |

OneSoftConnect (Canada), Trackplan Software Ltd (U.K.), Infor (U.S.), Mobility Work SAS (France), Blue Mountain Quality Resources, LLC (U.S.), OpenWrench (U.S.), Elecosoft (U.K.), Maintenance Coordinator (U.S.), DIMO Maint (France), Rockwell Automation (U.S.), Emerson Electric Co. (U.S.), General Electric Company (U.S.), Honeywell International, Inc. (U.S.), SAP (Germany), OMRON Corporation (Japan), Hexagon AB (Sweden), Siemens (Germany), Oracle (U.S.), ABB (Switzerland), AssetWorks Inc. (U.S.), IBM (U.S.), Schneider Electric (France), AspenTech (U.S.), AVEVA Group Limited (U.K.), Bentley Systems, Incorporated (U.S.) |

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis. |

Industrial Maintenance Management Software Market Definition

Industrial Maintenance Management Software refers to a specialized digital solution designed to streamline, automate, and optimize maintenance operations in industrial settings. It helps organizations efficiently manage assets, equipment, work orders, inventory, and compliance requirements, ensuring maximum uptime and operational efficiency.

Industrial Maintenance Management Software Market Dynamics

Drivers

- Rising Demand for Predictive Maintenance

The increasing adoption of predictive maintenance solutions is a significant driver of the Industrial Maintenance Management Software Market. With industries striving to minimize unplanned downtime and optimize asset performance, predictive maintenance is emerging as a game-changer. By leveraging AI, IoT sensors, and machine learning algorithms, organizations can continuously monitor real-time equipment data, detect anomalies, and predict potential failures before they occur. This proactive approach reduces maintenance costs enhances operational efficiency. For instance, in the automotive sector, manufacturers such as Ford and General Motors deploy AI-driven predictive maintenance solutions to analyze engine performance, transmission health, and production machinery conditions. By using real-time diagnostics, these companies prevent sudden breakdowns, optimize maintenance schedules, and extend the lifecycle of critical assets. The shift from reactive to proactive maintenance strategies is fueling the demand for intelligent maintenance management software, making it an essential investment for industries focused on long-term operational stability.

- Growth in Smart Manufacturing and Industry 4.0

The rise of Industry 4.0 and smart manufacturing has accelerated the adoption of automated maintenance management solutions, transforming traditional maintenance practices. Industry 4.0 integrates digital twins, cloud computing, and industrial IoT (IIoT) to create a connected ecosystem where machines communicate in real time, improving efficiency and predictive capabilities. These advancements allow manufacturers to monitor equipment health remotely, schedule maintenance automatically, and optimize workflows using data-driven insights. A prime instance is the aerospace industry, where companies such as Boeing implement cloud-based maintenance management software to track aircraft component health, enhance predictive analytics, and streamline compliance with aviation safety regulations. By utilizing digital twins, Boeing can create a virtual replica of aircraft parts, simulate wear and tear, and schedule preventive maintenance before any failure occurs. This approach reduces aircraft downtime, ensures regulatory compliance, and enhances safety and reliability. As industries worldwide continue to embrace industrial automation, the demand for intelligent maintenance solutions is expected to surge, driving market growth in the coming years.

Opportunities

- Increasing Focus on Reducing Operational Costs

The rising need to minimize operational expenses is a key opportunity in the Industrial Maintenance Management Software Market, as organizations across industries actively seek cost-efficient maintenance strategies. Traditional reactive maintenance methods often lead to unexpected equipment failures, costly repairs, and unplanned downtime, significantly impacting profitability. To combat these challenges, companies are turning to Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) solutions to streamline maintenance workflows, optimize resource allocation, and enhance asset performance. For instance, in the oil & gas sector, companies such as ExxonMobil and Shell implement CMMS solutions to reduce equipment failures, prevent expensive shutdowns, and ensure regulatory compliance. These systems enable predictive maintenance scheduling, real-time asset monitoring, and automated inventory management, ensuring that critical machinery operates efficiently with minimal disruptions. By integrating AI-driven analytics and IoT-enabled condition monitoring, maintenance management software helps industries optimize operational costs while maximizing equipment reliability, making it a strategic investment for long-term financial sustainability.

- Increasing Stringent Regulatory and Safety Compliance Requirements

With governments and regulatory bodies worldwide enforcing strict safety and compliance regulations, industries are under pressure to meet stringent operational standards. Non-compliance can result in hefty penalties, legal liabilities, and reputational damage, making regulatory adherence a top priority. Maintenance management software plays a crucial role in helping organizations document equipment inspections, track maintenance logs, and enforce safety protocols, ensuring seamless regulatory compliance and workplace safety. In highly regulated sectors such as power generation and pharmaceuticals, agencies such as the Occupational Safety and Health Administration (OSHA) and the Food and Drug Administration (FDA) require companies to maintain detailed maintenance records, conduct periodic inspections, and implement safety measures. For instance, pharmaceutical manufacturers rely on EAM software to monitor cleanroom equipment, sterilization units, and production machinery, ensuring compliance with Good Manufacturing Practices (GMP) and FDA guidelines. Similarly, power plants utilize CMMS solutions to schedule preventive maintenance for turbines, generators, and boilers, reducing the risk of failures and ensuring continuous power supply.

Restraints/Challenges

- High Initial Investment Costs

Implementing industrial maintenance management software often comes with significant upfront costs. These expenses can include purchasing the software licenses, acquiring necessary hardware, and conducting extensive employee training programs. For small and medium-sized enterprises (SMEs), these financial requirements may be prohibitive, as they might have limited resources for such investments. For instance, a small manufacturing plant in a developing country may struggle to adopt new technology due to its high cost, hindering its ability to streamline maintenance processes. This financial barrier restricts widespread adoption of the software, thereby slowing the growth of the market in regions with a higher concentration of SMEs.

- Data Security and Privacy Concerns

The increased adoption of cloud-based industrial maintenance management software raises concerns about the security of sensitive data. As organizations store critical operational and maintenance data on cloud platforms, they become more vulnerable to cyberattacks, data breaches, and unauthorized access. This is particularly concerning in industries such as healthcare, oil and gas, and manufacturing, where data breaches can have severe consequences on safety, compliance, and reputation. For instance, an oil and gas company with critical infrastructure may face a security breach that exposes operational data, potentially compromising the safety of its operations. Consequently, the need for robust security measures in industrial maintenance systems presents a major challenge for market growth.

Beyond legal compliance, organizations must also securely store and process voice data, which is a significant market challenge. Voice recordings often contain personally identifiable information (PII), sensitive health data, or financial details, making them prime targets for cyberattacks. The risk of data breaches discourages businesses from fully adopting Industrial Maintenance Management Software solutions. For instance, a major telecom provider faced a data leak in which thousands of customer support call recordings were exposed due to improper encryption. Ensuring end-to-end security, encryption, and access control is costly and adds technical complexity to implementation, limiting market growth.

This market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Industrial Maintenance Management Software Market Scope

The market is segmented on the basis of deployment type, industry, functionality, and enterprise size. The growth amongst these segments will help you analyse meagre growth segments in the industries, and provide the users. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Deployment Type

- On-premises

- Cloud-based

- Hybrid

Industry

- Manufacturing

- Oil and Gas

- Mining

- Transportation and Logistics

- Utilities

- Healthcare

Functionality

- Work Order Management

- Asset Management

- Inventory Management

- Preventive Maintenance

- Predictive Maintenance

- Condition Monitoring

Enterprise Size

- Small and Medium-sized Enterprises (SMEs)

- Large Enterprises

Industrial Maintenance Management Software Market Regional Analysis

The market is analyzed and market size insights and trends are provided by country, deployment type, industry, functionality, and enterprise size. The growth amongst these segments will help you analyse meagre growth segments in the industries, and provide the users as referenced above.

The countries covered in the market report are U.S., Canada, Mexico in North America, Germany, Sweden, Poland, Denmark, Italy, U.K., France, Spain, Netherland, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, New Zealand, Vietnam, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in Asia-Pacific (APAC), Brazil, Argentina, Rest of South America as a part of South America, U.A.E, Saudi Arabia, Oman, Qatar, Kuwait, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA).

North America holds a dominant position in the global Industrial Maintenance Management Software market, driven by the rapid adoption of advanced technologies and automation in industries such as manufacturing, oil and gas, and transportation. The region benefits from a well-established industrial sector that increasingly relies on predictive maintenance and asset management solutions to enhance operational efficiency and reduce downtime. In addition, the presence of major software providers and continuous investments in digital transformation further fuel market growth. The rising demand for cloud-based maintenance solutions and adherence to stringent regulatory standards also contribute to North America's leadership in the market.

Asia-Pacific is experiencing the fastest growth in the global Industrial Maintenance Management Software market, driven by the rapid expansion of manufacturing, oil and gas, and transportation industries. The region's increasing focus on industrial automation, predictive maintenance, and asset optimization is fueling the demand for advanced maintenance management solutions. In addition, rising investments in digital transformation, along with government initiatives supporting smart factories and infrastructure development, are accelerating market adoption. The growing presence of small and medium-sized enterprises (SMEs) integrating cloud-based maintenance software further contributes to the region’s rapid expansion.

The country section of the report also provides individual market impacting factors and changes in market regulation that impact the current and future trends of the market. Data points such as down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Industrial Maintenance Management Software Market Share

The market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to market.

Industrial Maintenance Management Software Market Leaders Operating in the Market Are:

- OneSoftConnect (Canada)

- Trackplan Software Ltd (U.K.)

- Infor (U.S.)

- Mobility Work SAS (France)

- Blue Mountain Quality Resources, LLC (U.S.)

- OpenWrench (U.S.)

- Elecosoft (U.K.)

- Maintenance Coordinator (U.S.)

- DIMO Maint (France)

- Rockwell Automation (U.S.)

- Emerson Electric Co. (U.S.)

- General Electric Company (U.S.)

- Honeywell International, Inc. (U.S.)

- SAP (Germany)

- OMRON Corporation (Japan)

- Hexagon AB (Sweden)

- Siemens (Germany)

- Oracle (U.S.)

- ABB (Switzerland)

- AssetWorks Inc. (U.S.)

- IBM (U.S.)

- Schneider Electric (France)

- AspenTech (U.S.)

- AVEVA Group Limited (U.K.)

- Bentley Systems, Incorporated (U.S.)

Latest Developments in Industrial Maintenance Management Software Market

- In May 2024, Accenture announced the acquisition of Teamexpat, a company specializing in embedded software for complex high-tech systems and products, particularly in software testing, development, and integration for lithography systems used in the semiconductor industry. These systems utilize ultraviolet light to project intricate patterns onto semiconductor materials, playing a crucial role in defining microchip performance

- In May 2024, Oceaneering International, Inc. and Global Design Innovation, Ltd. (GDi) entered into a strategic collaboration agreement to deliver innovative digital asset management solutions for asset-intensive industries such as oil & gas, utilities, and power generation. As part of this collaboration, Oceaneering leveraged GDi’s Vision software solution to streamline inspection processes, enable remote assessment of external conditions, and optimize on-site personnel presence

- In January 2024, ABB announced an agreement to acquire a majority stake in the software service provider Meshmind, aiming to enhance its research and development capabilities in AI, Industrial IoT, and machine vision. By integrating Meshmind’s engineering talent, AI expertise, and software knowledge, ABB plans to establish a new global R&D hub to accelerate the development of innovative automation solutions within its Machine Automation division (B&R)

- In April 2023, Siemens Digital Industries Software and IBM revealed plans to expand their software collaboration by developing a comprehensive suite of integrated tools to address system engineering across multiple domains. This partnership will focus on lifecycle management and asset management, with the ultimate goal of creating a unified digital thread throughout the entire manufacturing infrastructure

- In December 2022, Schneider Electric, a leading player in digital transformation for energy management and automation, introduced the latest version of EcoStruxure Automation Expert, the world’s first software-centric universal automation system. This update provides enhanced automation capabilities for industries such as consumer-packaged goods, logistics, and water and wastewater operations, offering next-generation automation features and unparalleled operational flexibility

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.