Global Polyurethane Catalyst Market

Market Size in USD Billion

CAGR :

%

USD

1.09 Billion

USD

1.72 Billion

2024

2032

USD

1.09 Billion

USD

1.72 Billion

2024

2032

| 2025 –2032 | |

| USD 1.09 Billion | |

| USD 1.72 Billion | |

|

|

|

|

What is the Global Polyurethane Catalyst Market Size and Growth Rate?

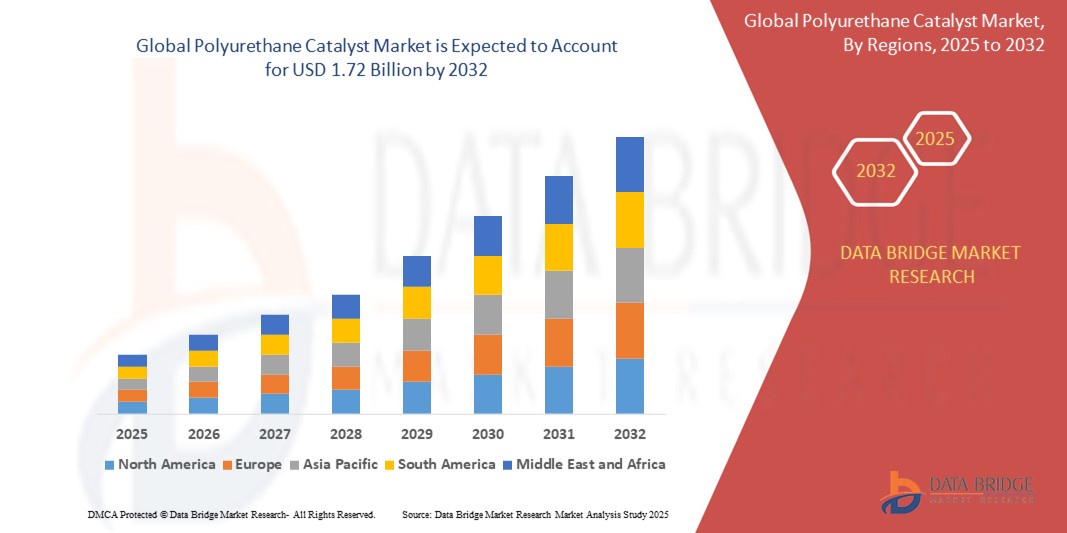

- The global polyurethane catalyst market size was valued at USD 1.09 billion in 2024 and is expected to reach USD 1.72 billion by 2032, at a CAGR of 5.90% during the forecast period

- The polyurethane catalyst market plays a crucial role in supporting the production of polyurethane-based products across various industries, including construction, automotive, electronics, and furniture. Polyurethane Catalysts are essential for accelerating the chemical reactions between polyols and isocyanates, enabling efficient production of foams, elastomers, coatings, adhesives, and sealants

- Growing demand for high-performance, lightweight, and durable materials in modern manufacturing is fueling the adoption of polyurethane catalysts, with a significant emphasis on applications that require energy efficiency, structural integrity, and environmental performance. Technological advancements in catalyst formulations are enhancing product quality, reducing emissions, and supporting sustainable production practices globally

What are the Major Takeaways of Polyurethane Catalyst Market?

- Increasing demand for energy-efficient insulation materials and lightweight components in construction, automotive, and industrial sectors is significantly driving the growth of the polyurethane catalyst market. Manufacturers are adopting advanced catalyst technologies to improve production efficiency and material performance while complying with environmental standards

- Polyurethane Catalysts enable the production of versatile foam products, which provide superior insulation, cushioning, and durability, making them integral to energy-saving construction practices and automotive weight reduction initiatives. These catalysts also play a vital role in producing coatings and adhesives that enhance durability and weather resistance in infrastructure and consumer goods

- Growing environmental concerns and regulatory pressures have accelerated the demand for eco-friendly, low-emission polyurethane catalyst formulations. This trend is expected to continue as industries worldwide prioritize sustainability, operational efficiency, and product performance, positioning polyurethane catalysts as an essential component of next-generation materials development

- Asia-Pacific dominated the polyurethane catalyst market with the largest revenue share of 45.7% in 2024, driven by the region's booming construction sector, rapid urbanization, and increasing demand for polyurethane-based insulation, coatings, adhesives, and foams

- Middle East & Africa polyurethane catalyst market is projected to witness the fastest CAGR of 12.1% from 2025 to 2032, driven by the region’s expanding construction sector, rising demand for energy-efficient materials, and increasing infrastructure development across the U.A.E., Saudi Arabia, South Africa, and other emerging markets

- The Amine Catalysts segment dominated the polyurethane catalyst market with the largest market revenue share of 48.6% in 2024, owing to their high reactivity, processing efficiency, and compatibility with a wide range of polyurethane applications, including foams, coatings, and adhesives

Report Scope and Polyurethane Catalyst Market Segmentation

|

Attributes |

Polyurethane Catalyst Key Market Insights |

|

Segments Covered |

|

|

Countries Covered |

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

|

|

Market Opportunities |

|

|

Value Added Data Infosets |

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, pricing analysis, brand share analysis, consumer survey, demography analysis, supply chain analysis, value chain analysis, raw material/consumables overview, vendor selection criteria, PESTLE Analysis, Porter Analysis, and regulatory framework. |

What is the Key Trend in the Polyurethane Catalyst Market?

“Eco-Friendly Formulations and Enhanced Performance Shaping Market Evolution”

- A major and rapidly emerging trend in the global polyurethane catalyst market is the shift toward sustainable, low-emission catalysts that align with tightening environmental regulations and the global focus on green chemistry

- Manufacturers are increasingly developing halogen-free, recyclable, and bio-based polyurethane catalysts that meet stringent safety and environmental standards for industries such as construction, automotive, and electronics

- Growing adoption of next-generation catalysts offering superior reactivity control, reduced VOC emissions, and compatibility with eco-friendly polyurethane systems is reshaping production processes across applications

- Innovations in amine-based and metal-free catalyst technologies are gaining momentum, enabling manufacturers to produce high-performance polyurethane foams, coatings, and adhesives with improved processing efficiency and reduced environmental impact

- Industry leaders including BASF, Evonik, and Huntsman are investing in advanced polyurethane catalyst solutions to support energy efficiency, regulatory compliance, and circular economy initiatives across global markets

- The convergence of environmental responsibility, product performance, and regulatory compliance is accelerating the market's transformation toward safer, more sustainable catalyst solutions worldwide

What are the Key Drivers of Polyurethane Catalyst Market?

- Rising demand for high-performance polyurethane products across construction, automotive, electronics, and consumer goods sectors is a primary growth driver for the polyurethane catalyst market. Catalysts play a vital role in improving production efficiency and achieving desired polyurethane properties

- For instance, in February 2024, Evonik launched a new range of low-emission polyurethane catalysts aimed at enhancing performance and sustainability in insulation and automotive applications, supporting global decarbonization goals

- The global push toward energy-efficient buildings, lightweight automotive components, and advanced insulation materials is fueling the need for innovative polyurethane catalyst solutions that enable reduced environmental impact

- The growing adoption of polyurethane-based thermal insulation, soundproofing materials, and energy-saving technologies in residential, commercial, and industrial infrastructure is creating consistent demand for catalysts

- In addition, technological advancements in polyurethane formulations, including fast-curing foams and high-performance elastomers, require precise catalyst solutions for optimized manufacturing processes

- Regulatory pressures to reduce VOC emissions and adopt environmentally safer chemical processes are driving rapid innovation and the adoption of sustainable polyurethane catalyst technologies worldwide

Which Factor is challenging the Growth of the Polyurethane Catalyst Market?

-

High production costs and complex manufacturing requirements for advanced polyurethane catalyst solutions, especially those that are halogen-free or based on specialty chemistries, present a significant challenge to widespread adoption

- For instance, small and medium-sized manufacturers often face price and technical barriers when integrating next-generation catalysts into their processes, limiting market expansion in cost-sensitive regions

- Regulatory scrutiny around the toxicity and environmental impact of traditional amine- and metal-based catalysts has raised concerns, requiring companies to invest heavily in R&D for safer alternatives

- Furthermore, fluctuations in raw material availability, such as specialty amines or metal compounds, can disrupt supply chains and affect production scalability for polyurethane catalyst suppliers

- Competitive pressure from alternative catalyst systems or lower-cost polyurethane production methods can hinder market growth, particularly in emerging economies with lower environmental enforcement

- To overcome these obstacles, market players are focusing on developing cost-effective, high-efficiency, and environmentally friendly catalyst solutions that meet evolving regulatory and performance demands across industries

How is the Polyurethane Catalyst Market Segmented?

The market is segmented on the basis of product and application.

• By Product

On the basis of product, the polyurethane catalyst market is segmented into Amine Catalysts, Metal Catalysts, Bismuth Catalysts, Organometallic Catalysts, Non-metal Catalysts, and Others. The Amine Catalysts segment dominated the polyurethane catalyst market with the largest market revenue share of 48.6% in 2024, owing to their high reactivity, processing efficiency, and compatibility with a wide range of polyurethane applications, including foams, coatings, and adhesives. Amine Catalysts are widely preferred for their ability to accelerate the reaction between isocyanates and polyols, ensuring fast curing and consistent product quality in diverse end-use industries.

The Bismuth Catalysts segment is expected to witness the fastest CAGR from 2025 to 2032, driven by increasing demand for environmentally friendly and low-toxicity alternatives to traditional metal-based catalysts. Bismuth Catalysts are gaining popularity in applications where health, safety, and regulatory compliance are critical, such as consumer goods, automotive interiors, and medical devices. Their reduced environmental impact and effective catalytic performance are contributing to rapid market adoption.

• By Application

On the basis of application, the polyurethane catalyst market is segmented into Flexible Foam, Rigid Foam, Coatings, Adhesives & Sealants, Elastomers, and Others. The Flexible Foam segment held the largest market revenue share of 42.3% in 2024, attributed to its extensive use in furniture, bedding, automotive interiors, and packaging applications. Flexible Foam production relies heavily on high-performance catalysts to achieve desired softness, durability, and resilience, making catalysts an essential component in this segment's growth.

The Rigid Foam segment is projected to register the fastest CAGR from 2025 to 2032, supported by its growing use in building insulation, refrigeration, and energy-efficient applications. The excellent thermal insulation properties, structural integrity, and lightweight nature of Rigid Foams are driving increased demand for catalysts that enable efficient production and consistent foam quality, particularly in the construction and appliance sectors.

Which Region Holds the Largest Share of the Polyurethane Catalyst Market?

- Asia-Pacific dominated the polyurethane catalyst market with the largest revenue share of 45.7% in 2024, driven by the region's booming construction sector, rapid urbanization, and increasing demand for polyurethane-based insulation, coatings, adhesives, and foams. Countries such as China, India, Japan, and South Korea are witnessing robust consumption of Polyurethane Catalyst due to rising infrastructure development, industrial expansion, and strict energy efficiency regulations

- Accelerated urban growth, favorable government initiatives for green construction, and the presence of cost-efficient manufacturers are collectively supporting market leadership across Asia-Pacific

- In addition, the region benefits from a strong automotive and consumer electronics manufacturing base, where polyurethane catalysts play a critical role in improving product performance, energy efficiency, and safety

China Polyurethane Catalyst Market Insight

The China polyurethane catalyst market accounted for the largest revenue share within Asia-Pacific in 2024, driven by the nation’s leadership in construction, automotive production, and industrial development. China's stringent building codes, growing adoption of energy-efficient materials, and government policies promoting green building solutions are significantly boosting the demand for polyurethane catalysts across various sectors. The country’s dominance in global polyurethane production and export further reinforces market growth.

India Polyurethane Catalyst Market Insight

The India polyurethane catalyst market is expected to grow at a notable CAGR during the forecast period, fueled by rapid infrastructure expansion, the Smart Cities initiative, and rising demand for advanced insulation and coatings in residential and industrial projects. Increased awareness of energy-efficient construction and favorable regulatory frameworks are accelerating polyurethane catalyst consumption, particularly in urban development and affordable housing sectors.

Japan Polyurethane Catalyst Market Insight

The Japan polyurethane catalyst market is experiencing steady growth, supported by the country's focus on innovative materials, strict environmental standards, and advanced automotive and electronics sectors. Japan’s aging infrastructure, combined with strong demand for sustainable, high-performance polyurethane products, is driving catalyst usage in both construction and industrial applications.

Which Region is the Fastest Growing Region in the Polyurethane Catalyst Market?

Middle East & Africa polyurethane catalyst market is projected to witness the fastest CAGR of 12.1% from 2025 to 2032, driven by the region’s expanding construction sector, rising demand for energy-efficient materials, and increasing infrastructure development across the U.A.E., Saudi Arabia, South Africa, and other emerging markets. Mega-projects such as smart cities, commercial hubs, and industrial zones, coupled with growing emphasis on fire safety and sustainable materials, are propelling the adoption of polyurethane catalysts in insulation, coatings, and sealants across the region. The combination of favorable government policies, investments in energy-efficient technologies, and the need for modern, durable construction materials is creating significant growth opportunities for polyurethane catalyst manufacturers in the Middle East & Africa.

U.A.E. Polyurethane Catalyst Market Insight

The U.A.E. polyurethane catalyst market is witnessing substantial growth, supported by large-scale construction projects, urban expansion, and sustainability initiatives such as the Dubai Clean Energy Strategy. Rising investments in green buildings, insulation materials, and advanced coatings are driving polyurethane catalyst demand across both residential and commercial sectors.

Saudi Arabia Polyurethane Catalyst Market Insight

The Saudi Arabia polyurethane catalyst market is expected to grow at a rapid pace, fueled by infrastructure development under Vision 2030, increased construction of energy-efficient buildings, and the nation’s focus on reducing energy consumption. Polyurethane catalysts are increasingly being used in insulation, industrial applications, and smart city developments, contributing to significant market expansion.

Which are the Top Companies in Polyurethane Catalyst Market?

The polyurethane catalyst industry is primarily led by well-established companies, including:

- BASF SE (Germany)

- Evonik Industries AG (Germany)

- Huntsman International LLC (U.S.)

- Covestro AG (Germany)

- Momentive Performance Materials Inc. (U.S.)

- Shepherd Chemical (U.S.)

- Umicore (Belgium)

- Tosoh Asia Pte. Ltd. (Singapore)

- Guangzhou Yourun Synthetic Material Co., Ltd. (China)

- King Industries, Inc. (U.S.)

- Wanhua Chemical Group Co., Ltd. (China)

- Air Products and Chemicals, Inc. (U.S.)

- LANXESS AG (Germany)

- Dorf Ketal Chemicals India Private Limited (India)

- KAO Corporation (Japan)

- KPX Chemical Co., Ltd. (South Korea)

- Dow Chemical Company (U.S.)

- Bayer AG (Germany)

- Mitsui Chemicals, Inc. (Japan)

- DIC Corporation (Japan)

- Carpenter Co. (U.S.)

- MOFAN POLYURETHANE CO., LTD. (China)

What are the Recent Developments in Global Polyurethane Catalyst Market?

- In August 2023, Covestro AG announced the introduction of a new range of polyurethane catalysts specifically designed for the construction sector. These catalysts are engineered to enhance production efficiency and performance in materials such as insulation and adhesives, supporting the growing demand for high-performance, energy-efficient construction solutions

- In September 2022, BASF SE and Evonik Industries AG entered into a strategic partnership to jointly develop innovative polyurethane catalysts for sustainable applications. The collaboration focuses on creating catalysts derived from renewable raw materials, with the goal of reducing environmental impact and promoting greener alternatives across the polyurethane industry

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Global Polyurethane Catalyst Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Polyurethane Catalyst Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Polyurethane Catalyst Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.