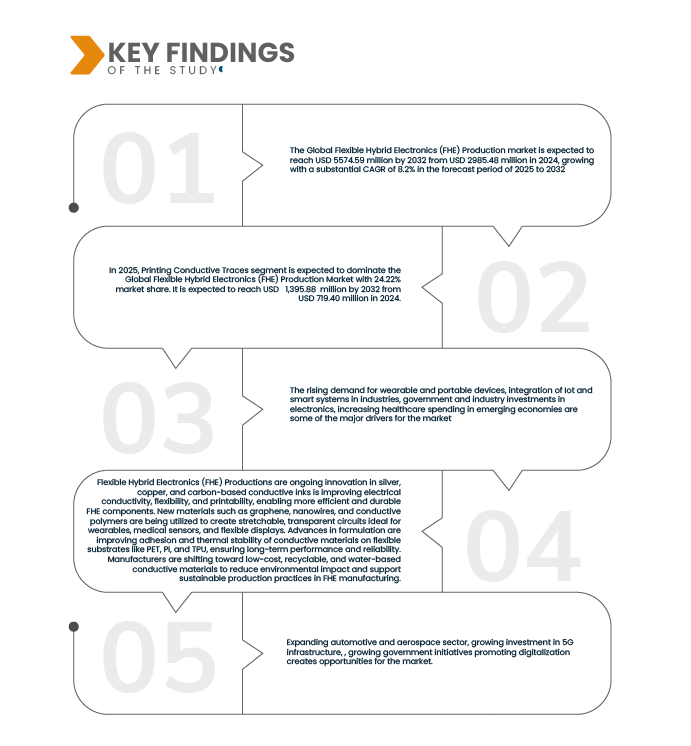

The rising demand for wearable and portable devices is propelling the growth of flexible hybrid electronics (FHE) production. Wearable technologies such as smartwatches, fitness trackers, medical monitoring patches, augmented reality (AR) glasses, and flexible displays require components that are lightweight, thin, and bendable, characteristics that conventional rigid electronics cannot offer. FHE, which seamlessly integrates printed electronics with traditional semiconductor devices on flexible substrates, provides the ideal technological foundation for such applications. Therefore, as consumers increasingly seek multifunctional, durable, and comfortable wearables, manufacturers are turning to FHE to enable advanced design flexibility and improved user experience. The rising adoption of portable devices such as smartphones worldwide is further driving increased production and exports, fueling demand for compact power sources, flexible interconnects, and integrated sensing solutions, all of which are efficiently supported by FHE technology.

Access Full Report @ https://www.databridgemarketresearch.com/reports/global-flexible-hybrid-electronics-fhe-productions-market

Data Bridge market research analyzes that Global Flexible Hybrid Electronics (FHE) Production Market is expected to reach USD 5574.59 million by 2032 from USD 2985.48 million in 2024, growing with a substantial CAGR of 8.2% in the forecast period of 2025 to 2032.

Key Findings of the Study

Growing Investment in 5G Infrastructure

The growing investment in 5g infrastructure is creating a significant opportunity for flexible hybrid electronics (FHE) production, as the technology’s unique properties align perfectly with the advanced performance, design, and connectivity requirements of next-generation communication networks. The rollout of 5g demands high-frequency, low-latency, and energy-efficient components that support dense network architectures, smart devices, and real-time data exchange across various sectors. FHE, which combines the mechanical flexibility of printed electronics with the functionality of conventional semiconductors, enables the development of lightweight, conformable, and cost-effective electronic systems ideally suited for 5g-enabled devices and infrastructure. One of the most promising applications lies in flexible antennas, sensors, and radio-frequency (rf) components that can be integrated into unconventional surfaces such as building facades, vehicles, and wearable devices. These flexible, printed components enhance signal coverage and connectivity without adding bulk or rigidity. The increasing investment by telecom operators and governments in 5g base stations, smart infrastructure, and network densification also expands the demand for flexible circuits and sensors capable of monitoring equipment health, optimizing energy consumption, and ensuring network reliability.

Report Scope and Market Segmentation

|

Report Metric

|

Details

|

|

Forecast Period

|

2025 to 2032

|

|

Base Year

|

2024

|

|

Historic Years

|

2023 (Customizable to 2018-2022)

|

|

Quantitative Units

|

Revenue in USD million

|

|

Segments Covered

|

By Manufacturing Process (Printing Conductive Traces, Substrate Preparation, Interconnection & Bonding, Cutting / Shaping / Final Assembly, Component Placement (Pick-and-Place), Printing / Depositing, Dielectric & Insulating Layers, Encapsulation / Protection, Testing & Quality Assurance), By Material (Substrate Materials, Conductor Material, Adhesives & Die Attach Materials, Encapsulation & Protective Materials, Insulating & Dielectric Materials, Stretchable Or Emerging Materials), By End User (Healthcare & Medical Sector, Consumer Electronics, Automotive, Industrial And Robotics, Aerospace & Defense, Telecommunications, Retail And Logistics, Textiles & Fashion, Energy & Utilities, Education & Research, Others),

|

|

Countries Covered

|

North America

Europe

Asia-Pacific

Middle East and Africa

South America

|

|

Market Players Covered

|

|

|

Data Points Covered in the Report

|

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

|

Segment Analysis

The Global flexible hybrid electronics (FHE) production market is segmented into three notable segments based on the manufacturing process, material, end user.

On the basis of manufacturing process, market is segmented into substrate preparation, printing conductive traces, printing/depositing dielectric and insulating layers, component placement (pick-and-place), interconnection & bonding, encapsulation/protection, testing & quality assurance, and cutting/shaping/final assembly.

In 2025, the printing conductive traces segment is expected to dominate the market

In 2025, the printing conductive traces segment is expected to dominate the market with a share of 24.22% due to its central role in enabling electrical functionality across a wide range of flexible devices. Conductive trace printing forms the backbone of FHE manufacturing, allowing the integration of electronic circuits onto flexible substrates such as polyimide, PET, and PEN.

On the basis of Material, the Global flexible hybrid electronics (FHE) production market is segmented into substrate materials, conductor materials, adhesives & die attach materials, encapsulation & protective materials, insulating & dielectric materials, and stretchable or emerging materials. In 2025, substrate materials segment is expected to dominate the global flexible hybrid electronics (FHE) production market share of 32.49% due to its fundamental importance in determining the overall performance, flexibility, and durability of electronic components. Substrates act as the foundational layer upon which conductive traces, sensors, and active components are printed or integrated, making them critical to the efficiency and reliability of FHE devices.

On the basis of end-user, the Global flexible hybrid electronics (FHE) production market is segmented into healthcare & medical, consumer electronics, automotive, industrial & robotics, retail & logistics, telecommunications, aerospace & defence, textiles & fashion, energy & utilities, education & research, and others. In 2025, the healthcare & medical sector segment is anticipated to dominate the global flexible hybrid electronics (FHE) production market share of 22.81% due to the rapid integration of flexible and wearable electronic technologies in medical diagnostics, monitoring, and therapeutic applications. FHE enables the development of lightweight, biocompatible, and highly flexible devices that can conform to the human body, making them ideal for continuous health monitoring and personalized care. The rising demand for wearable health sensors, smart patches, implantable devices, and remote patient monitoring systems is driving significant investment in this sector.

Major Players

Data Bridge Market Research recognizes the following companies as the major key players: Tapecon, Inc. (U.S.), CMTC (U.S.), In2tec (U.K.), ALMAX (U.S.), Elephantech Inc. (Japan) among others.

Latest Developments in Global Flexible Hybrid Electronics (FHE) Production Market

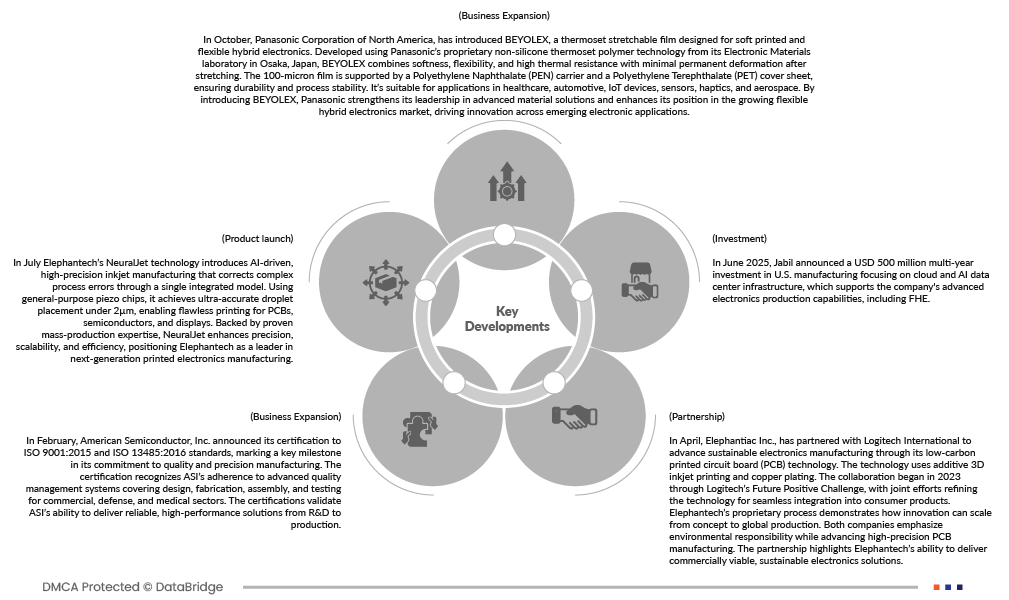

- In October 2024, In2tec showcased its Flexi-hibrid technology as a sustainable alternative to conventional resin PCBA, offering material cost savings and recyclable polyester substrates. They highlighted advanced 3D circuitry with capacitive touch, illuminated surfaces, and haptic feedback, aiding automotive manufacturers in meeting net-zero targets.

- In August 2024, Tapecon Inc., a leader in custom converting, printing, and advanced manufacturing, has partnered with CondAlign AS, a Norwegian deep-tech firm specializing in anisotropic conductive films. Under this collaboration, Tapecon becomes the exclusive Value-Added Reseller for CondAlign’s E-Align products across the U.S. and Canada. The E-Align technology enhances electronic connectivity and thermal management through particle alignment within a polymer matrix, offering high flexibility and performance for applications in IoT, smart cards, and medical devices.

- In February 2024, American Semiconductor, Inc. announced its certification to ISO 9001:2015 and ISO 13485:2016 standards, marking a key milestone in its commitment to quality and precision manufacturing. The certification recognizes ASI’s adherence to advanced quality management systems covering design, fabrication, assembly, and testing for commercial, defense, and medical sectors. The certifications validate ASI’s ability to deliver reliable, high-performance solutions from R&D to production.

- In May 2025, the Inkjet-BioAM project was officially launched in Granada, Spain, where partners gathered on March 31 to begin their collaborative efforts. This initiative focuses on enhancing healthcare by incorporating inkjet printing technology into the production processes of medical and pharmaceutical products. As a technology-driven engineering company, DoMicro B.V. is deeply committed to transforming advanced manufacturing methods into practical, real-world healthcare innovations. The Inkjet-BioAM project reflects this vision by promoting the development of inkjet-based drug delivery systems designed to improve patient outcomes, particularly for vulnerable groups such as children and individuals suffering from xerostomia.

- In July 2021, Innovaflex (formerly dpiX) and Mercury Systems signed an MOU to jointly develop and manufacture next-generation display technologies in the U.S. The partnership strengthens domestic value chains in reflective displays and semiconductors. Backed by potential U.S. initiatives like the CHIPS Act and American Jobs Plan, it supports national efforts to advance semiconductor innovation. Mercury will integrate Innovaflex’s U.S.-made microLED technology to create power-efficient, high-clarity displays for defense and aerospace systems. The collaboration enhances supply chain security and production scalability. This strengthens Innovaflex’s position in U.S. semiconductor manufacturing and expands Mercury’s advanced display capabilities for defense and avionics applications

As per Data Bridge Market Research analysis:

Geographically, the countries covered in the Global flexible hybrid electronics (FHE) production market report are North America, Europe, Asia-Pacific, Middle East and Africa, South America. Europe is further segmented into Germany, U.K., France, Italy, Spain, Russia, Turkey, Netherlands, Norway, Finland, Denmark, Sweden, Poland, Switzerland, Belgium, and rest of Europe. The Asia-Pacific is further segmented into China, Japan, India, South Korea, Australia, Indonesia, Thailand, Malaysia, Singapore, Philippines, Taiwan, Vietnam, New Zealand, and rest of Asia-Pacific. The North America is further segmented into U.S., Canada, and Mexico. The South America is further segmented into Brazil, Argentina, Colombia, Chile, Peru, Bolivia, Ecuador, Paraguay, Uruguay, Venezuela, Rest of South America. The Middle East and Africa is further segmented into Saudi Arabia, U.A.E., South Africa, Egypt, Israel, Kuwait, Qatar, Oman, Bahrain, Rest of Middle East and Africa.

Asia-Pacific is the dominating region in Global flexible hybrid electronics (FHE) production market

Asia-Pacific is the dominating region in Global flexible hybrid electronics (FHE) production market, driven by the rapid industrialization and urbanization, surging electricity demand, and expanding production of electric vehicles and consumer electronics. Moreover, large-scale investments in power and manufacturing infrastructure, coupled with the strong presence of major industrial and steel producers in countries such as China, Japan, and India, further consolidate the region’s dominance in global FHE production.

Asia-Pacific is expected to be the fastest growing region in Global flexible hybrid electronics (FHE) production market

Asia-Pacific is expected to witness significant growth in the Global flexible hybrid electronics (FHE) production market, driven by rapid industrialization and urbanization, rising electricity consumption, expanding electric-vehicle and consumer-electronics manufacturing, and substantial investments in power and production infrastructure. This growth is further supported by the region’s well-established manufacturing ecosystems, competitive supply-chain integration, and the presence of large industrial players (including steel and materials producers) in China, Japan, and India — all of which lower production costs, accelerate scale-up of roll-to-roll and printed-electronics processes, and shorten time-to-market for FHE innovations.

For more detailed information about the Global flexible hybrid electronics (FHE) production market report, click here – https://www.databridgemarketresearch.com/reports/global-flexible-hybrid-electronics-fhe-productions-market